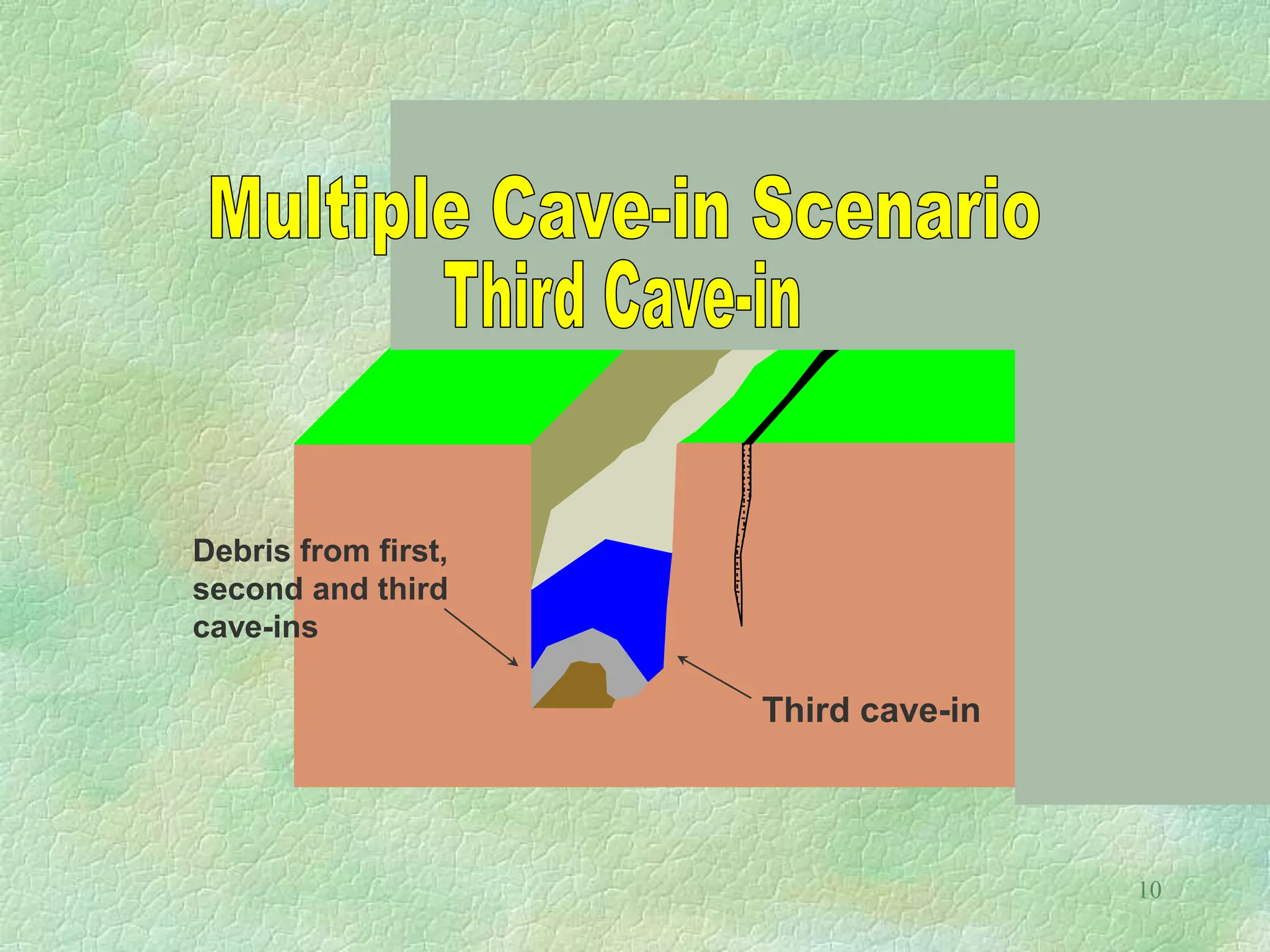

The document provides an overview of excavation safety and OSHA regulations regarding trenching and excavation. It discusses common causes of excavation cave-ins including tension cracks, saturated soil, and spoil piles. The OSHA excavation standard (29 CFR 1926 Subpart P) requires protective systems like sloping, shoring, or trench boxes to prevent cave-ins. It defines key terms and outlines requirements for soil classification, protective systems, inspections, means of egress, and hazard training. The goal is to educate workers on excavation hazards and OSHA standards to prevent injuries and fatalities from cave-ins and other dangers like exposure to equipment or toxic atmospheres.