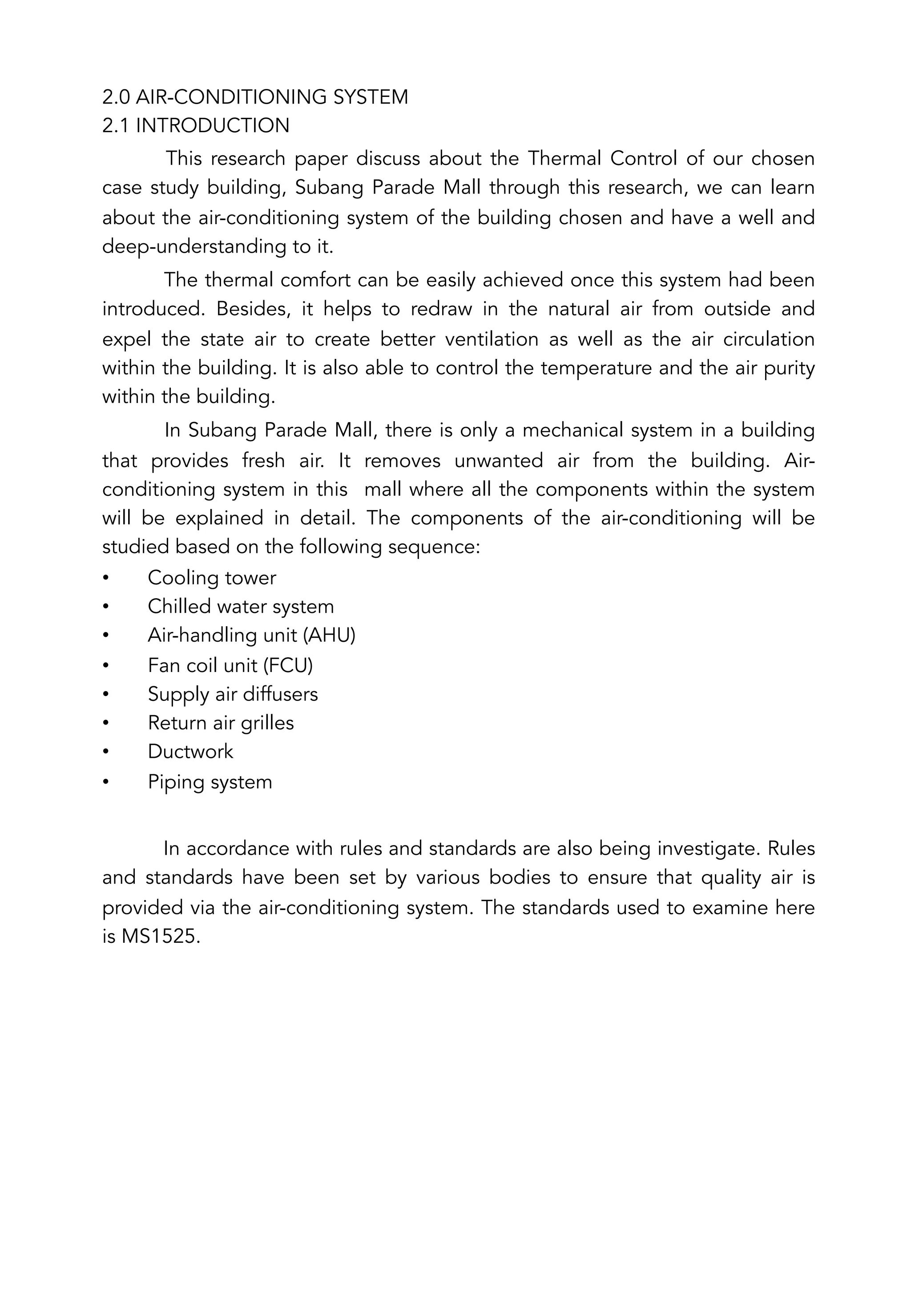

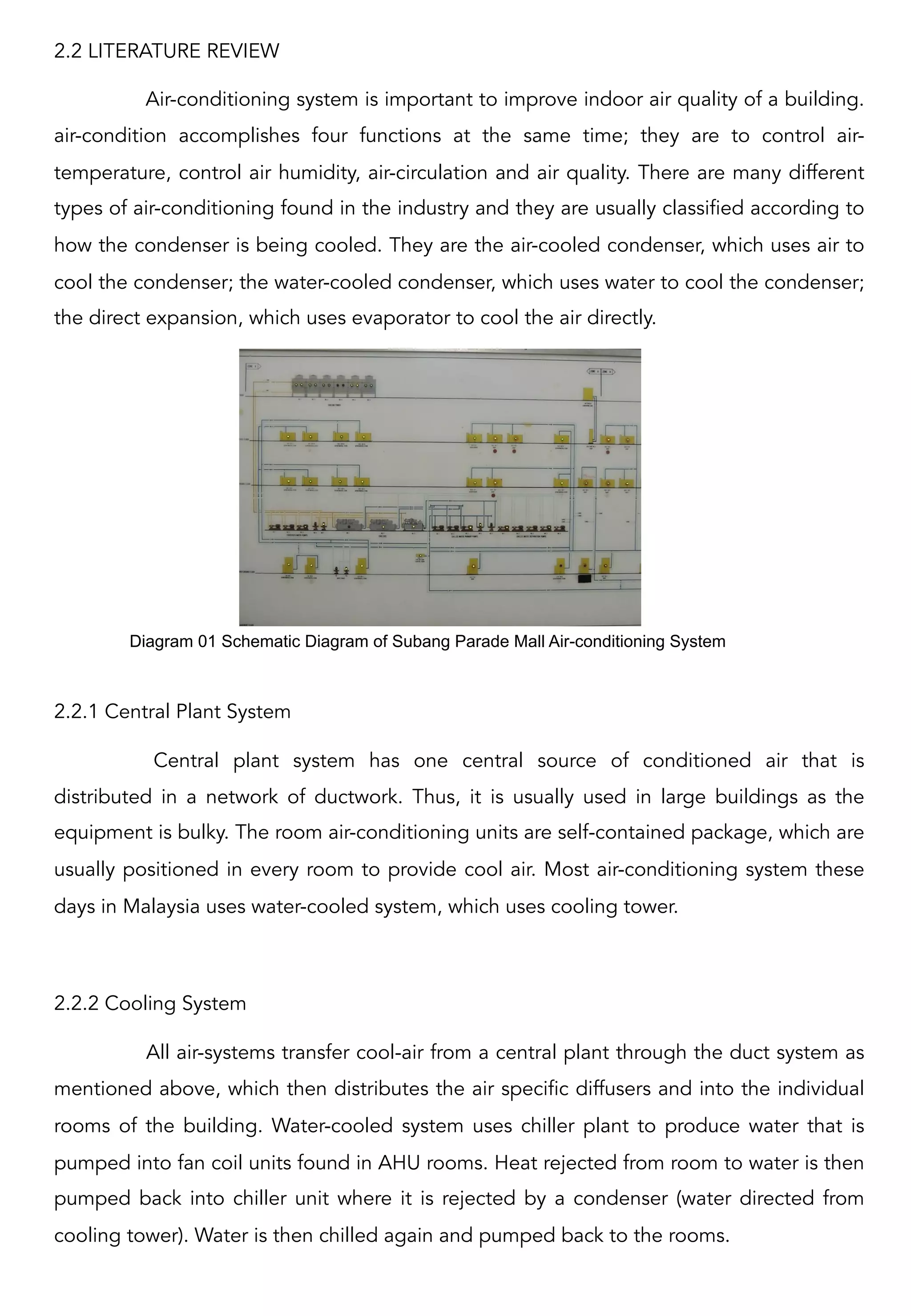

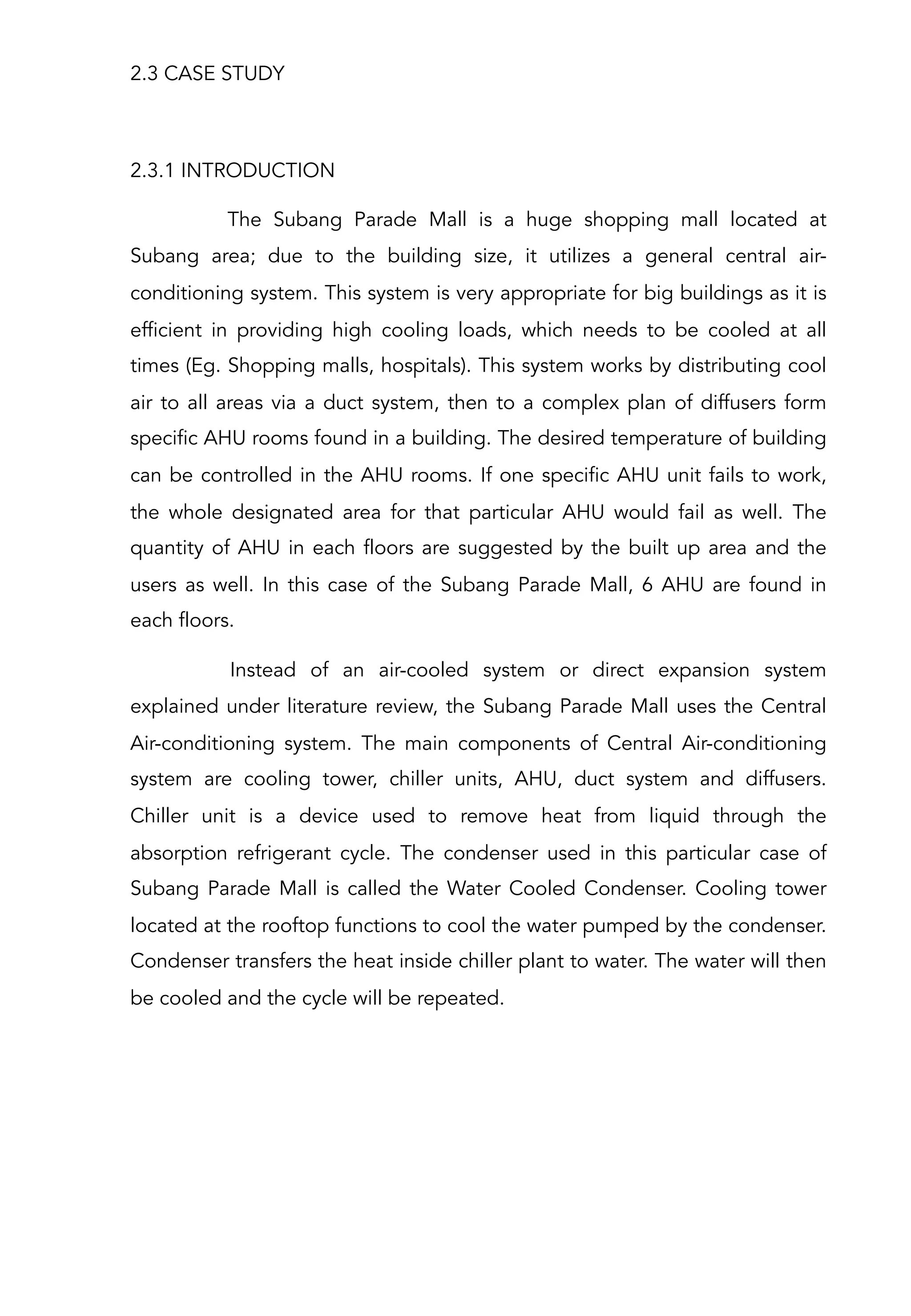

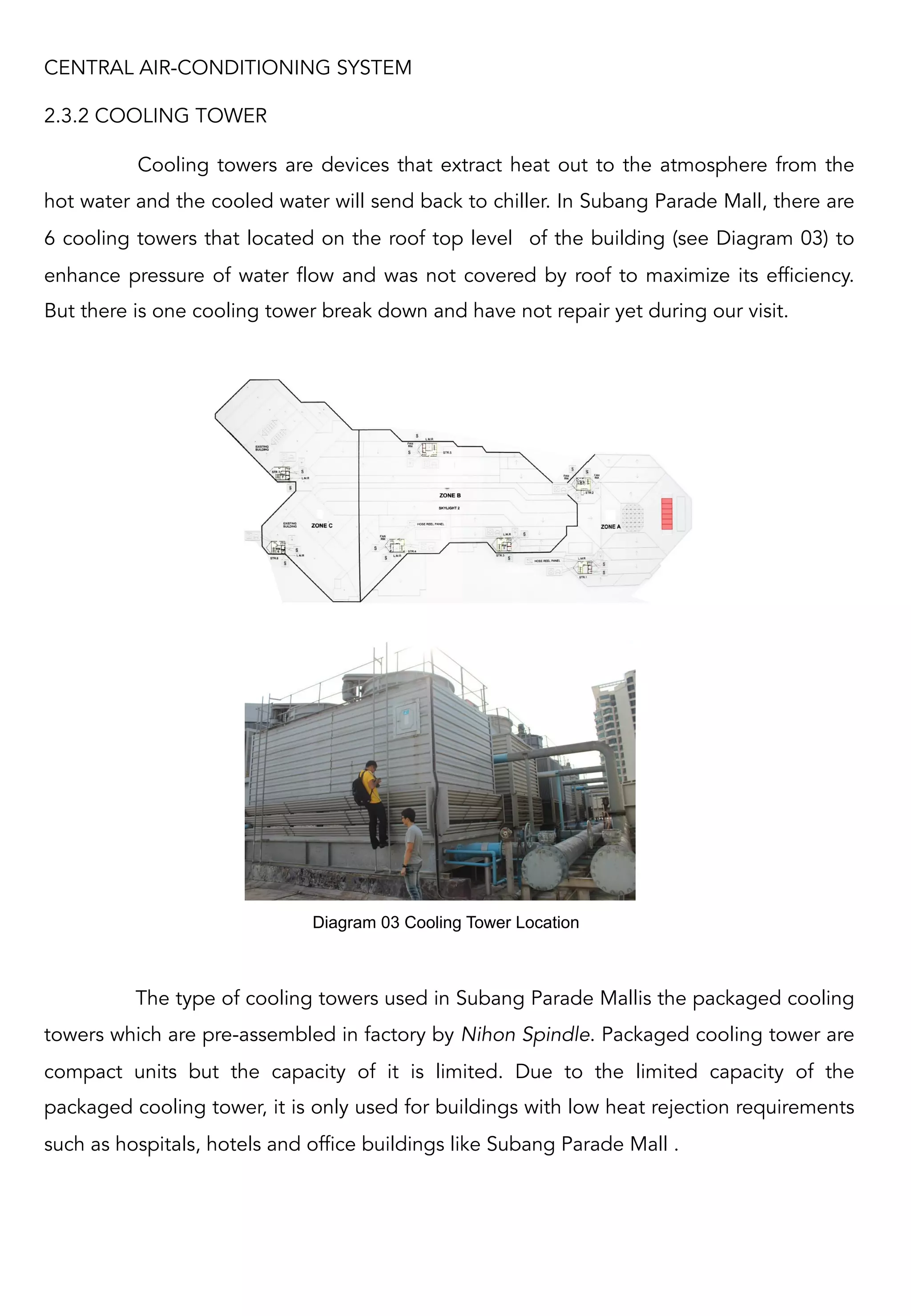

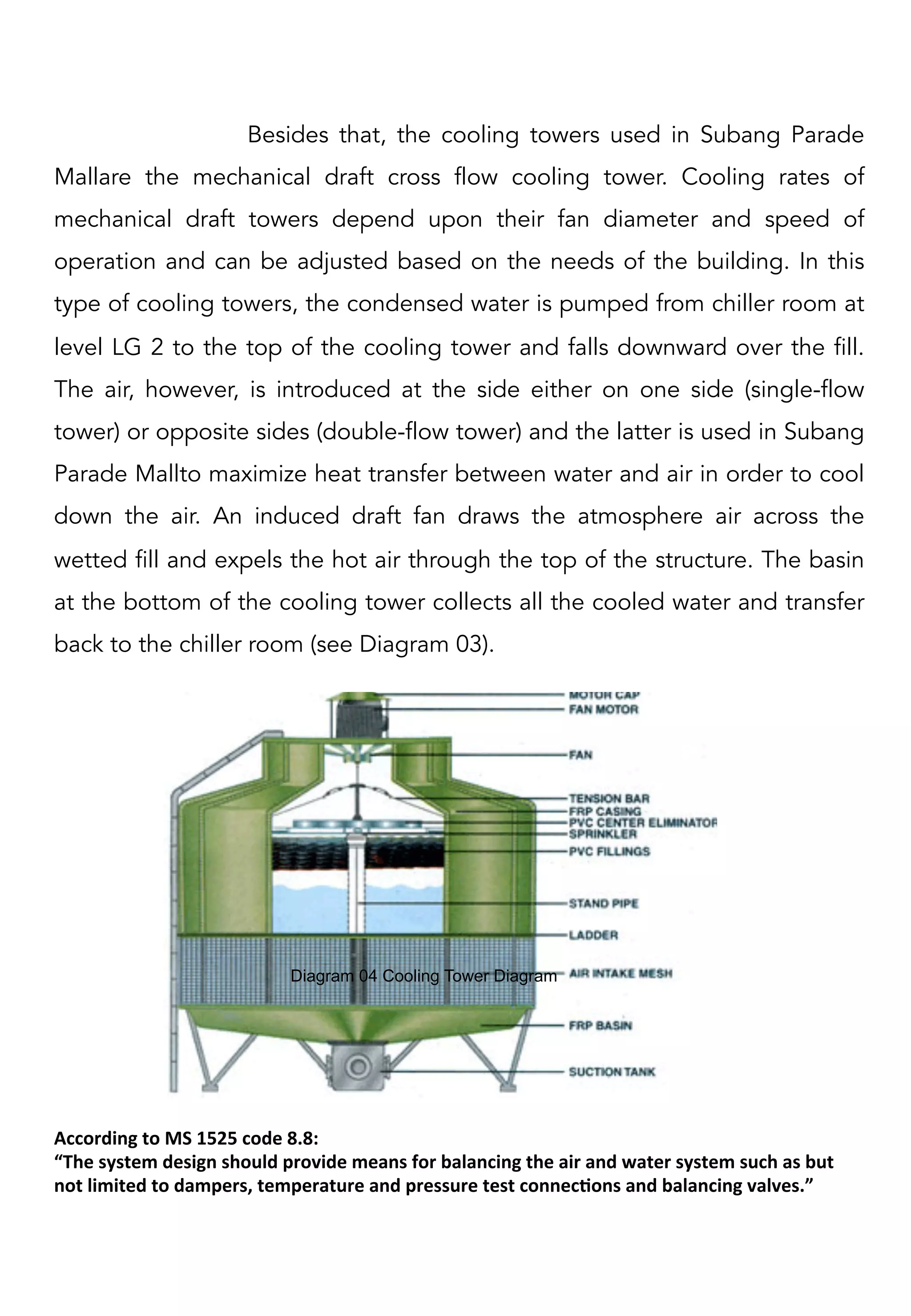

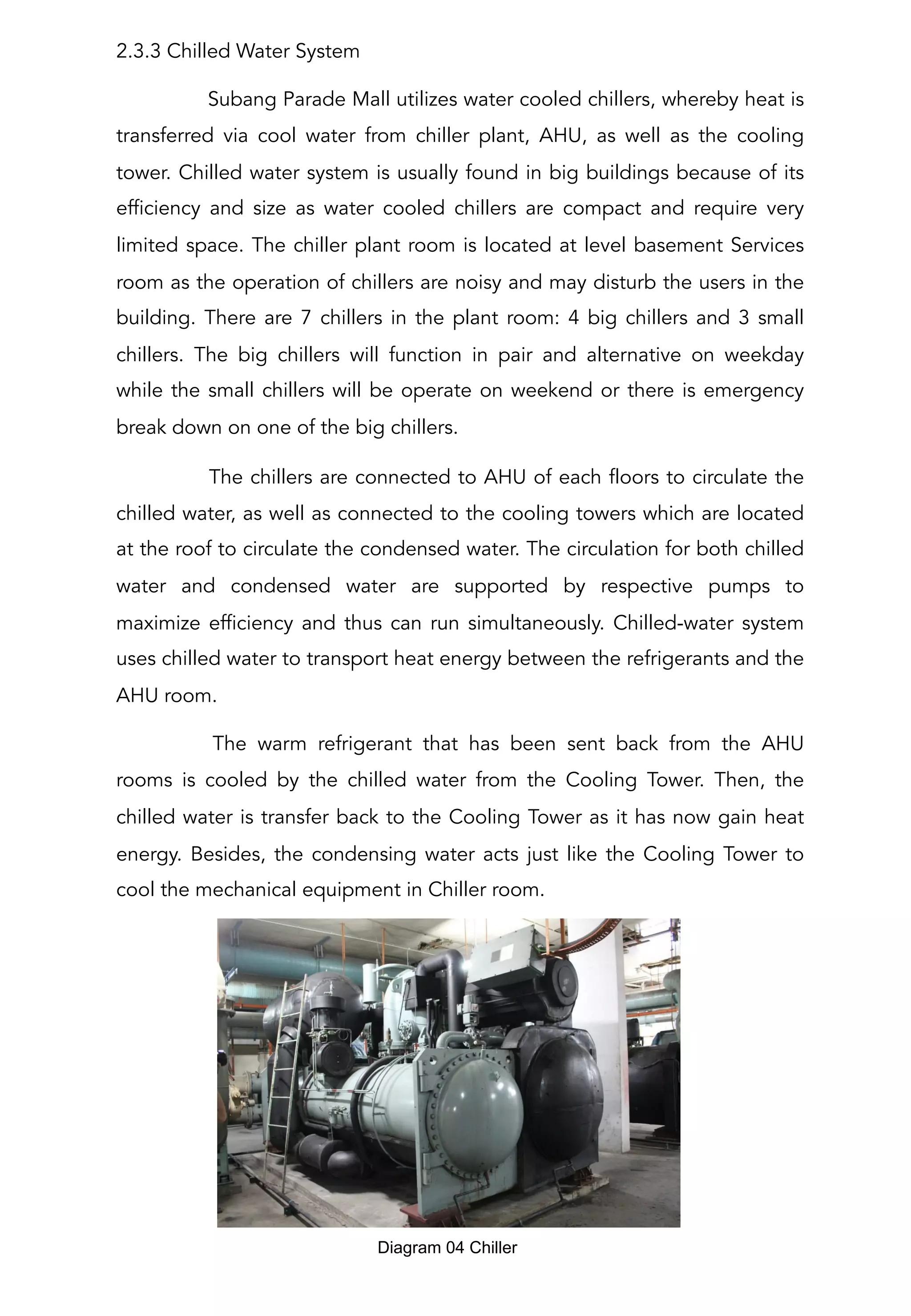

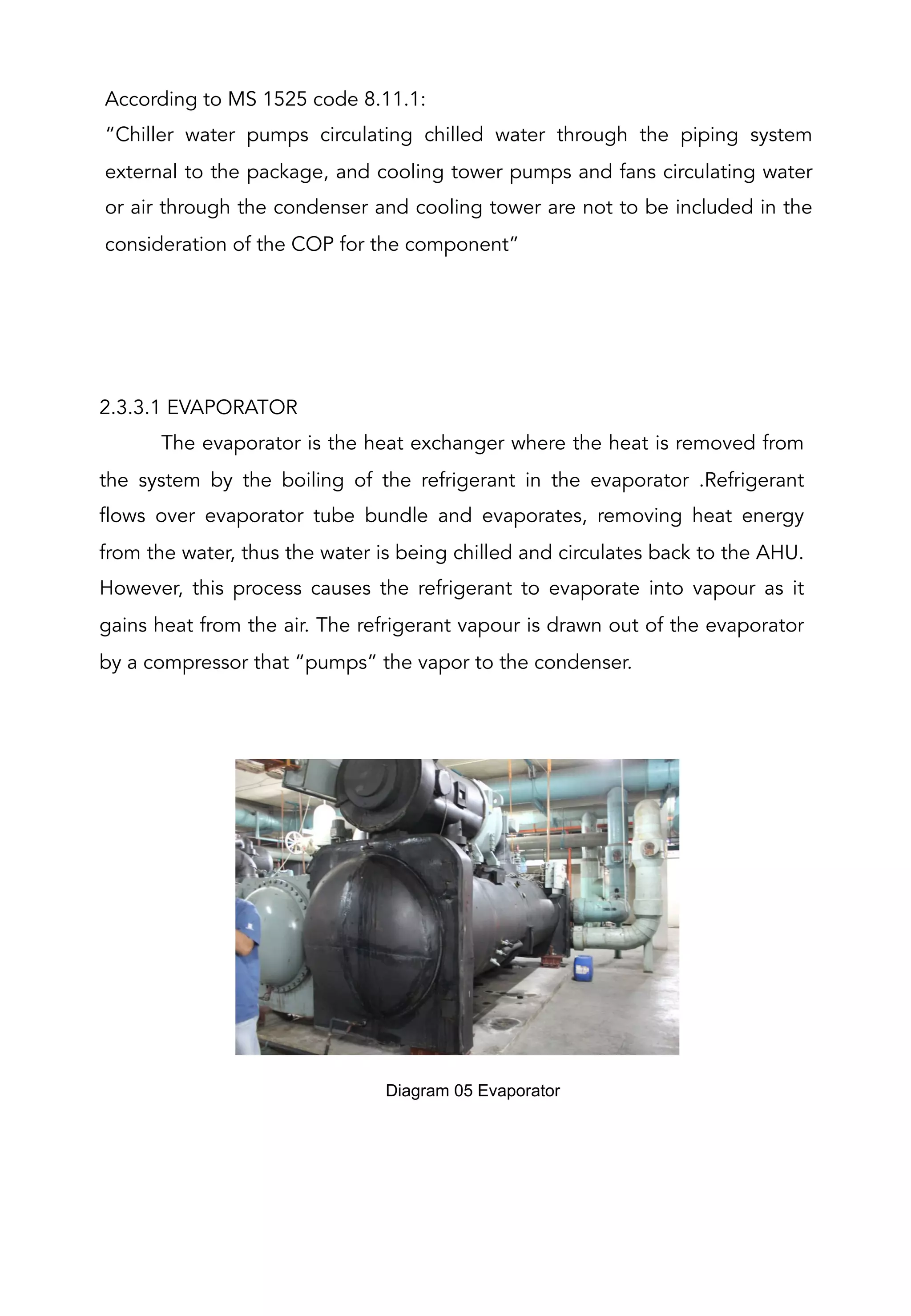

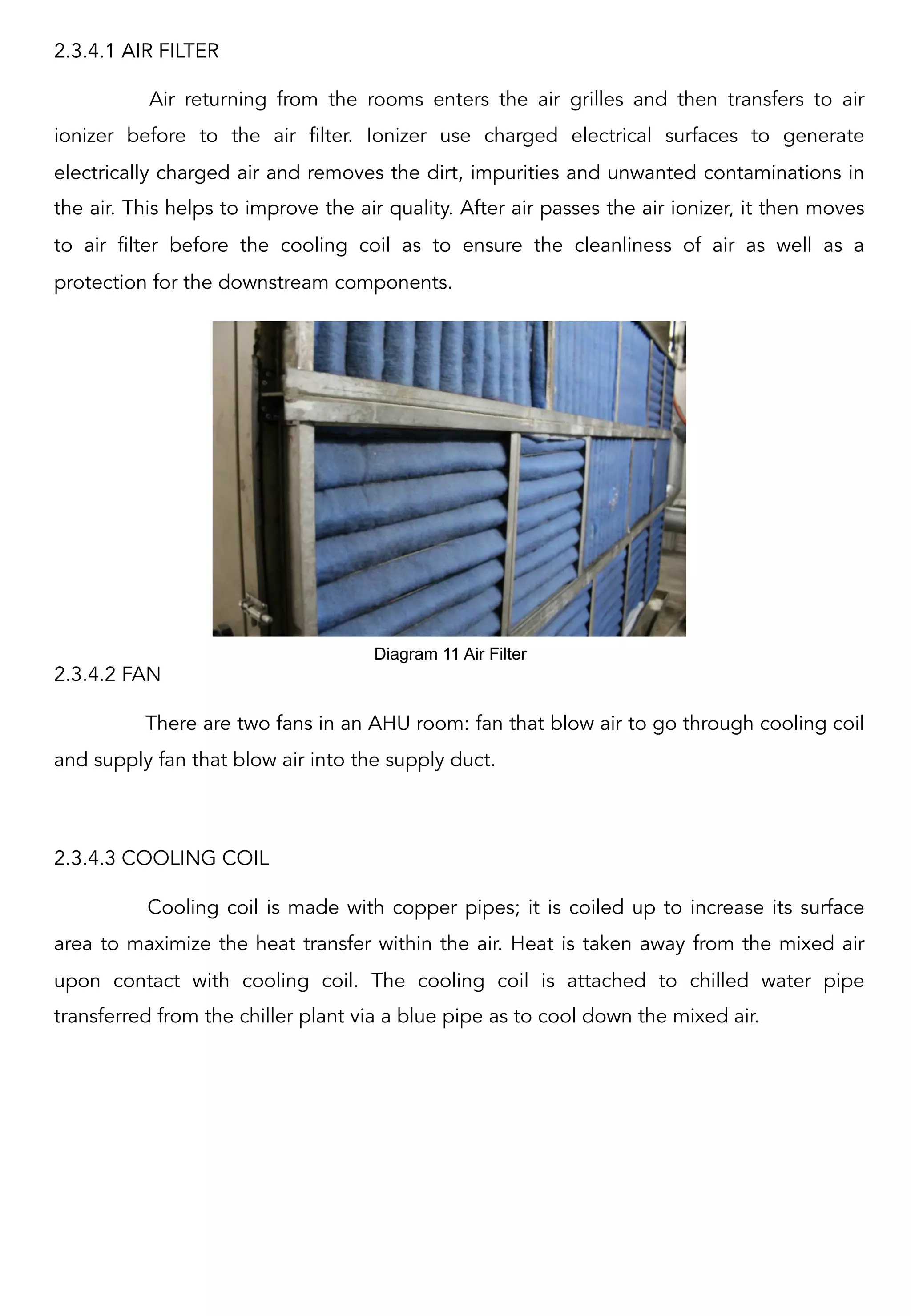

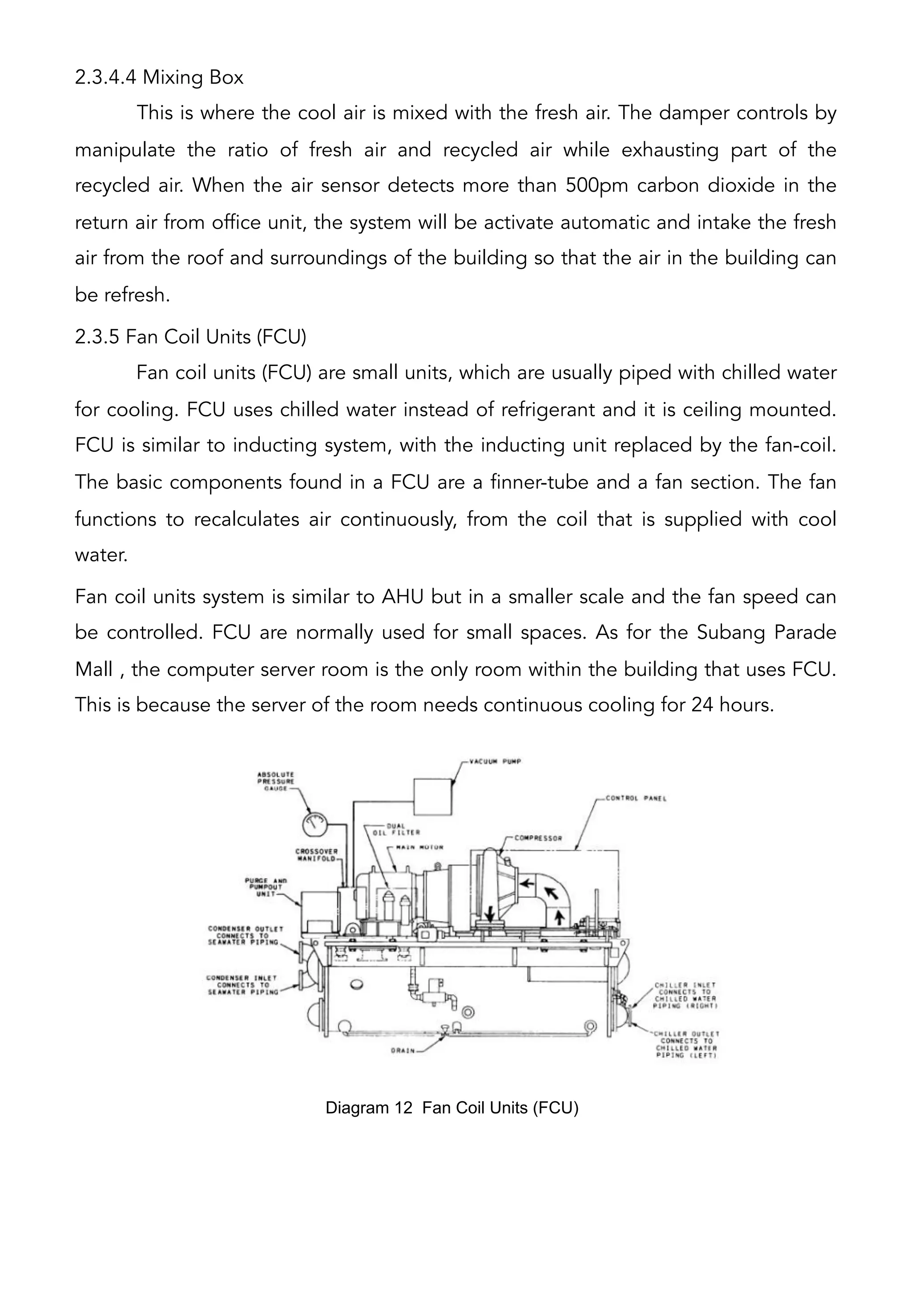

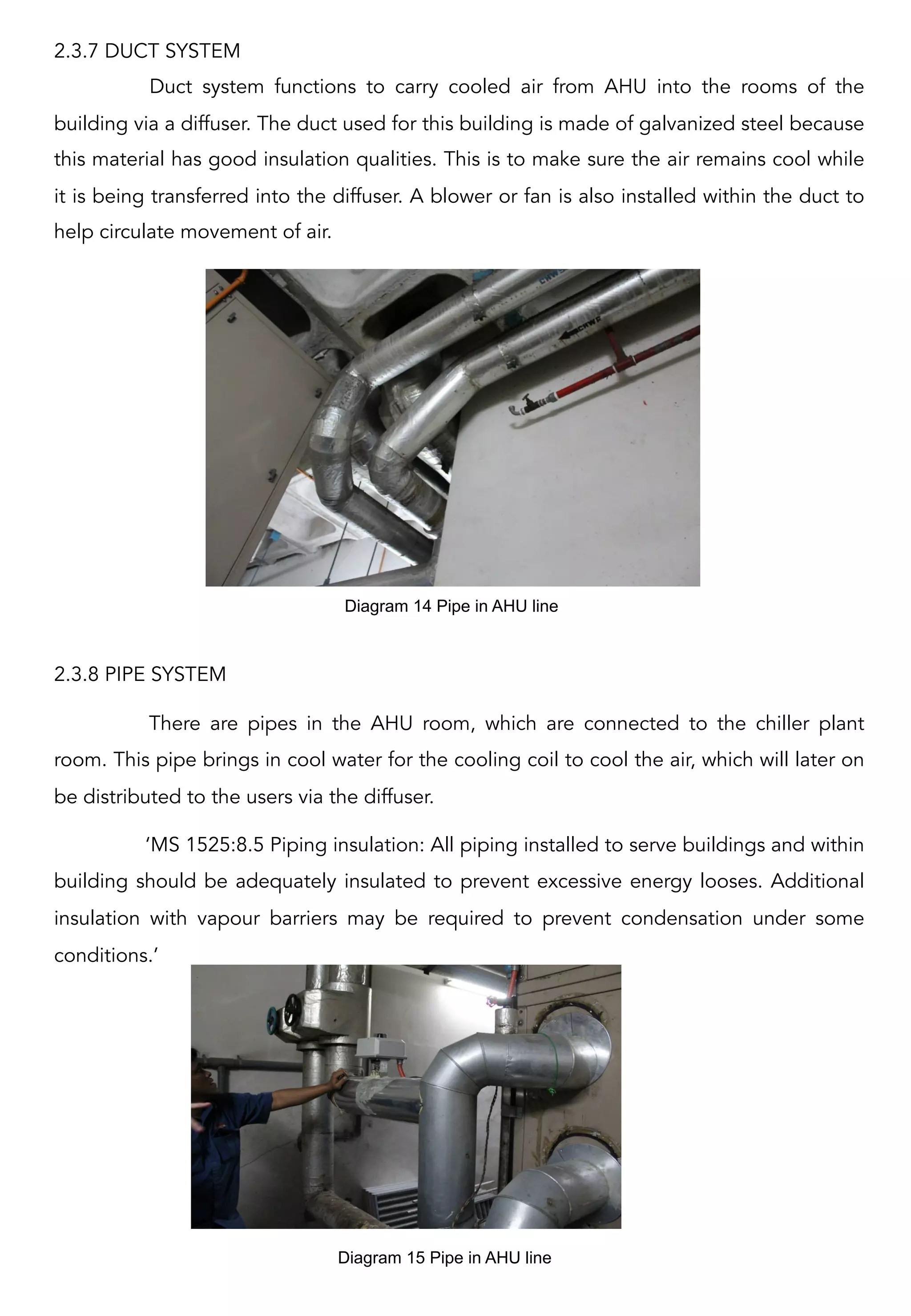

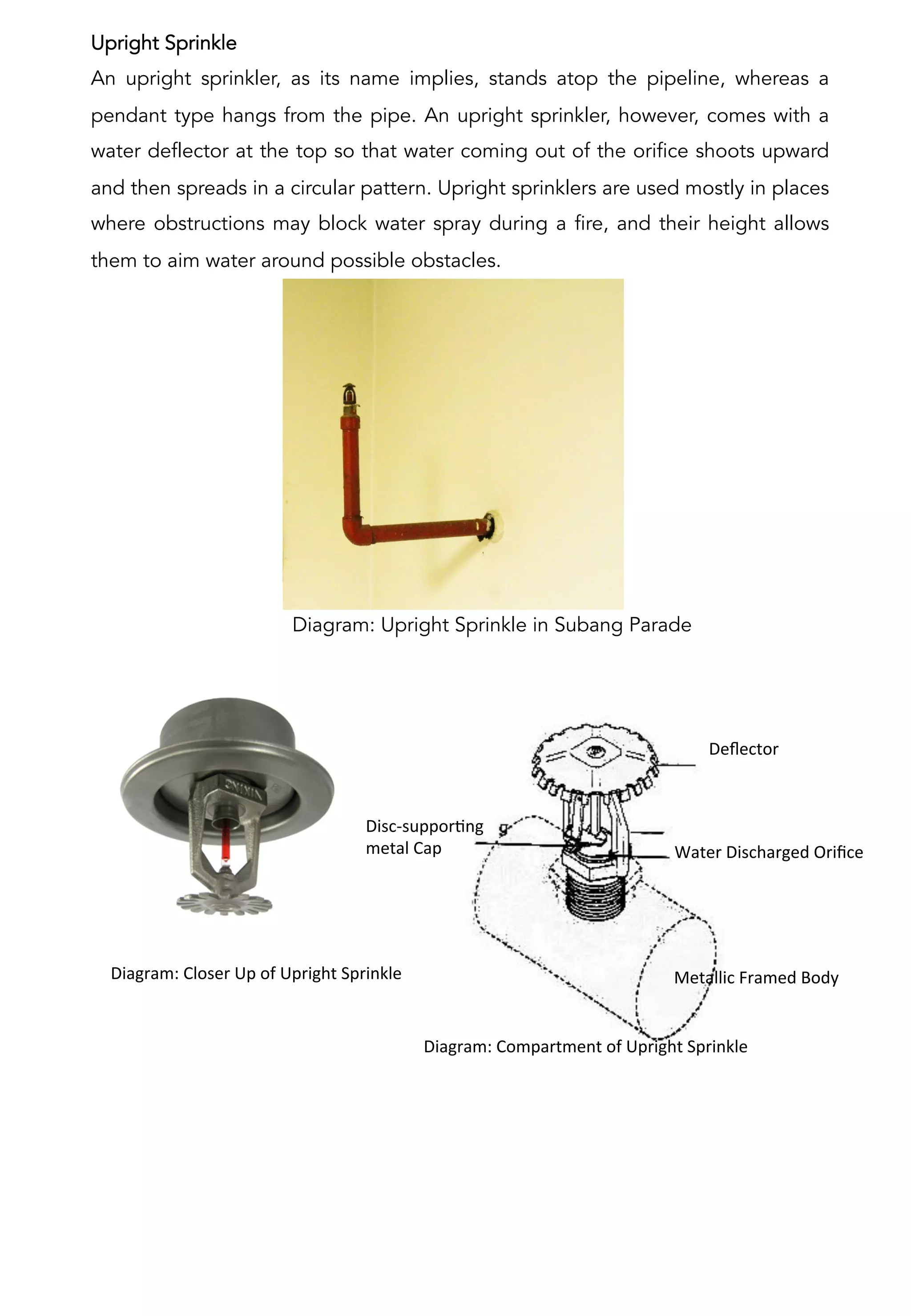

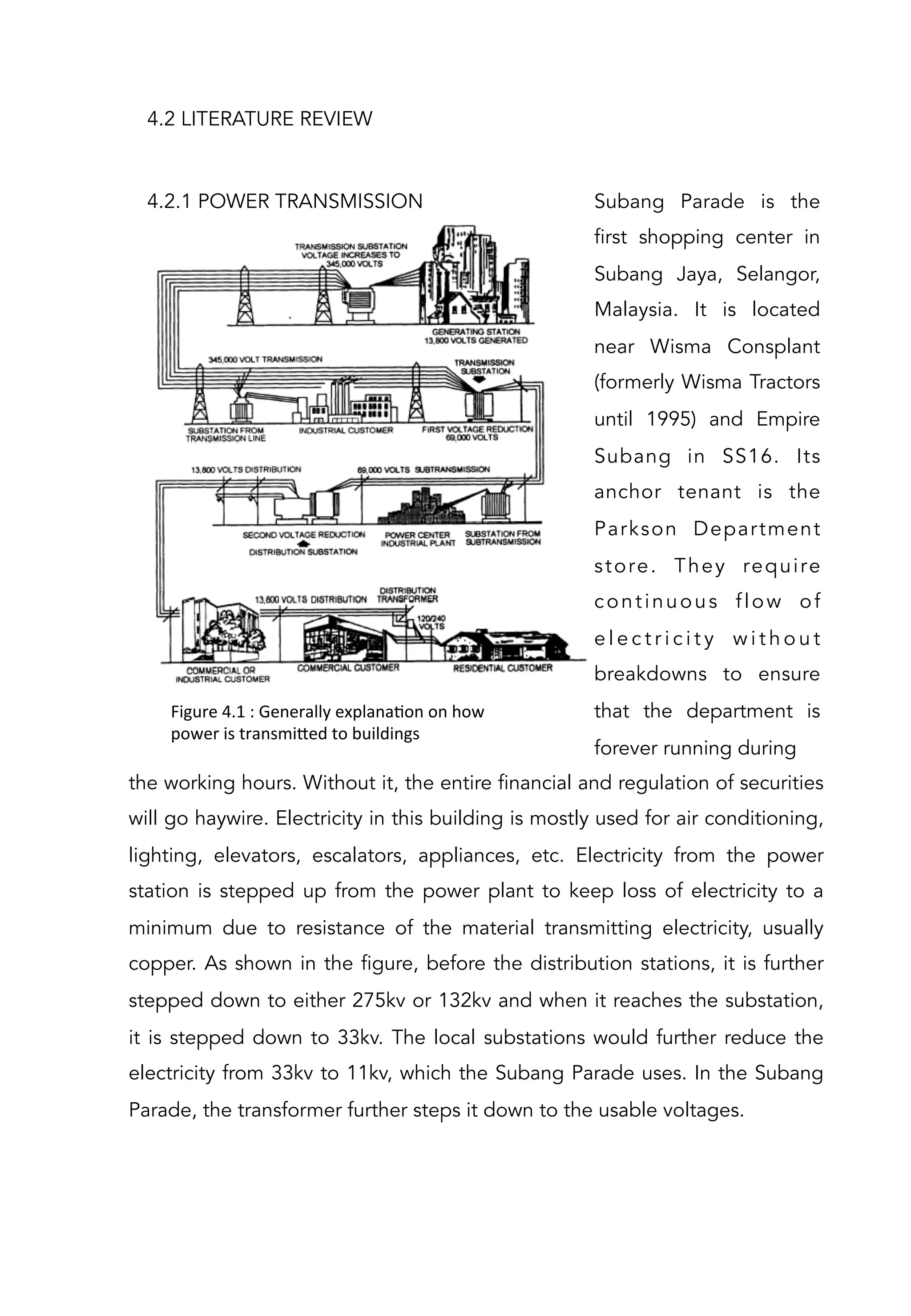

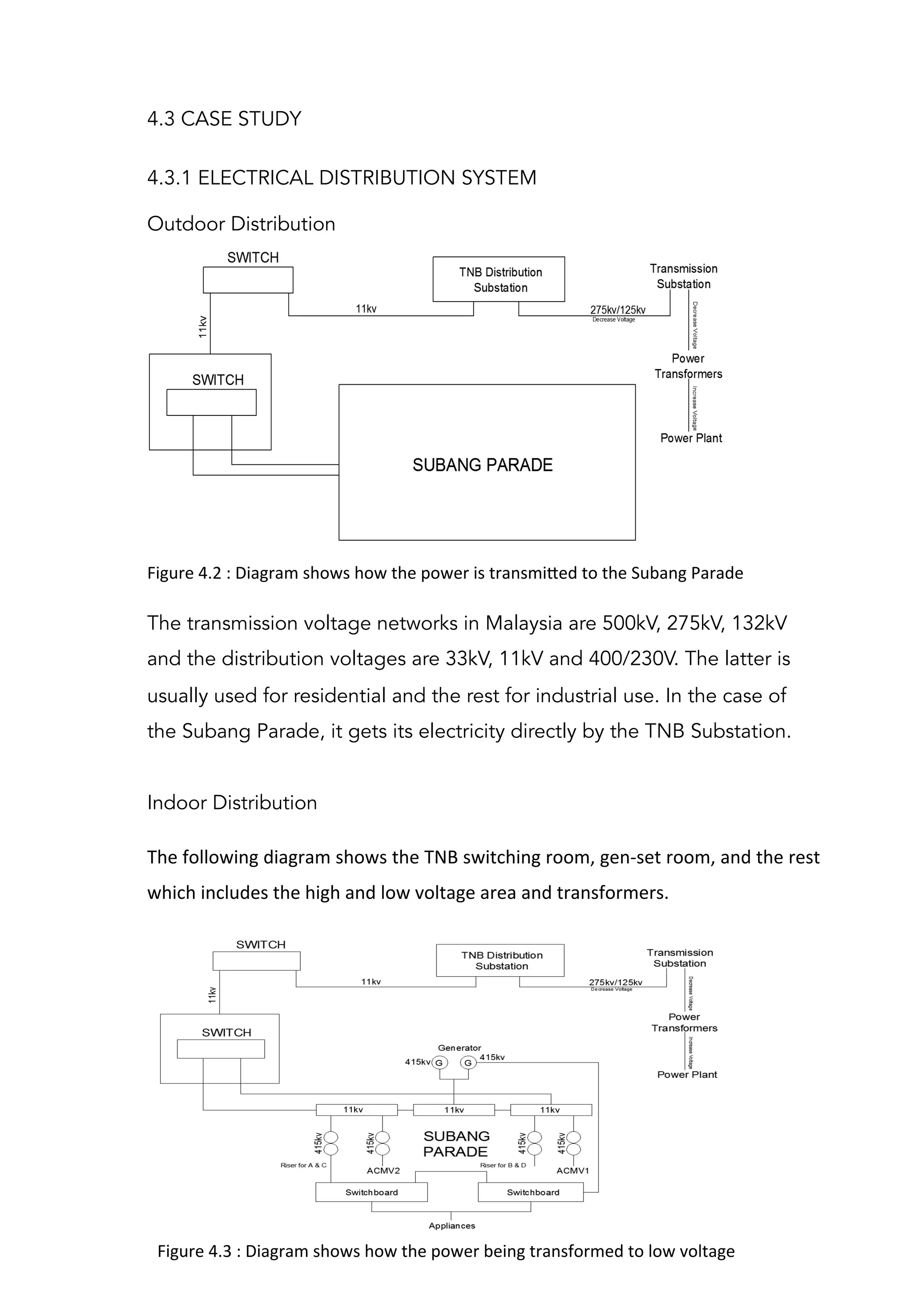

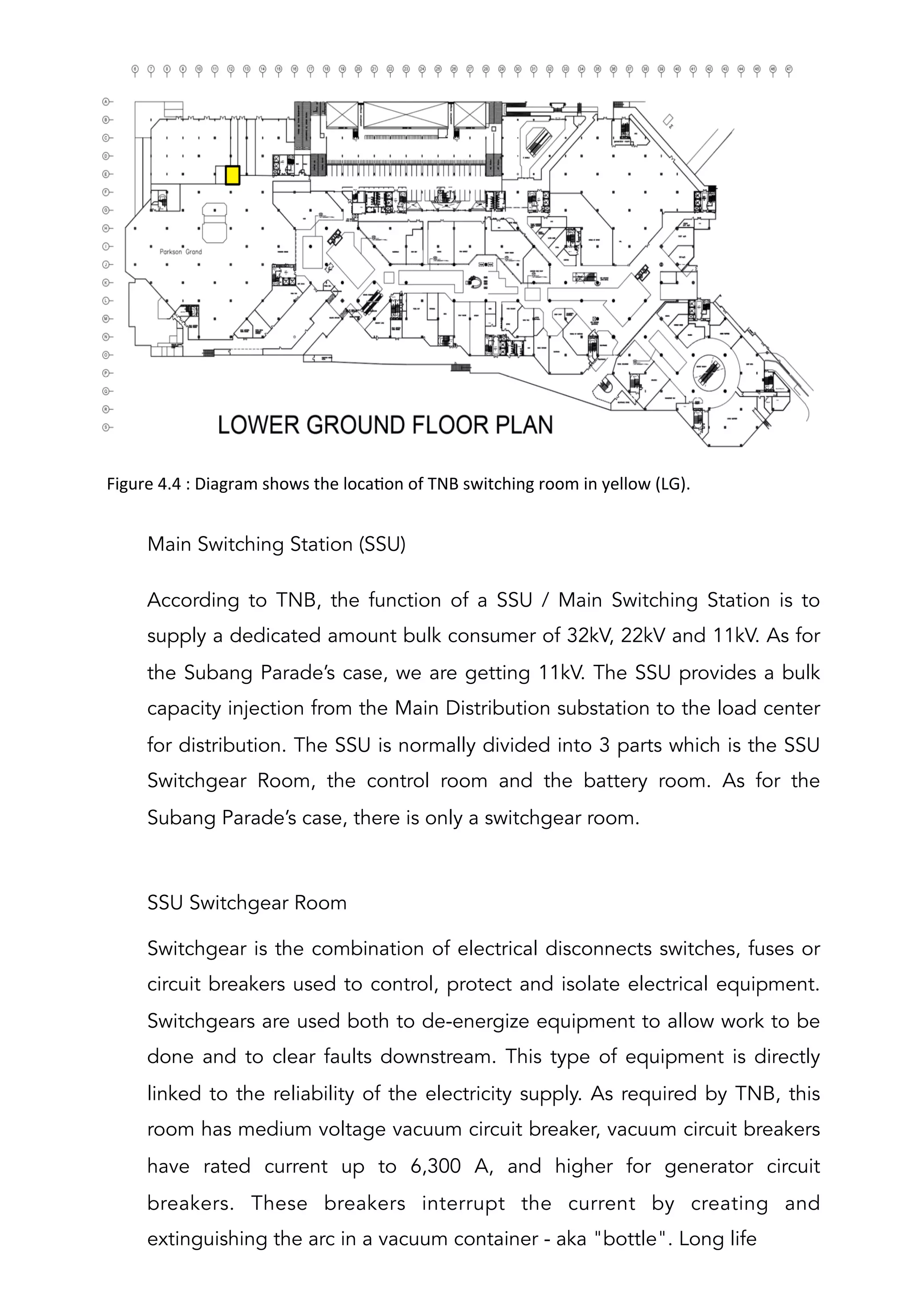

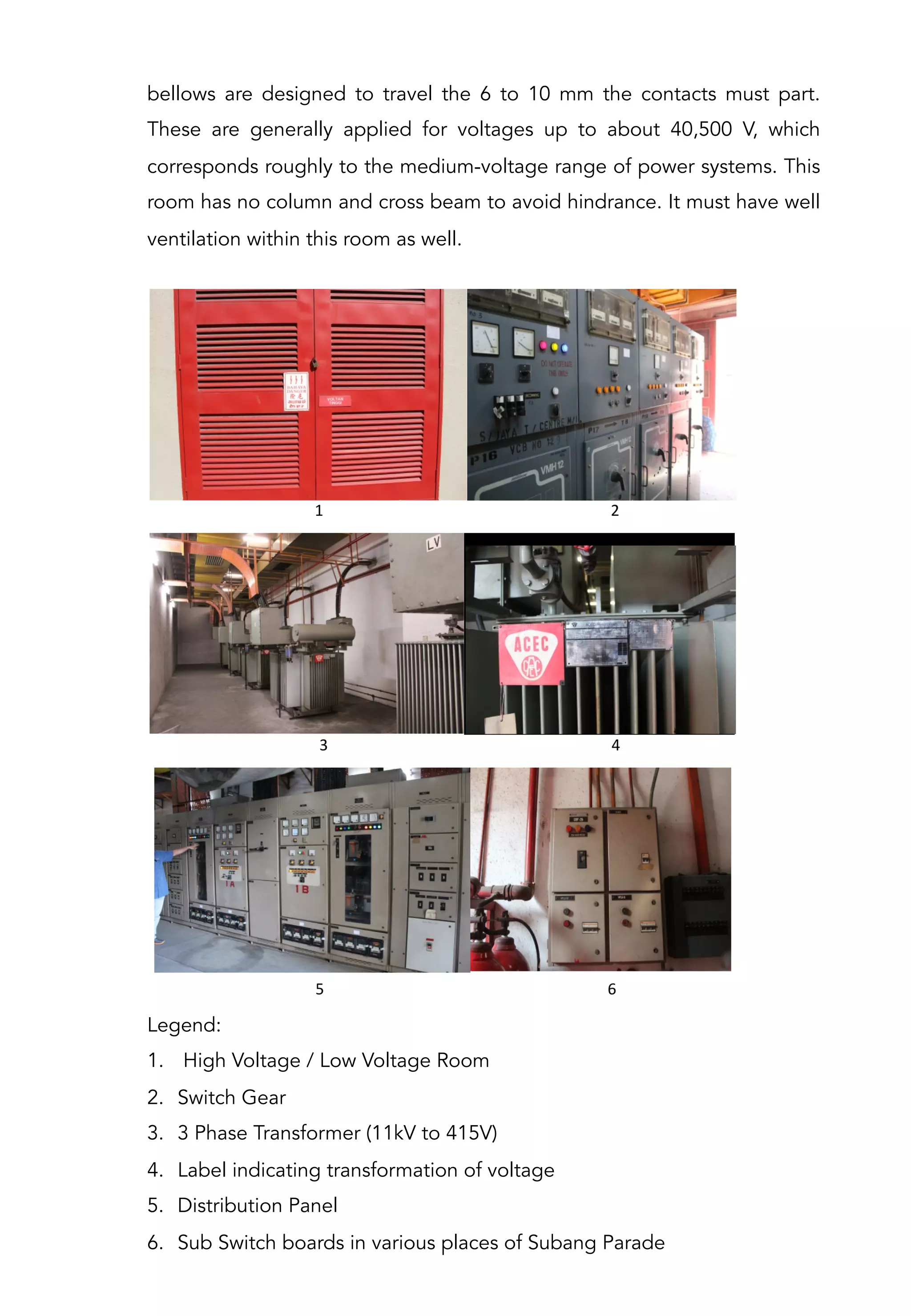

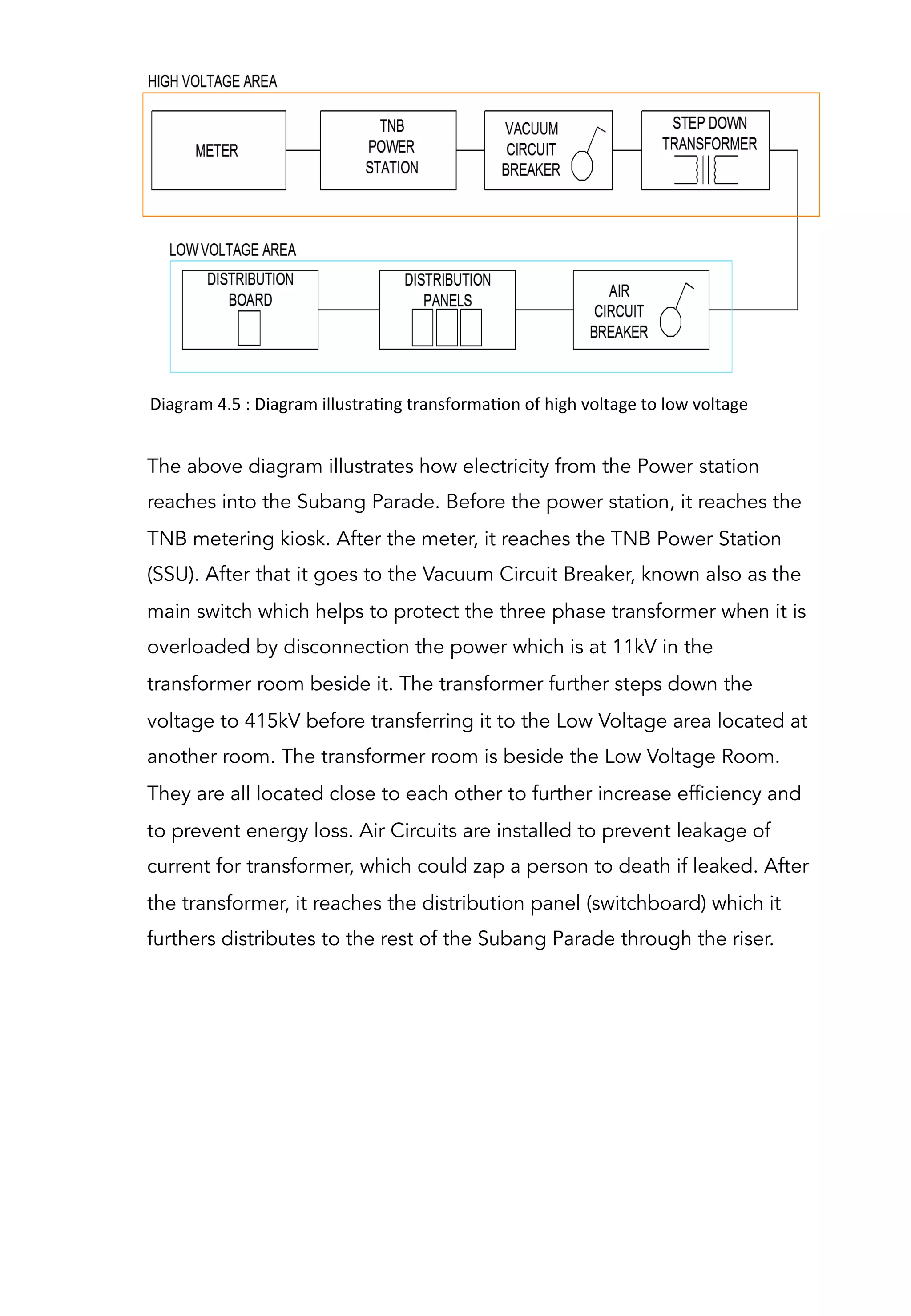

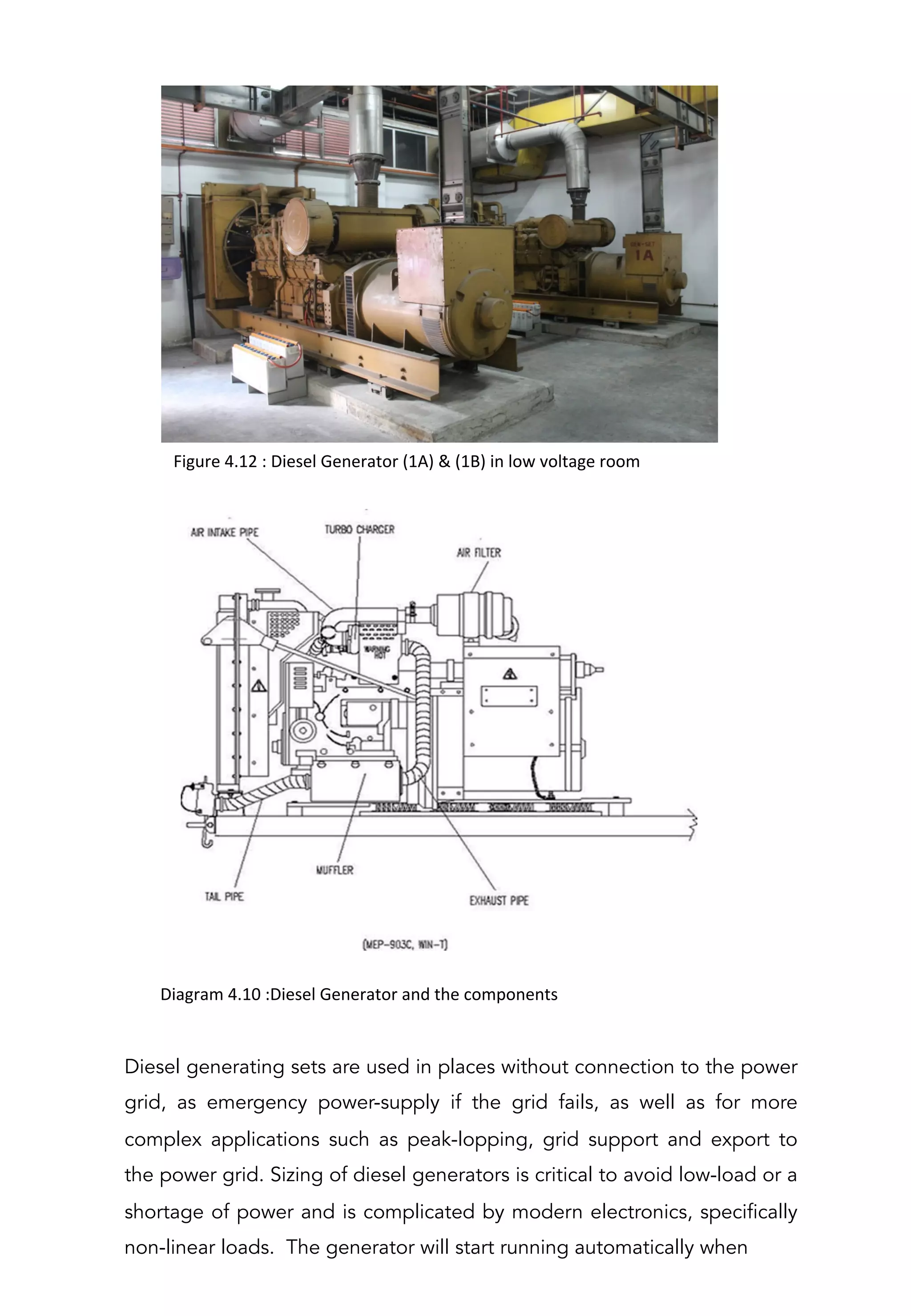

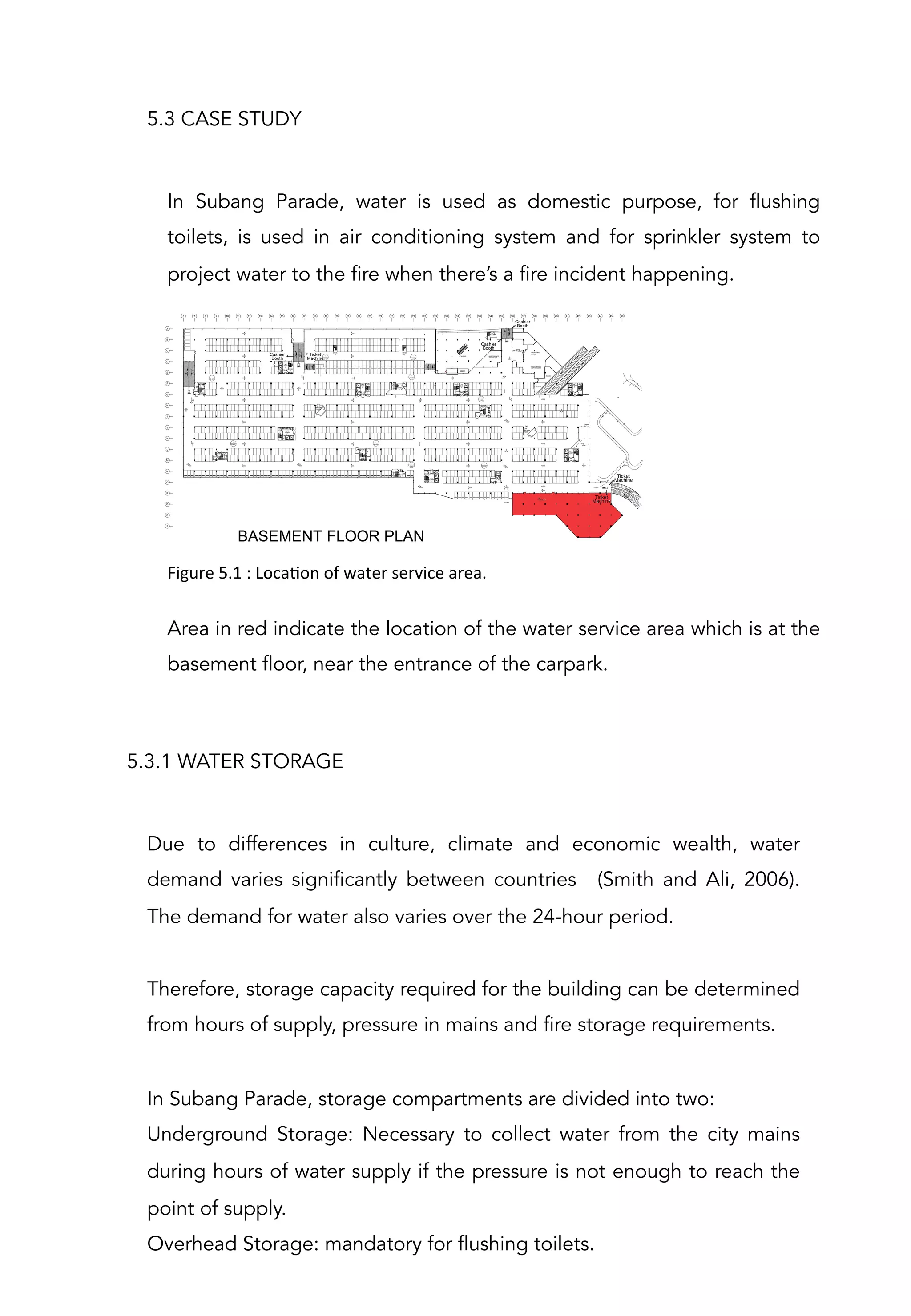

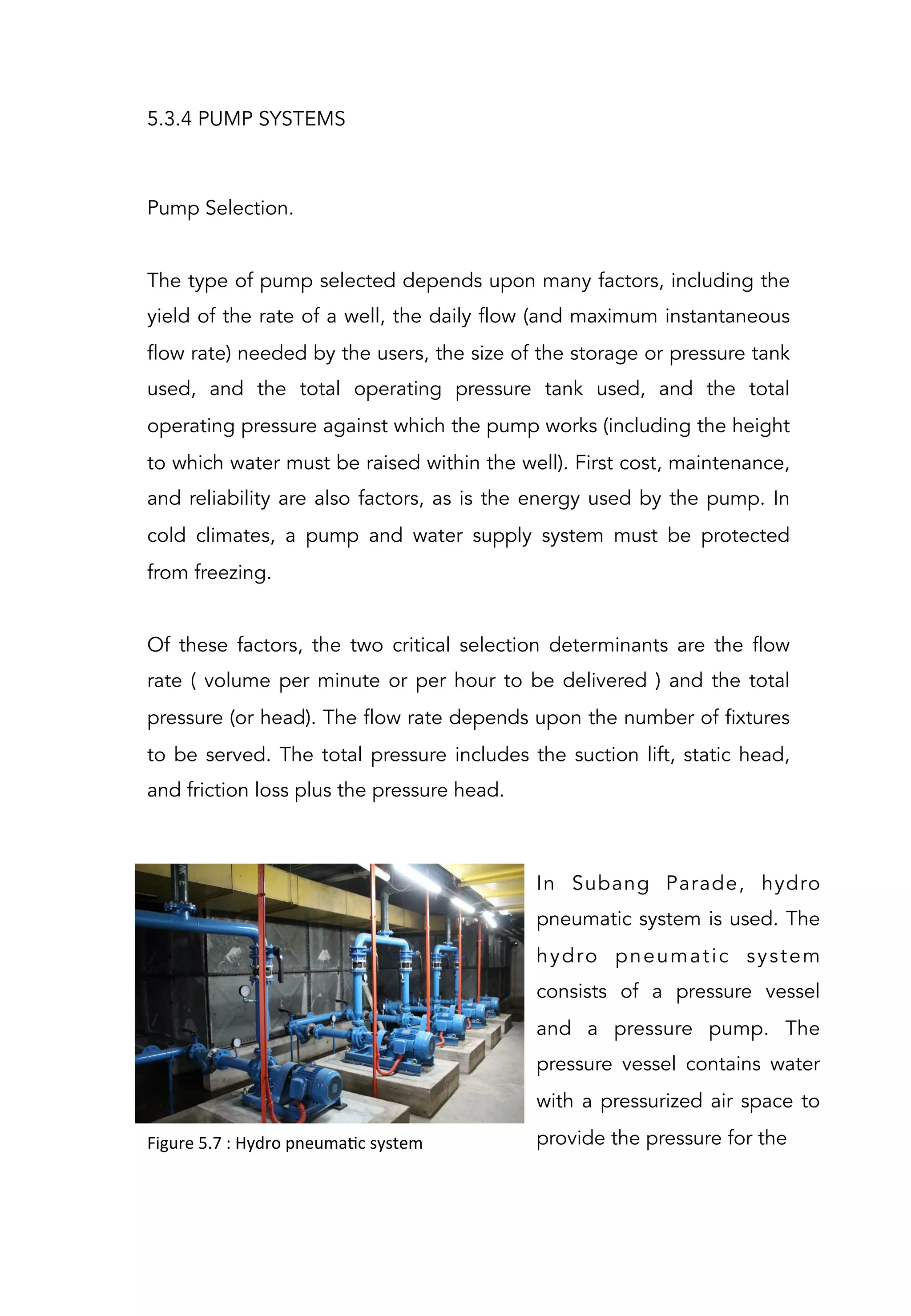

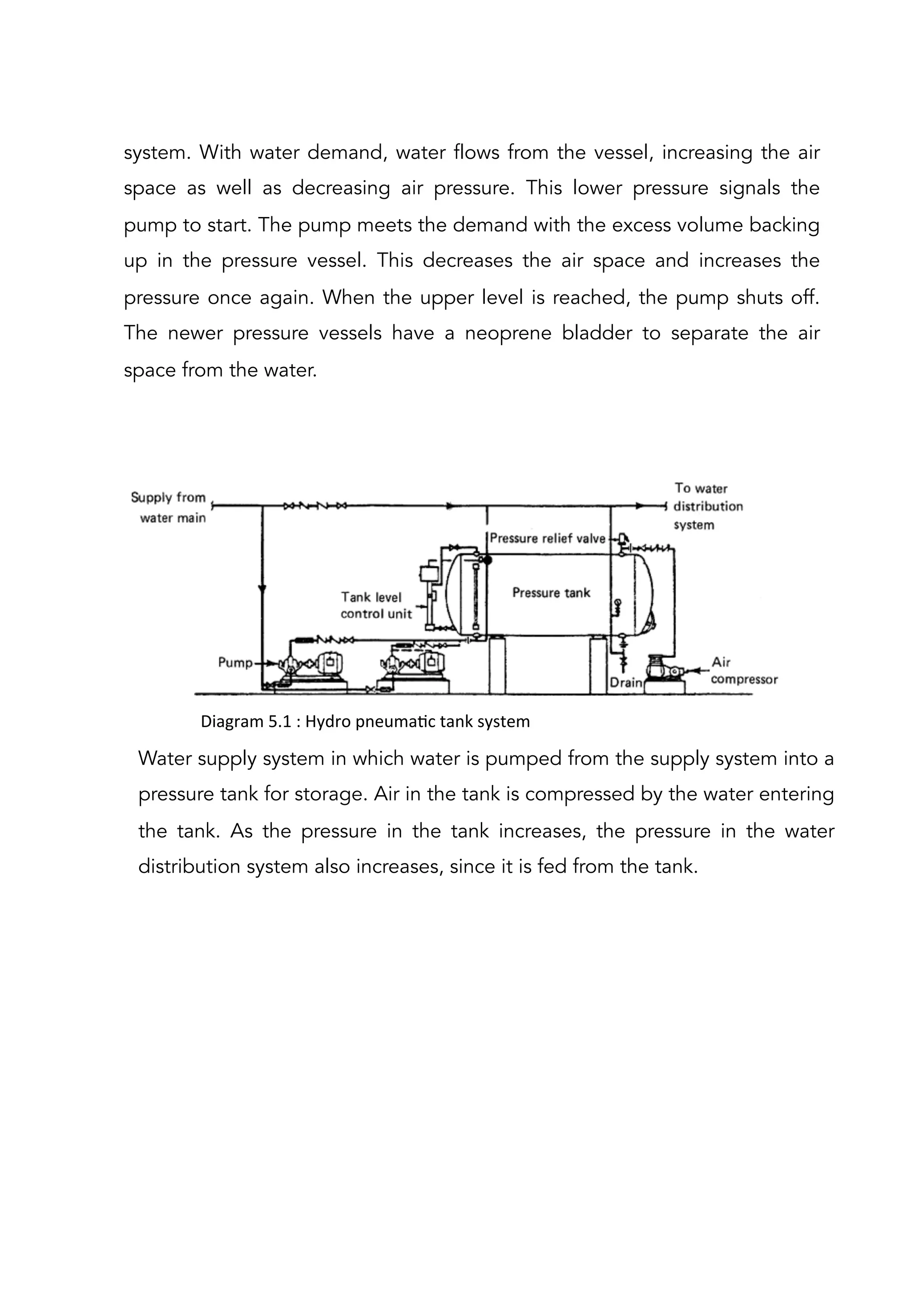

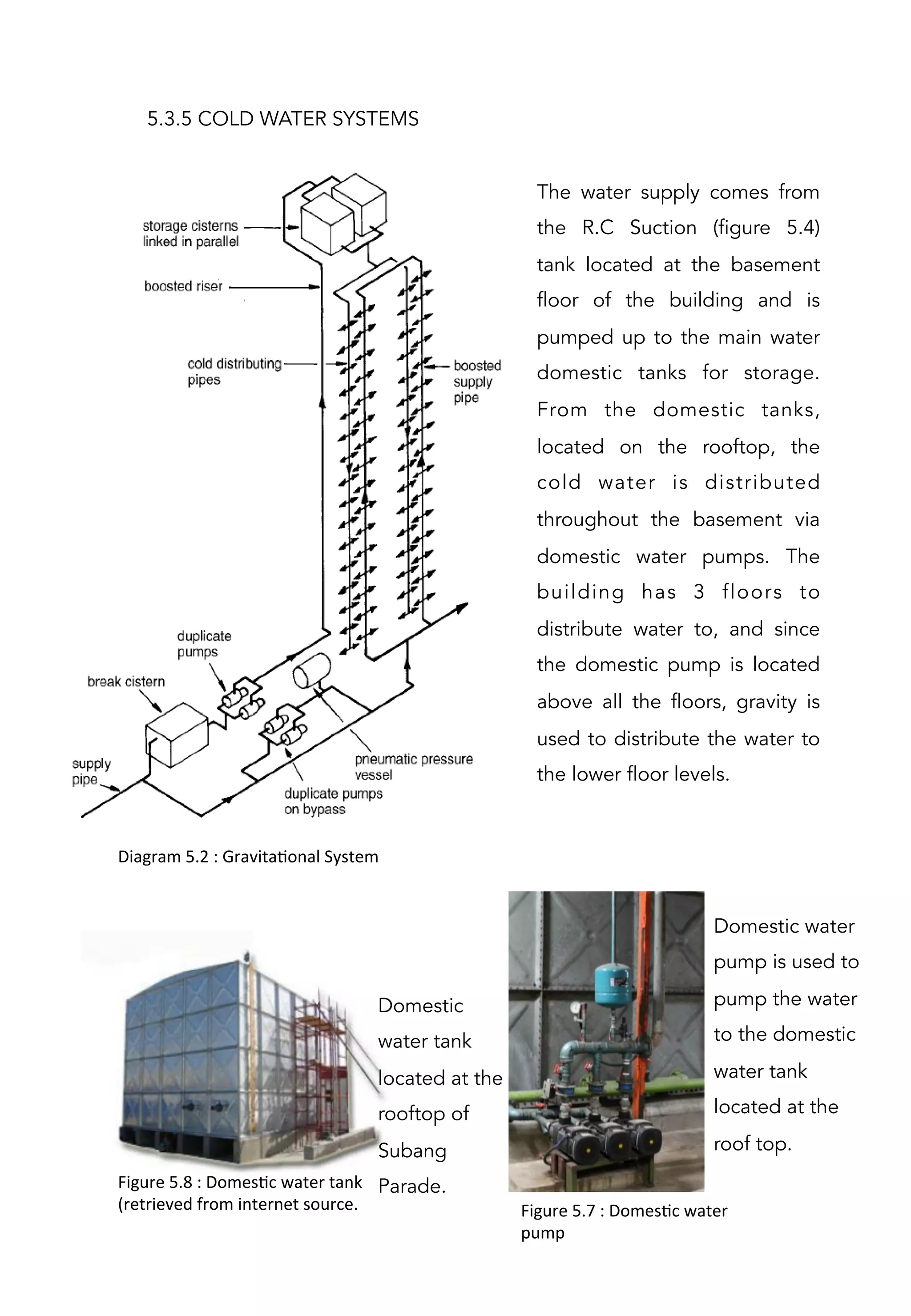

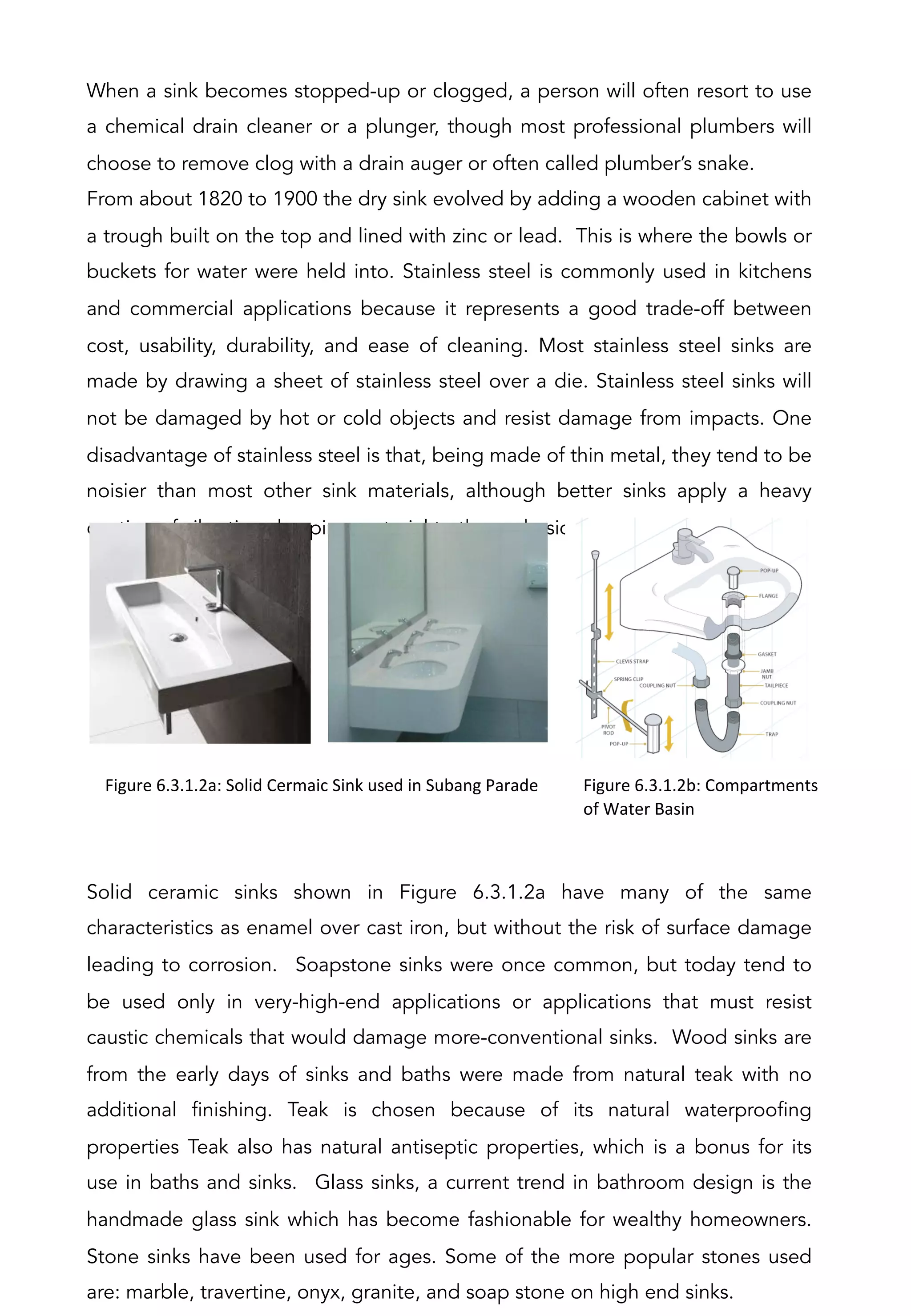

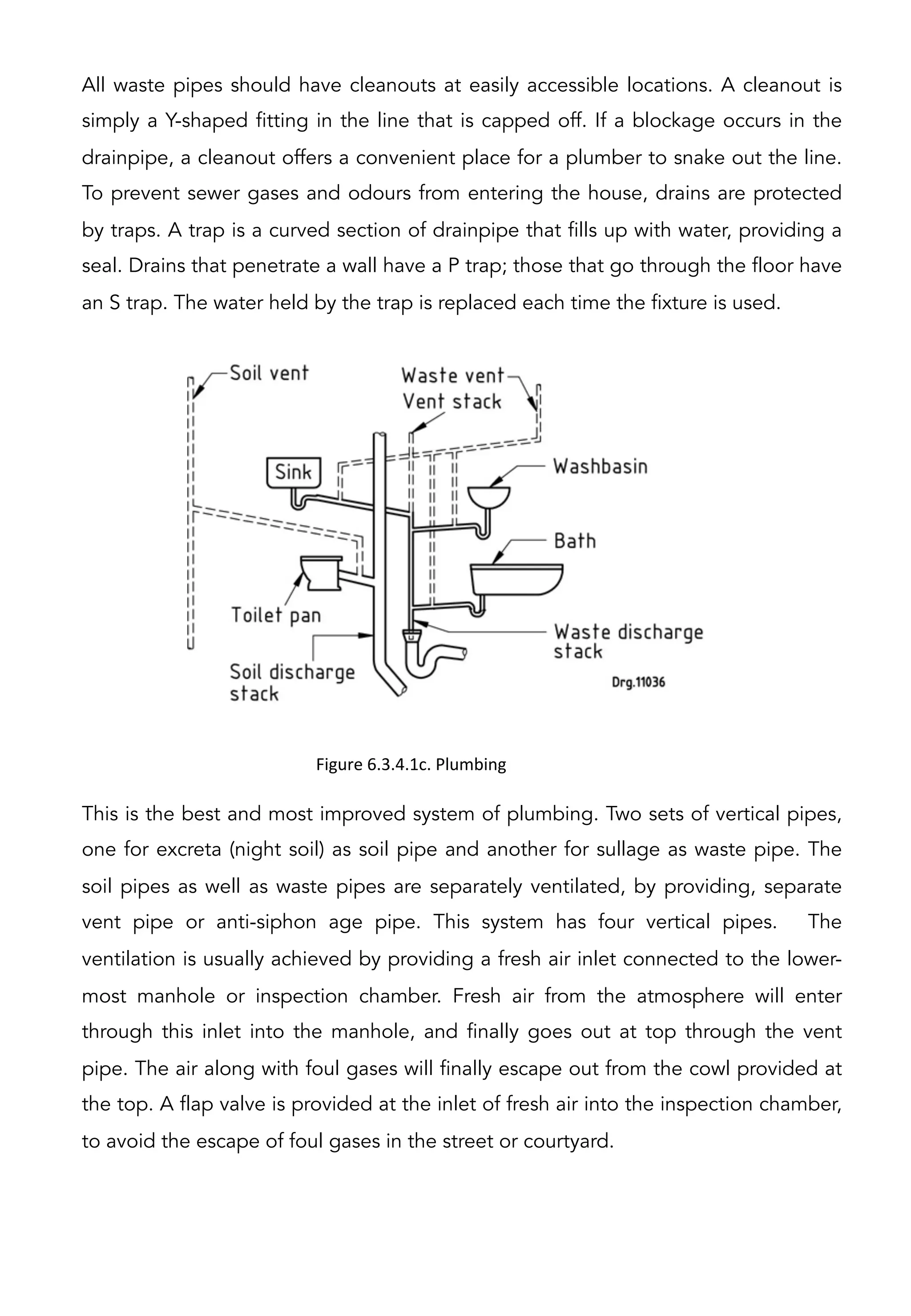

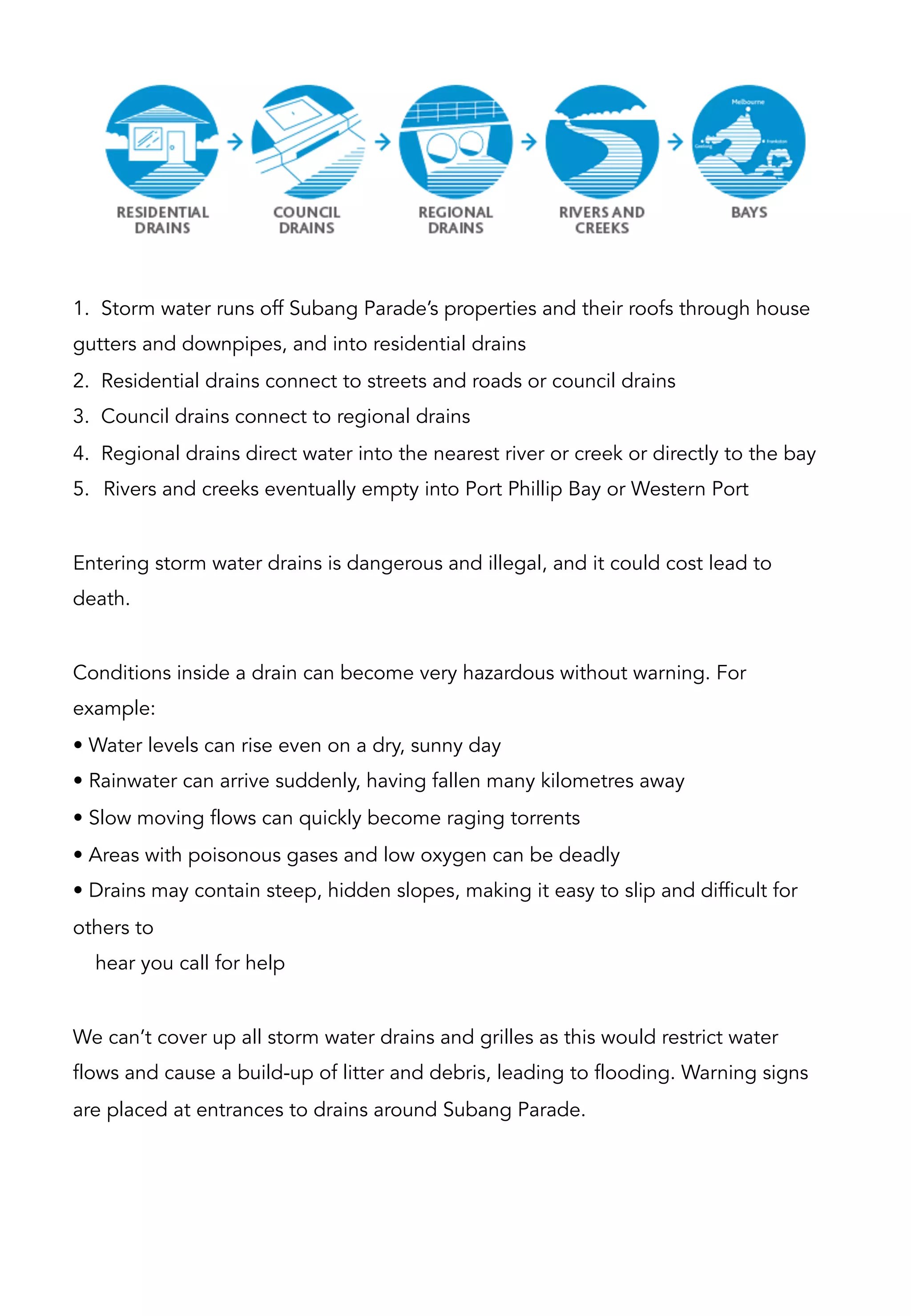

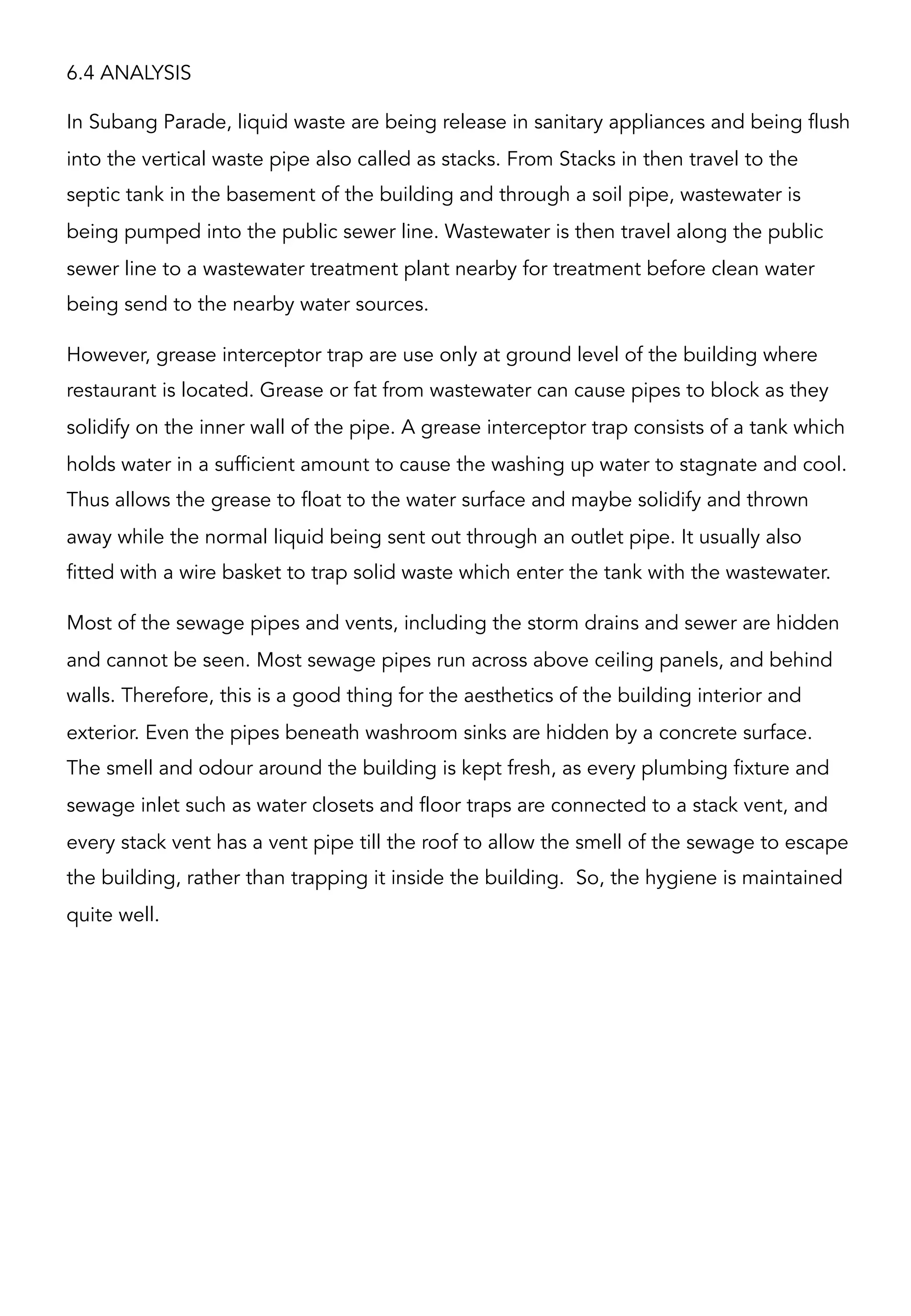

The document provides details about the building services systems at Subang Parade mall, including the air conditioning system. It discusses the key components of the central air conditioning system used at the mall such as the cooling towers, chilled water system, air handling units, fan coil units, ducting and piping. The cooling towers are located on the roof and help cool the water used in the chilled water system. Chilled water is pumped from the chiller room to the cooling towers and back to cool the air handled by the air handling units located in plant rooms on each floor. Regulations and standards like the MS 1525 code are also discussed.

![7.0 REFERENCES

AIR CONDITIONING. (n.d.). Building Services Engineering lecture notes. Retrieved

September 20, 2011,

Chiller Plant Design. (2002). Minnesota: McQuay Air Conditioning.

HVAC: sentrifugal chillers. (2004). Platts, a division of The McGraw-Hill Companies, Inc.

Water Cooled Chiller System. (n.d.). World Aircond Engineering (M) Sdn Bhd. Retrieved

September 26, 2011, from http://www.worldaircond.com/water-cooled-chiller-system.html

Tchobanoglous, G., Burton, F.L., and Stensel, H.D. (2003). Wastewater Engineering

(Treatment Disposal Reuse) / Metcalf & Eddy, Inc. (4th ed.). McGraw-Hill Book Company

Stanley W. Trimble (2007) Encyclopedia of Water Science, CRC Press

Isle of Wight Council. (2011). Means of Escape. [online]. Available at:

http://www.iow.gov.uk/living_here/planning/Building_Control/General_Advice/

meansofe.asp [Accessed 10th October 2012].

Sparks Electrical Wholesaler. (2012). Aico Heat Alarms. [online]. Available at:

http://www.fire-detect.co.uk/aico-heat-alarms.html

Severino and Son Inc. (2012). About Granite and Marble. [online]. Available at:

http://www.stonecountertop.com/index.php/natural-stone-quartz/about-granite-and-

marble [Accessed 10th October 2012].

Wikipedia. (2012). Smoke Detectors. [online]. Available at:

http://en.wikipedia.org/wiki/Smoke_detector [Accessed 10th October 2012].

Basic Design Guidelines for Mechanical Engineering Systems: A BASIC DESIGN

GUIDELINE FOR MECHANICAL ENGINEERING SYSTEMS COULD BE CATEGORISED

INTO FIVE (5) SECTIONS SUCH AS;. (n.d.). Basic Design Guidelines for Mechanical

Engineering Systems. Retrieved October 21, 2012, from http://leonim.blogspot.com/

2011/02/basic-design-guideline-for-mechanical.html

Electrical Installations: Electrical rooms design. (n.d.). Electrical Installations. Retrieved

October 21, 2012, from http://electricalinstallationblog.blogspot.com/2009/12/electrical-

rooms-design.html

Powering The Nation | Tenaga Nasional Berhad. (n.d.). Powering The Nation | Tenaga

Nasional Berhad. Retrieved October 21, 2012, from http://www.tnb.com.my

ROTARY UPS. (n.d.). UPS | Uninterruptible Power Supply Comparative Informant .

Retrieved October 21, 2012, from http://www.upsci.com/UPS-rotary.htm

Stein, B., Reynolds, J., & McGuinness, W. J. (1992). Mechanical and electrical equipment

for buildings (8th ed.). New York: J. Wiley & Sons.

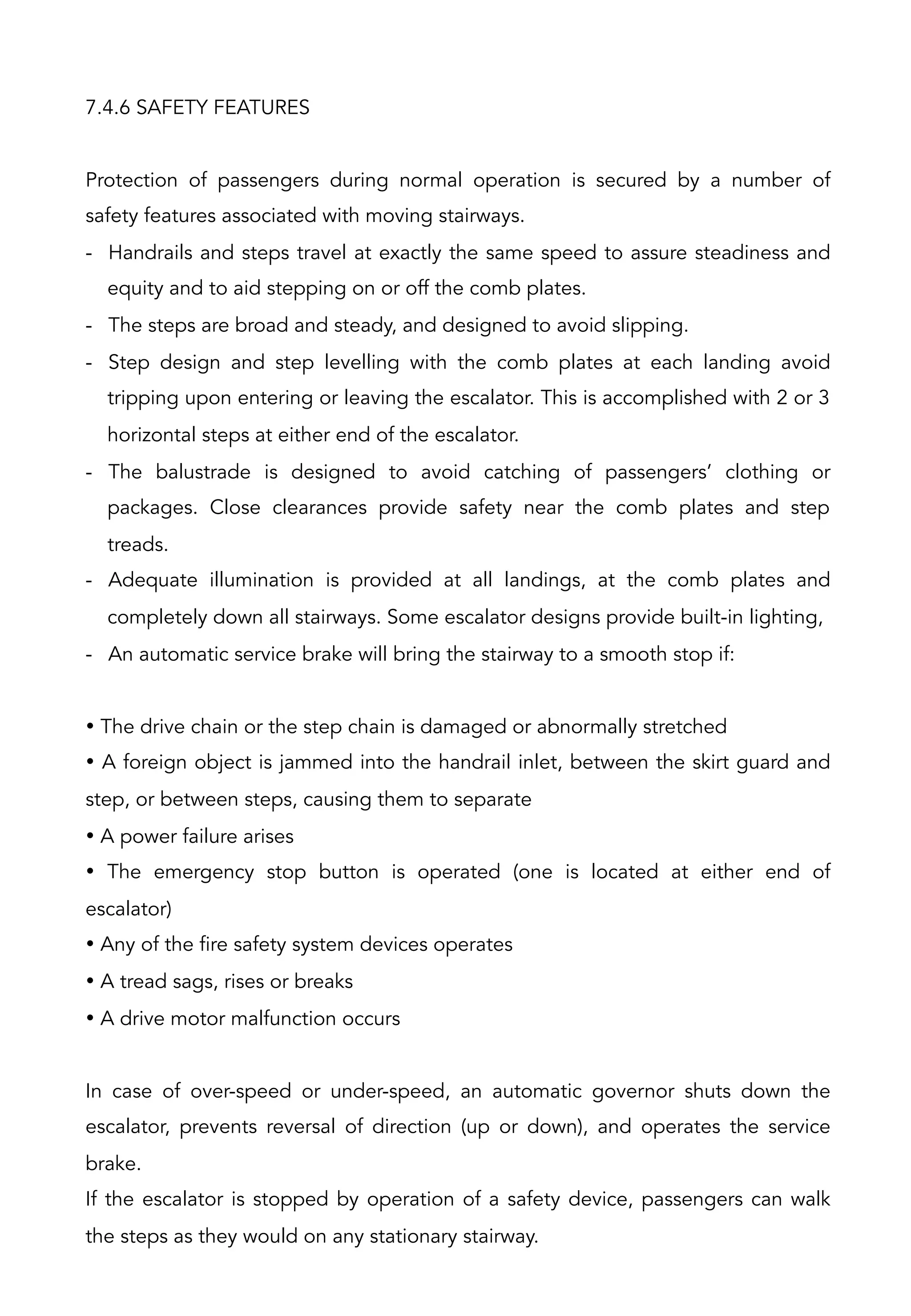

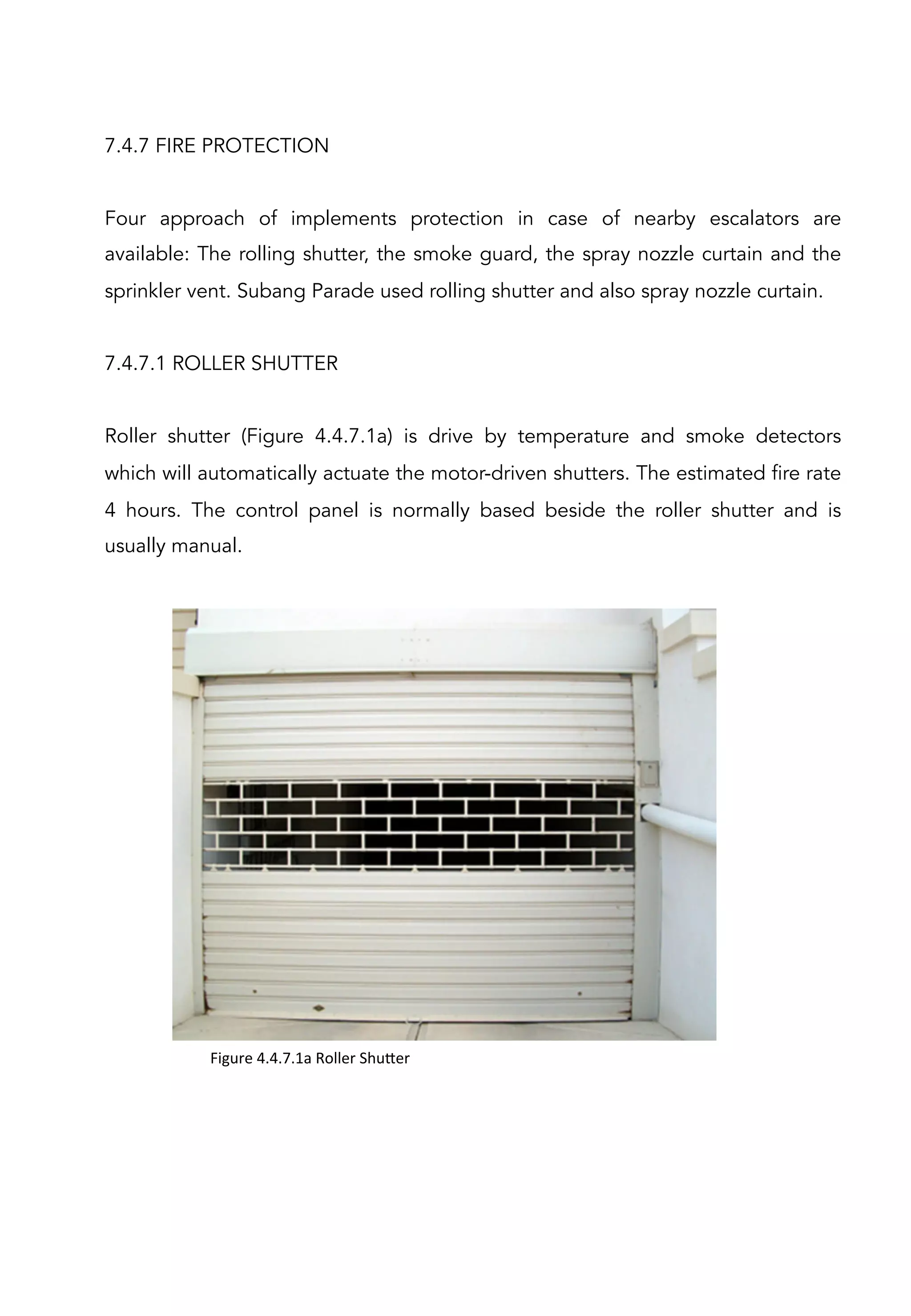

http://www.agc.gov.my/Akta/Vol.%2012/Act%20581.pdf](https://image.slidesharecdn.com/subangparadeb-140713104532-phpapp01/75/Subang-parade-b-service-154-2048.jpg)