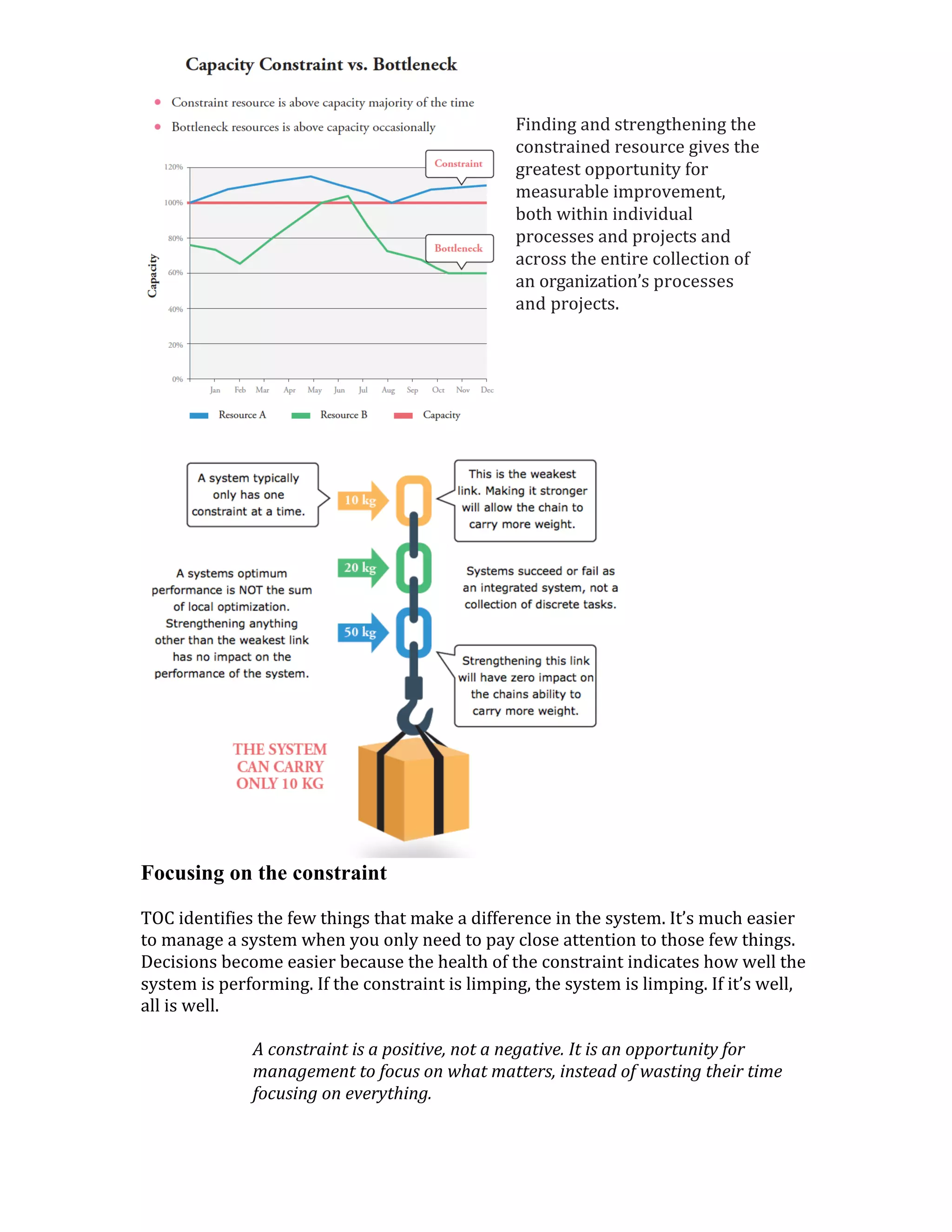

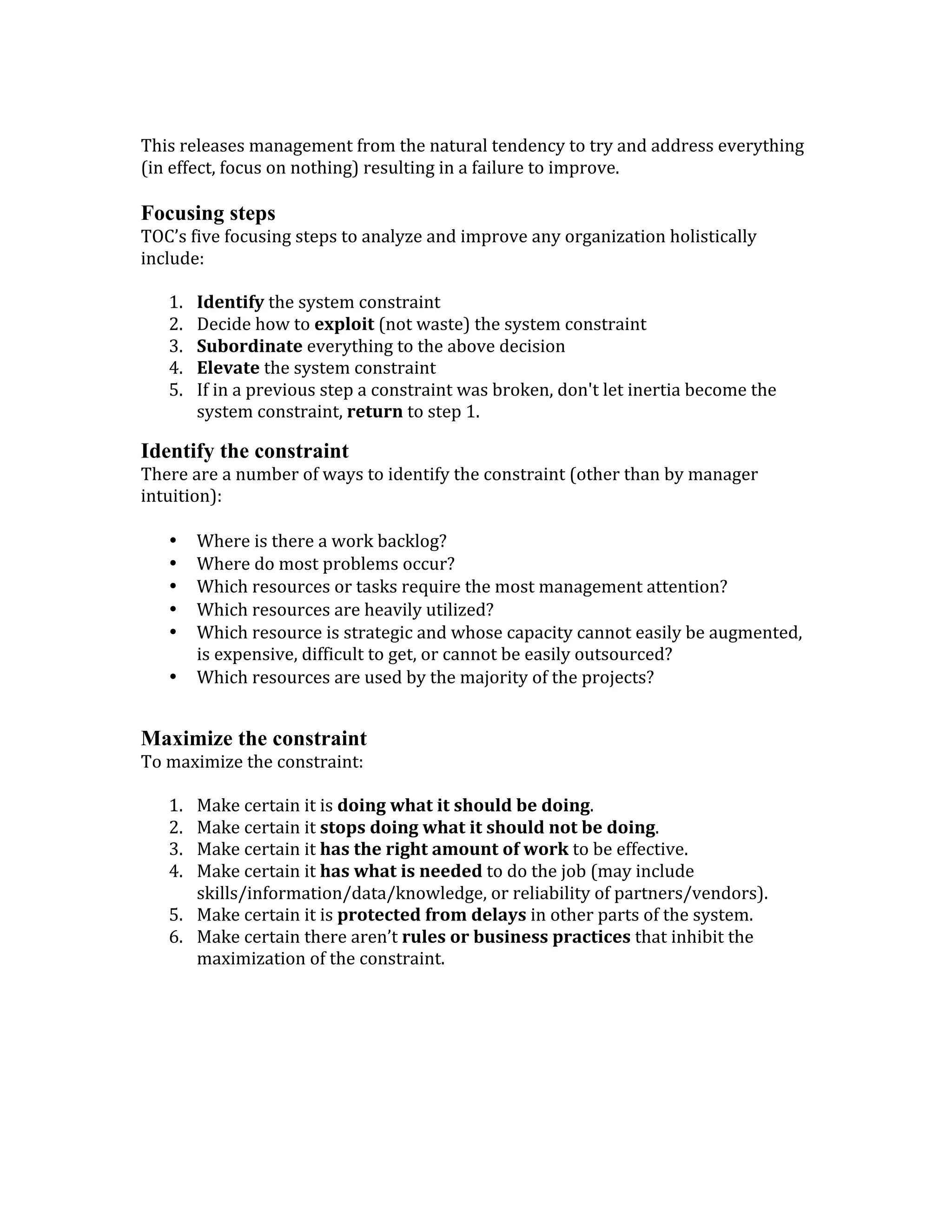

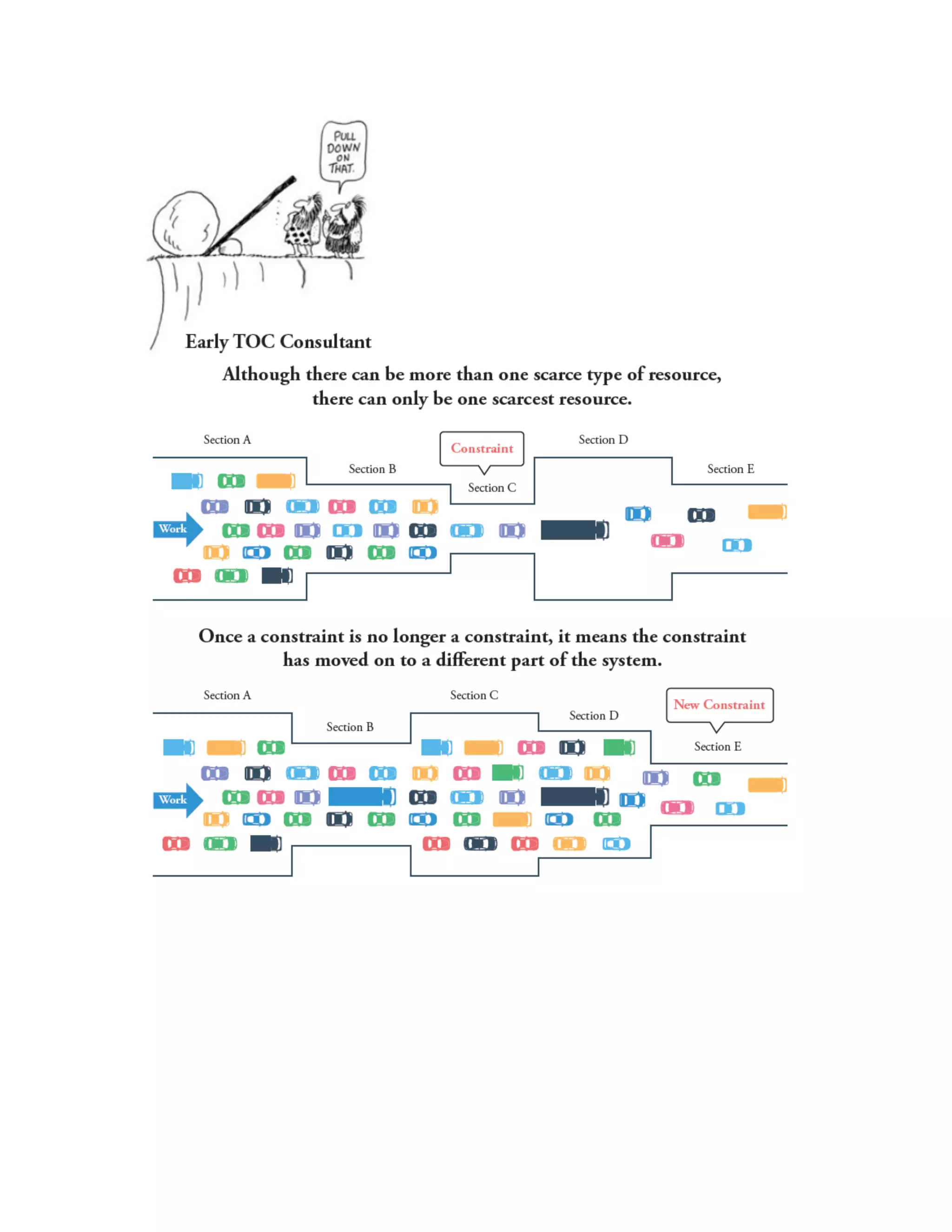

The Theory of Constraints (TOC) identifies that the throughput of any system is limited by at least one constraint, and emphasizes focusing management efforts on these constraints to enhance overall productivity. By following TOC's five focusing steps, organizations can systematically identify and optimize these constraints to improve processes and project outcomes. Effective management of these constraints leads to increased throughput and value delivery while minimizing inefficiencies.