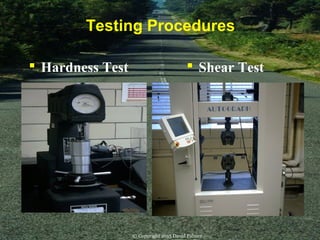

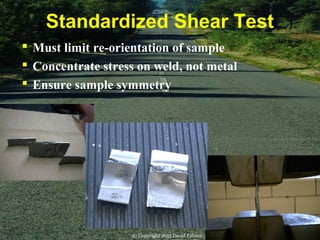

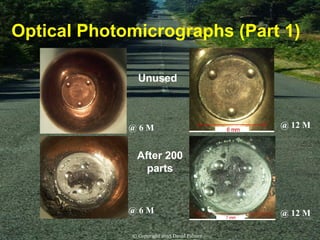

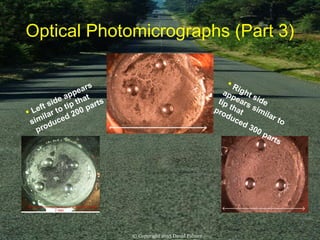

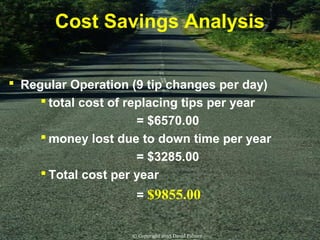

The document outlines an analysis of spot weld tip dressing at SKD Automotive, focusing on its benefits, costs, and performance compared to traditional methods. It discusses the effectiveness of copper tips, operational procedures, testing methods, and results related to tip life and weld quality. Overall, the study concludes that tip dressing enhances efficiency and could save the company between $6,500 to $7,500 annually.