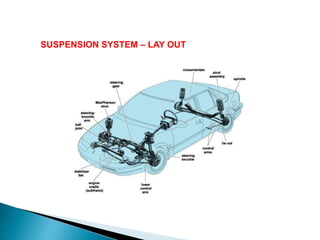

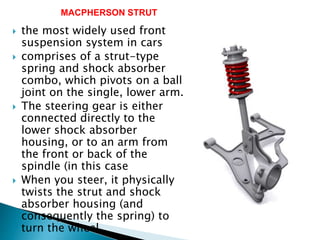

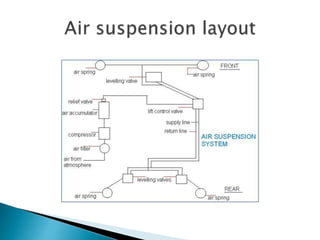

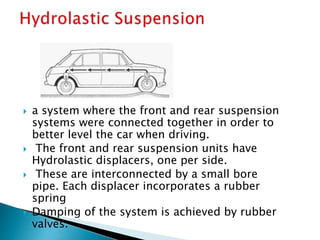

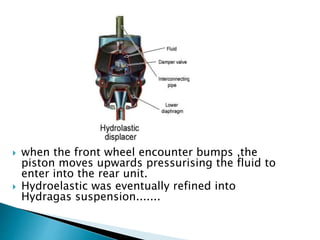

The document discusses different types of vehicle suspension systems. It describes conventional suspension using rigid axles and leaf springs, and independent suspension which allows each wheel to move independently. It provides details on various independent suspension designs including MacPherson strut, double wishbone, and multi-link systems. Air suspension, hydroelastic suspension, and hydragas suspension are also summarized. Common suspension system components and functions are outlined.