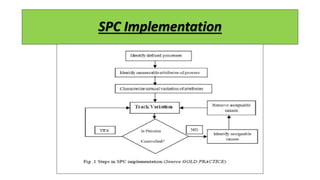

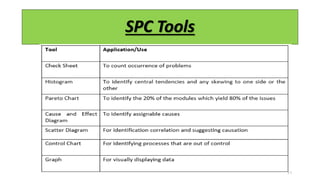

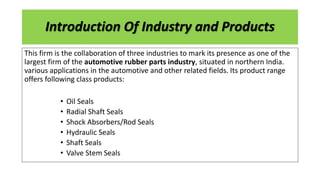

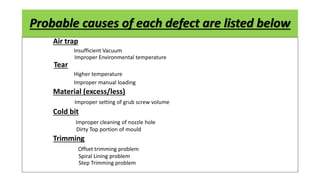

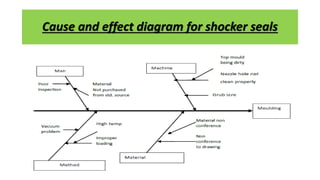

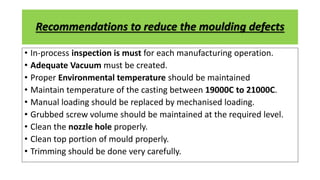

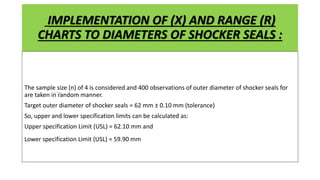

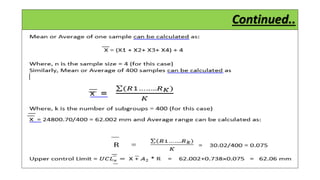

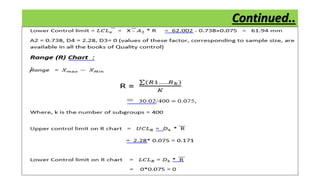

This document discusses the implementation of statistical process control (SPC) techniques at an automotive rubber parts manufacturing firm in India. It focuses on applying SPC to their production of shocker seals, which previously had an unacceptably high rejection rate of over 9%. Common defects causing shocker seal rejections are identified. Recommendations are provided to address defects, such as improving vacuum, temperature control, and inspection processes. SPC X-bar and R charts are created using data from 400 samples to monitor the diameter of shocker seals. No data points fell outside the control limits, indicating process capability was improved beyond requirements. In conclusion, applying SPC helped reduce rework costs and improve process efficiency.

![Reference

• Application of Statistical Process Control (SPC) in Manufacturing

Industry in a Developing Country.

By [Ignatio Madanhire,*, Charles Mbohwa]

• Implementation of SPC Techniques in Automotive Industry

By Dr. D. R. Prajapati

(Website: www.ijetae.com (ISSN 2250-2459, Volume 2, Issue 3,

March 2012)

• Wikipedia](https://image.slidesharecdn.com/presentationspc-180515154039/85/Statistical-process-control-15-320.jpg)