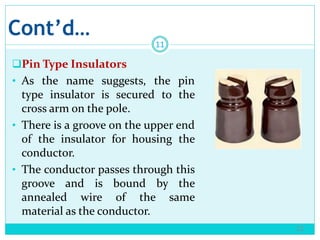

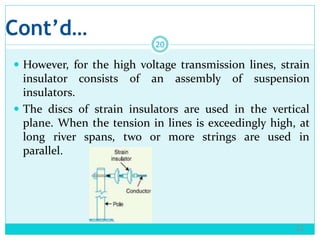

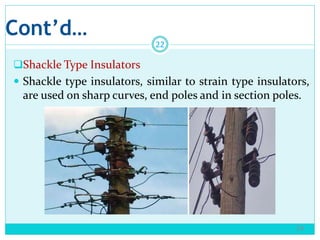

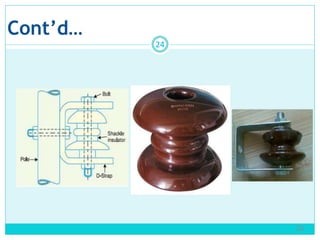

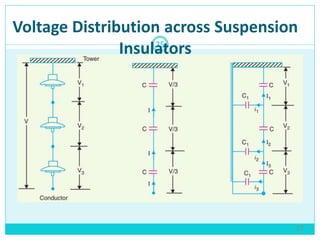

This document provides an overview of insulators used in power systems. It defines insulators as devices that support electric conductors and insulate them from ground or other conductors. The key properties of insulator materials are described, including high mechanical strength, electrical resistance, and dielectric strength. Common materials used are porcelain, toughened glass, and polymeric composites. Insulators are rated based on working voltage, flashover voltage, and puncture voltage. Common types of insulators discussed are pin, suspension, strain, and shackle insulators. The voltage distribution across suspension insulator strings is non-uniform due to shunt capacitance effects. Methods to improve string efficiency include using longer cross arms, capacitance grading,