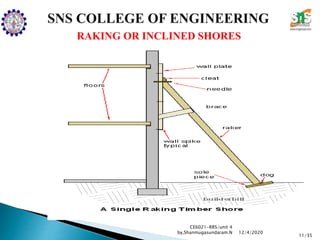

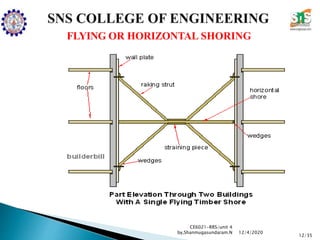

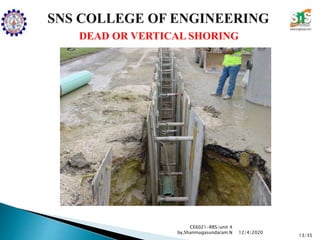

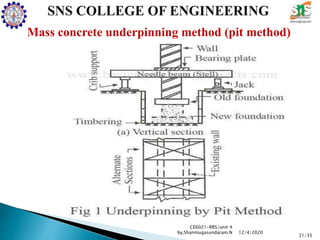

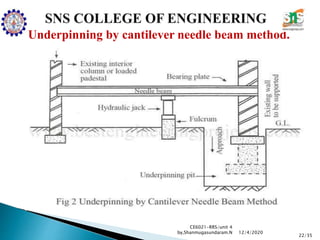

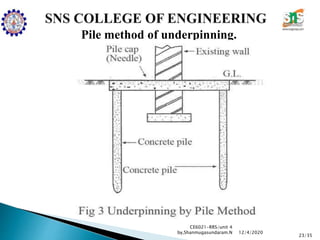

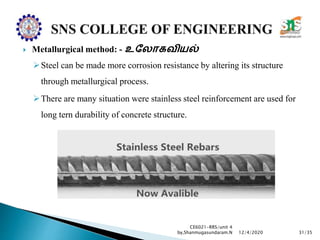

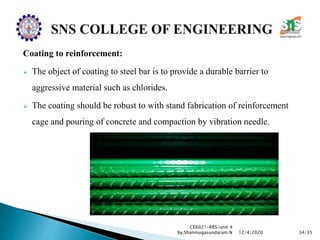

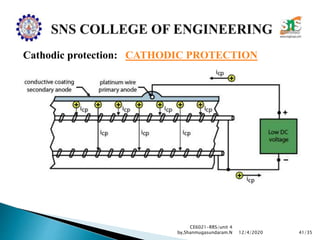

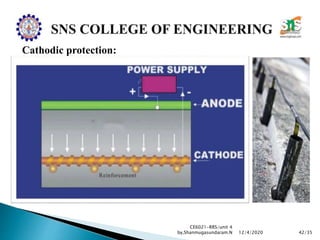

The document discusses various techniques for the repair and protection of structures in civil engineering, specifically focusing on shoring, underpinning, and corrosion protection methods. It outlines the conditions under which shoring is applied, methods of underpinning, and strategies to control corrosion, such as using corrosion inhibitors and protective coatings. It emphasizes the importance of stability during repairs and the need for appropriate design and materials for effective structural rehabilitation.