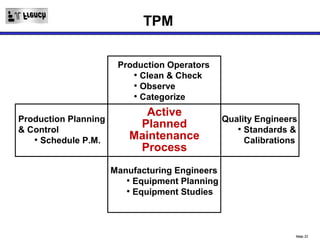

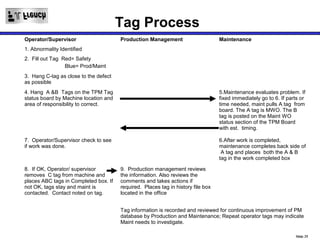

TPM (Total Productive Maintenance) is a proactive approach to maintenance that relies on operator involvement to optimize equipment effectiveness. It aims to eliminate equipment breakdowns and reduce defects through preventative and predictive maintenance practices. The presentation outlines TPM's role as a lean initiative, its 7 steps including operator autonomous maintenance and professional maintenance skills development. TPM begins with 5S and builds a comprehensive downtime database to predict and prevent issues through planned maintenance.