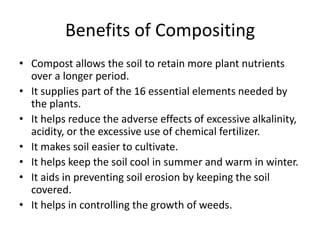

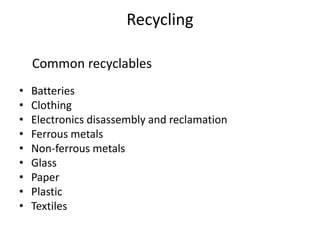

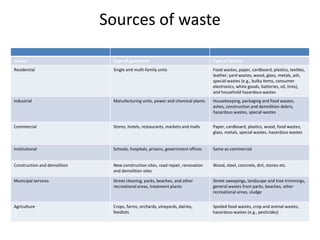

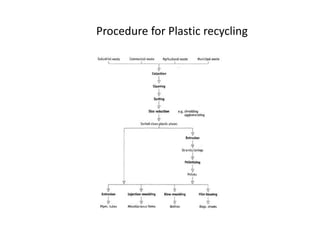

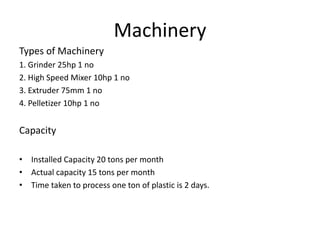

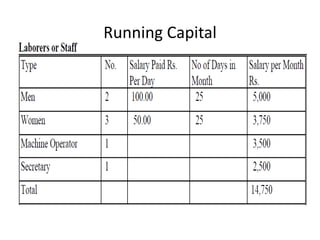

Hindustan Waste Management focuses on sustainable solid waste management in Chintamani, Karnataka, India. Their goals are to achieve sustainable development through professional waste management that balances economic, environmental and social impacts. They commit to minimizing waste disposal and maximizing recycling and recovery. Their mission is to fully integrate environmental stewardship by managing organic waste through composting and anaerobic digestion, and recycling inorganic waste. They describe the local area of Chintamani and their plans to process organic waste and details of composting and anaerobic digestion. They also discuss recycling of common materials and their recycling process and machinery.

![Chintamani Portfolio Chintamani is located at Karnataka. It has an average elevation of 865 meters (2837 ft). It is a taluk headquarter and part of Chikkaballapura district. It became a part of Chikkaballapura district in 2007 when Kolar district was split. The name Chintamani is supposed to be given by a Maratha warrior who had camped in this place long ago. The economy is agriculture based. Chintamani is famous for Tomato and Mango and Banana. Srinivaspur, an adjoining town 18 kilometers away, is very famous for Mango production.Country India State Karnataka District(s) Chikkaballapura Population* 65,456 (2001[update])Density *5,236.48 /km2 (13,562 /sq mi) Time zone IST (UTC+5:30) Area* Elevation 12.5 km² (5 sq mi) * 865 m (2,838 ft)](https://image.slidesharecdn.com/sustainablesolidwastemanagement-090706230307-phpapp01/85/Sustainable-Solid-Waste-Management-4-320.jpg)