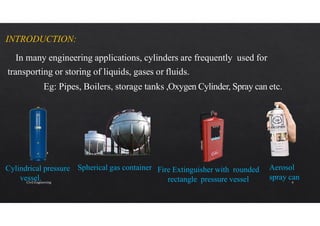

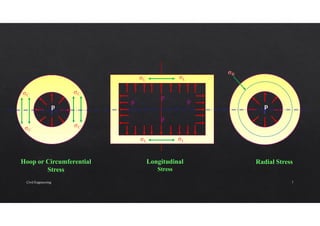

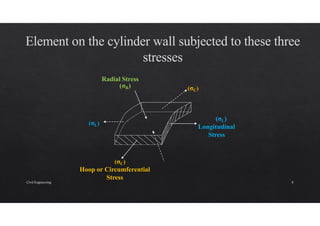

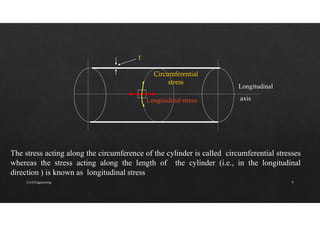

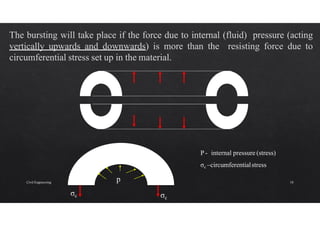

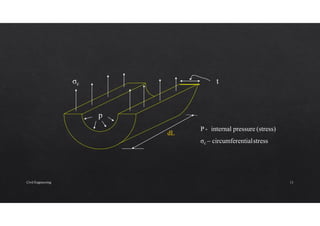

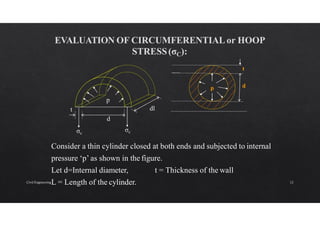

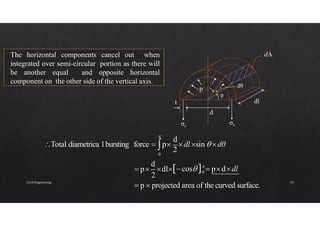

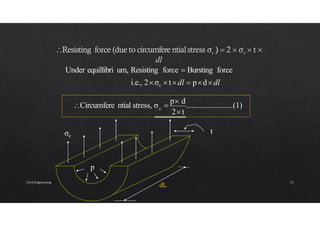

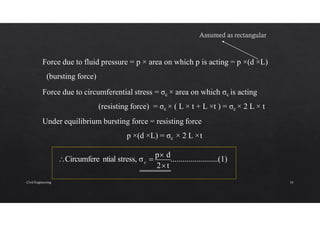

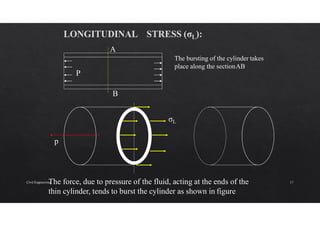

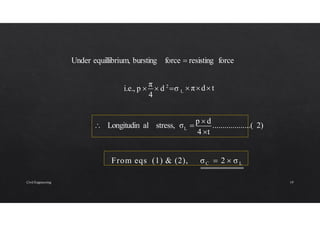

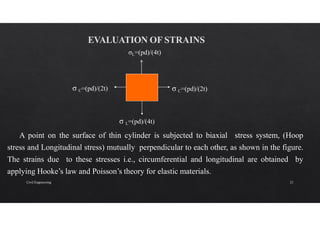

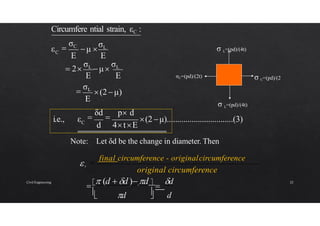

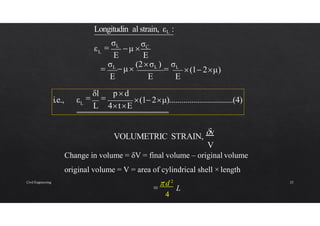

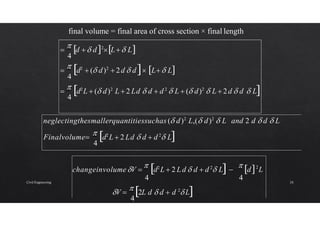

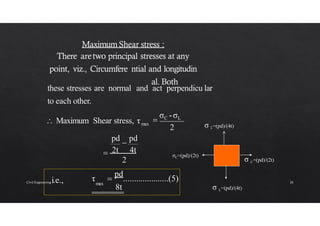

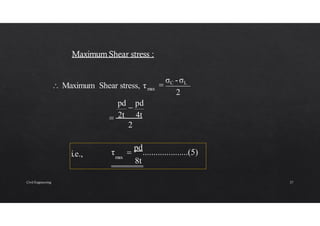

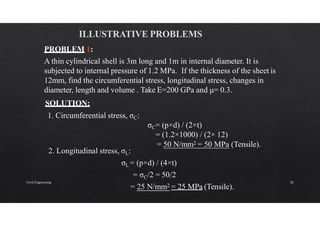

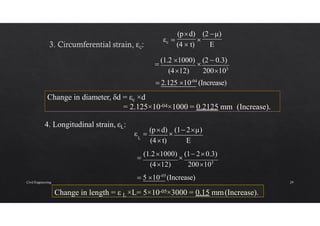

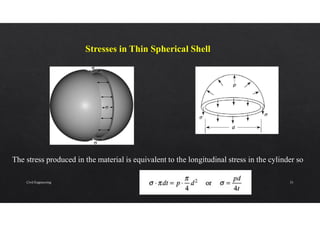

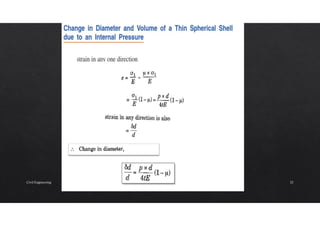

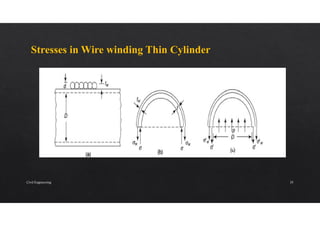

The document discusses the study of stresses and strains in cylindrical shells, specifically differentiating between thin and thick cylinders, their assumptions for analysis, and the calculations involving circumferential and longitudinal stresses. It emphasizes the practical applications of cylinders in engineering, such as pipes and pressure vessels, and incorporates equations and assumptions based on internal pressures and material properties. Moreover, the document addresses methods for evaluating the resulting strains and deformation, concluding with examples and derived formulas for stress analysis.