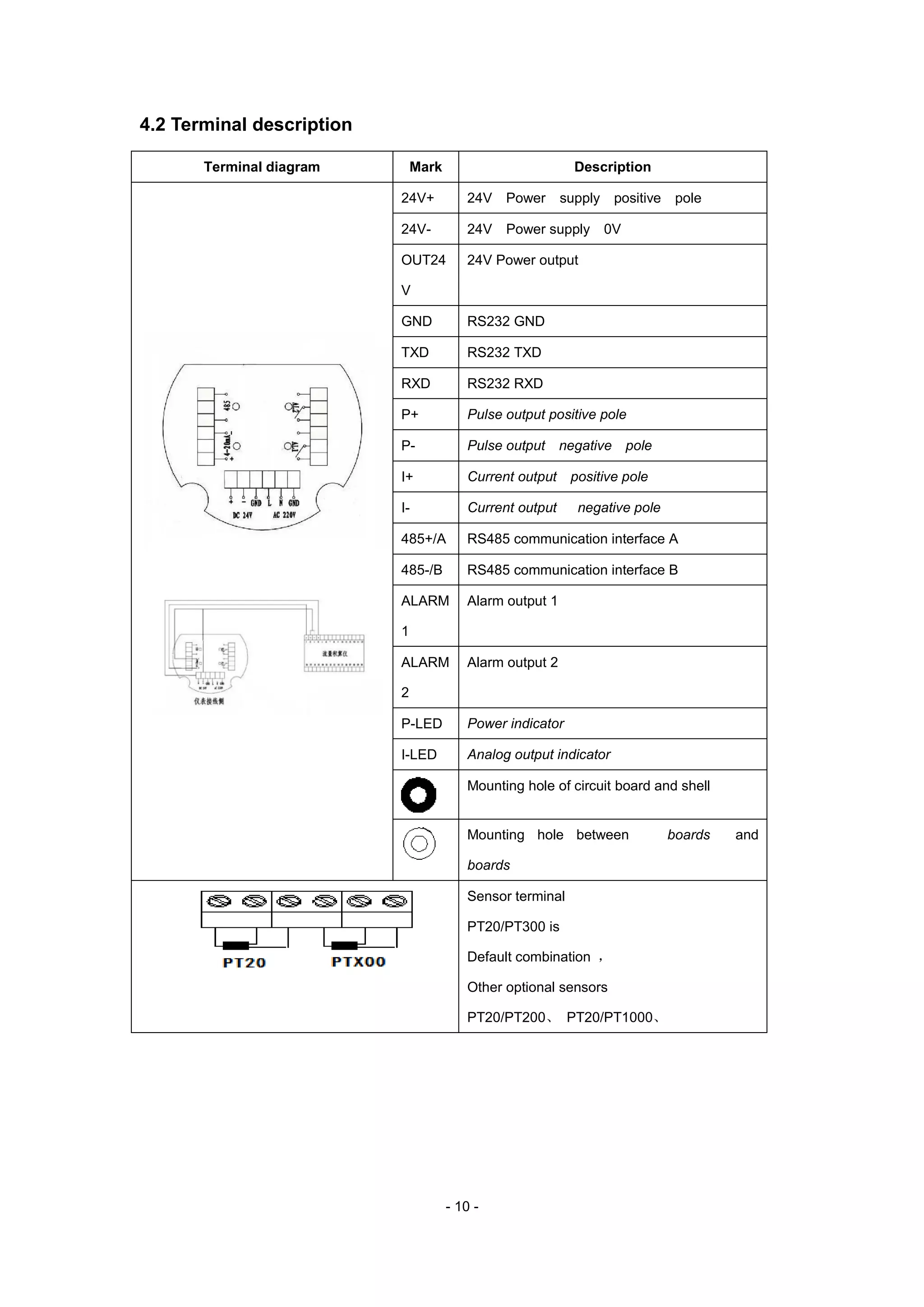

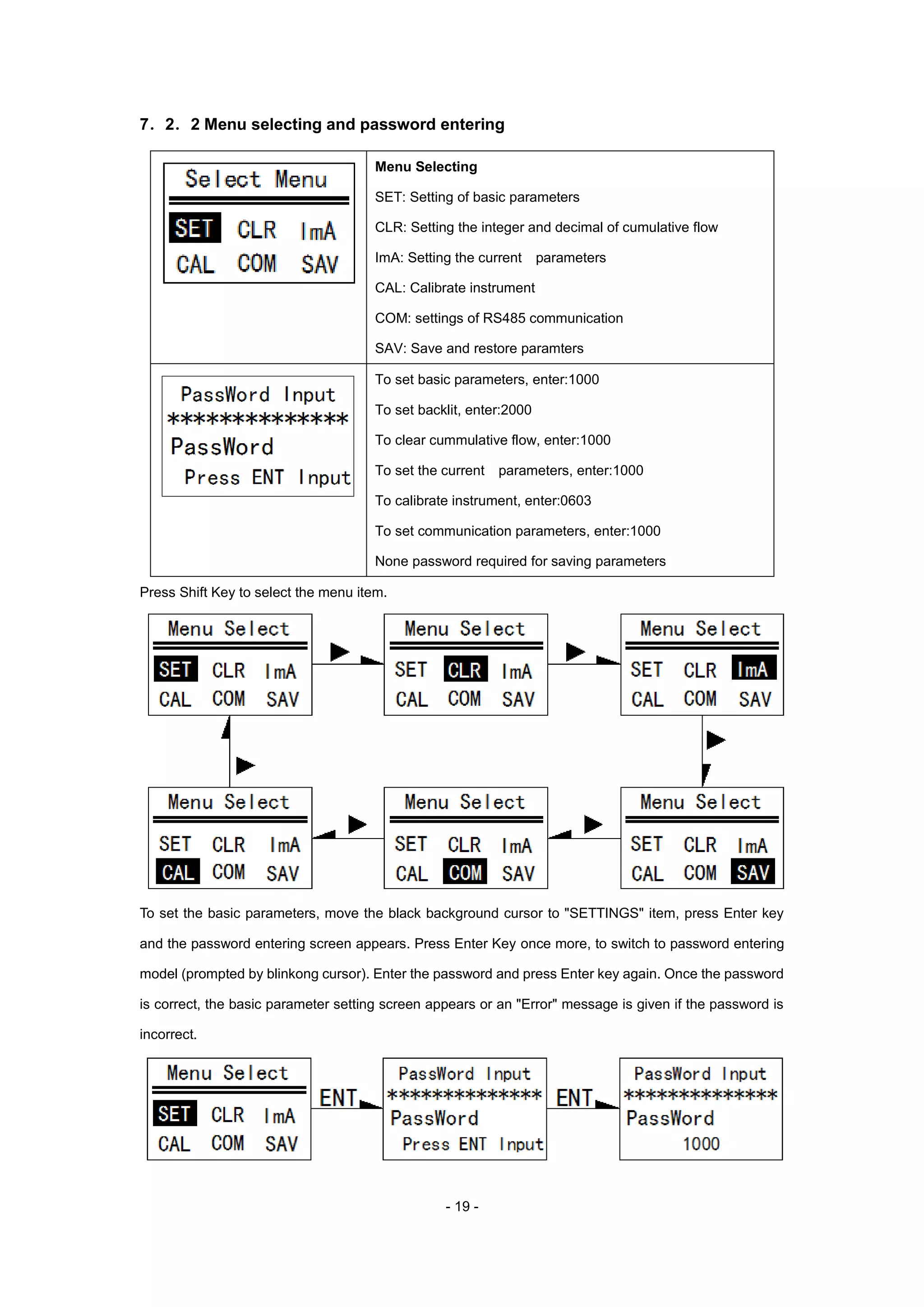

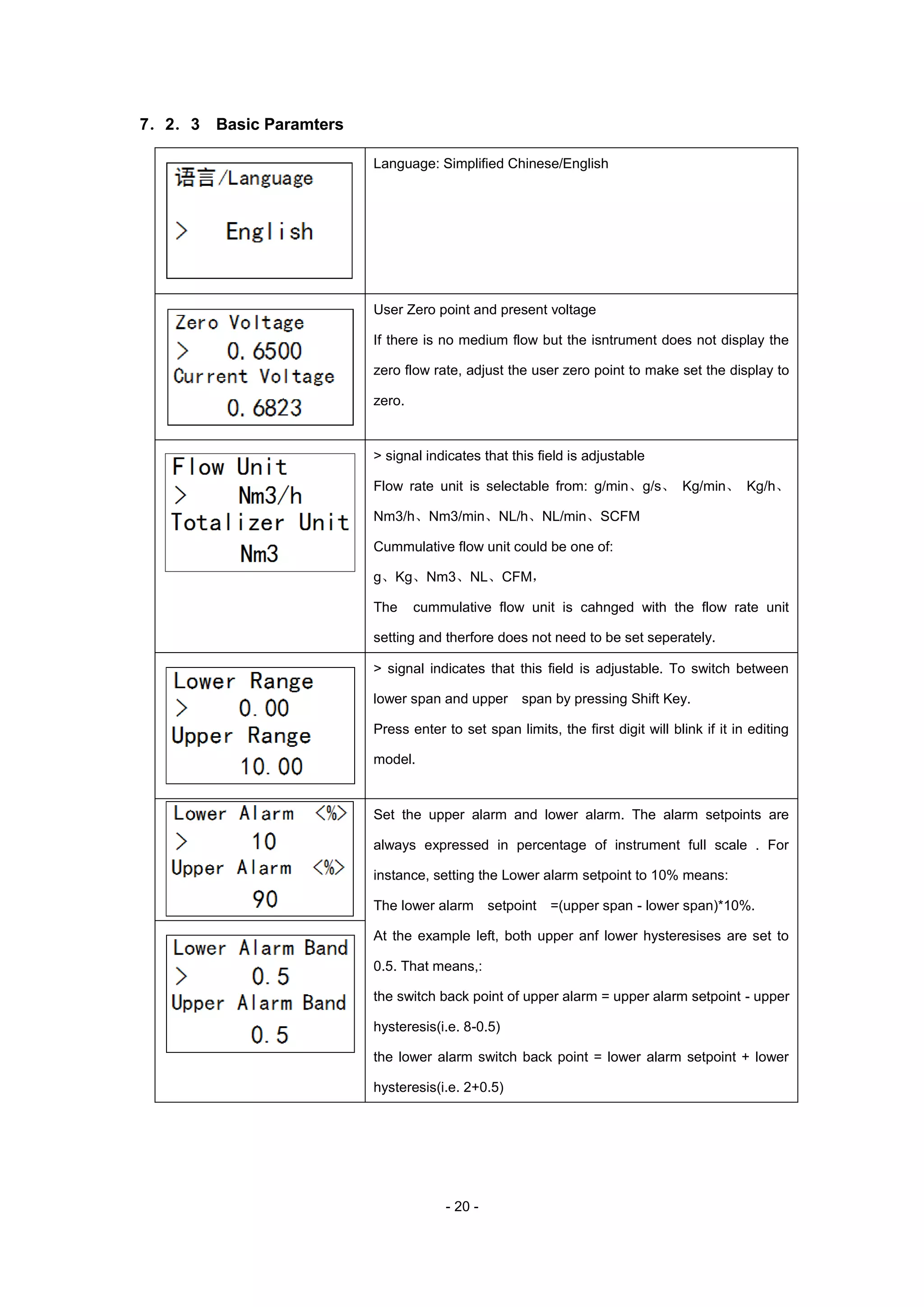

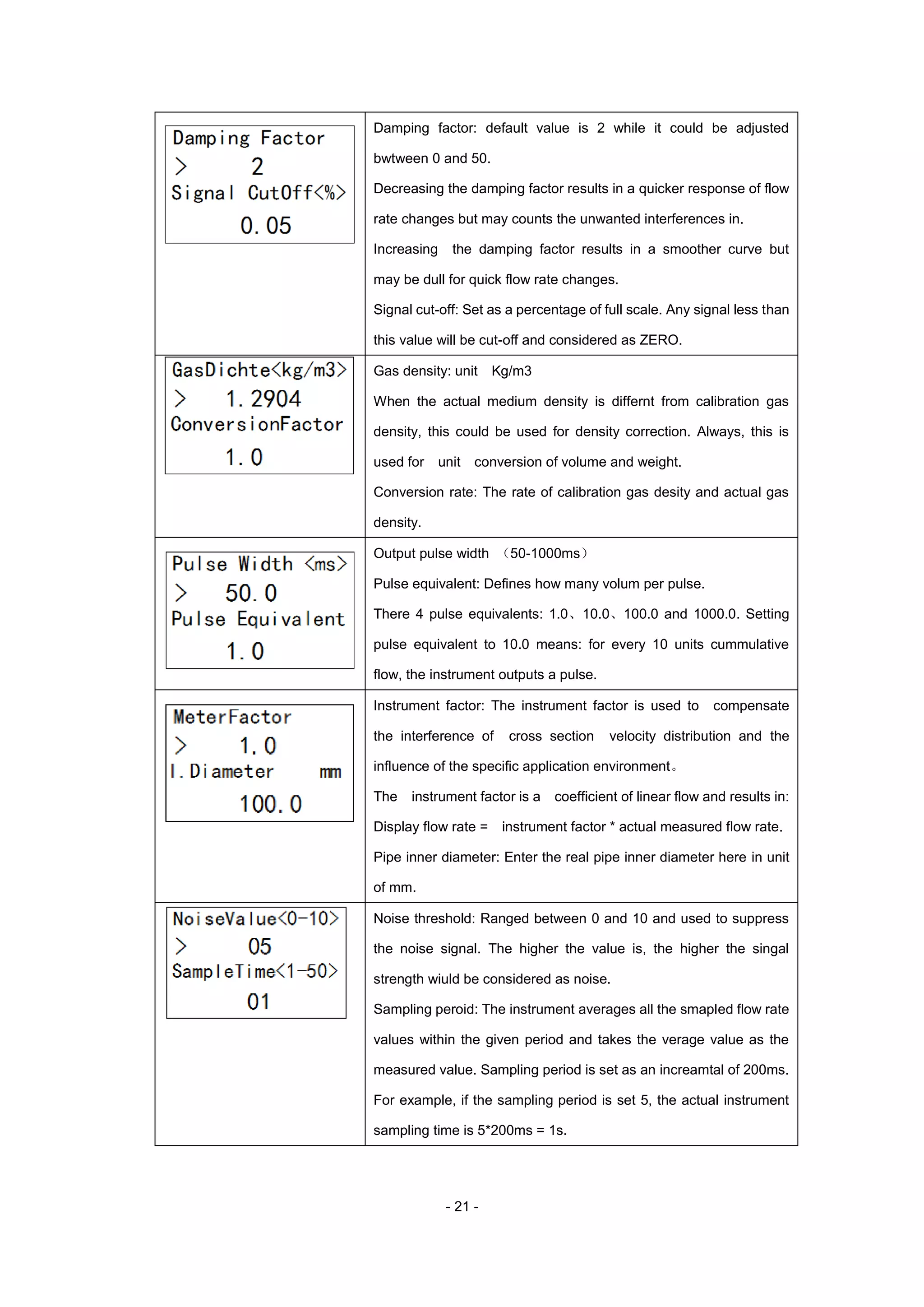

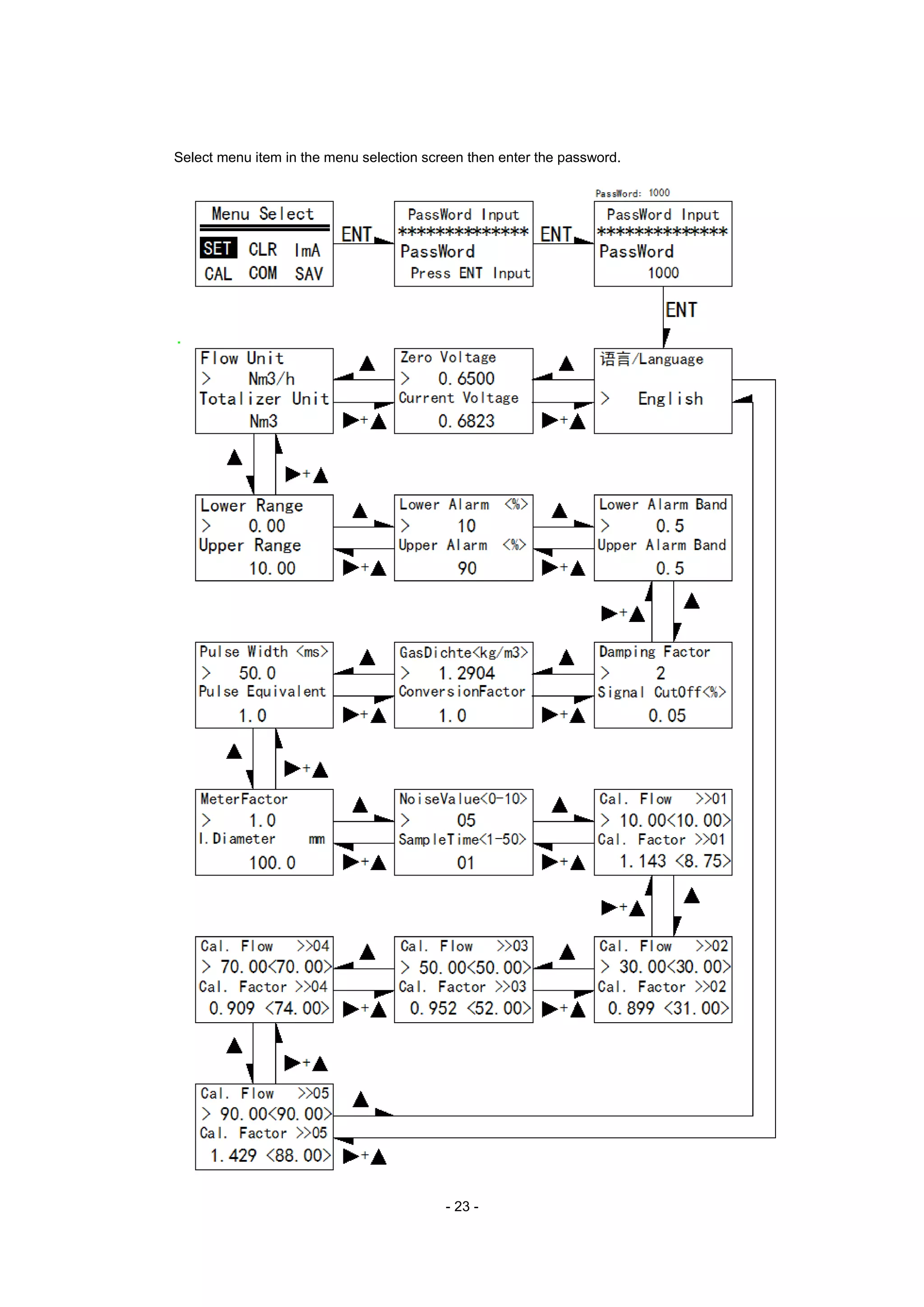

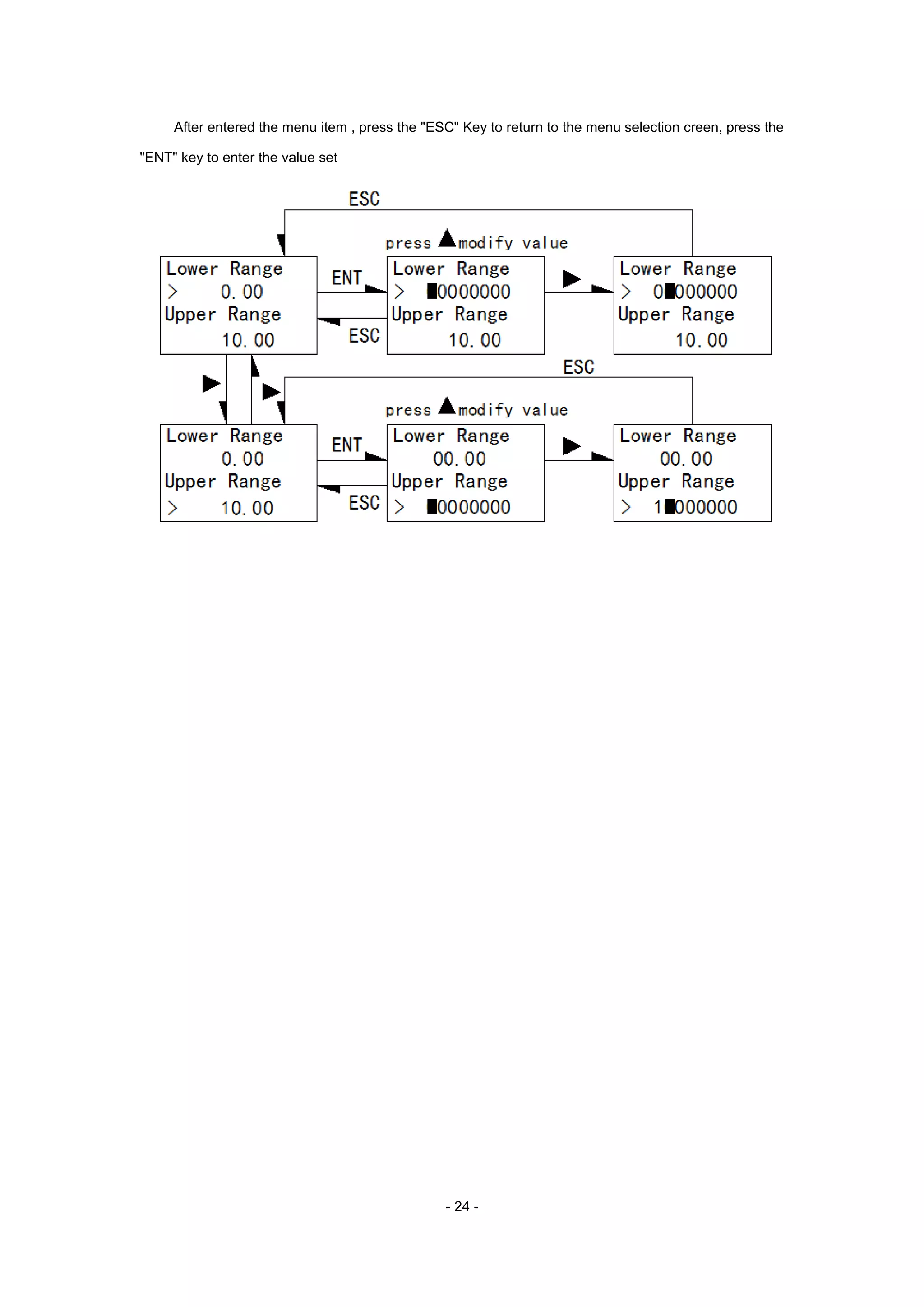

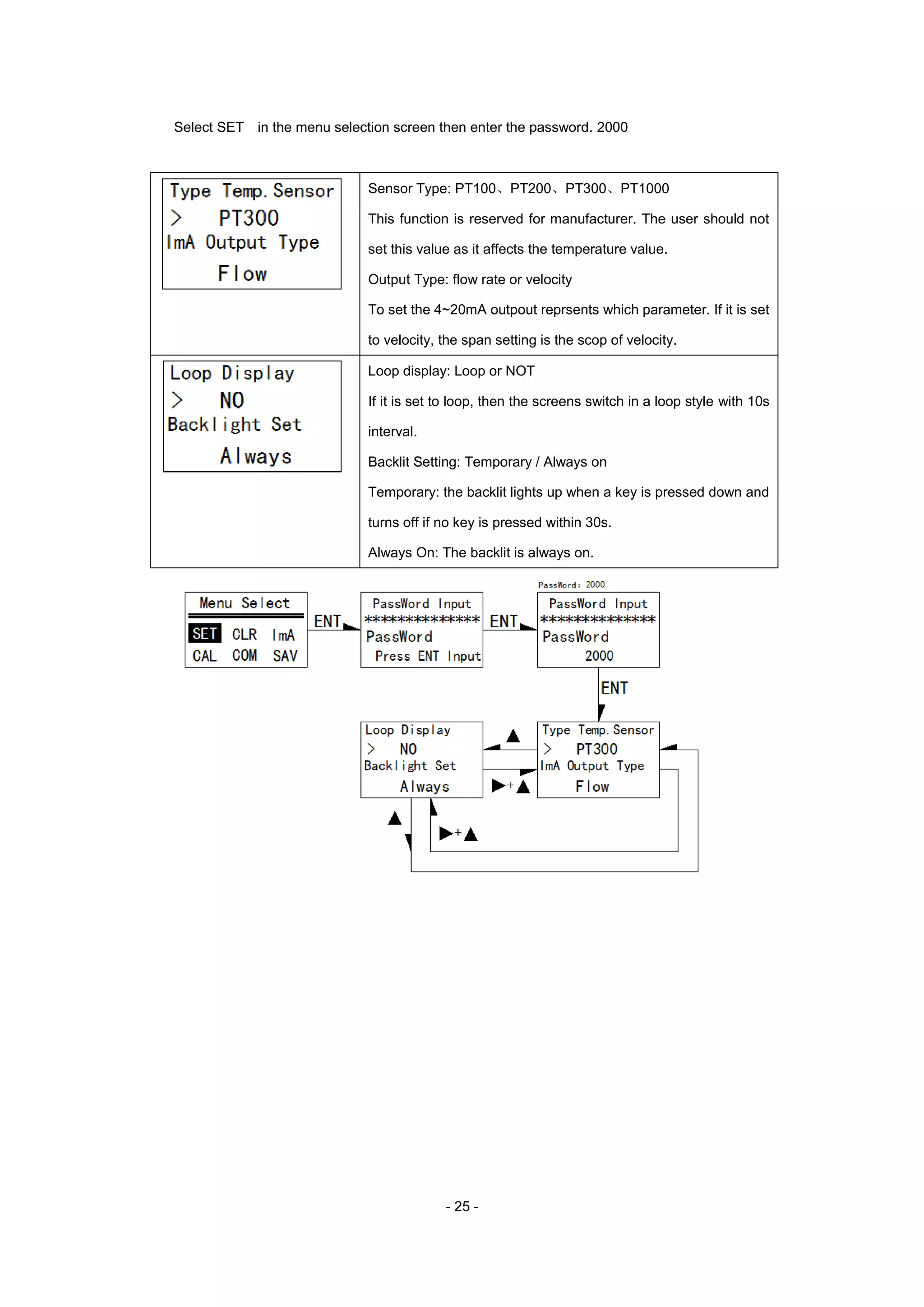

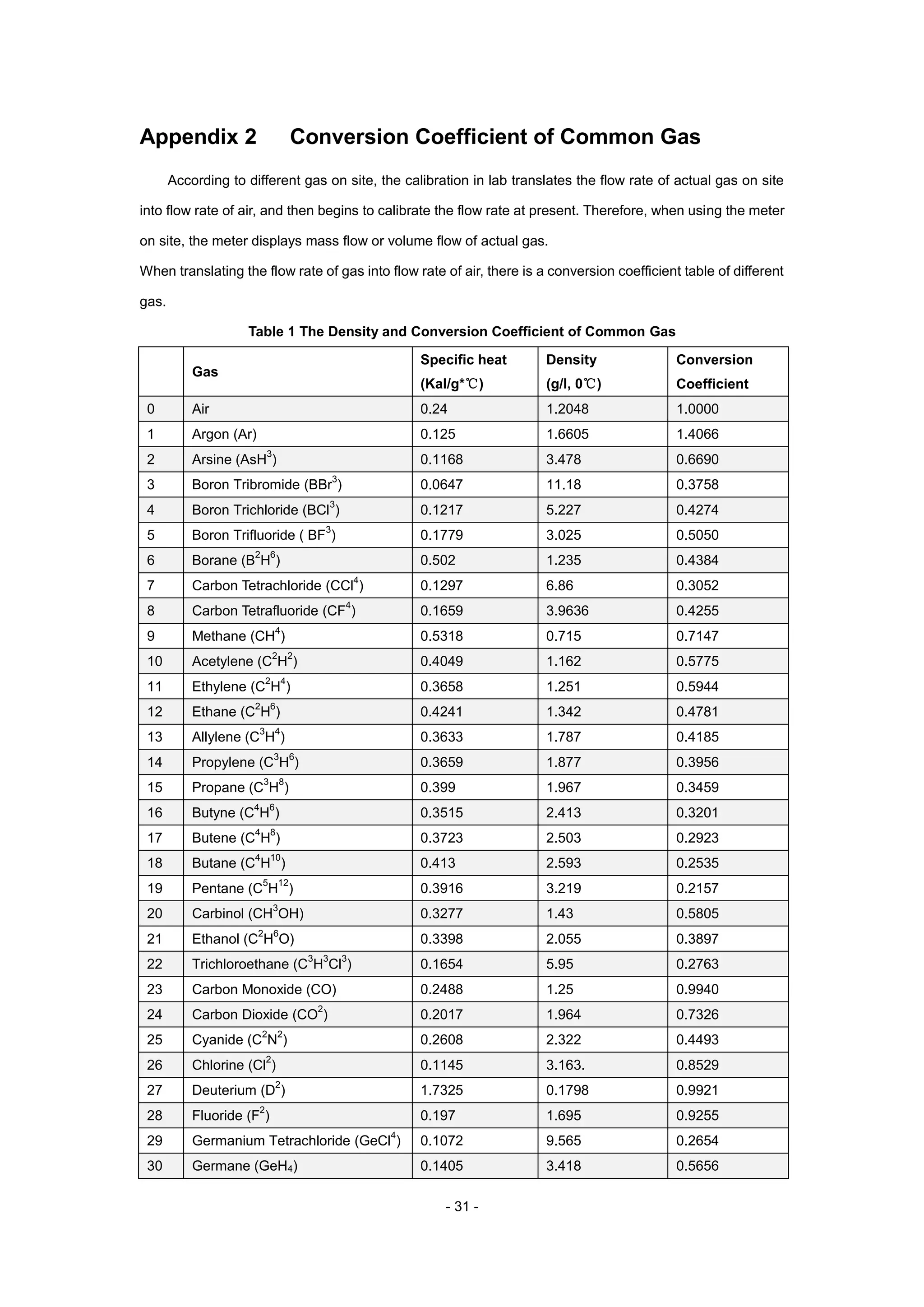

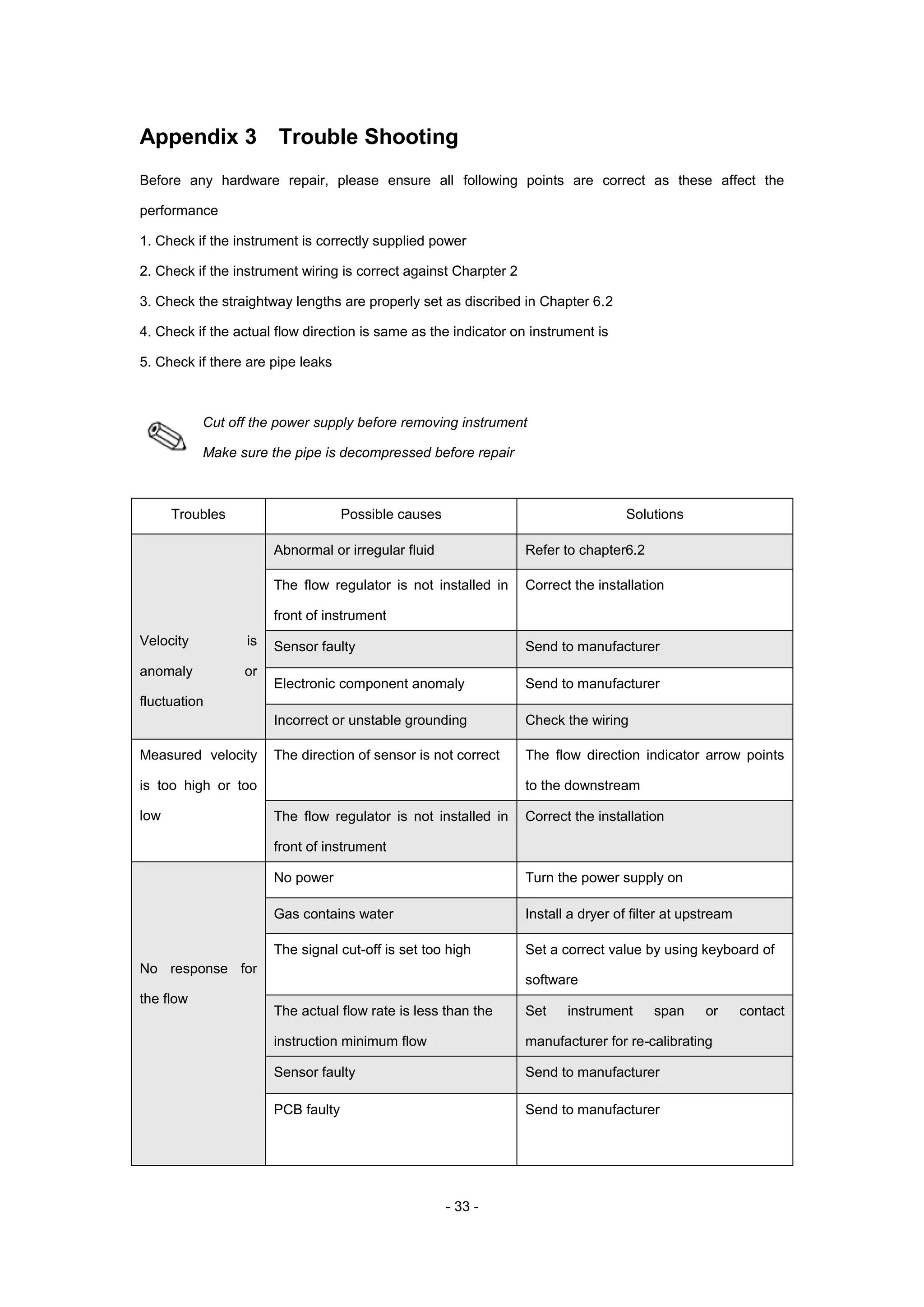

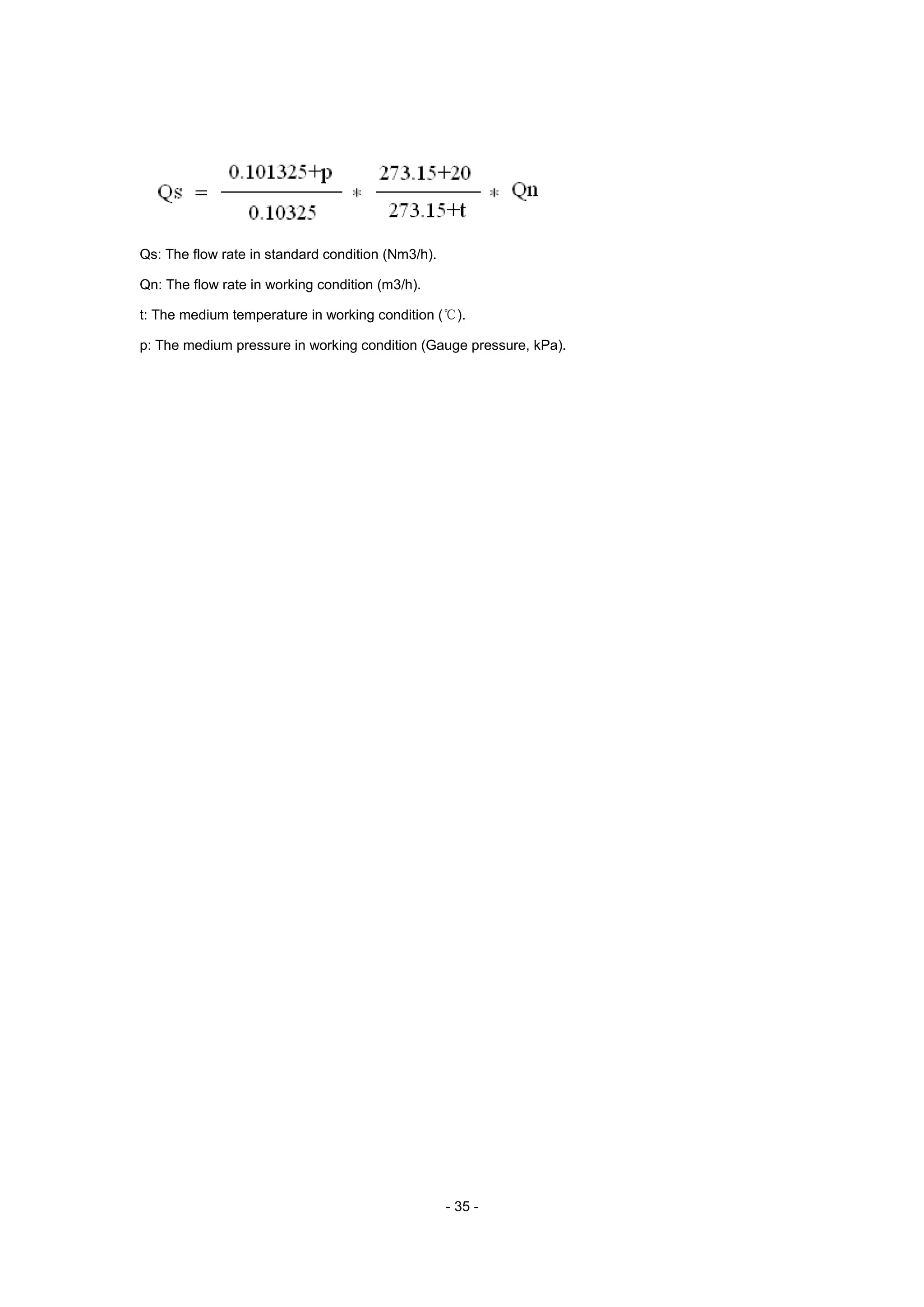

This document provides an installation and operation guide for a thermal gas mass flowmeter. It describes the measuring principle of using two temperature sensors, one heated, to monitor gas flow. Specifications include measuring various gases from 0.1-100 Nm/s with 1-2.5% accuracy from -40-220°C. Installation and wiring instructions are provided along with menus for the LCD display and appendices on conversions, troubleshooting and specifications.