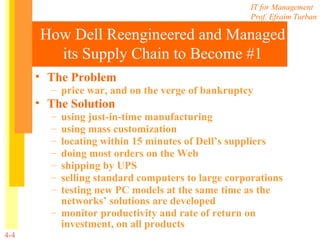

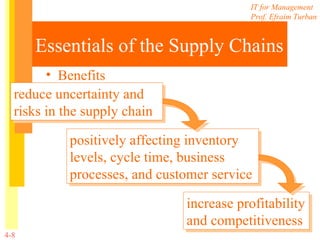

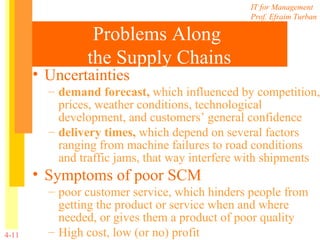

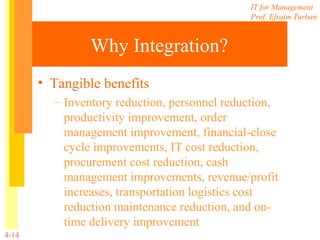

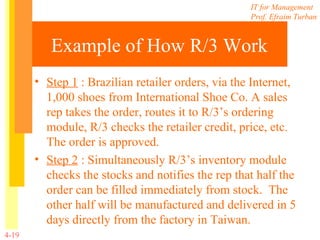

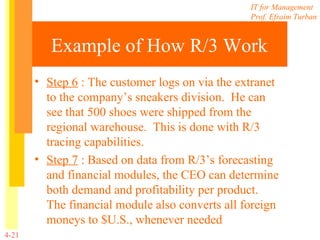

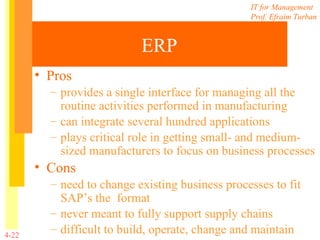

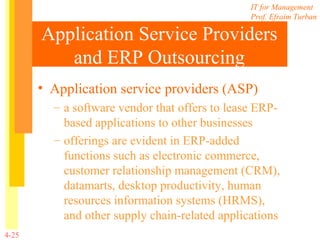

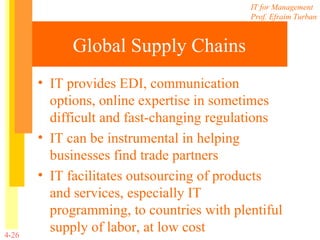

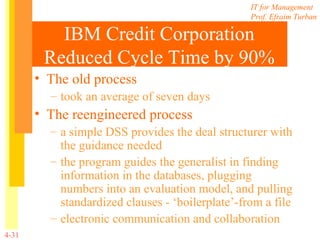

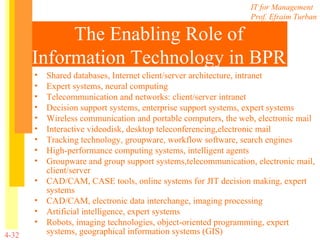

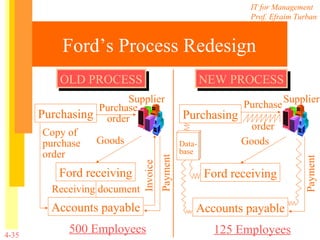

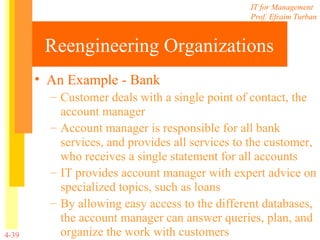

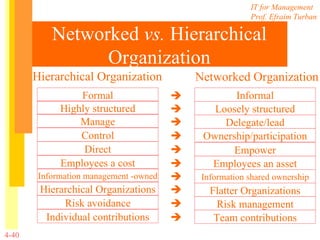

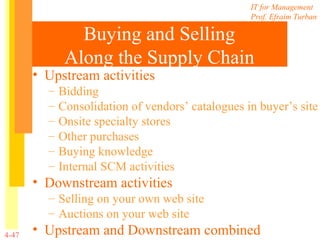

This document discusses supply chain management and business process engineering. It defines key terms like supply chain, enterprise resource planning (ERP), and business process reengineering (BPR). It also provides examples of how Dell and SAP implemented supply chain management and ERP systems to improve operations.