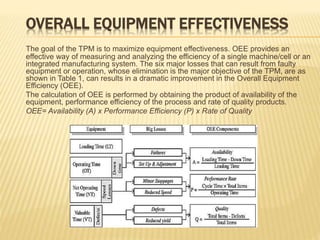

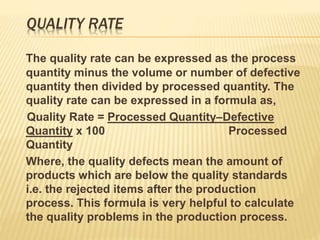

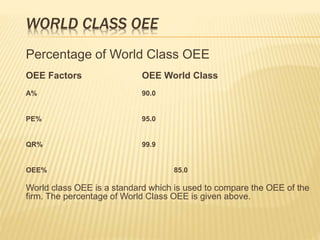

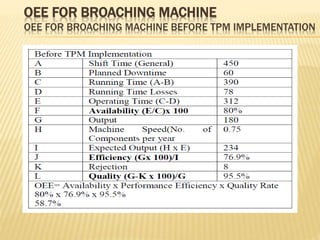

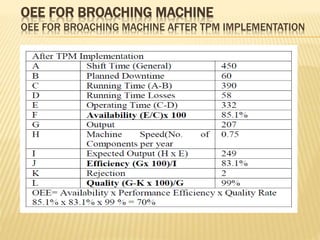

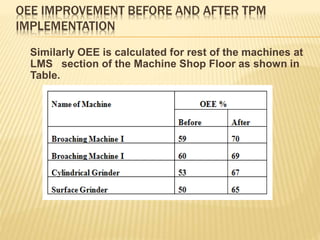

Total Productive Maintenance (TPM) is a Japanese methodology for optimizing equipment effectiveness through proactive maintenance and employee involvement. It aims for zero breakdowns, defects, and accidents. The document discusses TPM pillars and 5S methodology, and outlines steps for TPM implementation including establishing policies, training, and measuring Overall Equipment Effectiveness (OEE). It then provides a case study of a two-wheeler manufacturing plant that implemented TPM, showing significant improvements in OEE metrics like availability, performance efficiency, and quality rate.