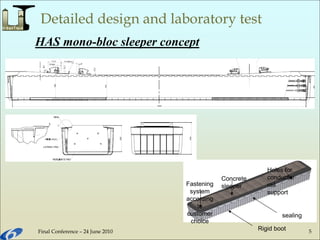

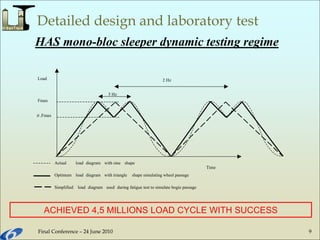

This document summarizes a study on developing an alternative to floating track slabs called a High Attenuation Sleeper track. It describes the objectives of developing a track that matches the vibration performance of floating slabs but with lower construction and maintenance costs. The chosen concept uses a mono-block resilient concrete sleeper with very soft pads. Laboratory and field tests showed the track met vibration targets. Initial cost estimates indicate it could provide up to 10% savings compared to floating slabs.