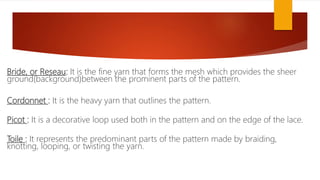

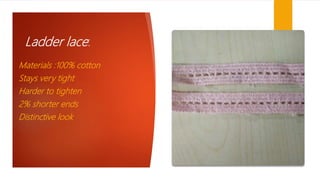

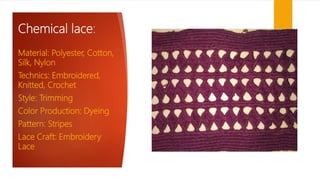

The document provides an overview of lace fabric, detailing its definition, features, types, and historical development from the sixteenth century in Europe. It explains the construction processes of both handmade and machine-made lace, descriptions of various types like bobbin and needle point lace, and the machinery used in production. Additionally, it discusses the uses of lace in apparel and home furnishings, highlighting its decorative role and material compositions.