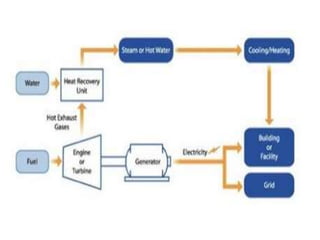

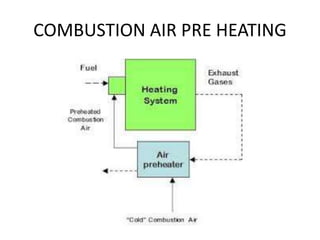

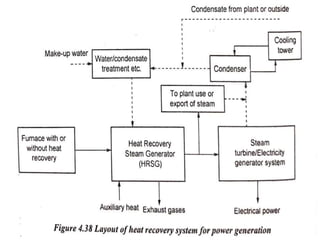

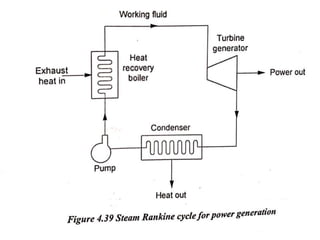

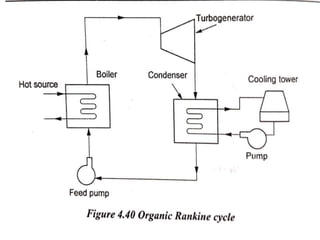

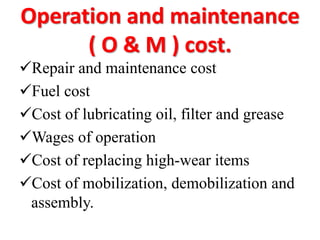

Cogeneration or combined heat and power (CHP) involves generating electricity and useful heat simultaneously. It is used in prisons, hospitals, data centers, industrial units, and other applications. Cogeneration improves efficiency, reduces costs and emissions, and is more economical than conventional power plants. Waste heat recovery units transfer heat from high-temperature processes to increase efficiency further. Cogeneration can achieve up to 80% efficiency and provides environmental and economic benefits.