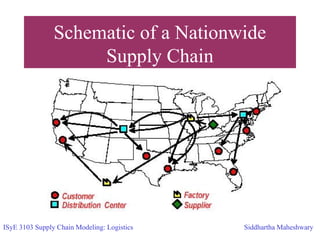

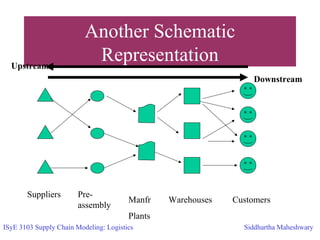

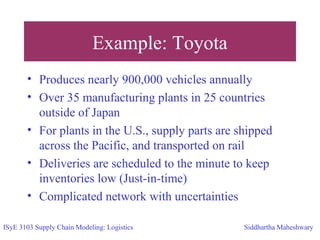

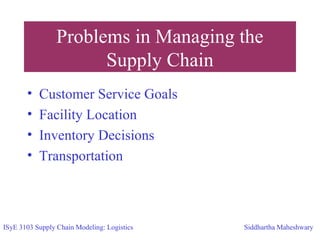

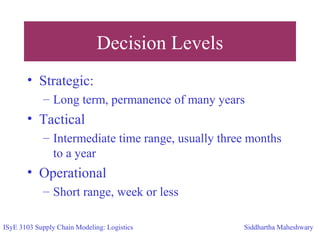

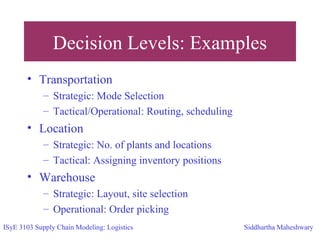

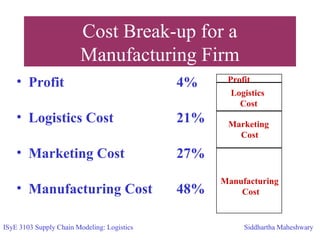

The document discusses supply chain concepts including defining a supply chain as a network of stages that fulfill customer demand and includes manufacturers, suppliers, transporters, warehouses, retailers, and customers. It provides examples of supply chains for Dell and Toyota. Key problems in managing supply chains are discussed as customer service goals, facility location, inventory decisions, and transportation. Decision levels in supply chain management are defined as strategic, tactical, and operational with examples given. Logistics costs for the economy and manufacturing firms are presented.