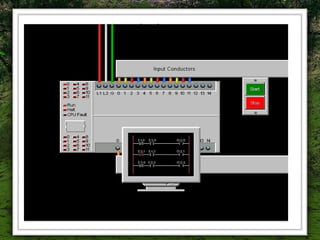

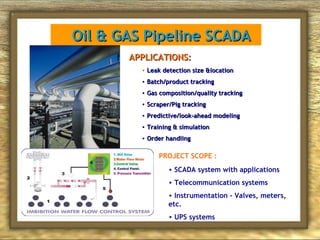

This document provides information about a presentation on industrial automation and process control instrumentation. It discusses that companies worldwide require skilled workers with expertise in automation. The presentation aims to impart these skills to students and professionals and bridge the gap between academic curriculum and industry requirements. It covers various topics related to automation including PLCs, SCADA, variable speed drives, servo motors, motion control, automation applications in different industries, and career prospects in this field. The document also mentions the advanced laboratory facilities provided by IAT to gain practical experience in automation, embedded systems, robotics and other areas.