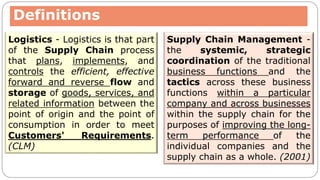

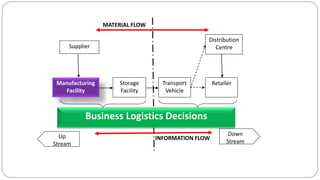

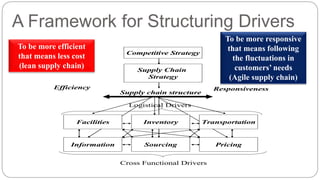

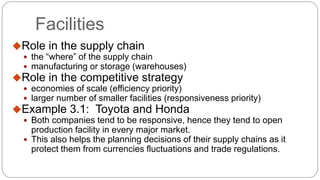

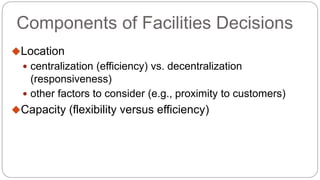

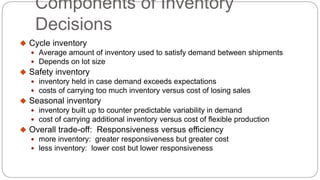

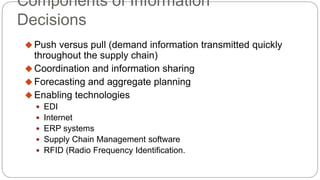

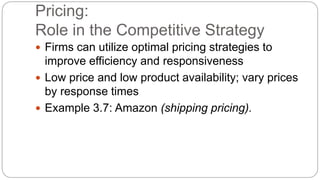

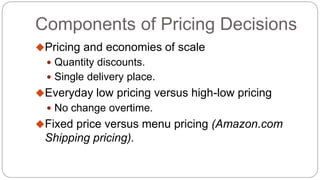

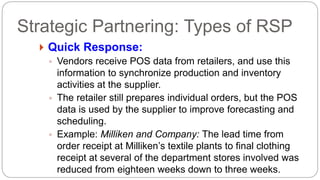

This document provides an overview of supply chain management concepts. It defines key terms like logistics and supply chain management. It then discusses various components of a supply chain like facilities, inventory, transportation, and information and how decisions around these components can impact efficiency and responsiveness. The document also examines sourcing, pricing and supply chain collaboration strategies and how they relate to the competitive strategy.