Spot welding lobe curve simulation

•

1 like•688 views

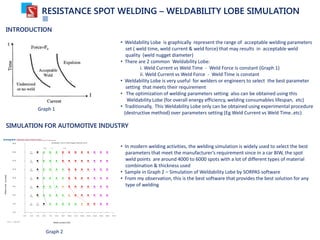

Graphical approach representing a group of spot welding parameters setting that falls under body manufacturing requirements. Used to optimize parameters setting to reduce input energy & increase productivity ( increase consumables life span)

Report

Share

Report

Share

Download to read offline

Recommended

Resistance spot welding - impact of process parameters on weld nugget formation

This article shows the relationship between spot welding parameters namely weld force, weld current and weld time & how they are inter related in weld nugget formation. Graphical lobe curve is used as presentation for better understanding. Lobe curve is very useful especially in spot welding process parameters optimization.

Resistance Spot Welding - Development of Simulation Tool for Engineers

The development of graphical tool for welding engineers & technicians to select the optimized welding parameters that suit with sheet metal and equipment to be used at production line side.

IRJET-A Study of Different Parameters of the Seam Welding Process for Reducin...

https://www.irjet.net/archives/V5/i6/IRJET-V5I6521.pdf

Optimization of mig welding parameters using taguchi optimization technique

major project on OPTIMIZATION OF MIG WELDING PARAMETERS USING TAGUCHI OPTIMIZATION TECHNIQUE

by vineet goud teja ram venkat ramana

Finite element modeling and bending stress analysis of non standard spur gear

Abstract Gears are toothed wheels, transmitting power and motion from one shaft to another by means of successive engagement of teeth. Having a higher degree of reliability, compactness, high velocity ratio and finally able to transmit motion at a very low velocity, gears are gaining importance as the most efficient means for transmitting power. A gearing system is susceptible to problems such as interference, backlash and undercut. The contact portions of tooth profiles that are not conjugate is called interference. Furthermore due to interference and in the absence of undercut, the involute tip or face of the driven gear tends to dig out the non-involute flank of the driver. The response of a spur gear and its wear is an engineering problem that has not been completely overcome yet. With the perspective of overcoming such defects and for increase the efficiency of gearing system, the use of a non-standard spur gear i.e., an asymmetric spur gear having different pressure angles for drive and coast side of the tooth comes into picture. This paper emphasis on the generation of an asymmetric spur gear tooth using modeling software and bending stress at the root of Asymmetric spur gear tooth is estimated by finite element analysis using ANSYS software and results were compared with the standard spur gear tooth. Keywords: Asymmetric spur gear, Bending stress, Finite element method, Pressure angle

Table of content

Spot Welding final year Project of B.Sc Engineering in Metallurgy and Material PU (Jameel_Sarwar)

Recommended

Resistance spot welding - impact of process parameters on weld nugget formation

This article shows the relationship between spot welding parameters namely weld force, weld current and weld time & how they are inter related in weld nugget formation. Graphical lobe curve is used as presentation for better understanding. Lobe curve is very useful especially in spot welding process parameters optimization.

Resistance Spot Welding - Development of Simulation Tool for Engineers

The development of graphical tool for welding engineers & technicians to select the optimized welding parameters that suit with sheet metal and equipment to be used at production line side.

IRJET-A Study of Different Parameters of the Seam Welding Process for Reducin...

https://www.irjet.net/archives/V5/i6/IRJET-V5I6521.pdf

Optimization of mig welding parameters using taguchi optimization technique

major project on OPTIMIZATION OF MIG WELDING PARAMETERS USING TAGUCHI OPTIMIZATION TECHNIQUE

by vineet goud teja ram venkat ramana

Finite element modeling and bending stress analysis of non standard spur gear

Abstract Gears are toothed wheels, transmitting power and motion from one shaft to another by means of successive engagement of teeth. Having a higher degree of reliability, compactness, high velocity ratio and finally able to transmit motion at a very low velocity, gears are gaining importance as the most efficient means for transmitting power. A gearing system is susceptible to problems such as interference, backlash and undercut. The contact portions of tooth profiles that are not conjugate is called interference. Furthermore due to interference and in the absence of undercut, the involute tip or face of the driven gear tends to dig out the non-involute flank of the driver. The response of a spur gear and its wear is an engineering problem that has not been completely overcome yet. With the perspective of overcoming such defects and for increase the efficiency of gearing system, the use of a non-standard spur gear i.e., an asymmetric spur gear having different pressure angles for drive and coast side of the tooth comes into picture. This paper emphasis on the generation of an asymmetric spur gear tooth using modeling software and bending stress at the root of Asymmetric spur gear tooth is estimated by finite element analysis using ANSYS software and results were compared with the standard spur gear tooth. Keywords: Asymmetric spur gear, Bending stress, Finite element method, Pressure angle

Table of content

Spot Welding final year Project of B.Sc Engineering in Metallurgy and Material PU (Jameel_Sarwar)

Design and Experimental study of Friction stir welding of AA6061-T6 Alloy for...

https://irjet.net/archives/V4/i3/IRJET-V4I307.pdf

Litrature review on numerical analysis on residual stress on plate guider

In weld, Large amount of heat is generated. For which near the welding zone some are experienced tension and some experienced compression.

That zone is called Heat Affected Zone(HAZ).

Investigation of Effect of Process Parameters on Maximum Temperature during F...

In case of friction stir welding, the maximum temperature along the weld line within appropriate range at tool workpiece interface is responsible for quality of welded joint. Through this paper, an attempt is made to establish a relationship between the input process parameters and the maximum temperature along the weld line during friction stir welding of aluminium alloy AA-7075. The design of pre-experimental simulation has been performed in accordance with full factorial technique. The simulation of friction stir welding has been performed by varying input parameters, tool rotational speed and welding speed. The analysis of variance (ANOVA) is used to investigate the effect of input parameters on maximum temperature during friction stir welding. A correlation was established between input parameters and maximum temperature by multiple regression lines. This study indicates that the tool rotational speed is the main input parameter that has high statistical influence on maximum temperature along the weld line during friction stir welding of aluminium alloy AA-7075.

Spatter Reduction by Prateek Biswas

Project on Spatter Analysis and Reduction in Automated Welding Plant B, Maruti Automobile Plant, Manesar.

Prateek Biswas

Summer Trainee

MSIL, WBMS

Manesar Plant

Study on Effect of Manual Metal Arc Welding Process Parameters on Width of He...

http://www.ijmer.com/pages/Paper-format-guidelines.html

IRJET- Effect of Al2O3 Nano-Particles on AA1060 Joints Fabricated by Friction...

https://www.irjet.net/archives/V5/i10/IRJET-V5I10275.pdf

TENSILE BEHAVIOUR OF ALUMINIUM PLATES (5083) WELDED BY FRICTION STIR WELDING

Using arc welding, gas welding and other welding process, it is very difficult to weld the aluminum alloys. Friction stir welding, on the other hand, can be used to join most Al alloys and

better surface finishing is achieved. Although the work piece does heat up during friction stir weld, the temperature does not reach the melting point.

Modeling and Simulation of Base Plate of Friction Stir Welding-Advanced Weldi...

Friction stir processing is an emerging technique based on the principles of friction stir welding (FSW). It is a solid-state joining method that is energy efficient, environmentally friendly, and versatile. It is considered by many to be the most significant development in metal joining in a decade. The basic concept of friction stir processing is remarkably simple. A rotating tool with pin and shoulder is inserted in the material to be joined, and traversed along the line of interest. The heating is localized, and is generated by friction between the tool and the work piece, with additional adiabatic heating from metal deformation. A processed zone is produced by movement of material from the front of the pin to the back of the pin.

Dynamic Response Analysis of Compressor Mounting Bracket of an Automobile Veh...

https://irjet.net/archives/V4/i9/IRJET-V4I987.pdf

IRJET- Friction Stir Welding of AA5052& AA6061 Aluminium Alloy by using T...

https://www.irjet.net/archives/V6/i3/IRJET-V6I31331.pdf

Design and Analysis of Connecting Rod of Diesel Engine

The main objective of this study is to review the weight optimization and cost reduction of a connecting rod in a Diesel engine. To get the idea about designing the connecting rod, various stresses to be considered while designing the connecting rod .This has entailed performing a detailed load analysis. The most important factors that are concentrated are stress distribution and deflections. In this project the connecting rod is designed with respect to all the available constraints using advanced cad software CATIA. Later the product file is converted to .stp file format standard exchange of product file and imported to ANSYS workbench to find deformation and analytic valve with respect to the model or product definitions. A. Vijay Kumar | K. Mihir | M. Mrudul | P. Pavan Kumar ""Design and Analysis of Connecting Rod of Diesel Engine"" Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-3 | Issue-3 , April 2019, URL: https://www.ijtsrd.com/papers/ijtsrd23182.pdf

Paper URL: https://www.ijtsrd.com/engineering/mechanical-engineering/23182/design-and-analysis-of-connecting-rod-of-diesel-engine/a-vijay-kumar

Optimization of mig welding parameters using taguchi optimization technique

major project on OPTIMIZATION OF MIG WELDING PARAMETERS USING TAGUCHI OPTIMIZATION TECHNIQUE by vineeth goud tejaram venkat ramana

IRJET- Analysis and Optimization of Weld Distortion in Automobile Chassis

https://www.irjet.net/archives/V6/i9/IRJET-V6I929.pdf

An Experimental Analysis and Optimization of Process Parameters on Friction S...

https://irjet.net/archives/V4/i7/IRJET-V4I7661.pdf

Experimental Investigations of Friction Stir Welding (FSW) on Al 6061 : A Cas...

https://irjet.net/archives/V4/i8/IRJET-V4I8228.pdf

Design and Analysis of Multi Spindle Drilling Head with Adjustable Centre Dis...

https://irjet.net/archives/V4/i9/IRJET-V4I994.pdf

A REVIEW ON OPTIMIZATION OF RESISTANCE SPOT WELDING OF ALUMINUM COMPONENTS US...

Resistance Spot welding (RSW) is one of the common welding processes used for sheet joining especially in the automobile and aerospace industry. It is used in a wide range of industries but notably for the assembly of sheet steel vehicle bodies. This is a type of resistance welding where the spot welds are made at regular intervals on overlapping sheets of metal. Spot welding is primarily used for joining parts that are normally up to 3 mm in thickness. The joint quality can be defined in terms of properties such as weld-bead geometry, mechanical properties and distortion.The objective of the research is to determine the optimum combination of parameters responsible for better quality of joints. The complicated behavior of the process must be analyzed to set the optimum parameters to get the optimum weld quality. The paper also presents the FEA simulation of the RSW process.

Study of Simulated Temperature of Butt Joint during Friction Stir Welding Of ...

Friction stir welding (FSW) is one of the latest welding technology that utilizes a special tool for generation of frictional heat in the work piece by its rotation due to which joining occurs without melting of metal. For this reason friction stir welding lies under the category of solid state joining. A part from experimental work, there is large space to work on simulation of FSW by using simulation tools. In the present paper, simulation of friction stir welding of aluminium alloy AA-6061 is done by using HyperWeld module of Altair HyperWorks. The virtual experiment of friction stir welding is conducted for variable tool rotational speeds with constant travelling speed and study of simulation results of variation in temperature distribution along the weld line of butt joint is done. The results of simulation shows that the temperature is symmetrically distributed along the weld line. It is observed that the maximum temperature along the weld line increases with the increase in rotational speed. It is also observed that the temperature at advancing side is greater that retreating side.

Effect on Width, Height and Penetration of V-Groove Butt Joint Weld Bead by V...

https://www.irjet.net/archives/V4/i12/IRJET-V4I12112.pdf

Development of Process for Replacement of Mill Roller

https://www.irjet.net/archives/V9/i6/IRJET-V9I6140.pdf

More Related Content

What's hot

Design and Experimental study of Friction stir welding of AA6061-T6 Alloy for...

https://irjet.net/archives/V4/i3/IRJET-V4I307.pdf

Litrature review on numerical analysis on residual stress on plate guider

In weld, Large amount of heat is generated. For which near the welding zone some are experienced tension and some experienced compression.

That zone is called Heat Affected Zone(HAZ).

Investigation of Effect of Process Parameters on Maximum Temperature during F...

In case of friction stir welding, the maximum temperature along the weld line within appropriate range at tool workpiece interface is responsible for quality of welded joint. Through this paper, an attempt is made to establish a relationship between the input process parameters and the maximum temperature along the weld line during friction stir welding of aluminium alloy AA-7075. The design of pre-experimental simulation has been performed in accordance with full factorial technique. The simulation of friction stir welding has been performed by varying input parameters, tool rotational speed and welding speed. The analysis of variance (ANOVA) is used to investigate the effect of input parameters on maximum temperature during friction stir welding. A correlation was established between input parameters and maximum temperature by multiple regression lines. This study indicates that the tool rotational speed is the main input parameter that has high statistical influence on maximum temperature along the weld line during friction stir welding of aluminium alloy AA-7075.

Spatter Reduction by Prateek Biswas

Project on Spatter Analysis and Reduction in Automated Welding Plant B, Maruti Automobile Plant, Manesar.

Prateek Biswas

Summer Trainee

MSIL, WBMS

Manesar Plant

Study on Effect of Manual Metal Arc Welding Process Parameters on Width of He...

http://www.ijmer.com/pages/Paper-format-guidelines.html

IRJET- Effect of Al2O3 Nano-Particles on AA1060 Joints Fabricated by Friction...

https://www.irjet.net/archives/V5/i10/IRJET-V5I10275.pdf

TENSILE BEHAVIOUR OF ALUMINIUM PLATES (5083) WELDED BY FRICTION STIR WELDING

Using arc welding, gas welding and other welding process, it is very difficult to weld the aluminum alloys. Friction stir welding, on the other hand, can be used to join most Al alloys and

better surface finishing is achieved. Although the work piece does heat up during friction stir weld, the temperature does not reach the melting point.

Modeling and Simulation of Base Plate of Friction Stir Welding-Advanced Weldi...

Friction stir processing is an emerging technique based on the principles of friction stir welding (FSW). It is a solid-state joining method that is energy efficient, environmentally friendly, and versatile. It is considered by many to be the most significant development in metal joining in a decade. The basic concept of friction stir processing is remarkably simple. A rotating tool with pin and shoulder is inserted in the material to be joined, and traversed along the line of interest. The heating is localized, and is generated by friction between the tool and the work piece, with additional adiabatic heating from metal deformation. A processed zone is produced by movement of material from the front of the pin to the back of the pin.

Dynamic Response Analysis of Compressor Mounting Bracket of an Automobile Veh...

https://irjet.net/archives/V4/i9/IRJET-V4I987.pdf

IRJET- Friction Stir Welding of AA5052& AA6061 Aluminium Alloy by using T...

https://www.irjet.net/archives/V6/i3/IRJET-V6I31331.pdf

Design and Analysis of Connecting Rod of Diesel Engine

The main objective of this study is to review the weight optimization and cost reduction of a connecting rod in a Diesel engine. To get the idea about designing the connecting rod, various stresses to be considered while designing the connecting rod .This has entailed performing a detailed load analysis. The most important factors that are concentrated are stress distribution and deflections. In this project the connecting rod is designed with respect to all the available constraints using advanced cad software CATIA. Later the product file is converted to .stp file format standard exchange of product file and imported to ANSYS workbench to find deformation and analytic valve with respect to the model or product definitions. A. Vijay Kumar | K. Mihir | M. Mrudul | P. Pavan Kumar ""Design and Analysis of Connecting Rod of Diesel Engine"" Published in International Journal of Trend in Scientific Research and Development (ijtsrd), ISSN: 2456-6470, Volume-3 | Issue-3 , April 2019, URL: https://www.ijtsrd.com/papers/ijtsrd23182.pdf

Paper URL: https://www.ijtsrd.com/engineering/mechanical-engineering/23182/design-and-analysis-of-connecting-rod-of-diesel-engine/a-vijay-kumar

Optimization of mig welding parameters using taguchi optimization technique

major project on OPTIMIZATION OF MIG WELDING PARAMETERS USING TAGUCHI OPTIMIZATION TECHNIQUE by vineeth goud tejaram venkat ramana

IRJET- Analysis and Optimization of Weld Distortion in Automobile Chassis

https://www.irjet.net/archives/V6/i9/IRJET-V6I929.pdf

An Experimental Analysis and Optimization of Process Parameters on Friction S...

https://irjet.net/archives/V4/i7/IRJET-V4I7661.pdf

Experimental Investigations of Friction Stir Welding (FSW) on Al 6061 : A Cas...

https://irjet.net/archives/V4/i8/IRJET-V4I8228.pdf

Design and Analysis of Multi Spindle Drilling Head with Adjustable Centre Dis...

https://irjet.net/archives/V4/i9/IRJET-V4I994.pdf

A REVIEW ON OPTIMIZATION OF RESISTANCE SPOT WELDING OF ALUMINUM COMPONENTS US...

Resistance Spot welding (RSW) is one of the common welding processes used for sheet joining especially in the automobile and aerospace industry. It is used in a wide range of industries but notably for the assembly of sheet steel vehicle bodies. This is a type of resistance welding where the spot welds are made at regular intervals on overlapping sheets of metal. Spot welding is primarily used for joining parts that are normally up to 3 mm in thickness. The joint quality can be defined in terms of properties such as weld-bead geometry, mechanical properties and distortion.The objective of the research is to determine the optimum combination of parameters responsible for better quality of joints. The complicated behavior of the process must be analyzed to set the optimum parameters to get the optimum weld quality. The paper also presents the FEA simulation of the RSW process.

Study of Simulated Temperature of Butt Joint during Friction Stir Welding Of ...

Friction stir welding (FSW) is one of the latest welding technology that utilizes a special tool for generation of frictional heat in the work piece by its rotation due to which joining occurs without melting of metal. For this reason friction stir welding lies under the category of solid state joining. A part from experimental work, there is large space to work on simulation of FSW by using simulation tools. In the present paper, simulation of friction stir welding of aluminium alloy AA-6061 is done by using HyperWeld module of Altair HyperWorks. The virtual experiment of friction stir welding is conducted for variable tool rotational speeds with constant travelling speed and study of simulation results of variation in temperature distribution along the weld line of butt joint is done. The results of simulation shows that the temperature is symmetrically distributed along the weld line. It is observed that the maximum temperature along the weld line increases with the increase in rotational speed. It is also observed that the temperature at advancing side is greater that retreating side.

What's hot (20)

Design and Experimental study of Friction stir welding of AA6061-T6 Alloy for...

Design and Experimental study of Friction stir welding of AA6061-T6 Alloy for...

Litrature review on numerical analysis on residual stress on plate guider

Litrature review on numerical analysis on residual stress on plate guider

Investigation of Effect of Process Parameters on Maximum Temperature during F...

Investigation of Effect of Process Parameters on Maximum Temperature during F...

Study on Effect of Manual Metal Arc Welding Process Parameters on Width of He...

Study on Effect of Manual Metal Arc Welding Process Parameters on Width of He...

IRJET- Effect of Al2O3 Nano-Particles on AA1060 Joints Fabricated by Friction...

IRJET- Effect of Al2O3 Nano-Particles on AA1060 Joints Fabricated by Friction...

TENSILE BEHAVIOUR OF ALUMINIUM PLATES (5083) WELDED BY FRICTION STIR WELDING

TENSILE BEHAVIOUR OF ALUMINIUM PLATES (5083) WELDED BY FRICTION STIR WELDING

Modeling and Simulation of Base Plate of Friction Stir Welding-Advanced Weldi...

Modeling and Simulation of Base Plate of Friction Stir Welding-Advanced Weldi...

Dynamic Response Analysis of Compressor Mounting Bracket of an Automobile Veh...

Dynamic Response Analysis of Compressor Mounting Bracket of an Automobile Veh...

IRJET- Friction Stir Welding of AA5052& AA6061 Aluminium Alloy by using T...

IRJET- Friction Stir Welding of AA5052& AA6061 Aluminium Alloy by using T...

Design and Analysis of Connecting Rod of Diesel Engine

Design and Analysis of Connecting Rod of Diesel Engine

Optimization of mig welding parameters using taguchi optimization technique

Optimization of mig welding parameters using taguchi optimization technique

IRJET- Analysis and Optimization of Weld Distortion in Automobile Chassis

IRJET- Analysis and Optimization of Weld Distortion in Automobile Chassis

An Experimental Analysis and Optimization of Process Parameters on Friction S...

An Experimental Analysis and Optimization of Process Parameters on Friction S...

Experimental Investigations of Friction Stir Welding (FSW) on Al 6061 : A Cas...

Experimental Investigations of Friction Stir Welding (FSW) on Al 6061 : A Cas...

Design and Analysis of Multi Spindle Drilling Head with Adjustable Centre Dis...

Design and Analysis of Multi Spindle Drilling Head with Adjustable Centre Dis...

A REVIEW ON OPTIMIZATION OF RESISTANCE SPOT WELDING OF ALUMINUM COMPONENTS US...

A REVIEW ON OPTIMIZATION OF RESISTANCE SPOT WELDING OF ALUMINUM COMPONENTS US...

Study of Simulated Temperature of Butt Joint during Friction Stir Welding Of ...

Study of Simulated Temperature of Butt Joint during Friction Stir Welding Of ...

Similar to Spot welding lobe curve simulation

Effect on Width, Height and Penetration of V-Groove Butt Joint Weld Bead by V...

https://www.irjet.net/archives/V4/i12/IRJET-V4I12112.pdf

Development of Process for Replacement of Mill Roller

https://www.irjet.net/archives/V9/i6/IRJET-V9I6140.pdf

An Experimental Study to Predict Optimum Weld Bead Geometry through Effect of...

International Journal of Modern Engineering Research (IJMER) is Peer reviewed, online Journal. It serves as an international archival forum of scholarly research related to engineering and science education.

International Journal of Modern Engineering Research (IJMER) covers all the fields of engineering and science: Electrical Engineering, Mechanical Engineering, Civil Engineering, Chemical Engineering, Computer Engineering, Agricultural Engineering, Aerospace Engineering, Thermodynamics, Structural Engineering, Control Engineering, Robotics, Mechatronics, Fluid Mechanics, Nanotechnology, Simulators, Web-based Learning, Remote Laboratories, Engineering Design Methods, Education Research, Students' Satisfaction and Motivation, Global Projects, and Assessment…. And many more.

IRJET - Mathematical Analysis of Angular Distortion on GTA Welded Hot Rolled ...

https://irjet.net/archives/V7/i3/IRJET-V7I3473.pdf

Weld Improvement Example in Offshore Oil & Gas

Weld improvement examples in offshore oil and gas platforms. Professional training courses in the energy industry, Methods to manage corrosion and crack growth. Where to perform grinding by a burr grinder?

THE EFFECT OF OPENINGS IN THE SLAB STIFFENED WITH SHALLOW BEAMS

https://www.irjet.net/archives/V10/i10/IRJET-V10I1097.pdf

Simulation of Deep-Drawing Process of Large Panels

The article deals with the analysis of formability of deep-drawing DC06 steel sheets. The aim of the investigations is to verify possibilities of formability of sheet metal with thickness of 0.85 mm. The mechanical parameters of the sheets have been determined in uniaxial tensile and bulge tests. The numerical simulations using AUTOFORM has been carried out for two drawpiece models. Obtained results can be used during the simulation of real forming process.

Multiphysics Modeling of Induction Machines_Jd'12 pres

in this paper we interest to how we can validate simultaneously a thermal model and estimated variable of induction motor. This approach is possible by using special simulation package frequently exploited bout in university and industry. A simple description of each one of this famous software is presented.

According to our needs and means; I took a justified choice of the used software in this validation context. In this moment, I make

only the modeling of an induction machine without takes into account the heating effects. Same simulation results of induction

motor model by Maxwell software is given and commented.

Design and Stress Analysis of High Pressure Accumulator

https://irjet.net/archives/V4/i7/IRJET-V4I742.pdf

Resistance Spot Welding - Process Optimization using Lobe Curve Generator

In spot welding process, process parameters optimization means improve spot welding quality while reduce operational cost especially power consumption and welding consumables. Lobe curve generators may assist welding engineers and technicians to select the best welding parameters according to their requirements.

IRJET- Experimental Parametric Study of Diagrid Structure under Seismic Forces

https://www.irjet.net/archives/V6/i4/IRJET-V6I4929.pdf

IRJET- Experimental Study on Behaviour of Cold-Formed Steel Castellated Beam

https://www.irjet.net/archives/V6/i4/IRJET-V6I4800.pdf

International Journal of Engineering Research and Development

International Journal of Engineering Research and Development

Effect of Factors Influencing of Shear Resistance on the Energy Dissipation C...

https://www.irjet.net/archives/V9/i8/IRJET-V9I8133.pdf

Ijsea04031001

“Laser Cutting of weldox-700 materials is popular processes in manufacturing industries This research paper for primary study for evaluate the effect of the processing parameters (Laser Power, gas pressure, pulse frequency and Cutting speed) under the quality of the cut for weldox-700 materials. Then the experiment was done by 6mm thick weldox-700 material plates. In this experiment focused on establish relation of different parameters on Cutting quality, which is decided by the Surface Roughness and Kerf Width.

Design and Finite Element Analysis of Fixture for Milling of Cummins Engine B...

https://irjet.net/archives/V4/i8/IRJET-V4I8400.pdf

IRJET- Effectiveness of Different Crack Depth at Various Locations of Ste...

https://www.irjet.net/archives/V6/i9/IRJET-V6I9274.pdf

Similar to Spot welding lobe curve simulation (20)

Effect on Width, Height and Penetration of V-Groove Butt Joint Weld Bead by V...

Effect on Width, Height and Penetration of V-Groove Butt Joint Weld Bead by V...

Development of Process for Replacement of Mill Roller

Development of Process for Replacement of Mill Roller

An Experimental Study to Predict Optimum Weld Bead Geometry through Effect of...

An Experimental Study to Predict Optimum Weld Bead Geometry through Effect of...

IRJET - Mathematical Analysis of Angular Distortion on GTA Welded Hot Rolled ...

IRJET - Mathematical Analysis of Angular Distortion on GTA Welded Hot Rolled ...

THE EFFECT OF OPENINGS IN THE SLAB STIFFENED WITH SHALLOW BEAMS

THE EFFECT OF OPENINGS IN THE SLAB STIFFENED WITH SHALLOW BEAMS

Simulation of Deep-Drawing Process of Large Panels

Simulation of Deep-Drawing Process of Large Panels

Multiphysics Modeling of Induction Machines_Jd'12 pres

Multiphysics Modeling of Induction Machines_Jd'12 pres

Design and Stress Analysis of High Pressure Accumulator

Design and Stress Analysis of High Pressure Accumulator

Resistance Spot Welding - Process Optimization using Lobe Curve Generator

Resistance Spot Welding - Process Optimization using Lobe Curve Generator

IRJET- Experimental Parametric Study of Diagrid Structure under Seismic Forces

IRJET- Experimental Parametric Study of Diagrid Structure under Seismic Forces

IRJET- Experimental Study on Behaviour of Cold-Formed Steel Castellated Beam

IRJET- Experimental Study on Behaviour of Cold-Formed Steel Castellated Beam

International Journal of Engineering Research and Development

International Journal of Engineering Research and Development

Effect of Factors Influencing of Shear Resistance on the Energy Dissipation C...

Effect of Factors Influencing of Shear Resistance on the Energy Dissipation C...

Design and Finite Element Analysis of Fixture for Milling of Cummins Engine B...

Design and Finite Element Analysis of Fixture for Milling of Cummins Engine B...

IRJET- Effectiveness of Different Crack Depth at Various Locations of Ste...

IRJET- Effectiveness of Different Crack Depth at Various Locations of Ste...

More from Rashidi Asari

Automotive Industrial Robot-Total Cost of Ownership

A financial approach in evaluating & selecting industrial robot brand to be used in automotive body assembly processes

Automotive Body Shop Industry 4.0

Future plan for automotive body assembly line to align with industry 4.0, towards smart & adaptive factory system

Process Time & Ergonomics - Case Study

The simple projects improving process time & ergonomics in sub assembly line

Basic of manufacturing system

A basic manufacturing system adopted from Toyota Production System that mostly implemented in automotive industries

Aku bermimpi suatu hari aku pergi ke surga

Slides from Malaysian writer, promoting to always be thankful in the life (In Malay)

Spot welding basic parameters setting - basic calculations / equations

Basic mathematical equations used to approximate the optimum spot welding parameters setting for AC & DC welding through Lobe Curve

Automotive Laser Welding Application

The comparison of automotive assembly method between spot welding & laser welding in term of application and cost

Automated Guided Dolly (AGD)

Inspired by Automated Guided Vehicle (AGV) concepts, the 'Automated Guided Dolly' is designed, fabricated & programmed to carry the total load of 750kg (body + dolly) and transfer body from starting point to the next point. Then, the empty dolly will go back to the starting point once the body is delivered.

More from Rashidi Asari (11)

Automotive Industrial Robot-Total Cost of Ownership

Automotive Industrial Robot-Total Cost of Ownership

Spot welding basic parameters setting - basic calculations / equations

Spot welding basic parameters setting - basic calculations / equations

Recently uploaded

J.Yang, ICLR 2024, MLILAB, KAIST AI.pdf

Language-Interfaced Tabular Oversampling Via Progressive Imputation And Self Autentication

Runway Orientation Based on the Wind Rose Diagram.pptx

Runway Orientation Based on the Wind Rose Diagram

在线办理(ANU毕业证书)澳洲国立大学毕业证录取通知书一模一样

学校原件一模一样【微信:741003700 】《(ANU毕业证书)澳洲国立大学毕业证》【微信:741003700 】学位证,留信认证(真实可查,永久存档)原件一模一样纸张工艺/offer、雅思、外壳等材料/诚信可靠,可直接看成品样本,帮您解决无法毕业带来的各种难题!外壳,原版制作,诚信可靠,可直接看成品样本。行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备。十五年致力于帮助留学生解决难题,包您满意。

本公司拥有海外各大学样板无数,能完美还原。

1:1完美还原海外各大学毕业材料上的工艺:水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠。文字图案浮雕、激光镭射、紫外荧光、温感、复印防伪等防伪工艺。材料咨询办理、认证咨询办理请加学历顾问Q/微741003700

【主营项目】

一.毕业证【q微741003700】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【q/微741003700】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

RAT: Retrieval Augmented Thoughts Elicit Context-Aware Reasoning in Long-Hori...

RAT: Retrieval Augmented Thoughts Elicit Context-Aware Reasoning in Long-Horizon Generation

Nuclear Power Economics and Structuring 2024

Title: Nuclear Power Economics and Structuring - 2024 Edition

Produced by: World Nuclear Association Published: April 2024

Report No. 2024/001

© 2024 World Nuclear Association.

Registered in England and Wales, company number 01215741

This report reflects the views

of industry experts but does not

necessarily represent those

of World Nuclear Association’s

individual member organizations.

The Benefits and Techniques of Trenchless Pipe Repair.pdf

Explore the innovative world of trenchless pipe repair with our comprehensive guide, "The Benefits and Techniques of Trenchless Pipe Repair." This document delves into the modern methods of repairing underground pipes without the need for extensive excavation, highlighting the numerous advantages and the latest techniques used in the industry.

Learn about the cost savings, reduced environmental impact, and minimal disruption associated with trenchless technology. Discover detailed explanations of popular techniques such as pipe bursting, cured-in-place pipe (CIPP) lining, and directional drilling. Understand how these methods can be applied to various types of infrastructure, from residential plumbing to large-scale municipal systems.

Ideal for homeowners, contractors, engineers, and anyone interested in modern plumbing solutions, this guide provides valuable insights into why trenchless pipe repair is becoming the preferred choice for pipe rehabilitation. Stay informed about the latest advancements and best practices in the field.

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Governing Equations for Fundamental Aerodynamics

Top 10 Oil and Gas Projects in Saudi Arabia 2024.pdf

Saudi Arabia stands as a titan in the global energy landscape, renowned for its abundant oil and gas resources. It's the largest exporter of petroleum and holds some of the world's most significant reserves. Let's delve into the top 10 oil and gas projects shaping Saudi Arabia's energy future in 2024.

WATER CRISIS and its solutions-pptx 1234

Water scarcity is the lack of fresh water resources to meet the standard water demand. There are two type of water scarcity. One is physical. The other is economic water scarcity.

Cosmetic shop management system project report.pdf

Buying new cosmetic products is difficult. It can even be scary for those who have sensitive skin and are prone to skin trouble. The information needed to alleviate this problem is on the back of each product, but it's thought to interpret those ingredient lists unless you have a background in chemistry.

Instead of buying and hoping for the best, we can use data science to help us predict which products may be good fits for us. It includes various function programs to do the above mentioned tasks.

Data file handling has been effectively used in the program.

The automated cosmetic shop management system should deal with the automation of general workflow and administration process of the shop. The main processes of the system focus on customer's request where the system is able to search the most appropriate products and deliver it to the customers. It should help the employees to quickly identify the list of cosmetic product that have reached the minimum quantity and also keep a track of expired date for each cosmetic product. It should help the employees to find the rack number in which the product is placed.It is also Faster and more efficient way.

一比一原版(UofT毕业证)多伦多大学毕业证成绩单如何办理

UofT毕业证原版定制【微信:176555708】【多伦多大学毕业证成绩单-学位证】【微信:176555708】(留信学历认证永久存档查询)采用学校原版纸张、特殊工艺完全按照原版一比一制作(包括:隐形水印,阴影底纹,钢印LOGO烫金烫银,LOGO烫金烫银复合重叠,文字图案浮雕,激光镭射,紫外荧光,温感,复印防伪)行业标杆!精益求精,诚心合作,真诚制作!多年品质 ,按需精细制作,24小时接单,全套进口原装设备,十五年致力于帮助留学生解决难题,业务范围有加拿大、英国、澳洲、韩国、美国、新加坡,新西兰等学历材料,包您满意。

◆◆◆◆◆ — — — — — — — — 【留学教育】留学归国服务中心 — — — — — -◆◆◆◆◆

【主营项目】

一.毕业证【微信:176555708】成绩单、使馆认证、教育部认证、雅思托福成绩单、学生卡等!

二.真实使馆公证(即留学回国人员证明,不成功不收费)

三.真实教育部学历学位认证(教育部存档!教育部留服网站永久可查)

四.办理各国各大学文凭(一对一专业服务,可全程监控跟踪进度)

如果您处于以下几种情况:

◇在校期间,因各种原因未能顺利毕业……拿不到官方毕业证【微信:176555708】

◇面对父母的压力,希望尽快拿到;

◇不清楚认证流程以及材料该如何准备;

◇回国时间很长,忘记办理;

◇回国马上就要找工作,办给用人单位看;

◇企事业单位必须要求办理的

◇需要报考公务员、购买免税车、落转户口

◇申请留学生创业基金

留信网认证的作用:

1:该专业认证可证明留学生真实身份

2:同时对留学生所学专业登记给予评定

3:国家专业人才认证中心颁发入库证书

4:这个认证书并且可以归档倒地方

5:凡事获得留信网入网的信息将会逐步更新到个人身份内,将在公安局网内查询个人身份证信息后,同步读取人才网入库信息

6:个人职称评审加20分

7:个人信誉贷款加10分→ 【关于价格问题(保证一手价格)

我们所定的价格是非常合理的,而且我们现在做得单子大多数都是代理和回头客户介绍的所以一般现在有新的单子 我给客户的都是第一手的代理价格,因为我想坦诚对待大家 不想跟大家在价格方面浪费时间

对于老客户或者被老客户介绍过来的朋友,我们都会适当给一些优惠。

8:在国家人才网主办的国家网络招聘大会中纳入资料,供国家高端企业选择人才

选择实体注册公司办理,更放心,更安全!我们的承诺:可来公司面谈,可签订合同,会陪同客户一起到教育部认证窗口递交认证材料,客户在教育部官方认证查询网站查询到认证通过结果后付款,不成功不收费!

学历顾问:微信:176555708

Recently uploaded (20)

Runway Orientation Based on the Wind Rose Diagram.pptx

Runway Orientation Based on the Wind Rose Diagram.pptx

RAT: Retrieval Augmented Thoughts Elicit Context-Aware Reasoning in Long-Hori...

RAT: Retrieval Augmented Thoughts Elicit Context-Aware Reasoning in Long-Hori...

ML for identifying fraud using open blockchain data.pptx

ML for identifying fraud using open blockchain data.pptx

The Benefits and Techniques of Trenchless Pipe Repair.pdf

The Benefits and Techniques of Trenchless Pipe Repair.pdf

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Governing Equations for Fundamental Aerodynamics_Anderson2010.pdf

Top 10 Oil and Gas Projects in Saudi Arabia 2024.pdf

Top 10 Oil and Gas Projects in Saudi Arabia 2024.pdf

Cosmetic shop management system project report.pdf

Cosmetic shop management system project report.pdf

Pile Foundation by Venkatesh Taduvai (Sub Geotechnical Engineering II)-conver...

Pile Foundation by Venkatesh Taduvai (Sub Geotechnical Engineering II)-conver...

MCQ Soil mechanics questions (Soil shear strength).pdf

MCQ Soil mechanics questions (Soil shear strength).pdf

Spot welding lobe curve simulation

- 1. RESISTANCE SPOT WELDING – WELDABILITY LOBE SIMULATION INTRODUCTION • Weldability Lobe is graphically represent the range of acceptable welding parameters set ( weld time, weld current & weld force) that may results in acceptable weld quality (weld nugget diameter) • There are 2 common Weldability Lobe: i. Weld Current vs Weld Time - Weld Force is constant (Graph 1) ii. Weld Current vs Weld Force - Weld Time is constant • Weldability Lobe is very useful for welders or engineers to select the best parameter setting that meets their requirement • The optimization of welding parameters setting also can be obtained using this Weldability Lobe (for overall energy efficiency, welding consumables lifespan, etc) • Traditionally, This Weldability Lobe only can be obtained using experimental procedure (destructive method) over parameters setting (Eg Weld Current vs Weld Time..etc) Graph 1 SIMULATION FOR AUTOMOTIVE INDUSTRY Graph 2 • In modern welding activities, the welding simulation is widely used to select the best parameters that meet the manufacturer’s requirement since in a car BIW, the spot weld points are around 4000 to 6000 spots with a lot of different types of material combination & thickness used • Sample in Graph 2 – Simulation of Weldability Lobe by SORPAS software • From my observation, this is the best software that provides the best solution for any type of welding

- 2. RESISTANCE SPOT WELDING – WELDABILITY LOBE SIMULATION • SIMULATION FOR AUTOMOTIVE INDUSTRY (SIMPLIFIED) kg 450 2.4 2.6 2.9 3.1 3.3 3.5 3.7 4.0 4.2 4.4 4.6 4.8 5.1 5.3 5.5 5.7 425 2.5 2.7 2.9 3.2 3.4 3.6 3.9 4.1 4.3 4.5 4.8 5.0 5.2 5.4 5.7 5.9 400 2.6 2.8 3.0 3.3 3.5 3.7 4.0 4.2 4.4 4.7 4.9 5.1 5.4 5.6 5.8 6.1 375 2.7 2.9 3.1 3.4 3.6 3.9 4.1 4.3 4.6 4.8 5.1 5.3 5.6 5.8 6.0 6.3 350 2.7 3.0 3.2 3.5 3.7 4.0 4.2 4.5 4.7 5.0 5.2 5.5 5.7 6.0 6.2 6.5 325 2.9 3.1 3.4 3.6 3.9 4.1 4.4 4.7 4.9 5.2 5.4 5.7 6.0 6.2 6.5 6.7 300 3.0 3.2 3.5 3.8 4.0 4.3 4.6 4.9 5.1 5.4 5.7 5.9 6.2 6.5 6.7 7.0 275 3.1 3.4 3.7 3.9 4.2 4.5 4.8 5.1 5.4 5.6 5.9 6.2 6.5 6.8 7.0 7.3 250 3.3 3.5 3.8 4.1 4.4 4.7 5.0 5.3 5.6 5.9 6.2 6.5 6.8 7.1 7.4 7.7 225 3.4 3.7 4.1 4.4 4.7 5.0 5.3 5.6 5.9 6.2 6.5 6.9 7.2 7.5 7.8 8.1 200 3.6 4.0 4.3 4.6 5.0 5.3 5.6 5.9 6.3 6.6 6.9 7.3 7.6 7.9 8.3 8.6 175 3.9 4.2 4.6 4.9 5.3 5.7 6.0 6.4 6.7 7.1 7.4 7.8 8.1 8.5 8.8 9.2 150 4.2 4.6 5.0 5.3 5.7 6.1 6.5 6.9 7.2 7.6 8.0 8.4 8.8 9.2 9.5 9.9 125 4.6 5.0 5.4 5.9 6.3 6.7 7.1 7.5 7.9 8.4 8.8 9.2 9.6 10.0 10.4 10.9 100 5.1 5.6 6.1 6.5 7.0 7.5 7.9 8.4 8.9 9.3 9.8 10.3 10.7 11.2 11.7 12.2 5,500 6,000 6,500 7,000 7,500 8,000 8,500 9,000 9,500 10,000 10,500 11,000 11,500 12,000 12,500 13,000 A Lobe Curve (Simulation) - 2 Ply WeldingForce,Kg Weld Current, A • In order to ease the simulation, The Weldability Lobe Simulator is programmed using basic equations as shown in next slide. The simulator may simulate different panels combination (types & thickness) to predict the best welding parameters to be used • This simulator also may predict the failure mode due to process parameters (welding current & force fluctuation) from the graph • Basically, the simulator may generates 2 types of graph as shown; i. Weld Current vs Weld Time - Weld Force constant ii. Weld Current vs Weld Force – Weld Time constant • Physical confirmation at line side is required using test piece (destruct) or NDT device (ultrasonic) • From the test conducted from the past, the minimum 90% accuracy is achieved (simulation vs actual) Input Data (Sample)

- 3. 2 Where; k : Energy Efficient Constant I : Welding Current (A) R : Panel Contact Resistance (Ω) Jv : Melting energy (J/mm3 ) S : Surface contact (mm2 ) L : Total plate thickness combination (mm) d : Required nugget diameter (mm) RESISTANCE SPOT WELDING – BASIC CALCULATION Equation: Portable Spot Welding Robot Spot Welding – Trans Gun Parameters Value (Low carbon Steel) Jv 9.7 J/mm3 R 0.1 mΩ k 0.241 (Portable Spot Welding - AC) 0.29 (Trans Gun – AC) 0.37 (Trans Gun – DC) F˳ Ratio : Fs / Fi Where Fs (Setting weld force) Fi (Ideal weld force for R = 0.1 mΩ) – Thickness dependant (Fi(t)) 1