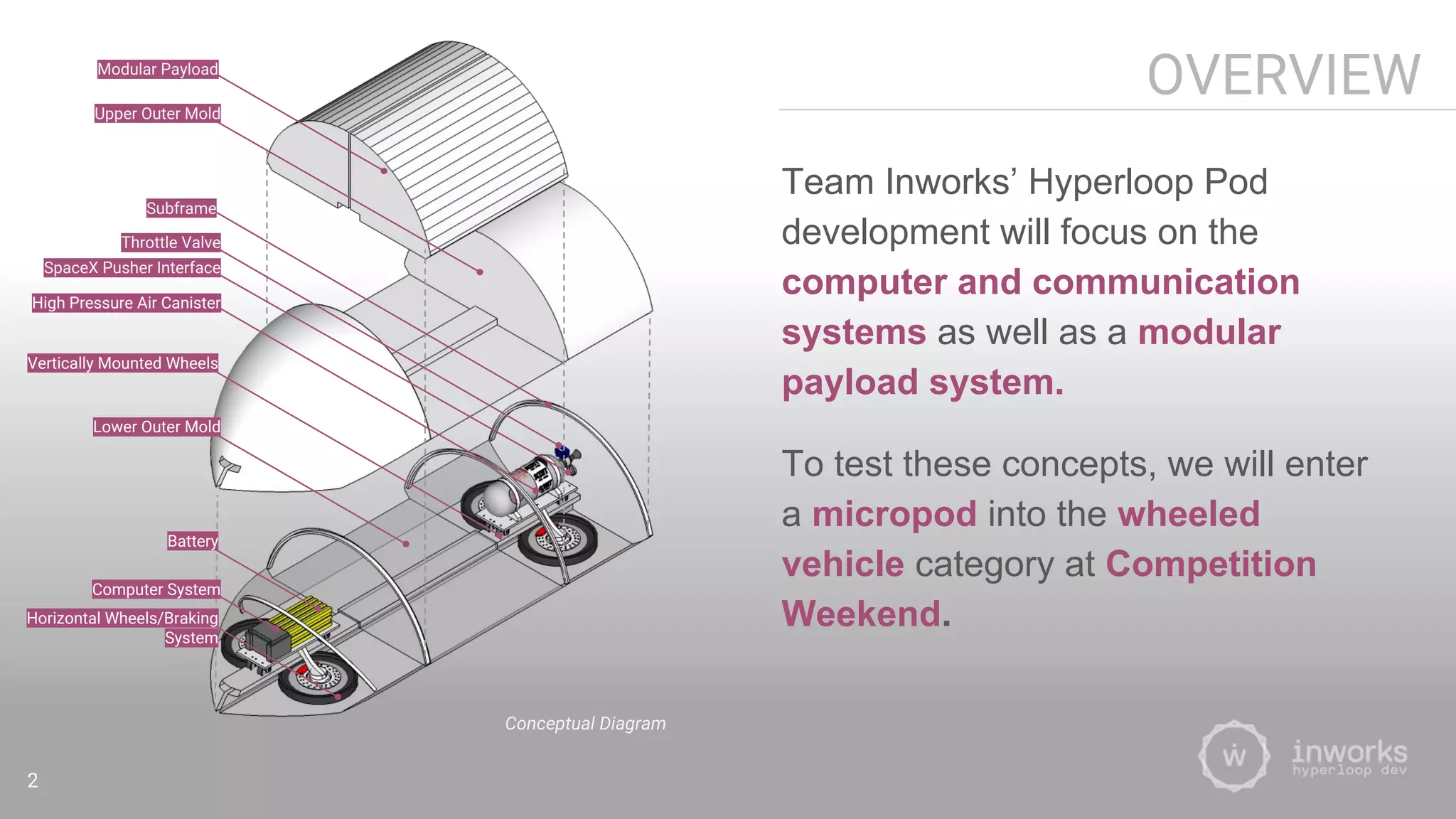

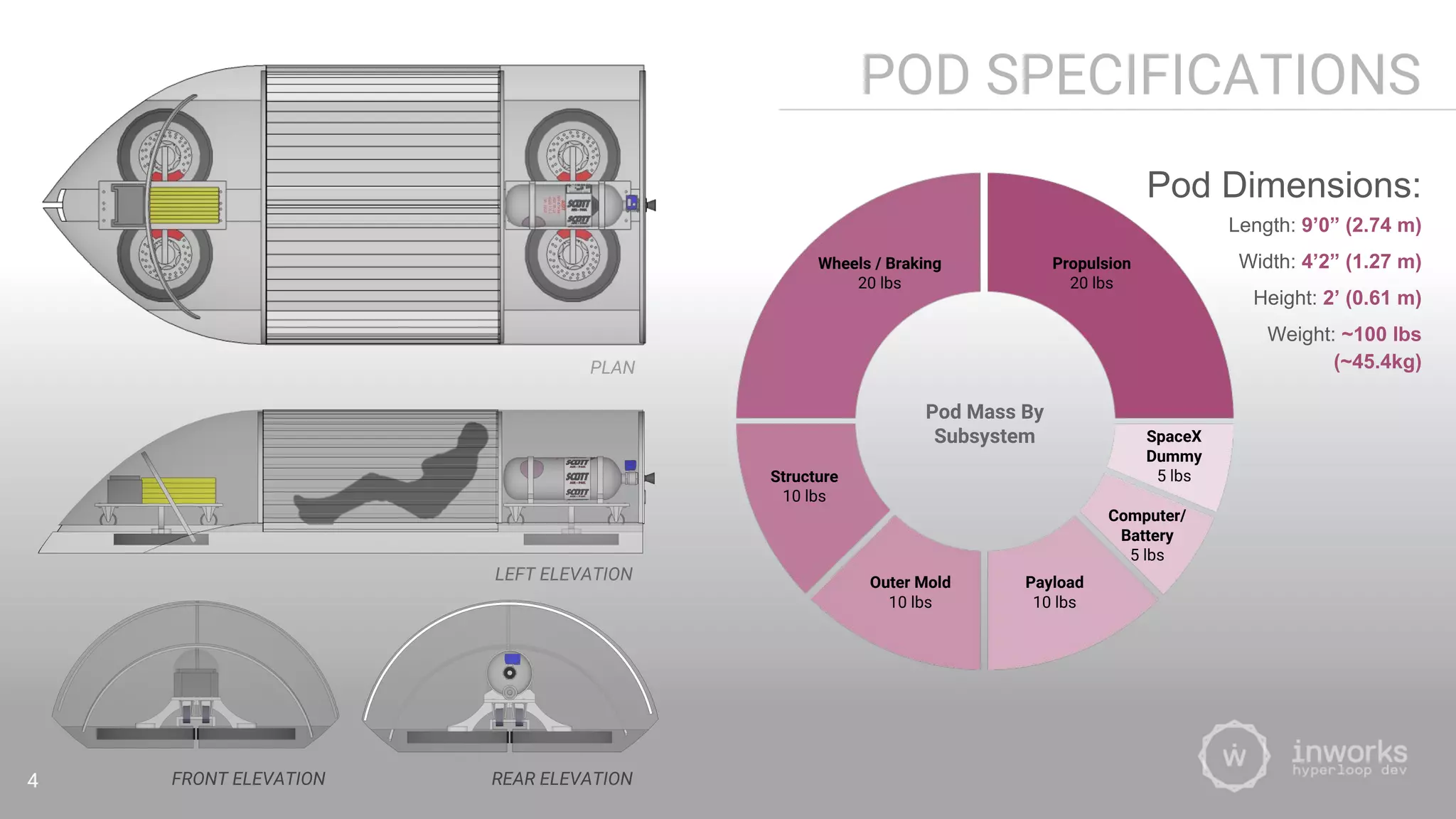

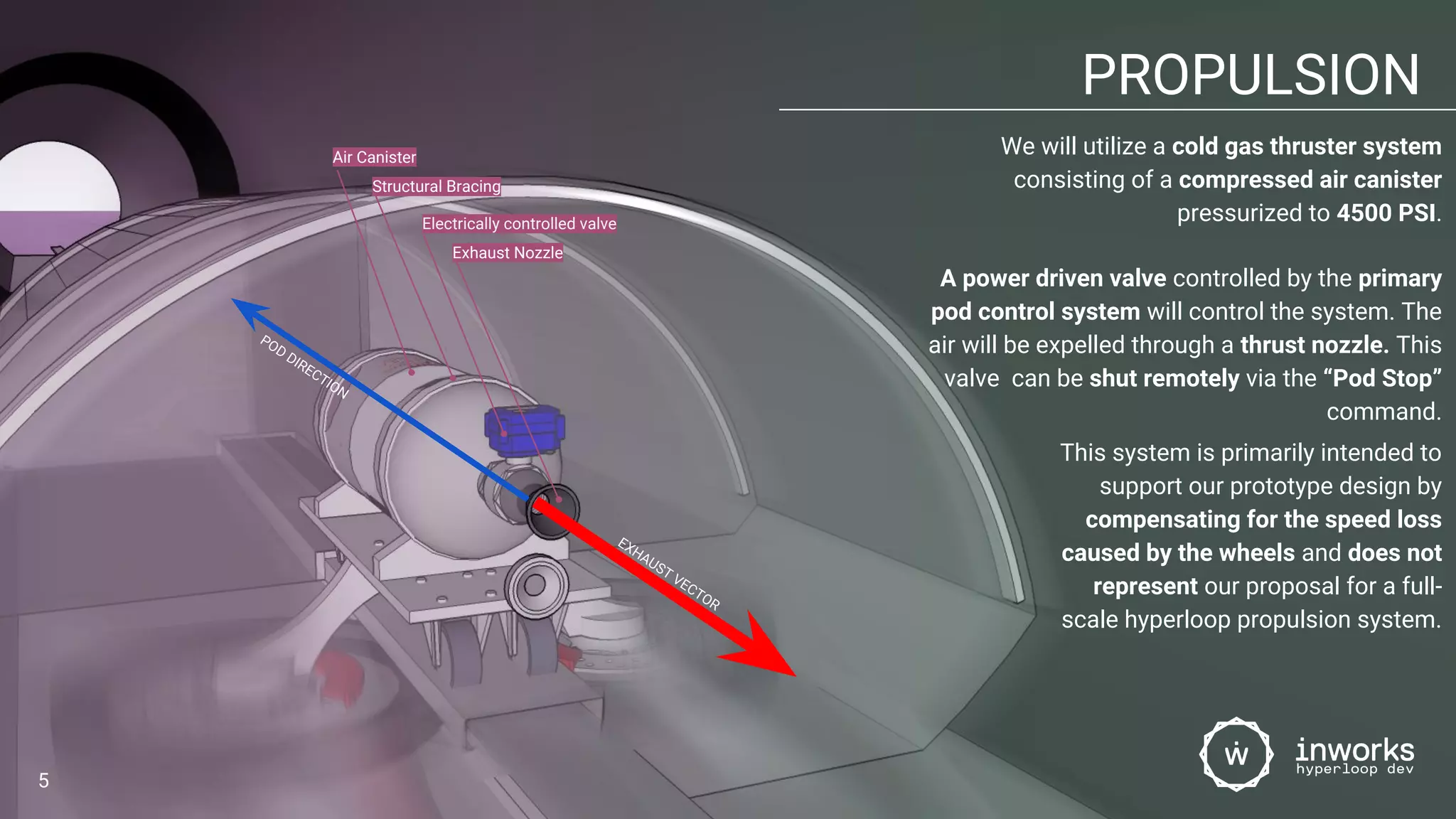

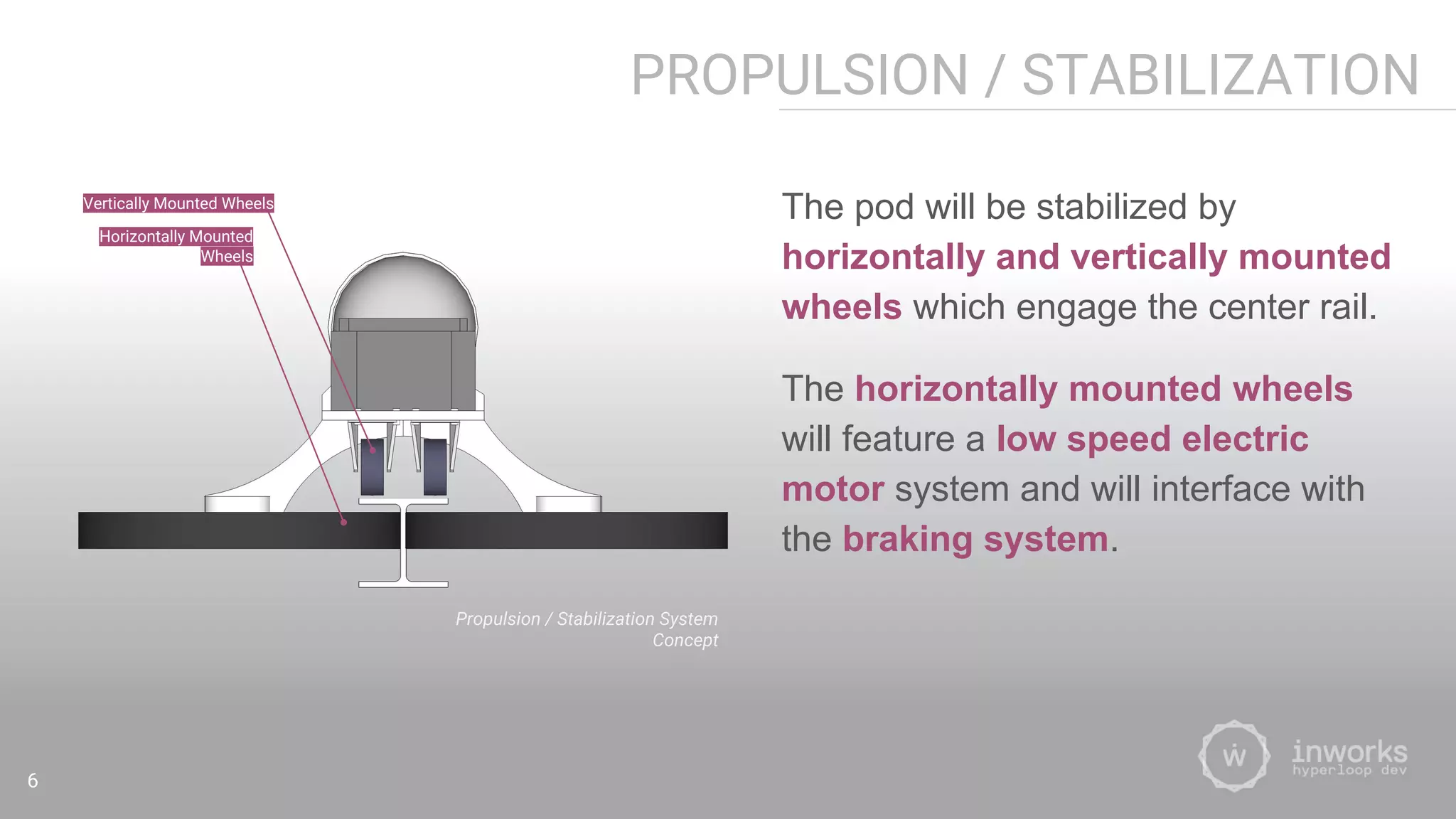

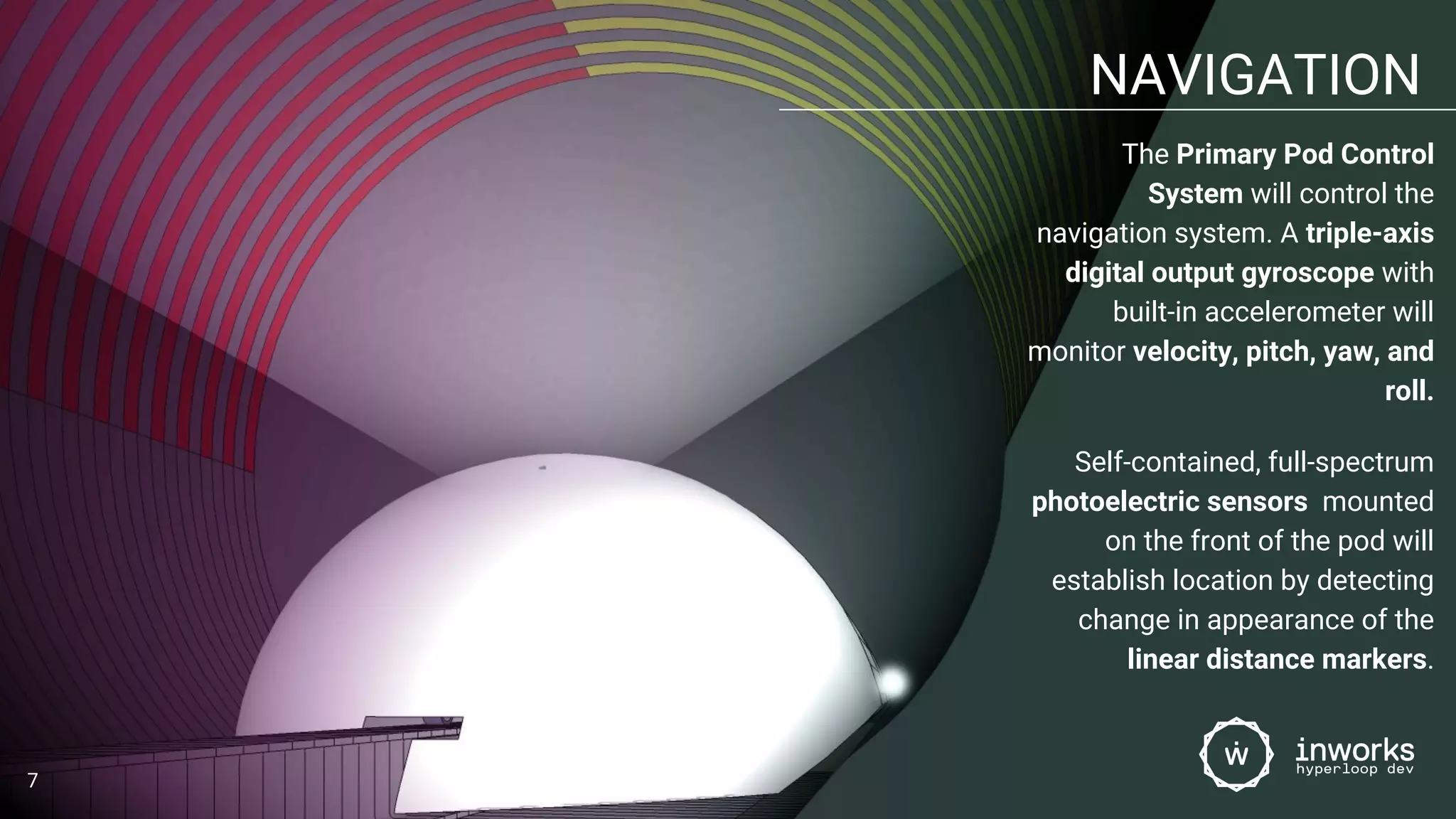

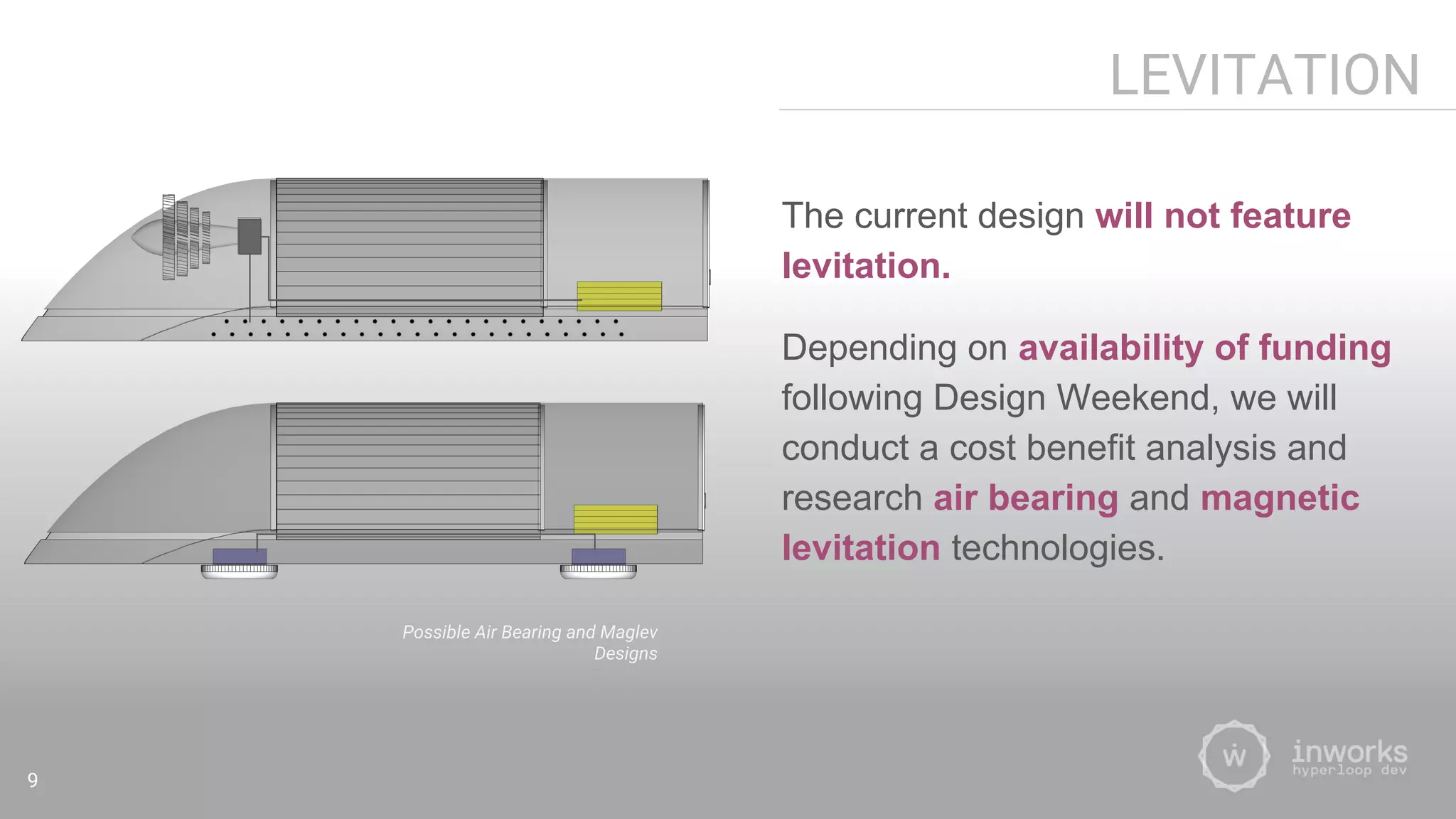

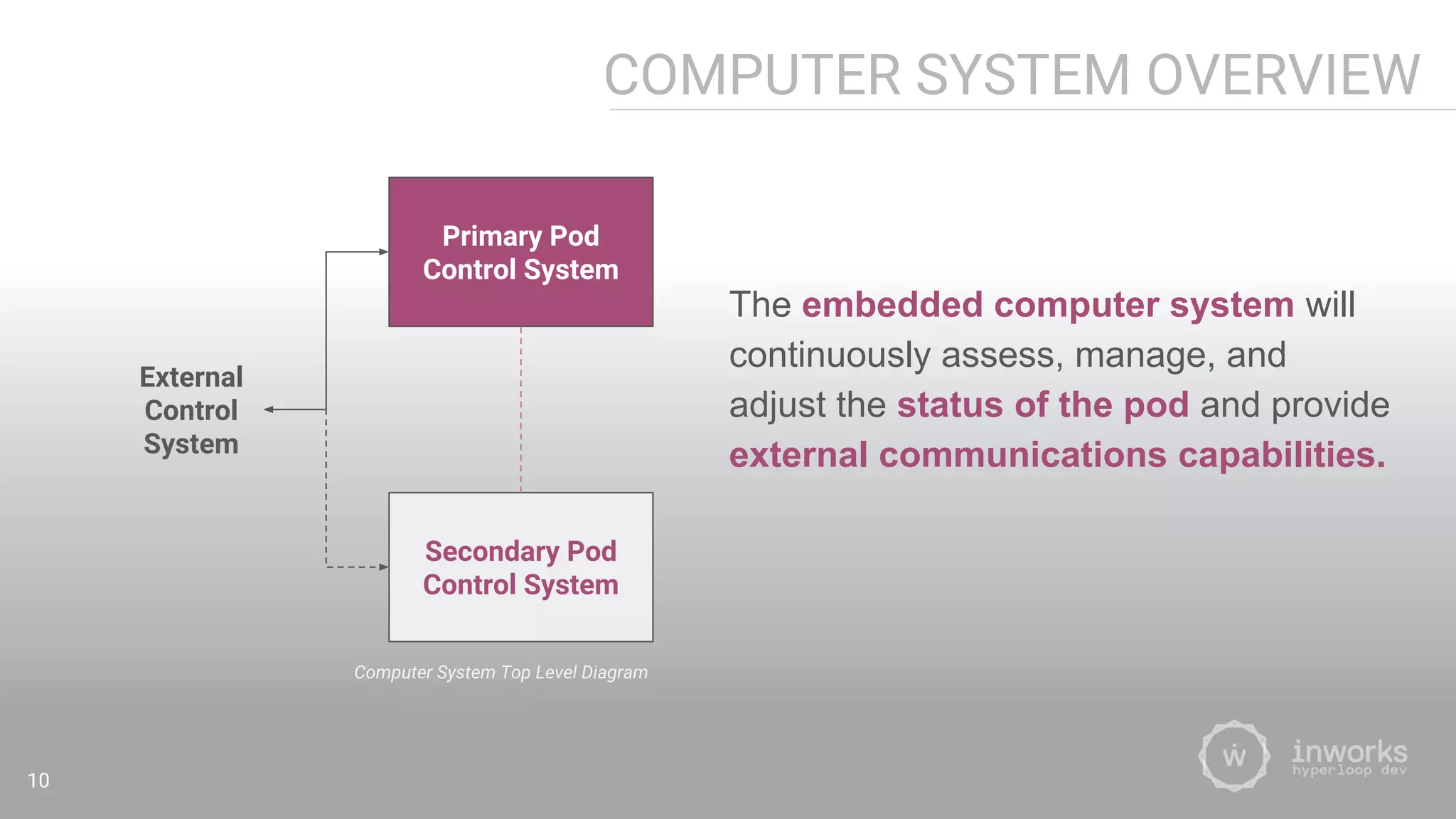

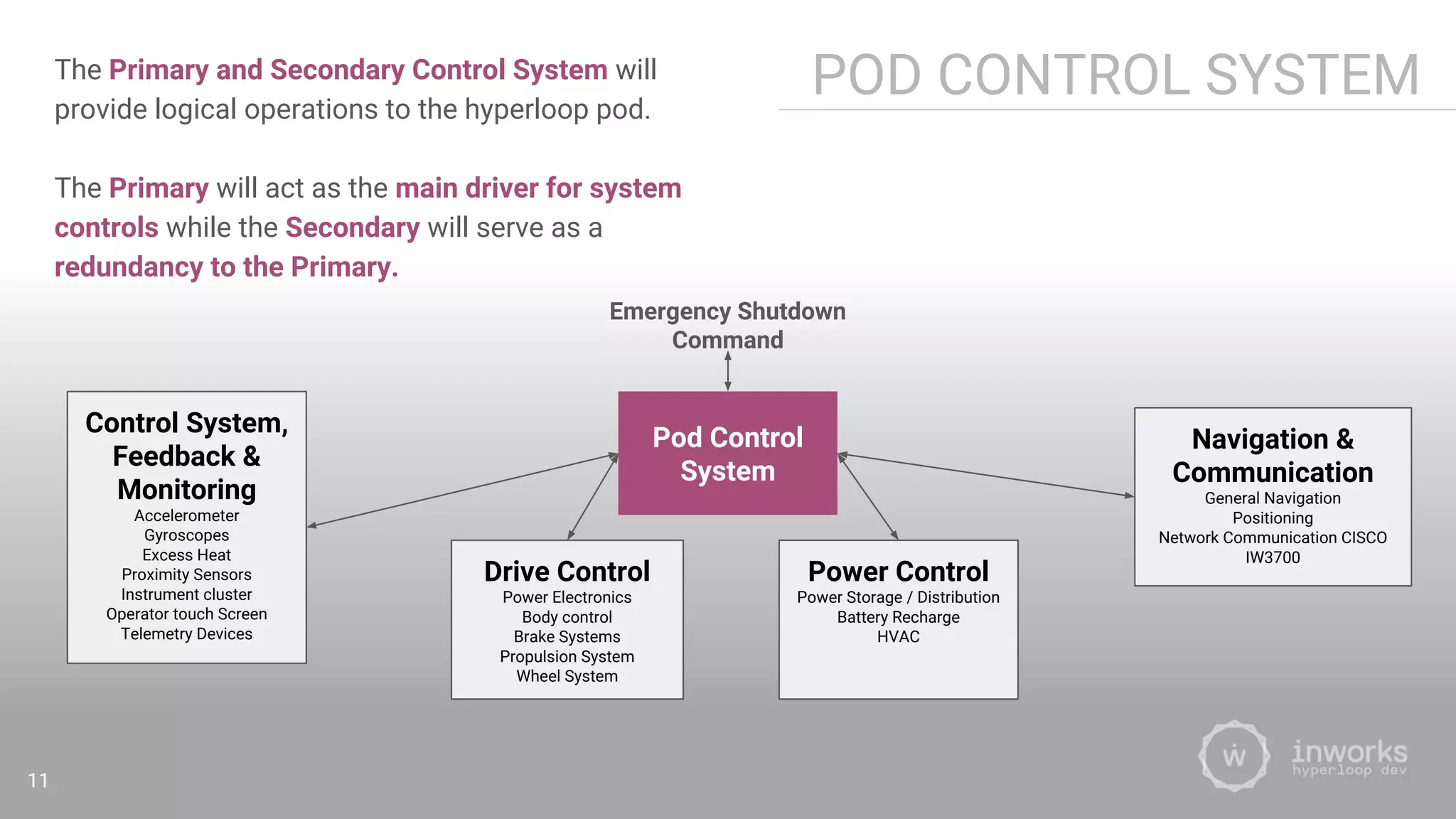

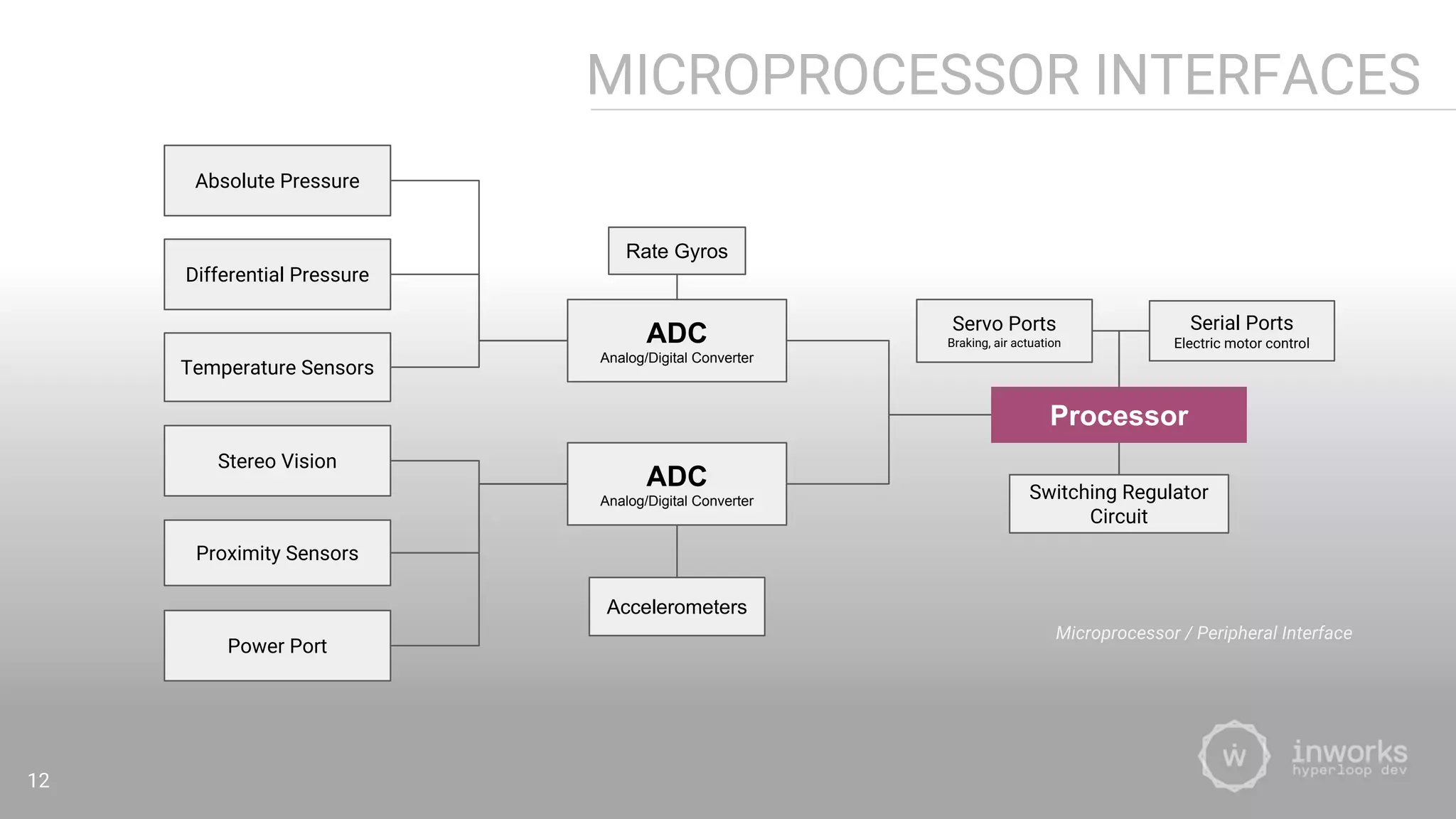

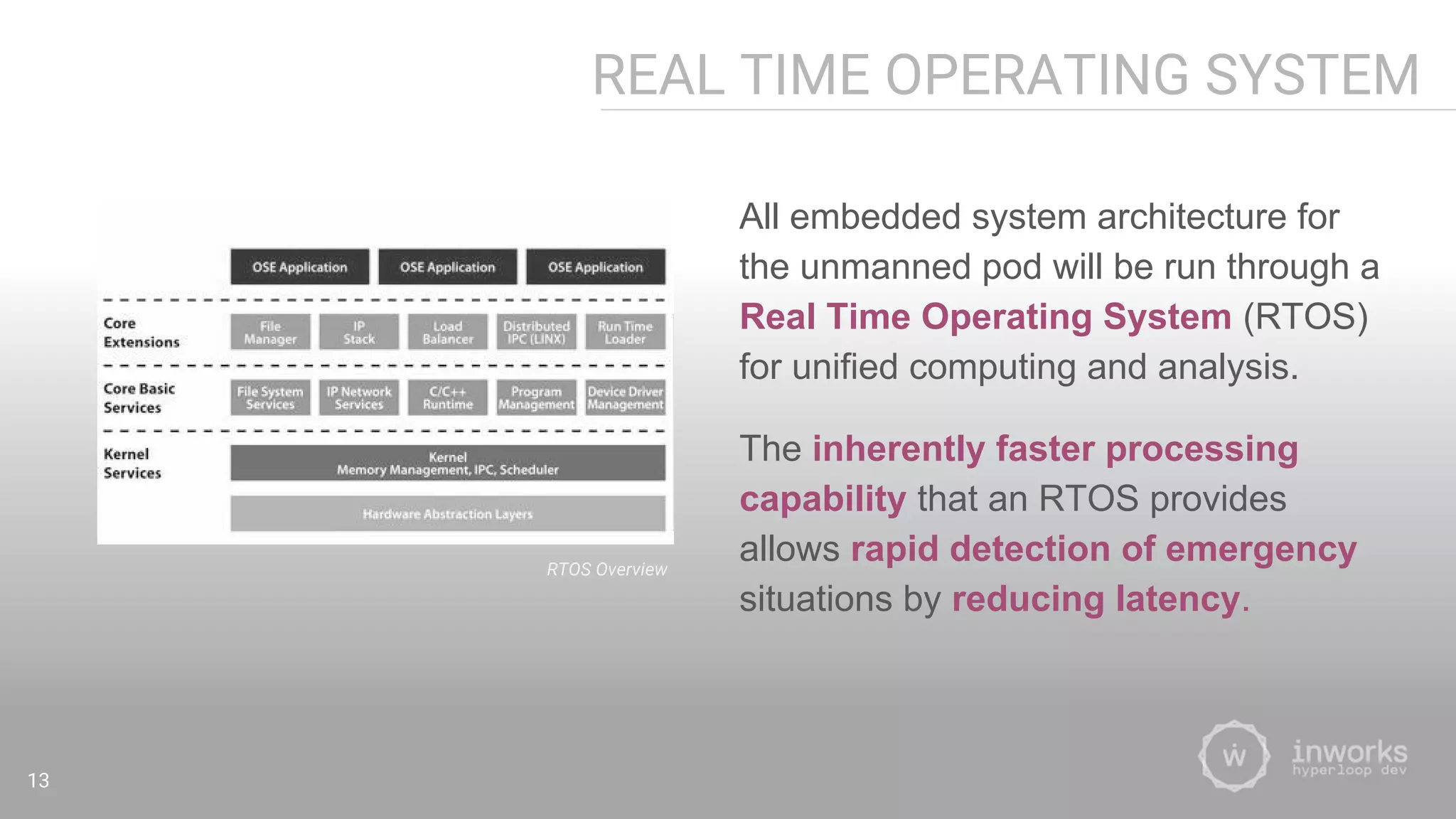

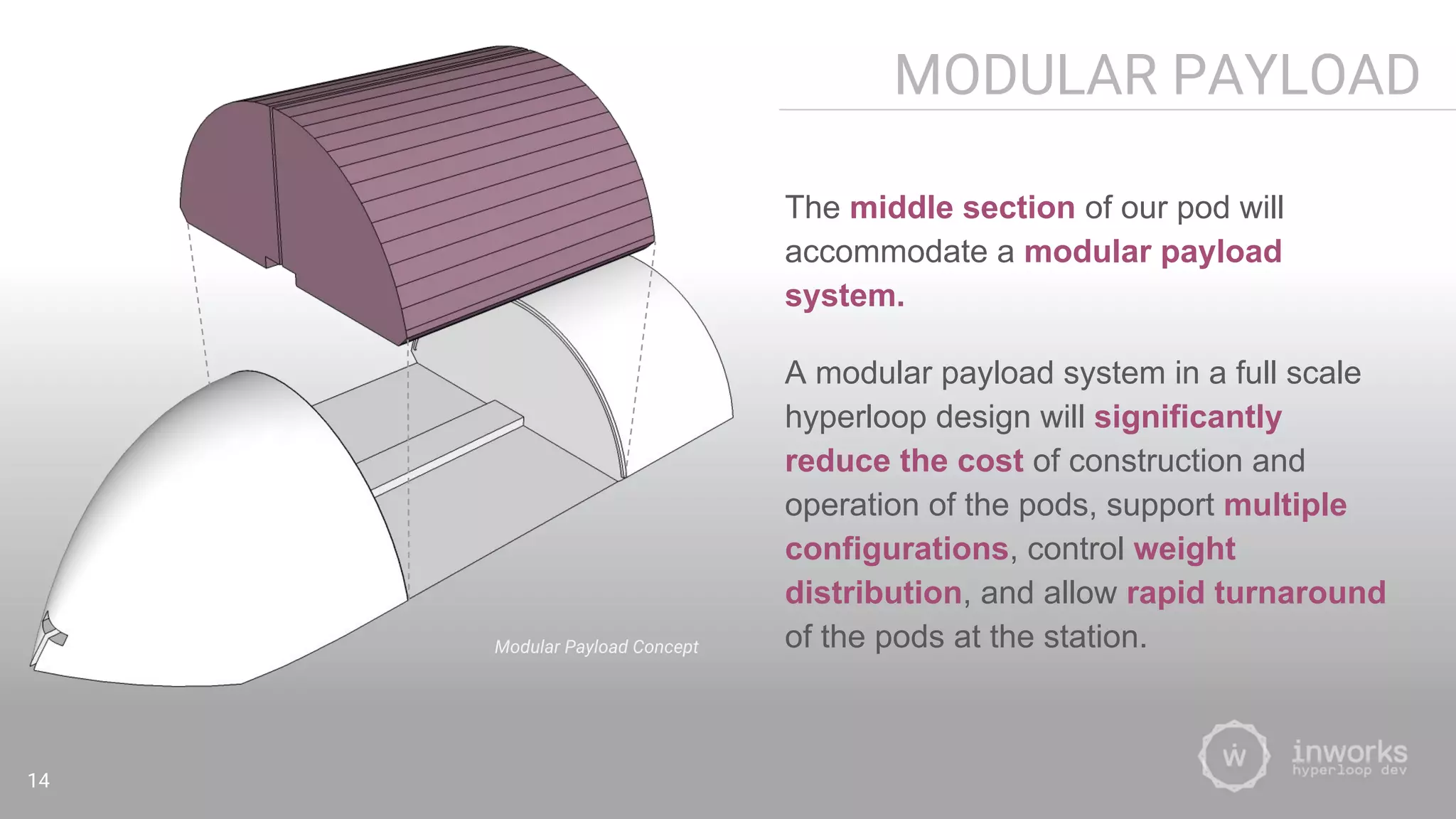

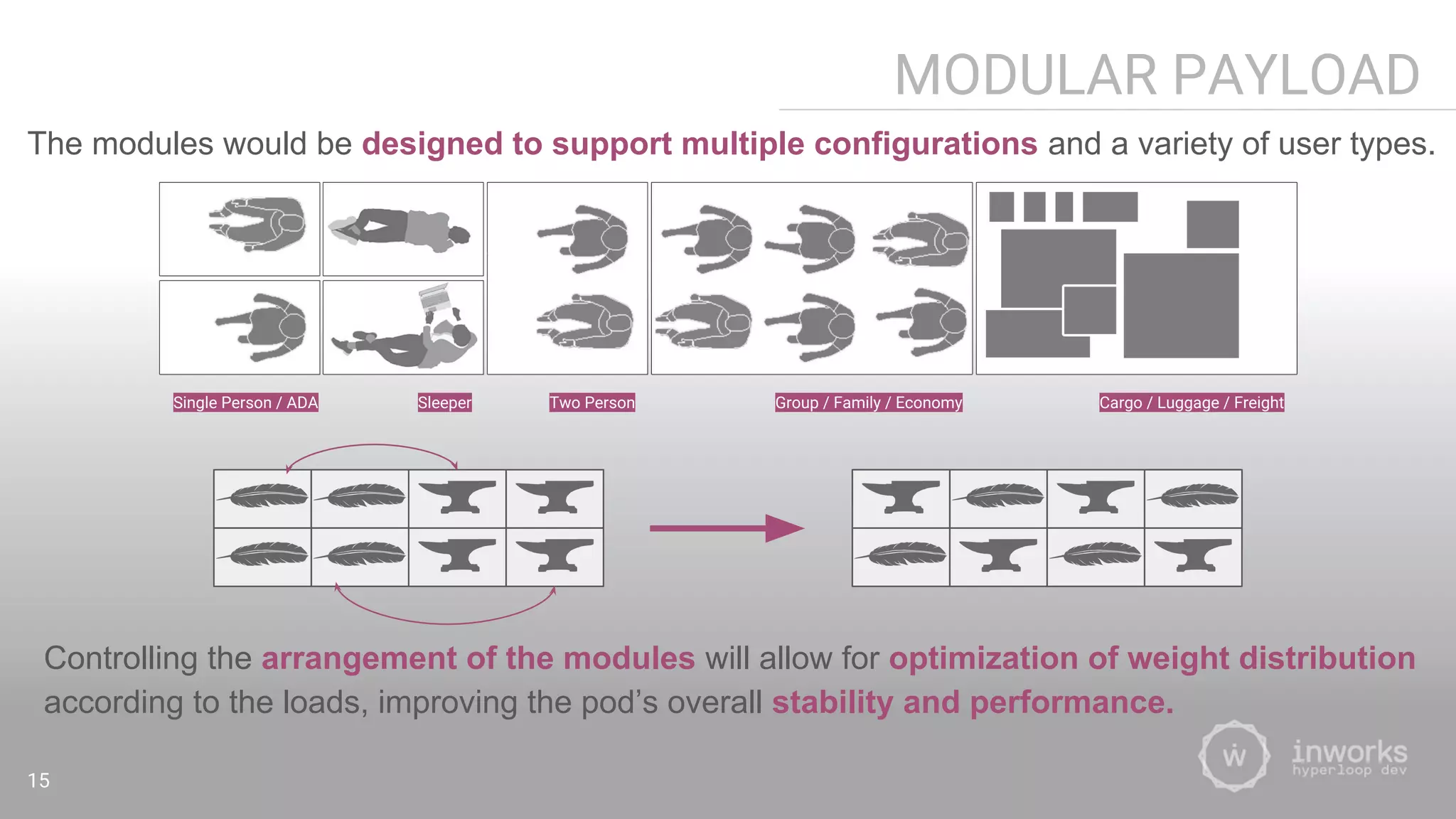

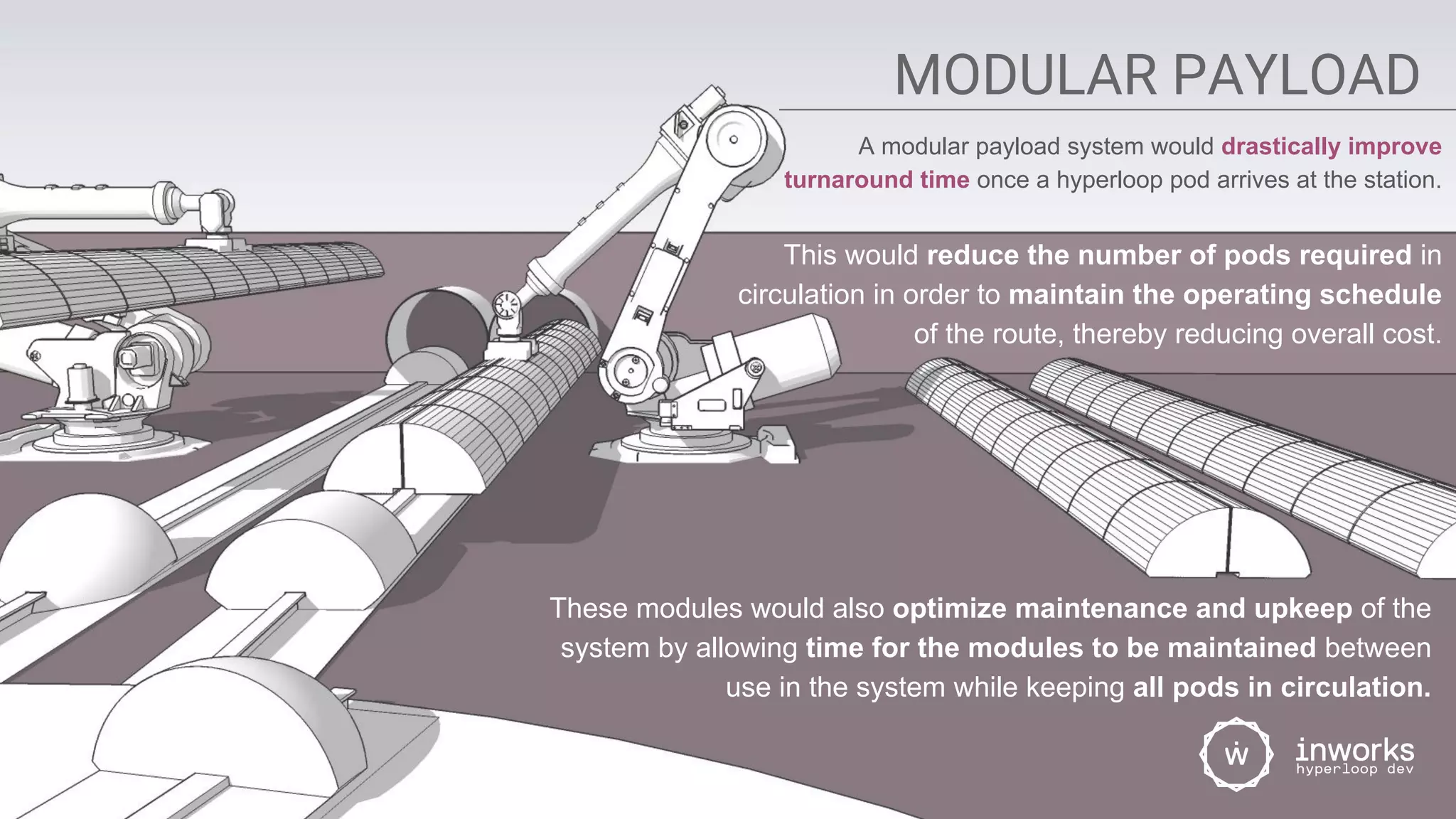

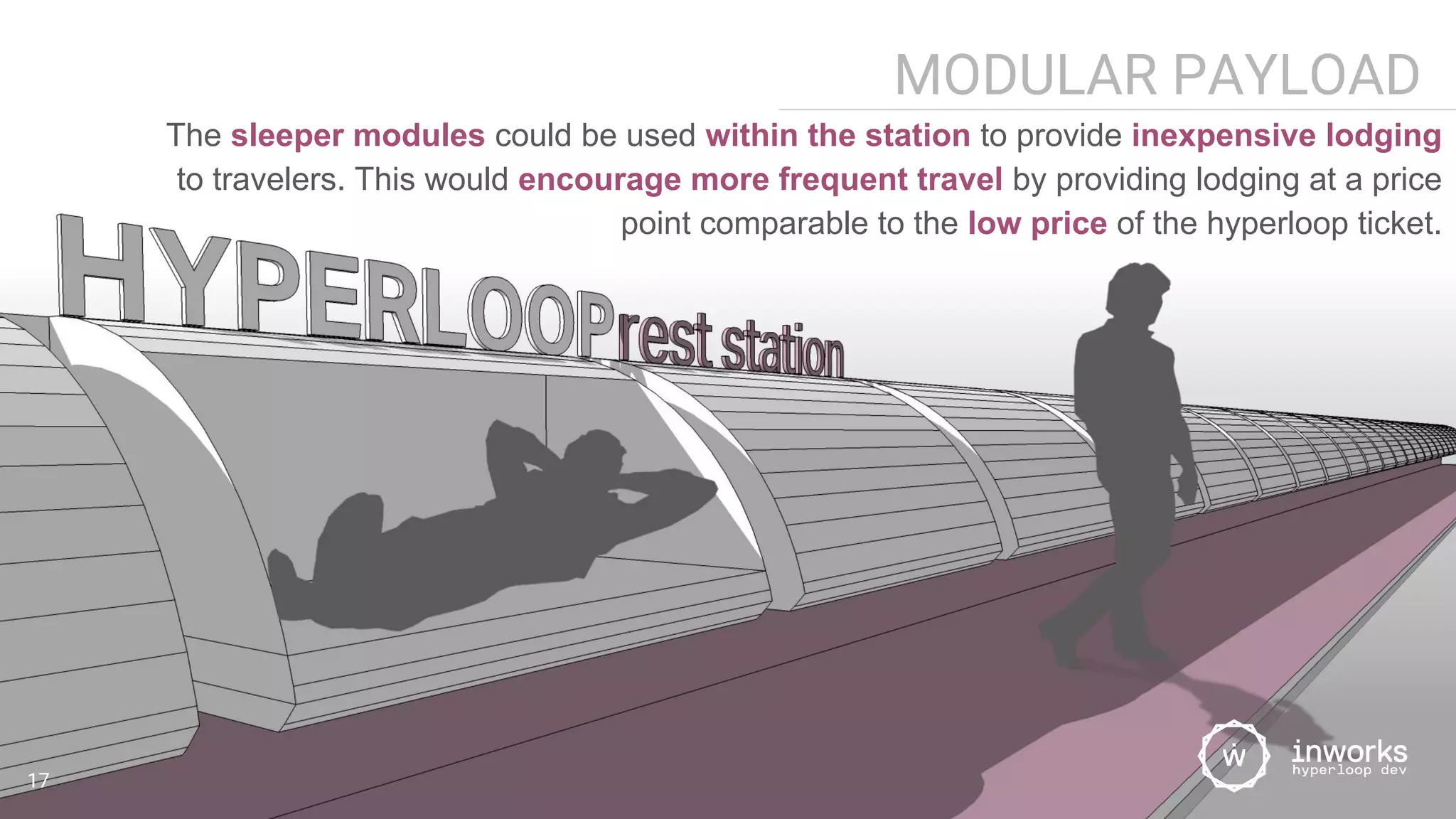

The InWorks team at the University of Colorado Denver is developing a hyperloop pod focusing on computer, communication, and modular payload systems to participate in a competition. The design includes a cold gas thruster propulsion system, advanced navigation controls, and a modular payload for versatile configurations. The initiative aims to address societal challenges while developing collaborative skills among participants.