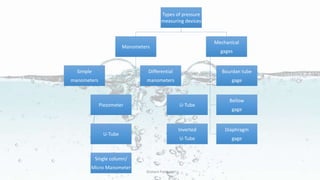

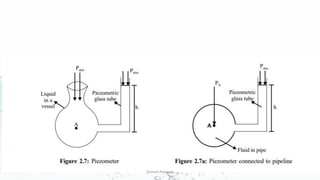

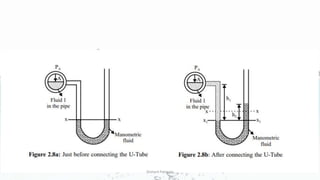

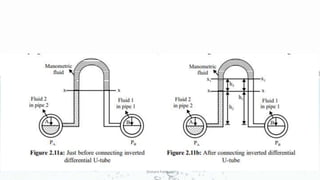

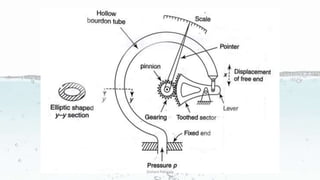

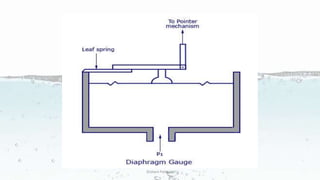

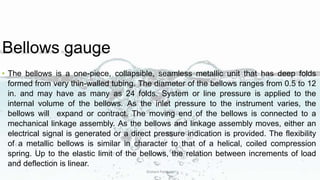

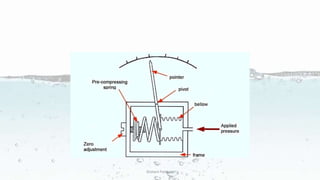

The document discusses various types of pressure measuring devices in fluid mechanics, focusing on manometers, which are categorized as simple or differential. It describes specific types of manometers, including piezometers, U-tube manometers, and Bourdon tube gauges, emphasizing their construction and application in measuring pressure at specific points in fluids. Additional devices like diaphragm and bellows gauges are also explained, highlighting their operational principles and how they measure pressure changes.