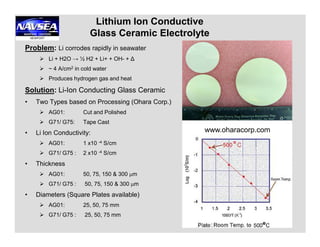

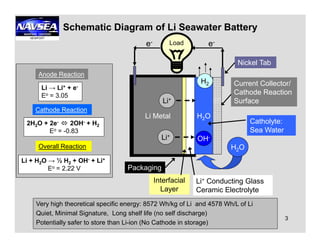

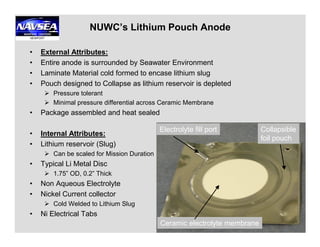

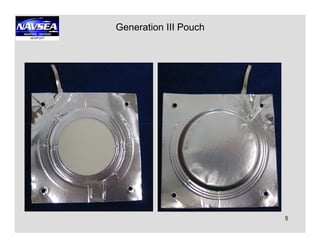

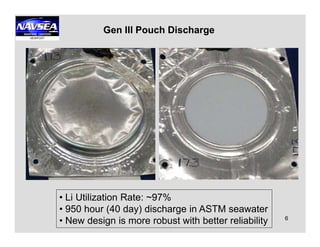

This document presents a lithium-seawater battery developed for undersea sensors and vehicles, addressing the issue of lithium corrosion in seawater. It describes advancements in lithium-ion conductive glass ceramic electrolytes and the overall battery design, which boasts high theoretical specific energy and long-lasting performance. The new generation of pouches features better reliability and pressure tolerance, making them suitable for prolonged underwater missions.