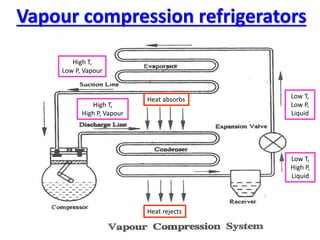

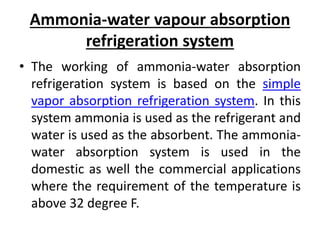

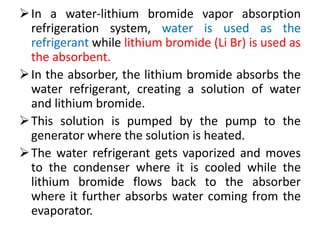

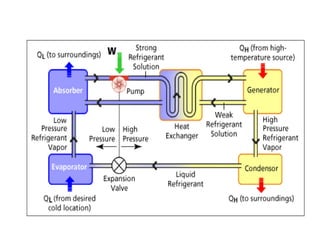

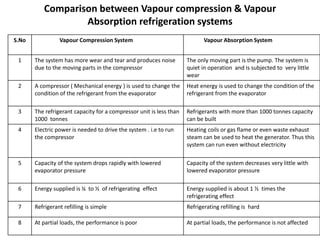

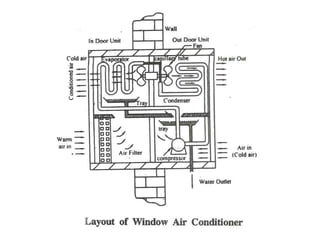

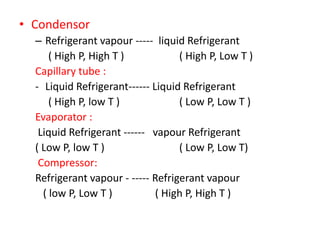

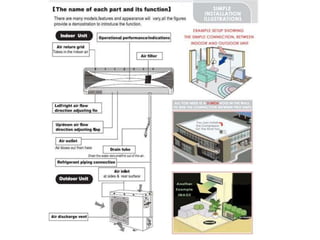

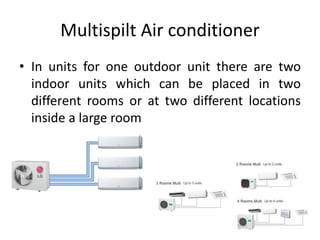

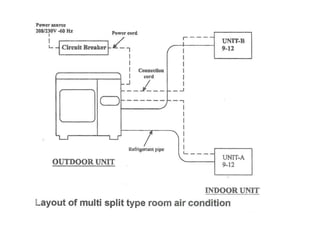

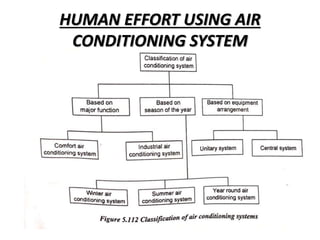

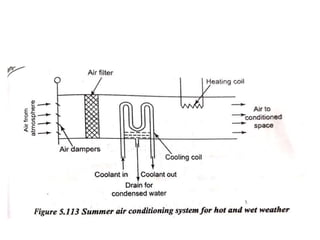

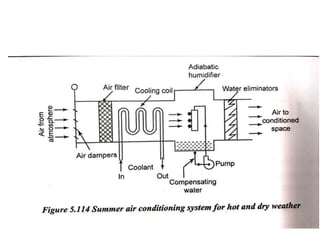

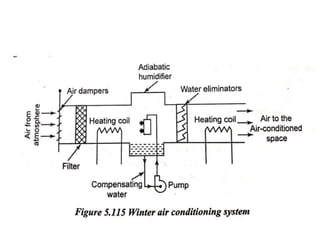

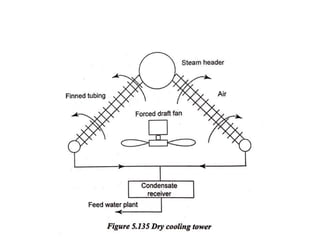

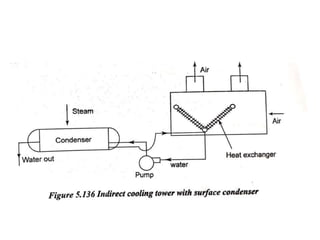

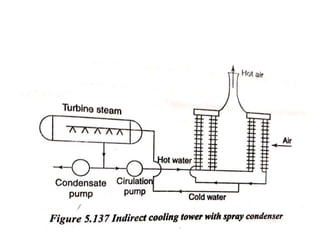

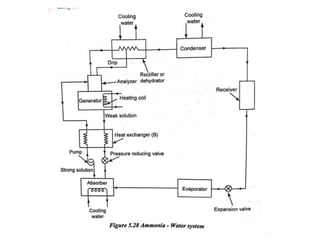

Refrigeration is the process of removing heat from an object or space to lower its temperature below the surrounding environment. It uses refrigerants and works by continuously absorbing heat and rejecting it at higher temperatures. There are two main types of refrigeration systems - vapor compression, which uses a compressor, and vapor absorption, which uses heat to power the refrigeration process. Air conditioning builds on refrigeration to condition air for human comfort by controlling temperature and humidity levels. There are various types of air conditioning units and cooling towers that reject waste heat to cool water or air.