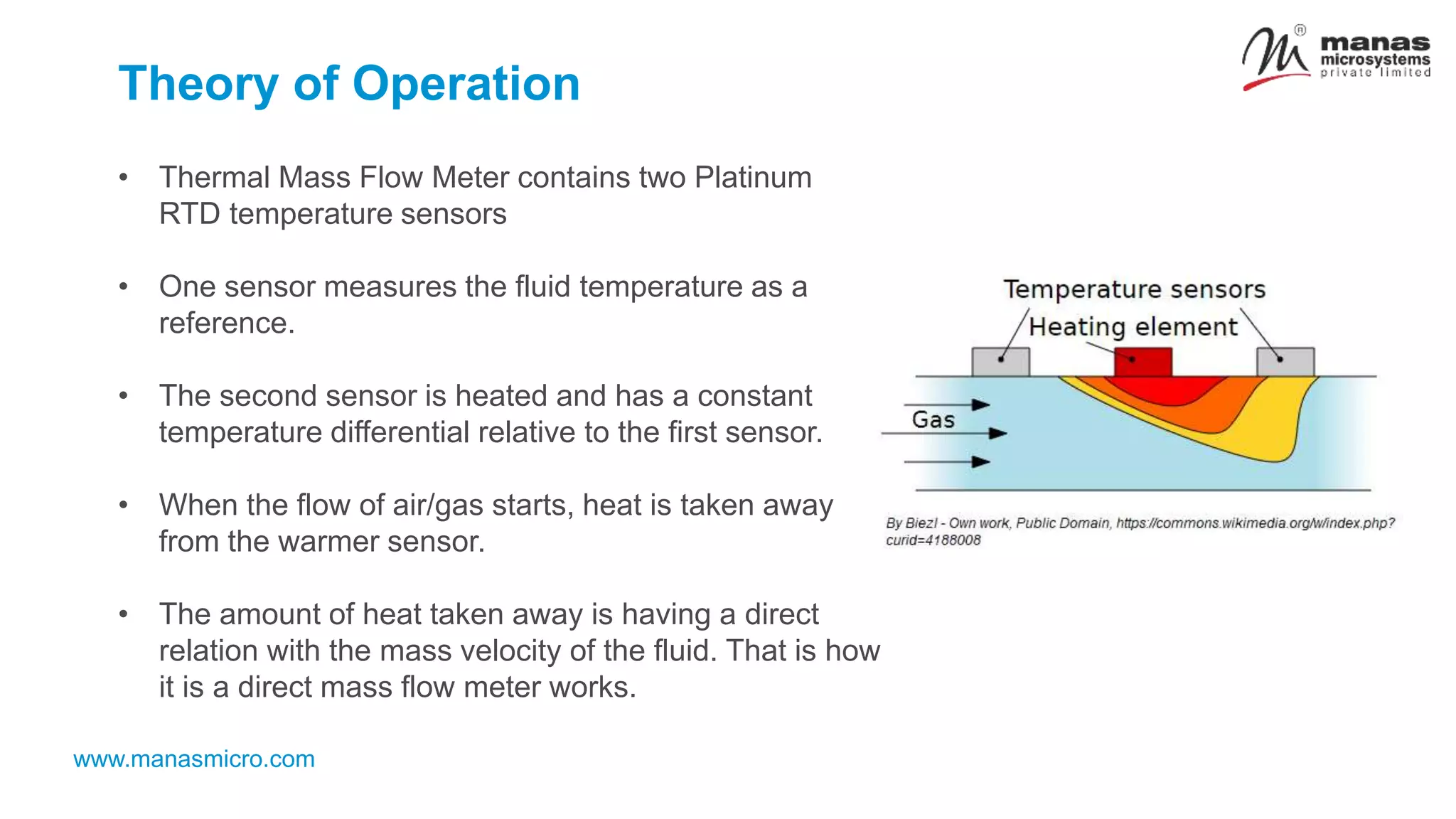

The thermal mass flow meter is a direct mass flow meter used to measure the total mass flow rate of gases through closed conduits, with no moving parts and no need for pressure or temperature compensation. It operates using two platinum RTD temperature sensors, allowing for accurate measurements even in low-pressure conditions. The meter is suitable for various applications including gas consumption measurement, automobile testing, and industrial monitoring.