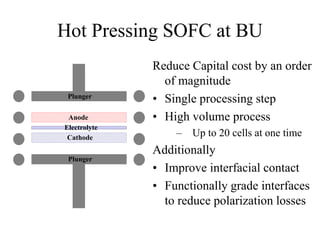

The document presents a thesis defense on a one-step process for solid oxide fuel cell (SOFC) fabrication, outlining the motivation, experimental background, results, and future work. SOFCs are highlighted as efficient and pollution-free power sources with various advantages, including flexible fuel options and scalability. The research successfully developed a method to achieve dense electrolytes and porous electrodes while maintaining structural integrity, paving the way for further testing and potential production scaling.

![Energy Generating Devices

a- Stack lifetime only, balance of plant ~ 20 yr.

After, http://energy.annualreviews.org/cgi/content/full/24/1/281

Energy Conversion

Method

Efficiency

[%]

Power

Range

[MW]

Lifetime

[Yrs]

Capital

Cost

[$/kW]

Gas Turbines 35-40 10-1000 >20 250-700

Molten-carbonate FC 50-55 1-100 5 a 1000

Thermal (Coal, oil, gas) 25-35 ~1000 >20 1500

Phosphoric Acid FC 40-45 0.2-10 5 a 1500

Hydroelectric 65 0.1-1000 >20 1500

Wind 75 0.1-1 >10 1500

Nuclear 35 ~1000 >20 2000

Magneto Hydrodynamic 40 0.1-100 >10 2000

Solid Oxide FC 50-70 1-100 5 a 1500- 3000

Photovoltaic 10 0.1-1 >10 5000

Least

Expensive

Most

Expensive](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-4-320.jpg)

![Capital Cost Cutting Required

• Order of magnitude reduction in cost will not be met by optimization

• Will need new processing techniques to meet these goals

http://energy.annualreviews.org/cgi/content/full/24/1/281

Comparison of System Expense

0

1000

2000

3000

4000

5000

Diesel Gas

Turbine

Power Generating Systems

Capital Cost

[$/kW]

United

Technology

Alkaline Fuel Cell

Siemens-

Westinghouse

Tubular

Fuel Cell](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-6-320.jpg)

![Equipment Limits

0

500

1000

1500

2000

2500

3000

0 2000 4000 6000 8000 10 000 12 000

Pressure [psi]

Temperature[C]

High Pressure RegimeModerate Pressure Regime

Maximum HP Temperature

Maximum

Graphite

Compressive

Stress](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-17-320.jpg)

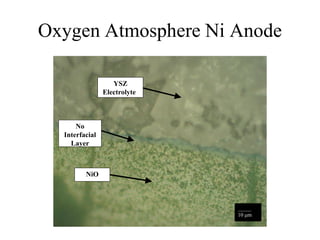

![Chemical Interaction Limits

MP: 1880 C

500

1000

1500

2000

2500

3000

Temperature[C]

ElectrolyteCathode Anode Interconnect

La

2

Zr

2

O

7

Formation

Mn

+2

Diffusion NiCrO

4

Formation

MP: 2660 C

MP: 1453 C

MP: 2510 C

MP: 1990 C](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-18-320.jpg)

![Established Sintering Cycles

500

700

900

1100

1300

1500

Temperature[C]

YSZ Air Sintered

Monolithic Fabrication Temperature

Interconnect

Nano YSZ Air Sintered

Ni 98% Density

NiO 57% Density

LSM 80% Density

500

700

900

1100

1300

1500

Temperature[C]

ElectrolyteCathode Anode

YSZ Air Sintered

Monolithic Fabrication Temperature

Nano YSZ Air Sintered

Ni 98% Density

NiO 57% Density

LSM 80% Density](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-19-320.jpg)

![1

10

100

1000

10000

100000

1000000

10000000

0.01 0.1 1 10 100 1000

Particle Radius [um]

Pressure[psi]

90% of Densification due to Applied Pressure 90% of Densification due to Particle Size

Pressure Dominated

Densification

Particle Size Dominated

Densification

Unity Line

RP

C

C a

rgySurfaceEne

essureApplied

Pr

RP

kT

DF

dt

dV A

**](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-25-320.jpg)

![Particle Size / Pressure Regime

RP

CCF

a

essureAppliedessureAppliedceDrivingForEquivalent

PrPr

Applied

Pressure

[psi]

Particle Size Radius [m]

0.01 0.1 1 10 100 1000

10 000

55 596 14 560 10 456 10 046 10 005 10 000

5000

50 596 9560 5456 5046 5005 5000

2500

48 096 7060 2956 2546 2505 2500

1000

46 596 5560 1456 1046 1005 1000

100

45 696 4660 556 145.6 104.6 100.5](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-26-320.jpg)

![Equilibrium Oxygen Partial Pressures

1E-30

1E-24

1E-18

1E-12

1E-06

1

500 600 700 800 900 1000 1100 1200 1300 1400 1500

Temperature [C]

PartialPressureofOxygen

2Ni + O2(g) = 2NiO 2CO(g) + O2(g) = 2CO2(g) 2H2(g) + O2(g) = 2H2O(g)

NiO Stable

Ni Stable

P O2 = 1.17 x10 -9 (1100 C) P O2 = 3.55 x10 -13 (1100 C) P O2 = 8.70 x10 -17 (1100 C)](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-31-320.jpg)

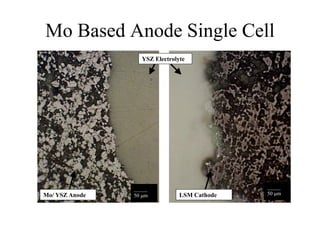

![Anode 2 [Mo-YSZ] / Electrolyte

Interface

YSZ Electrolyte

Mo/ YSZ Anode

Poor Adherence

_____

50 m

•Excessive Porosity

•Poor Adherence](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-38-320.jpg)

![Anode 3 [Mo-3wt% Ni] / Electrolyte

Interface

_______

50 m

YSZ Electrolyte

Mo/ YSZ Anode

Adequate Adherence](https://image.slidesharecdn.com/thesisdefenseschumacherdec2002-180904233817/85/Thesis-Defense-Presentation-ONE-STEP-PROCESS-FOR-SOLID-OXIDE-FUEL-CELL-FABRICATION-42-320.jpg)