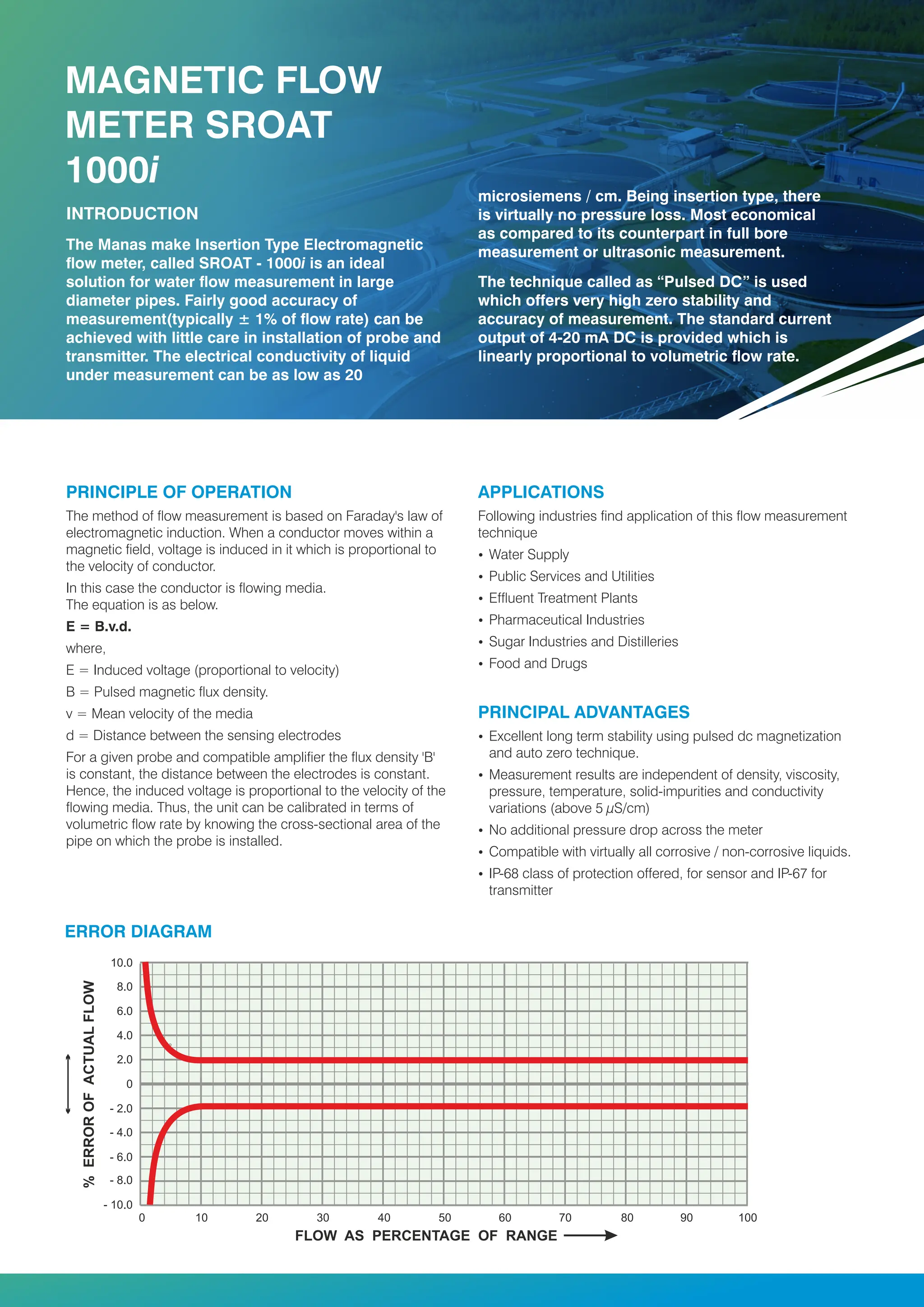

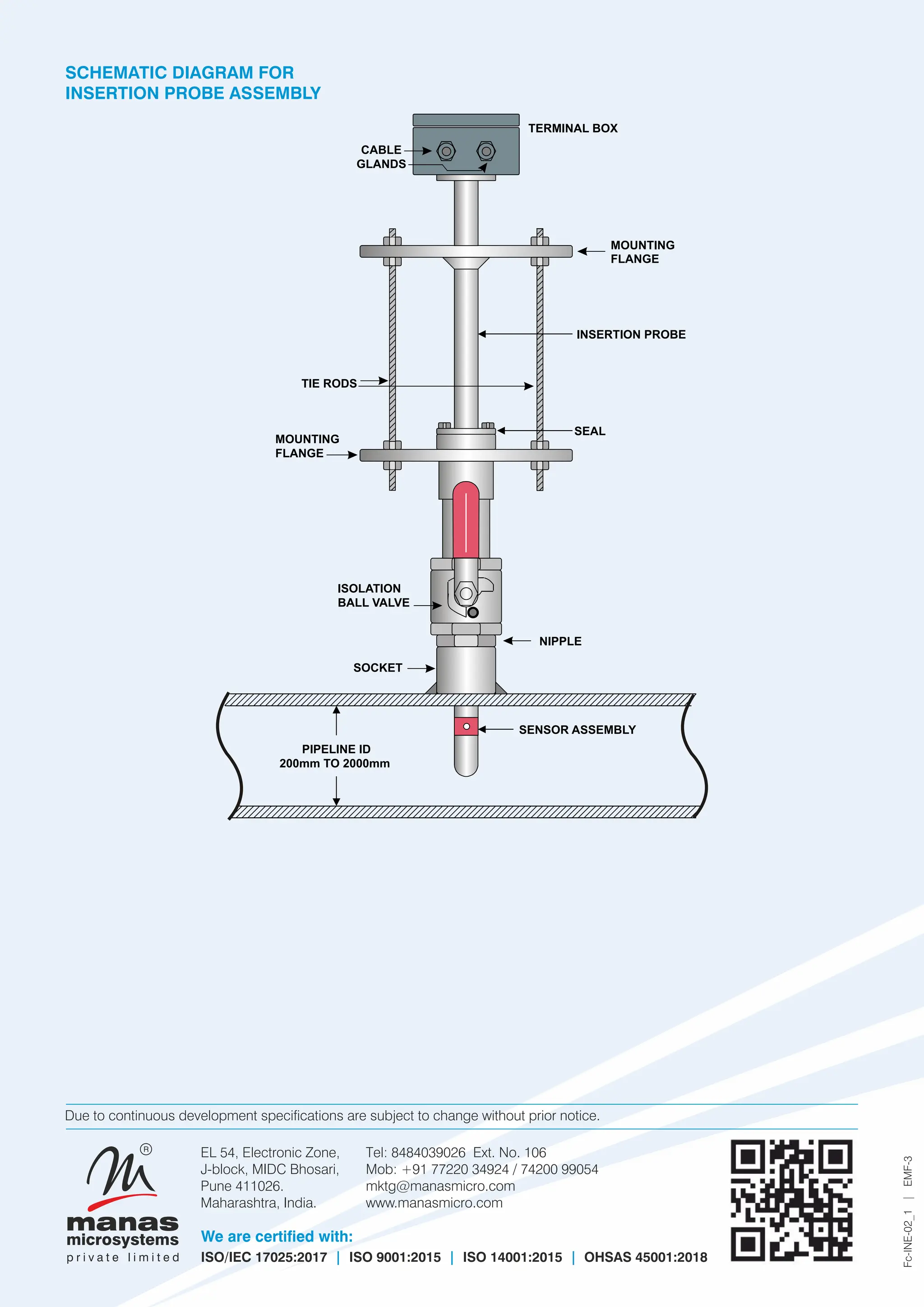

The document discusses the Sroat 1000i insertion type electromagnetic flow meter by Manas Microsystems, which is designed for measuring water flow in large diameter pipes with an accuracy of ±1%. It operates based on Faraday's law of electromagnetic induction and provides a standard current output of 4-20 mA DC, with advantages such as excellent long-term stability and compatibility with various liquids. The flow meter is applicable in multiple industries, including water supply, effluent treatment, and pharmaceuticals, and is certified to several international quality standards.