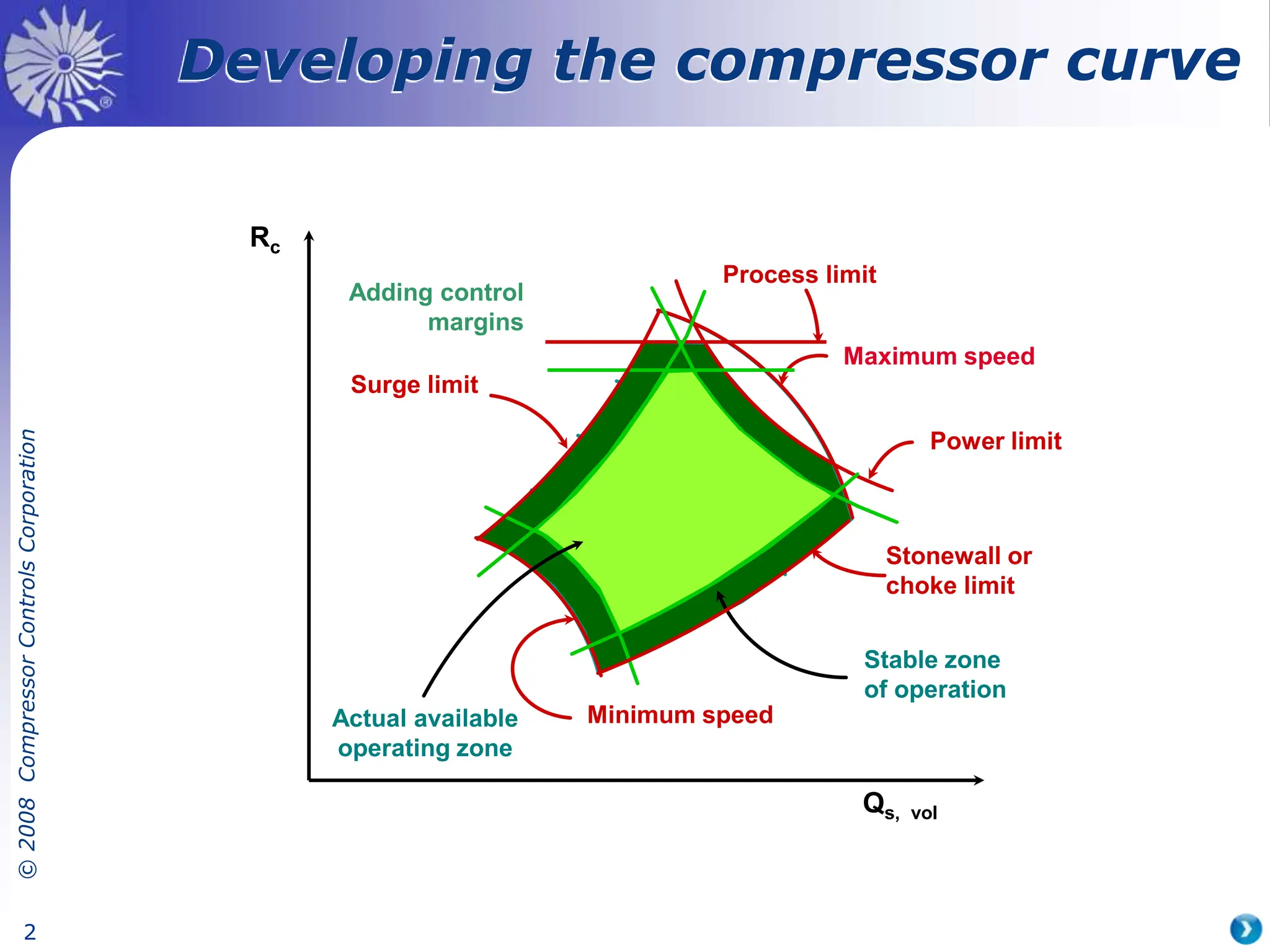

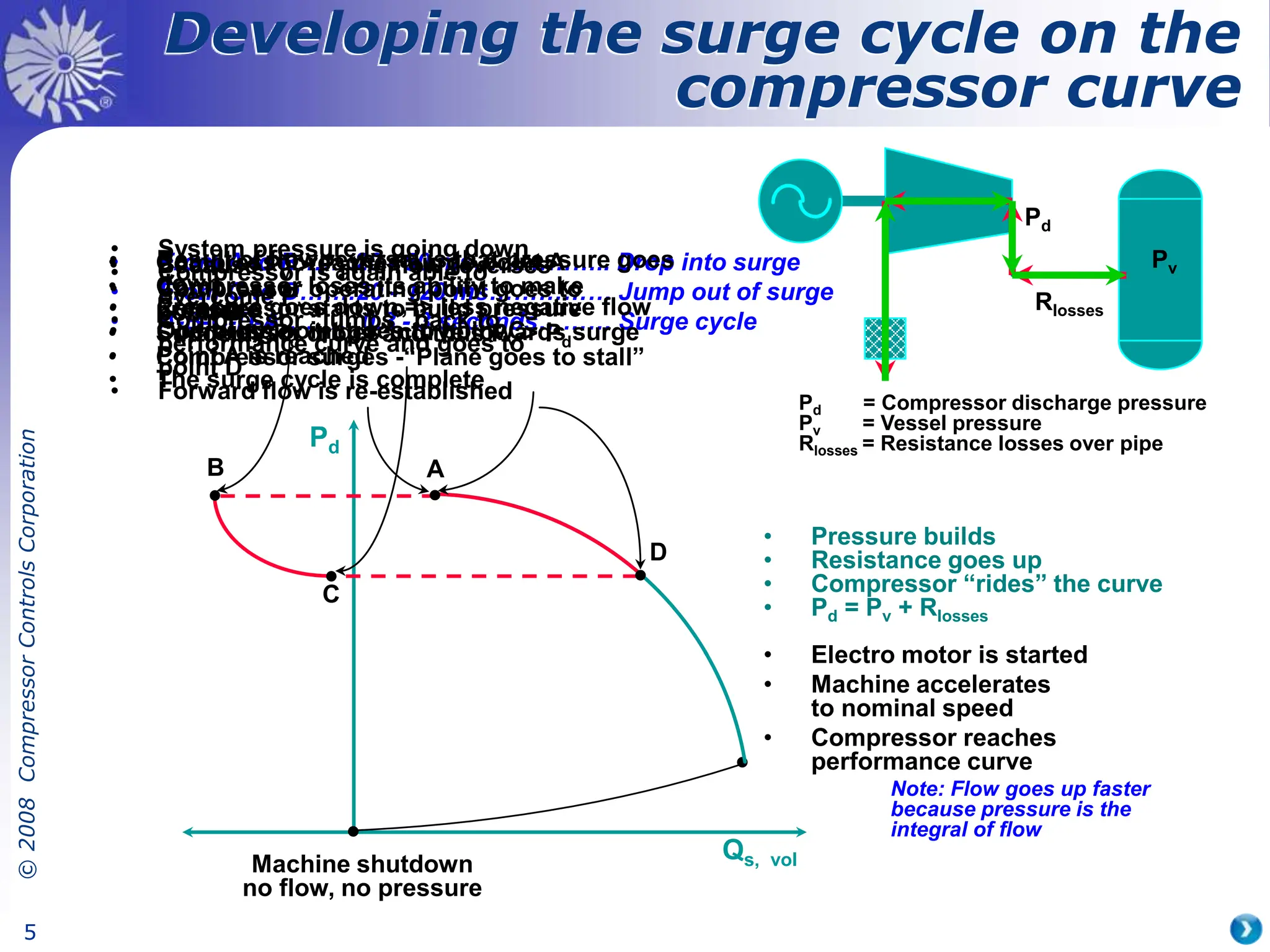

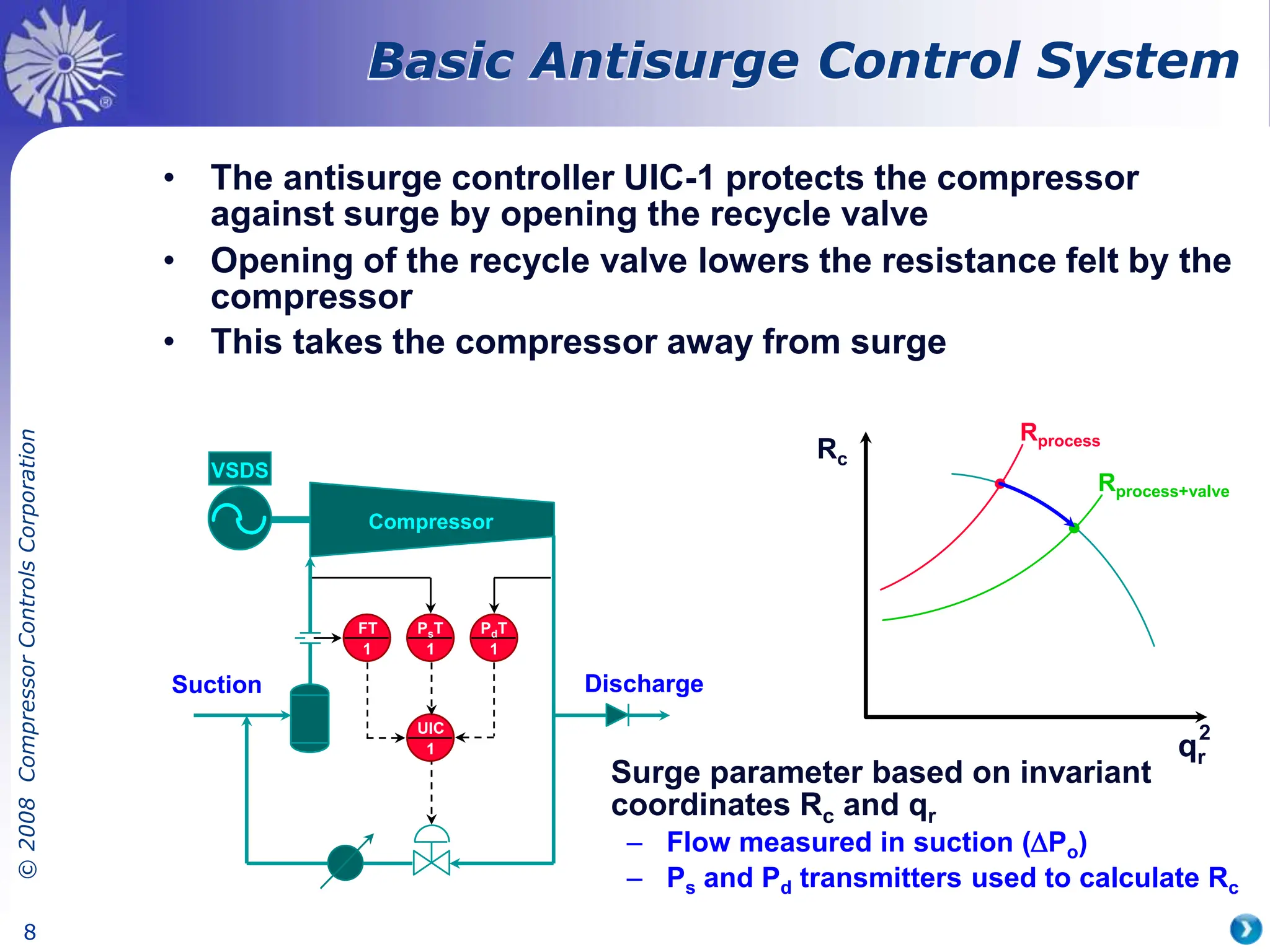

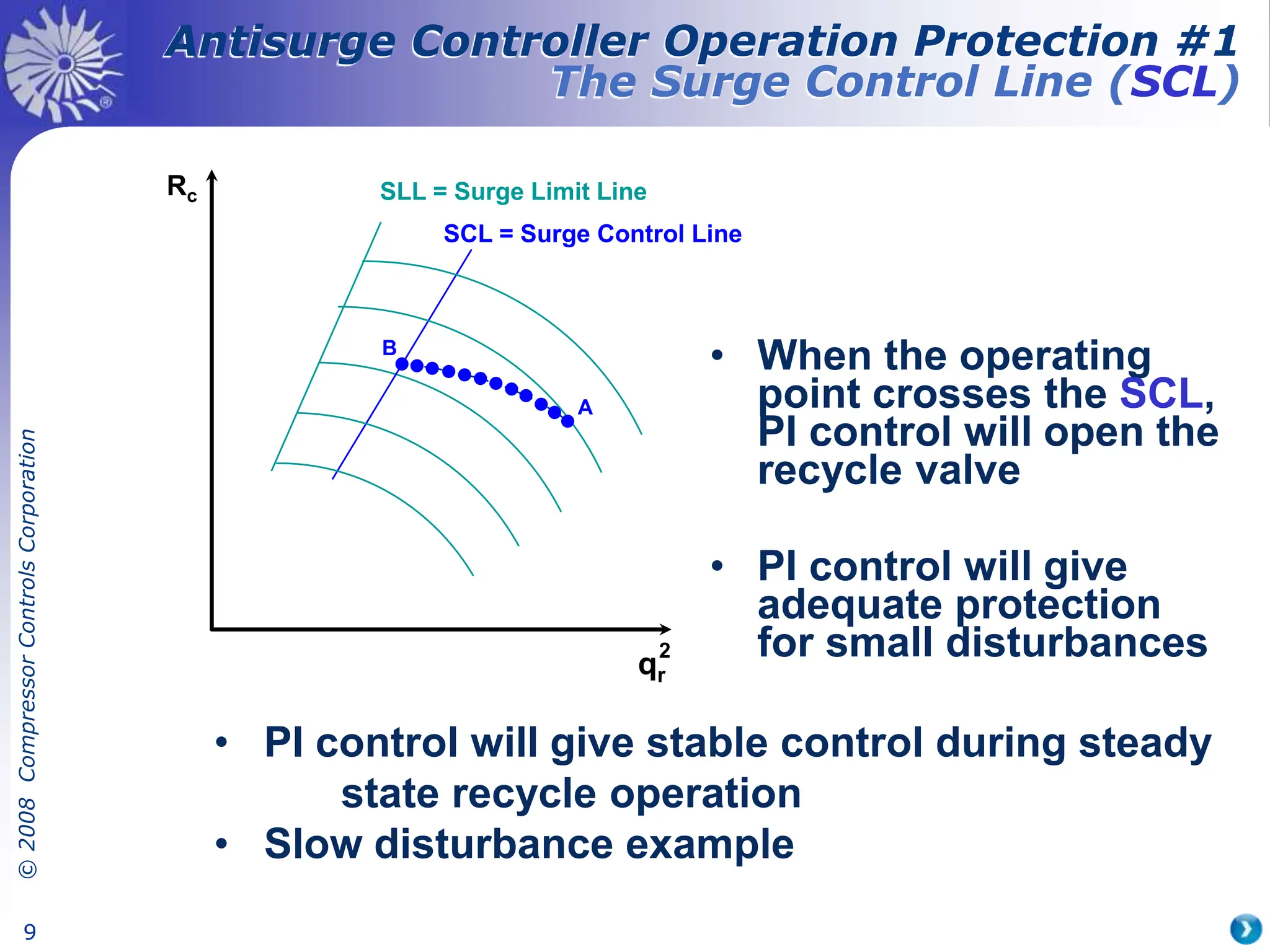

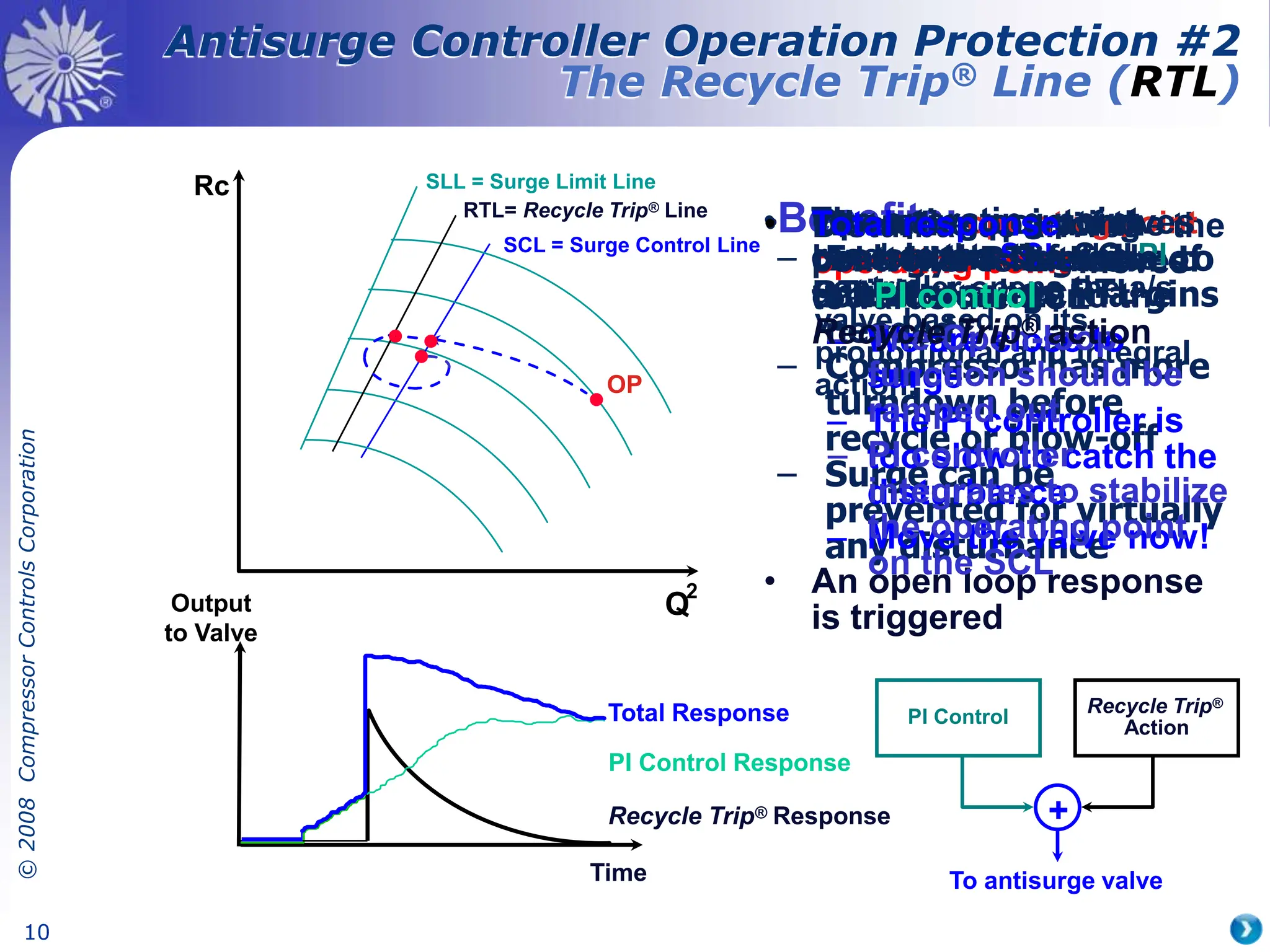

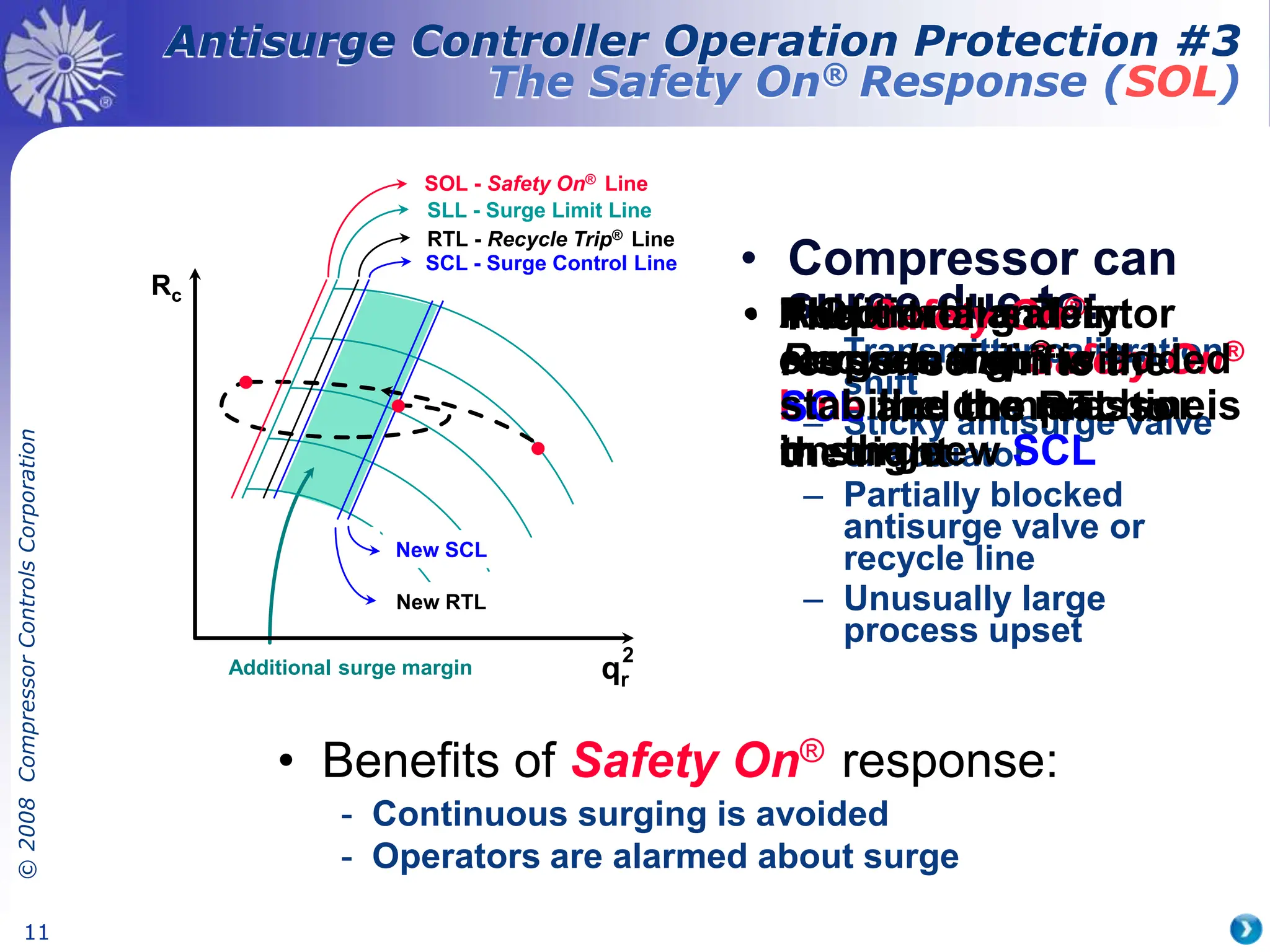

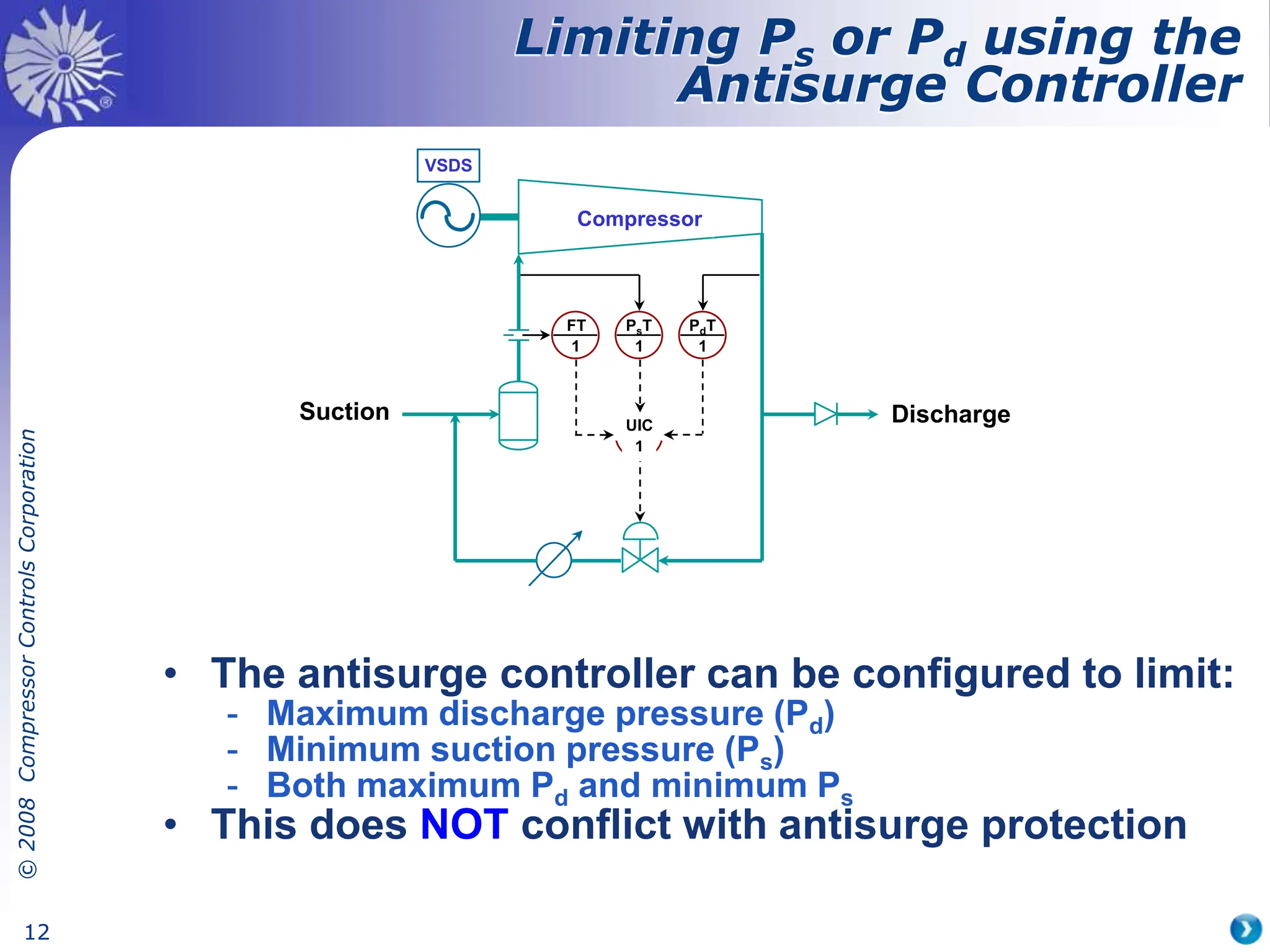

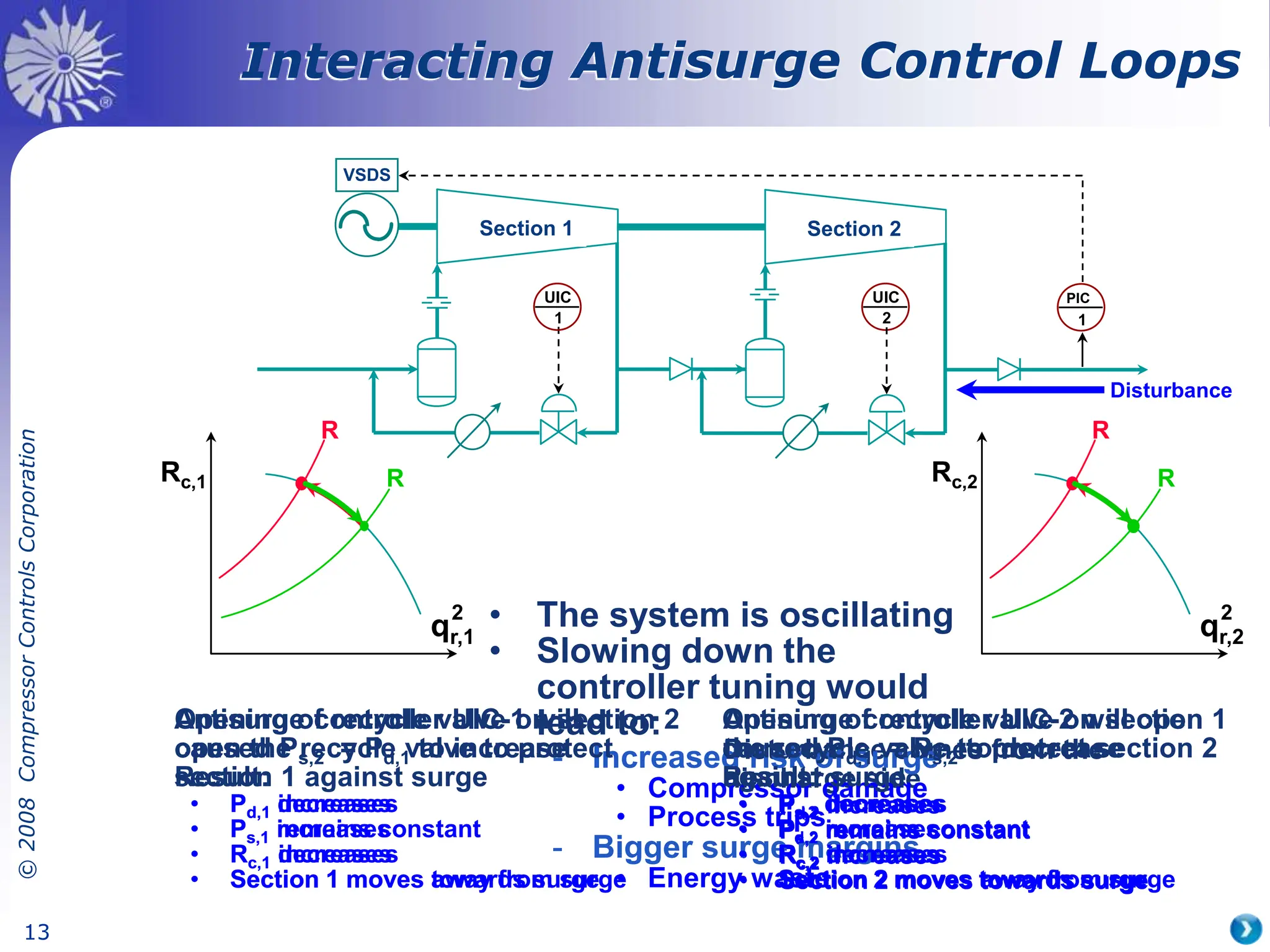

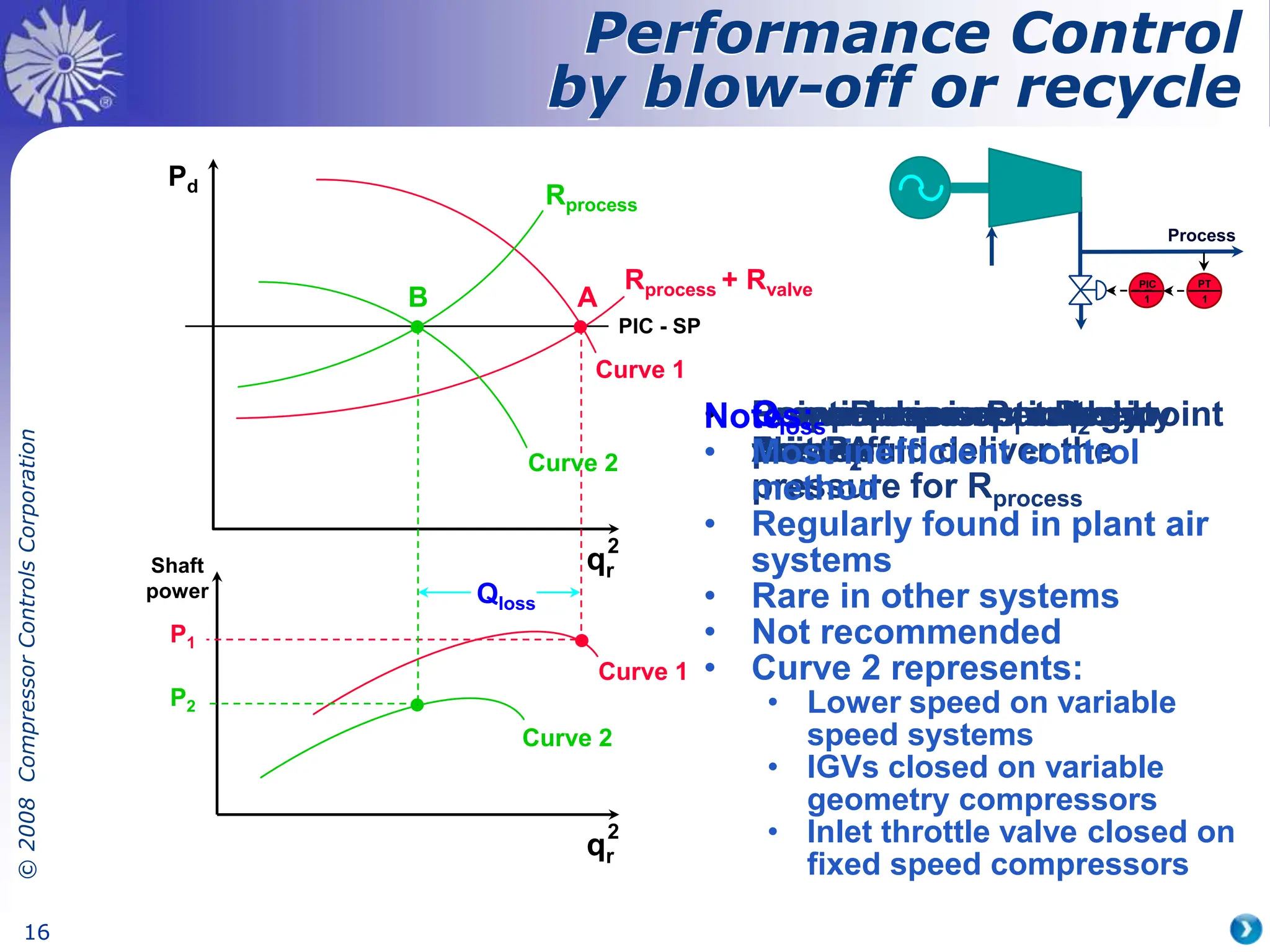

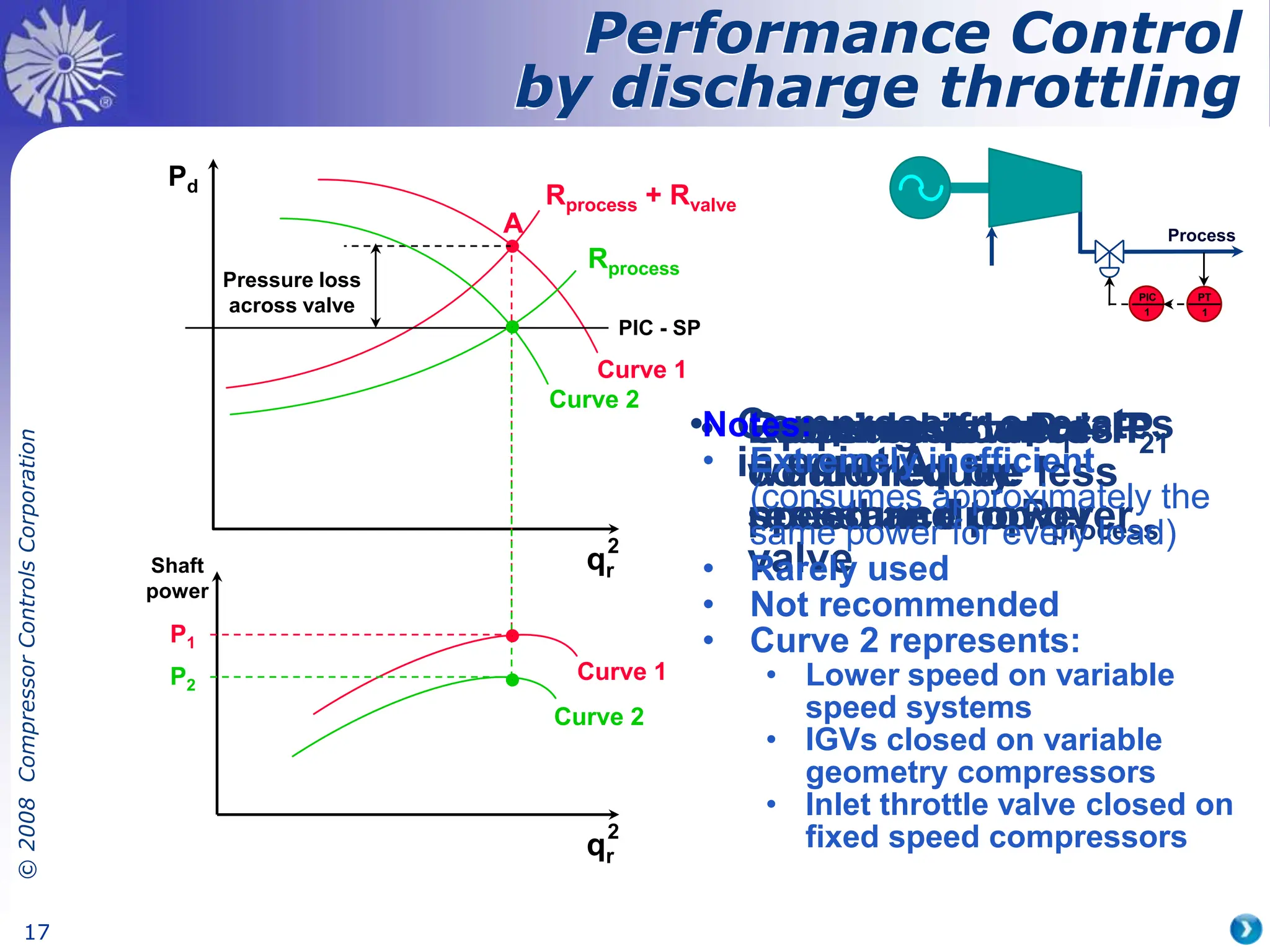

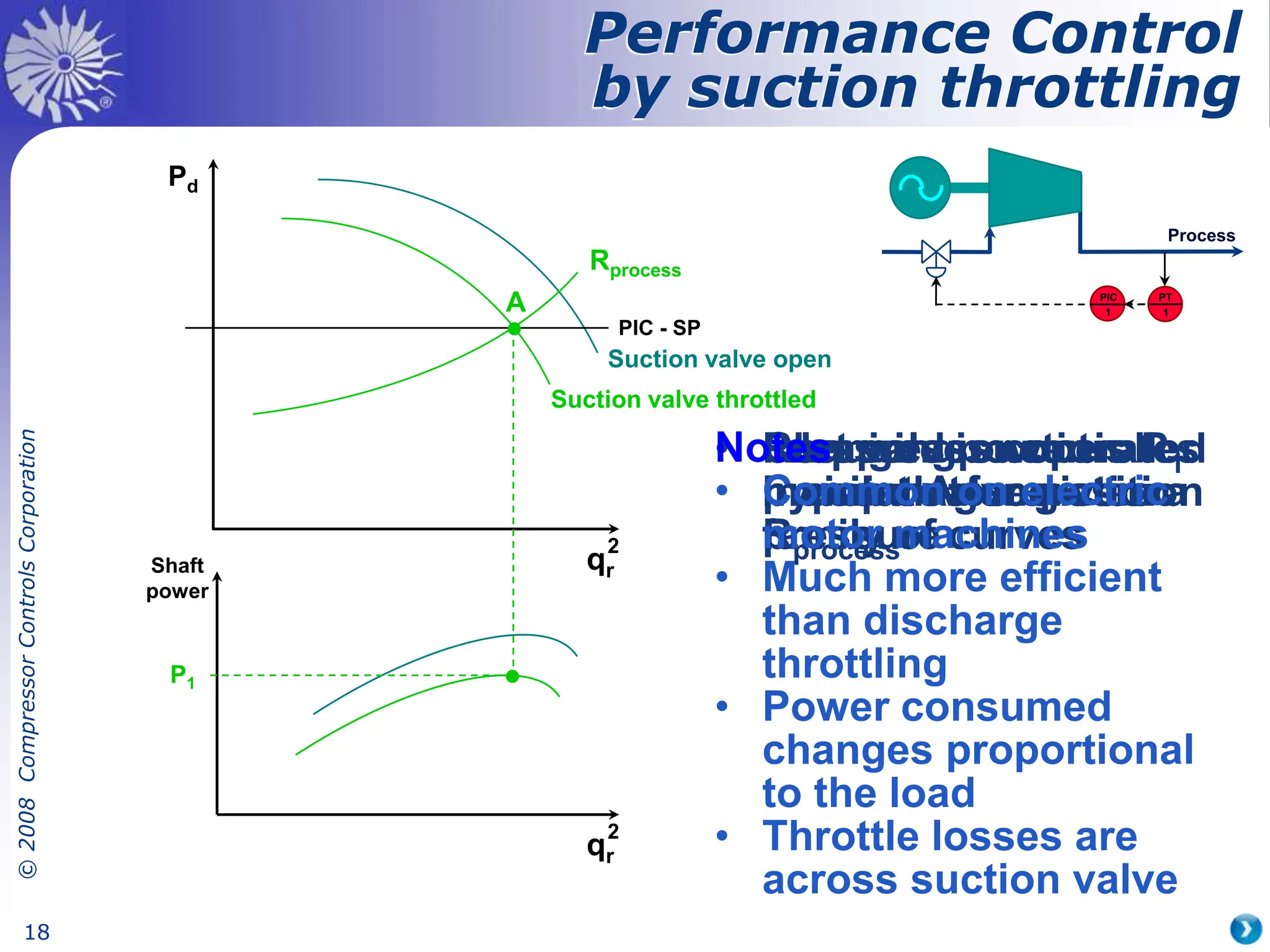

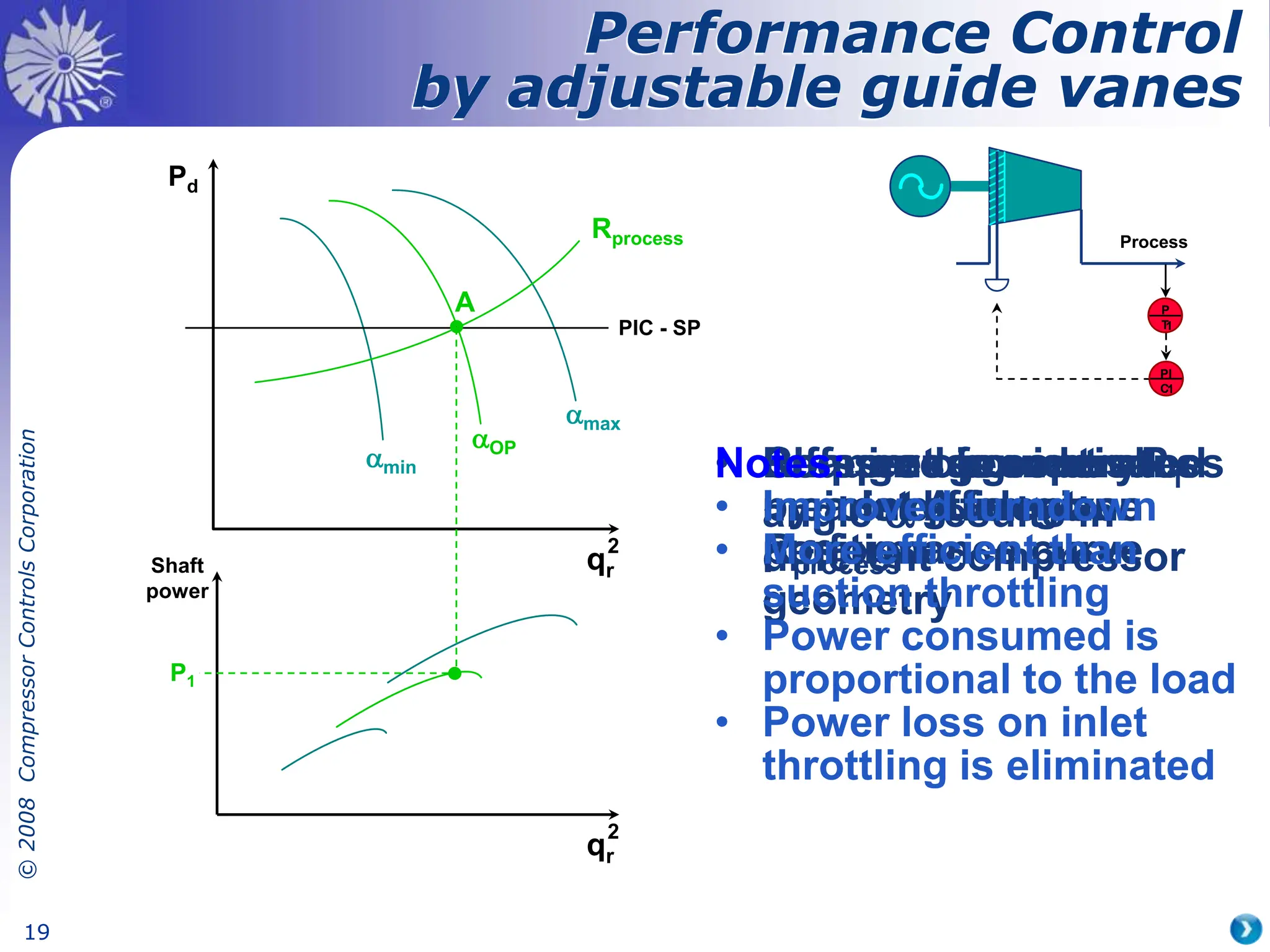

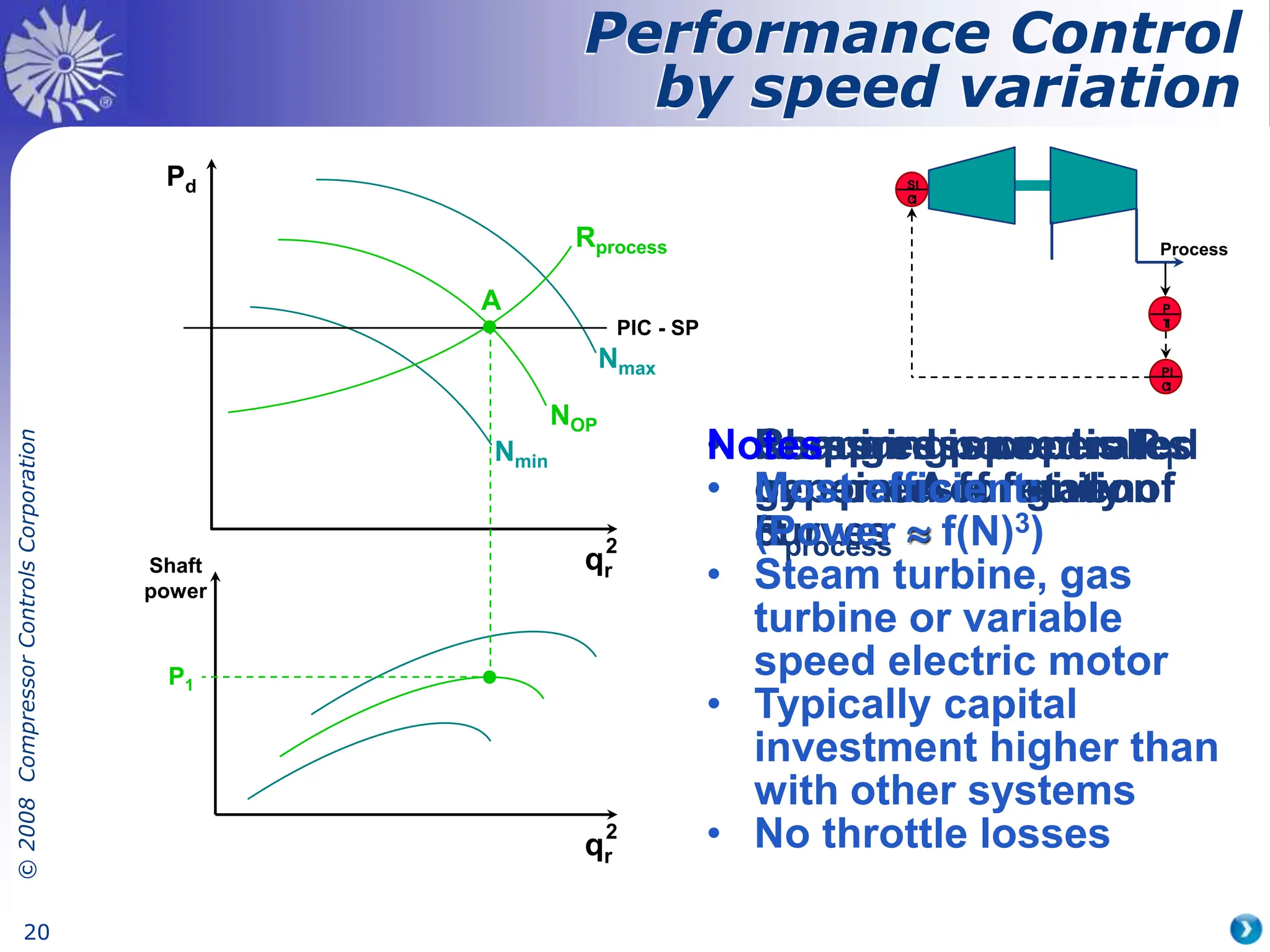

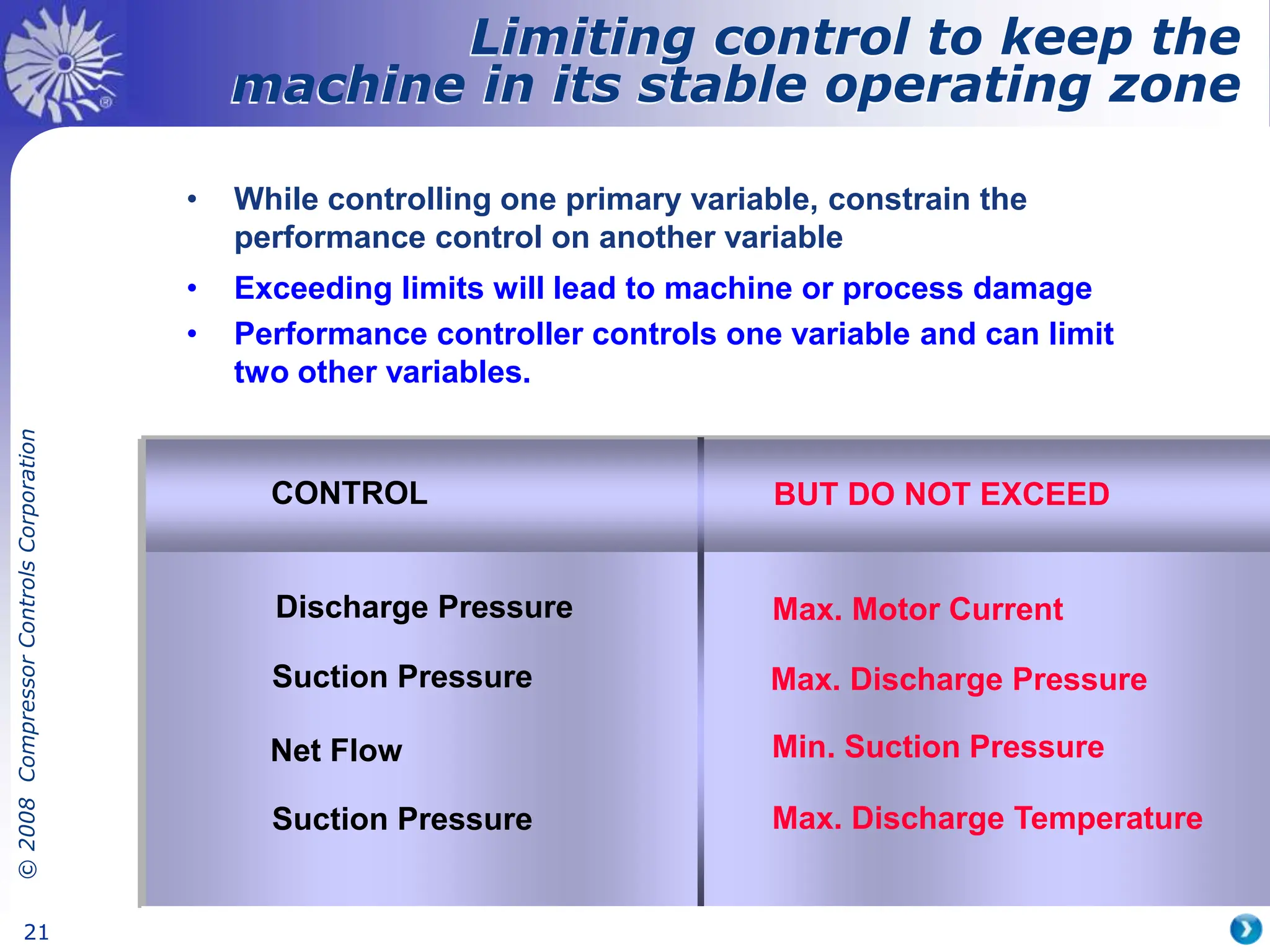

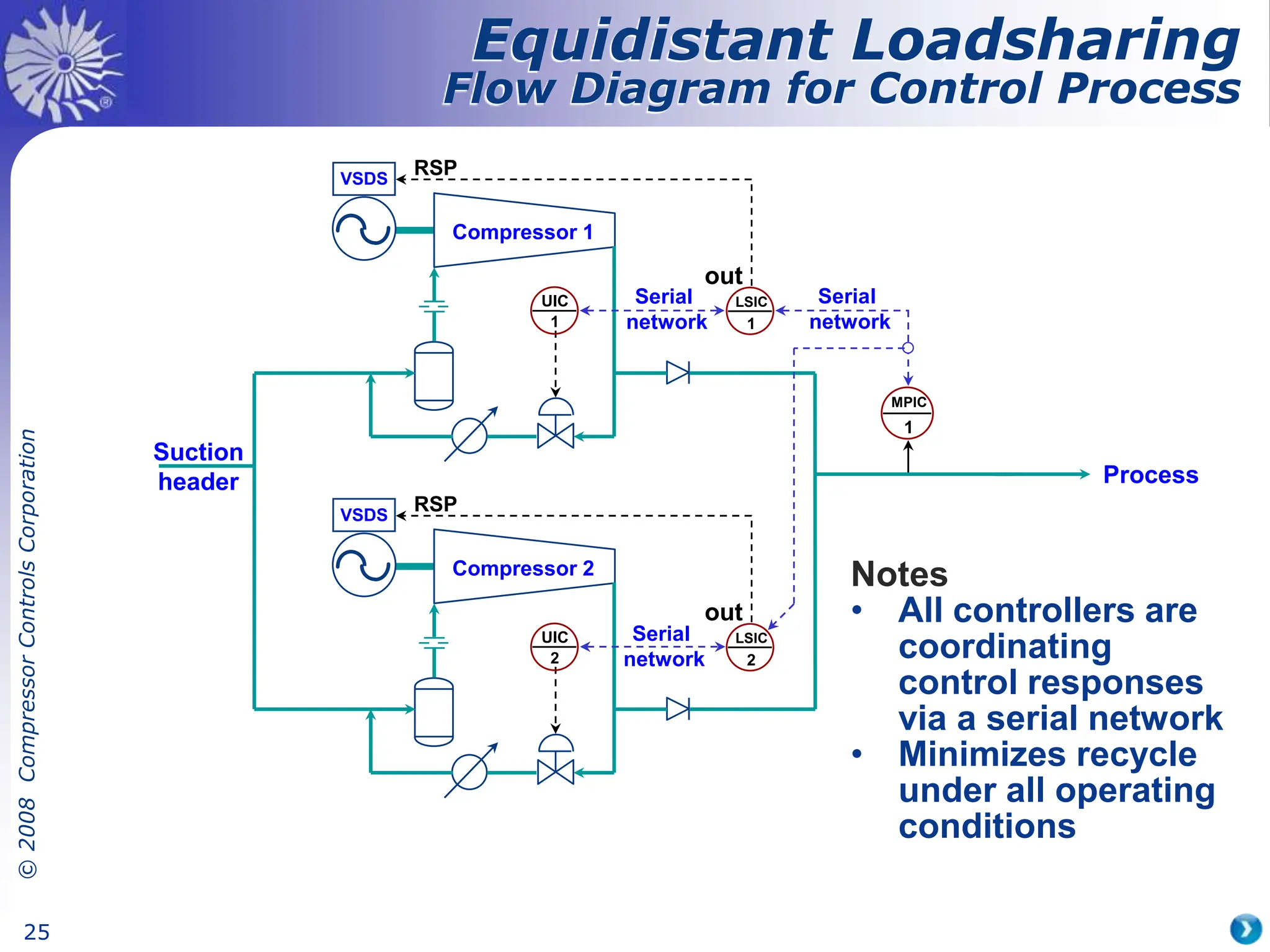

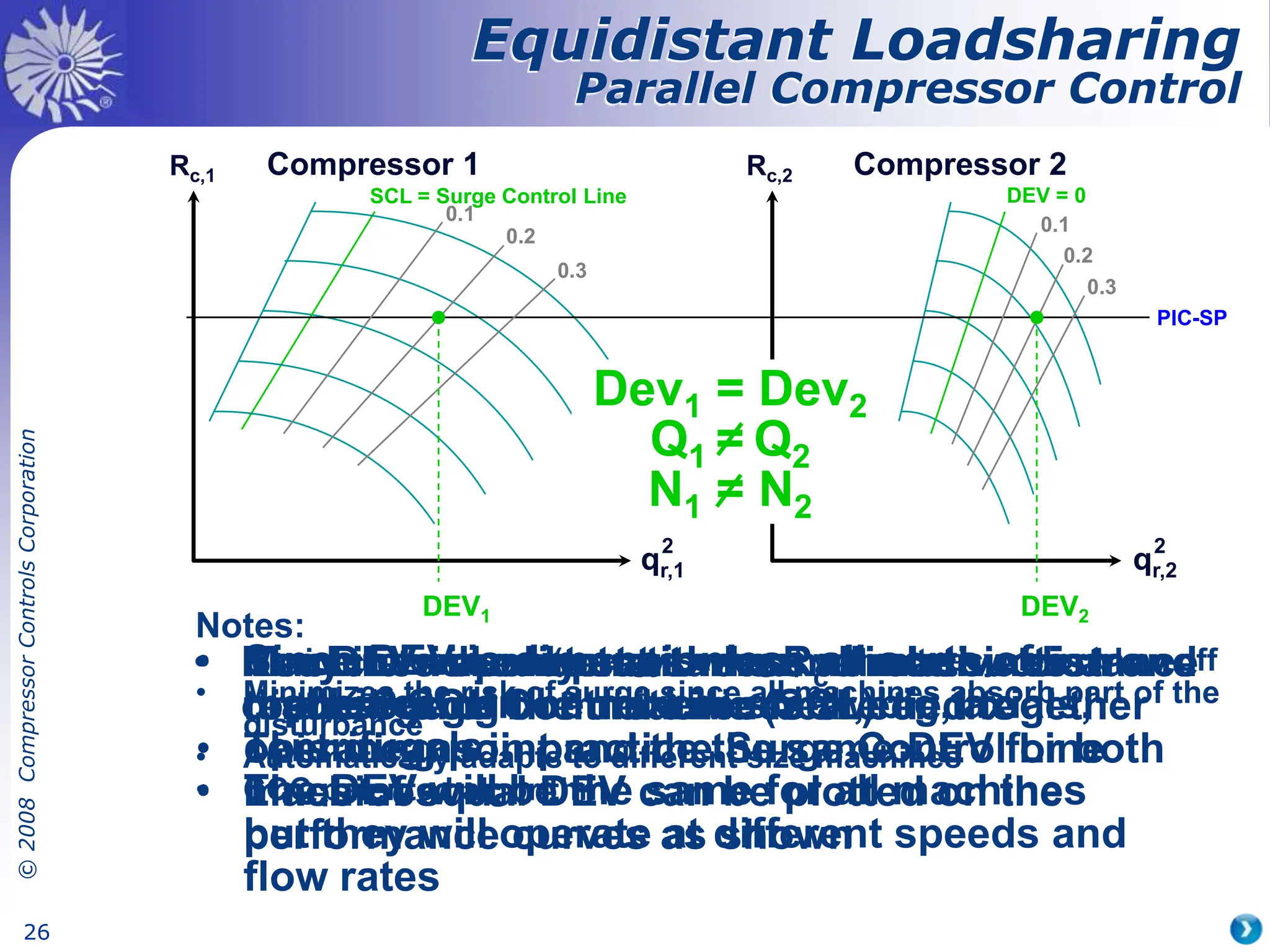

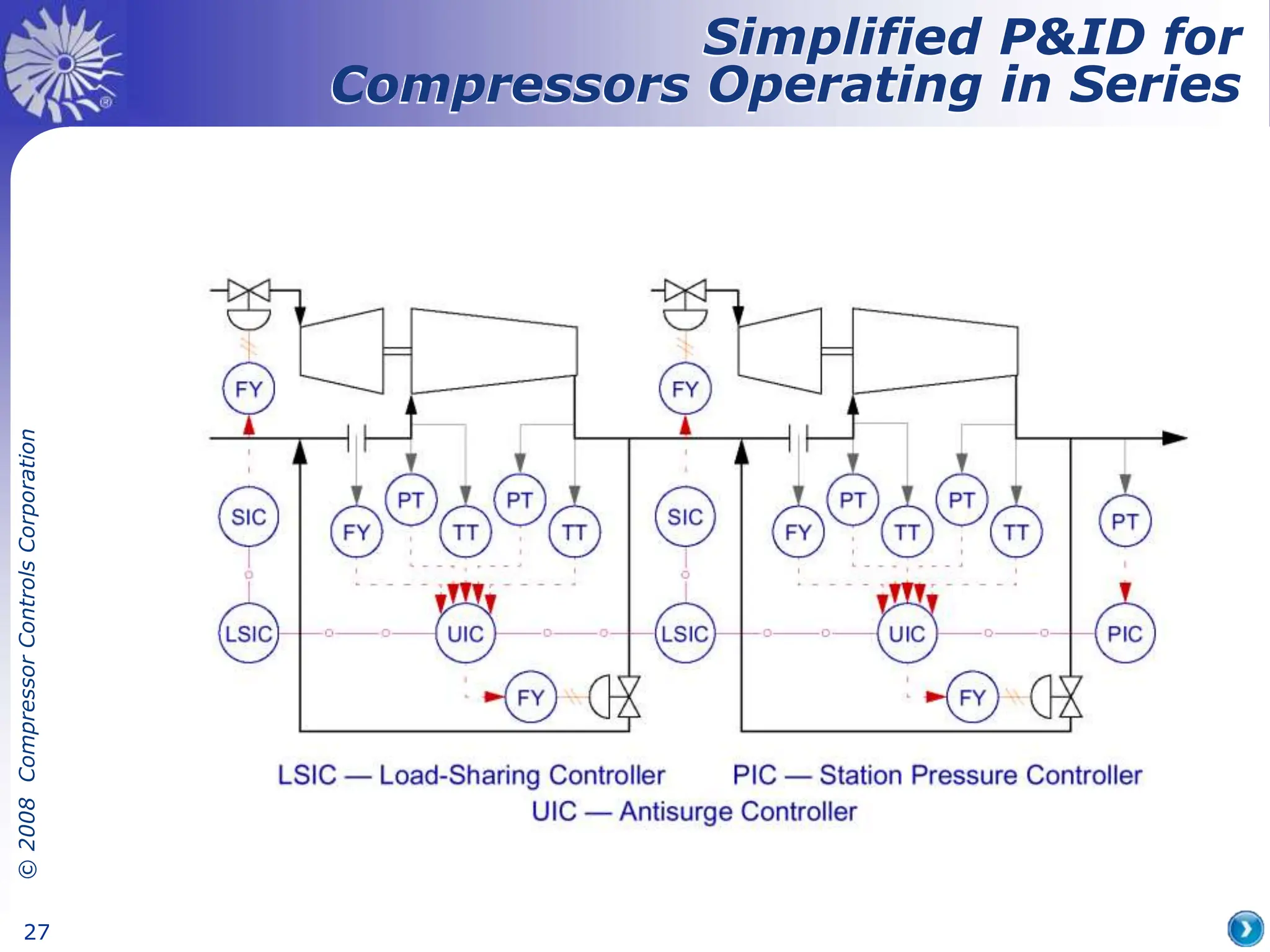

This document discusses surge in compressors and methods for controlling and preventing surge. It defines surge as a condition where the flow of gas reverses in a compressor. Left uncontrolled, surge can damage compressor components. The document describes several antisurge control methods that use recycle valves and control lines to detect impending surge and take corrective action by adjusting compressor operating points away from the surge limit. It also discusses using compressor performance control to match throughput to load by regulating discharge pressure, suction pressure, or net flow through adjustments to blow-off valves, throttling valves, inlet guide vanes, or compressor speed.