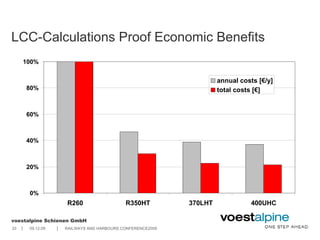

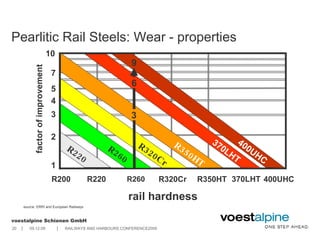

The document summarizes research on advanced high-strength rail steels and their performance in track testing. It discusses targets to develop steels with the longest lifetime, highest reliability, and lowest maintenance needs. Track tests on wear and rolling contact fatigue are described, showing improved performance of head-hardened rail steels over traditional pearlitic rails. Life-cycle cost calculations demonstrate the economic benefits of head-hardened rails through reduced maintenance requirements.

![Dimensions of the Head Check ed Area R220 R260 R350HT R350HT R260 R220 grade 15 1,2 12 0,8 18 b [mm] 1,7 a [mm] a b](https://image.slidesharecdn.com/2franknorberttrackperformance-090310165820-phpapp01/85/Track-Performance-28-320.jpg)

![Crack Depth – Grinding Requirements 2,3 mm 1,3 mm 0,4 mm R220 240 BHN 0,0 0,5 1,0 1,5 2,0 2,5 3,0 [mm] R260 280 BHN R350HT 360 BHN Metallographic Eddy Curren t](https://image.slidesharecdn.com/2franknorberttrackperformance-090310165820-phpapp01/85/Track-Performance-29-320.jpg)