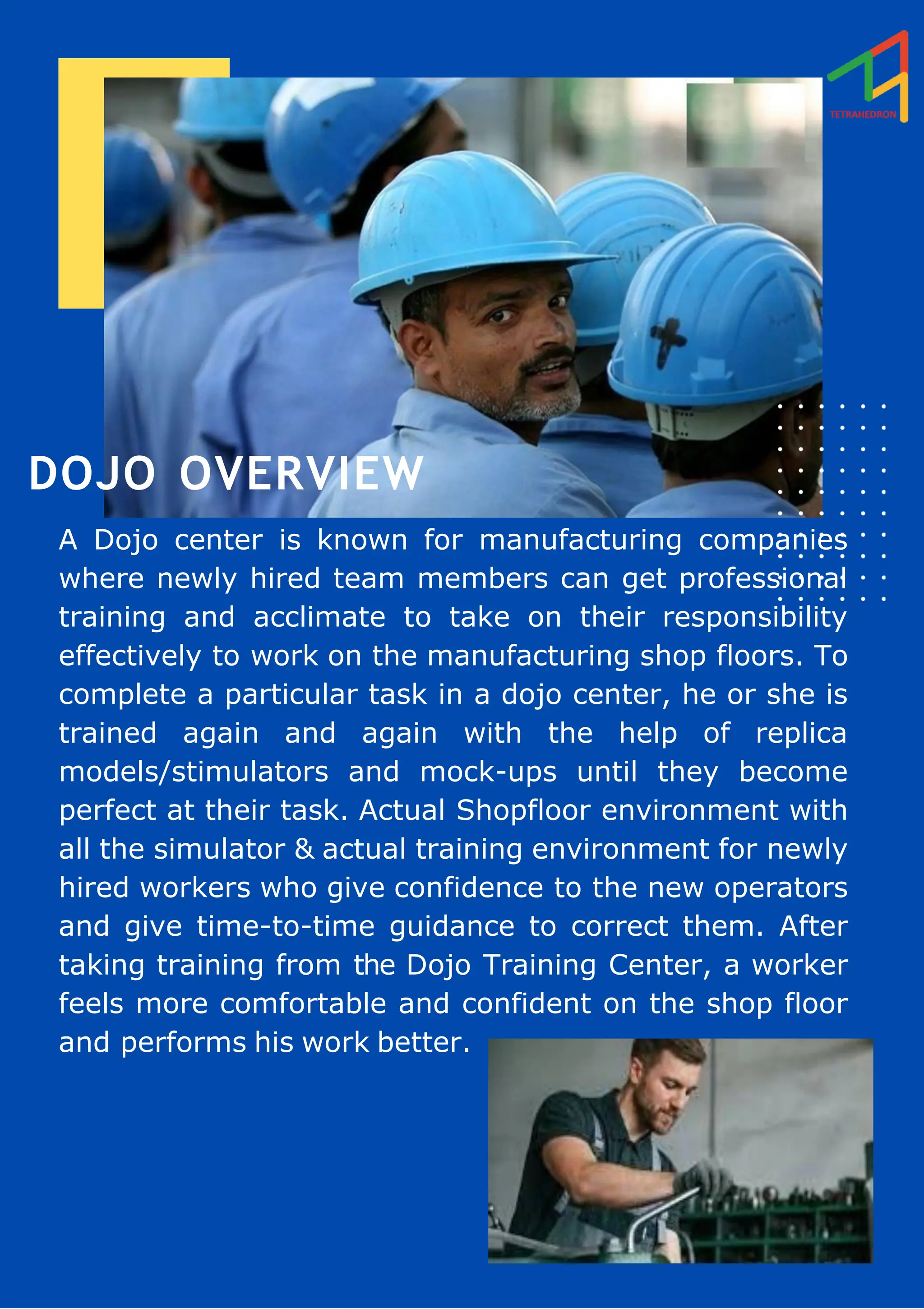

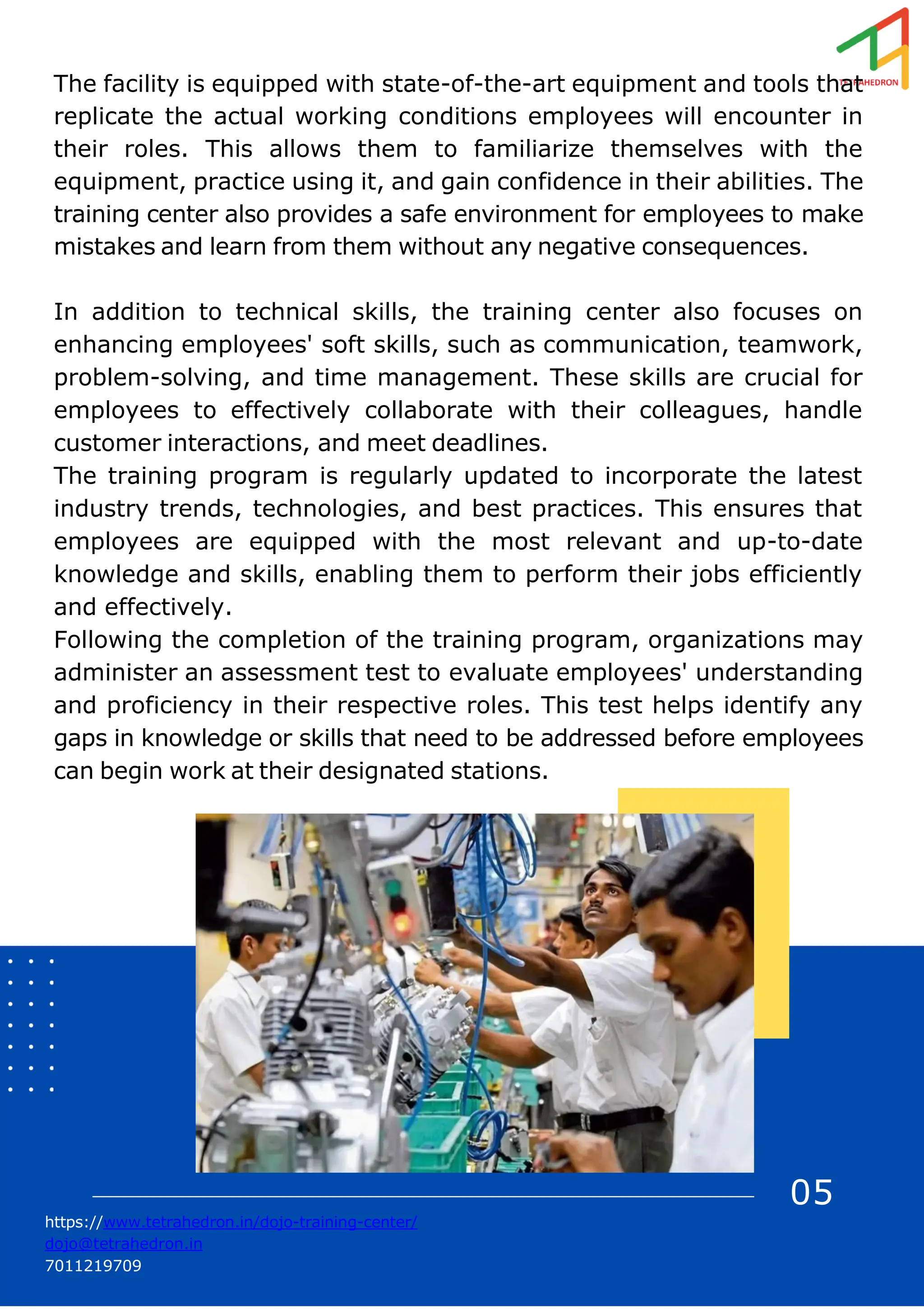

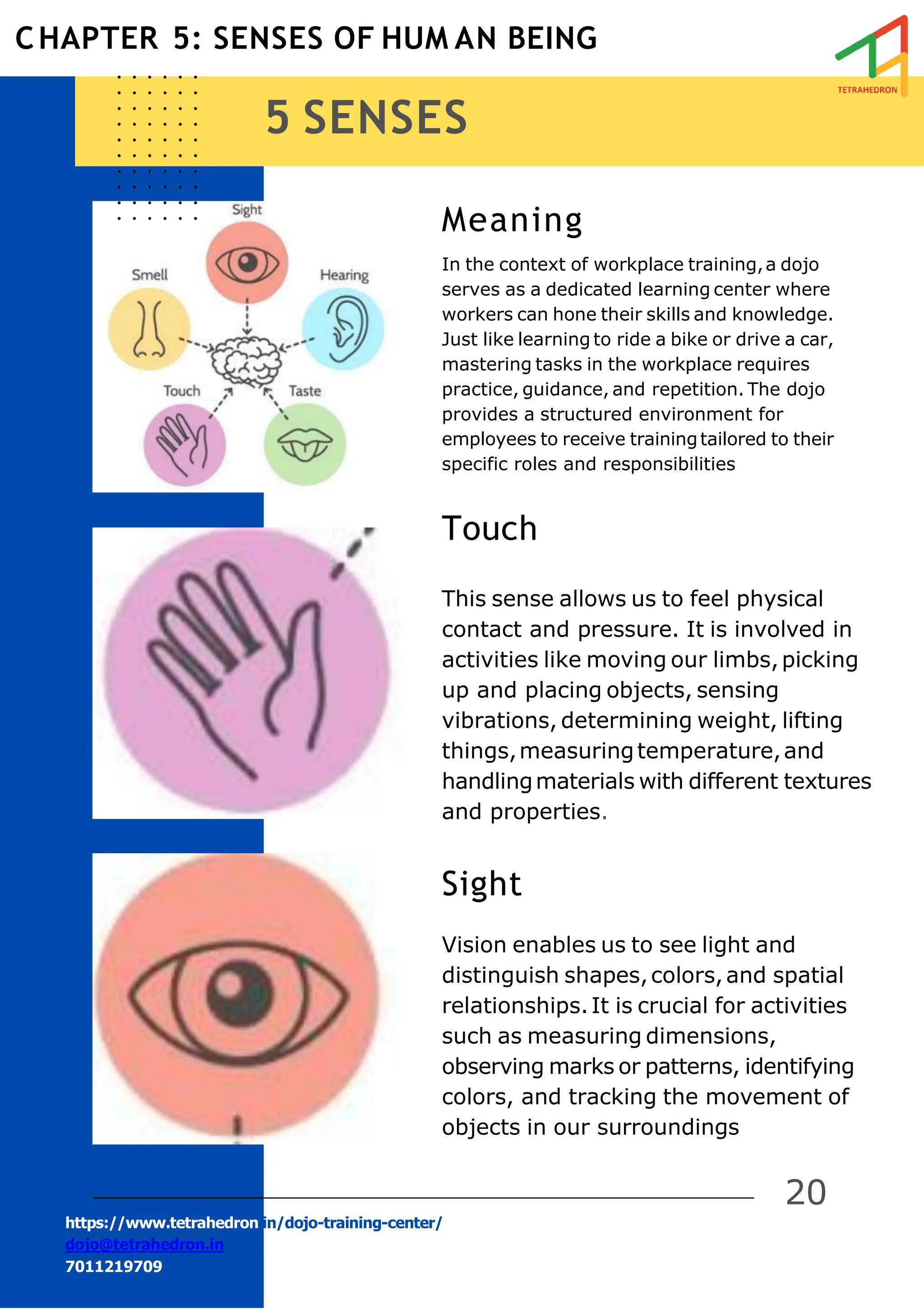

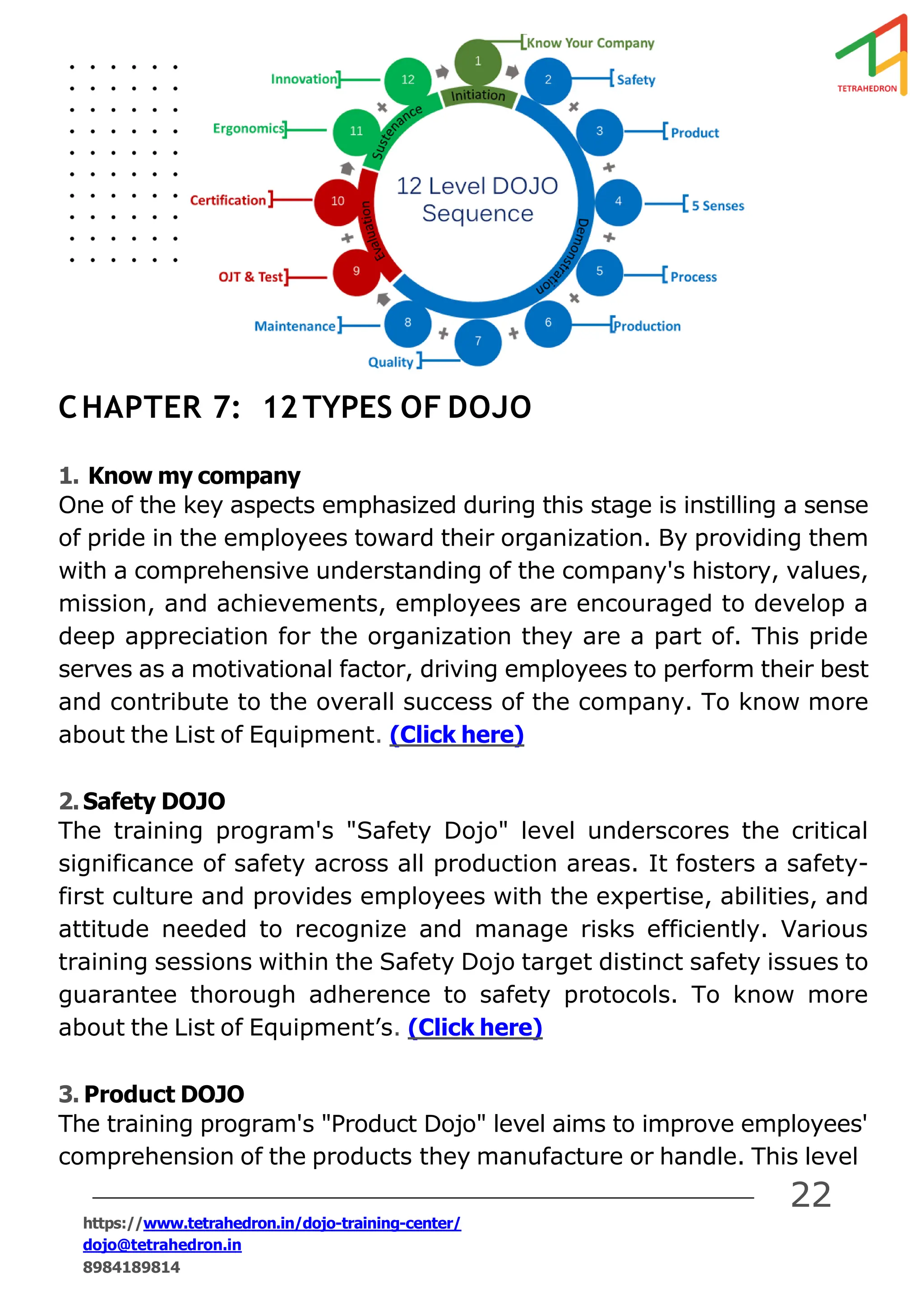

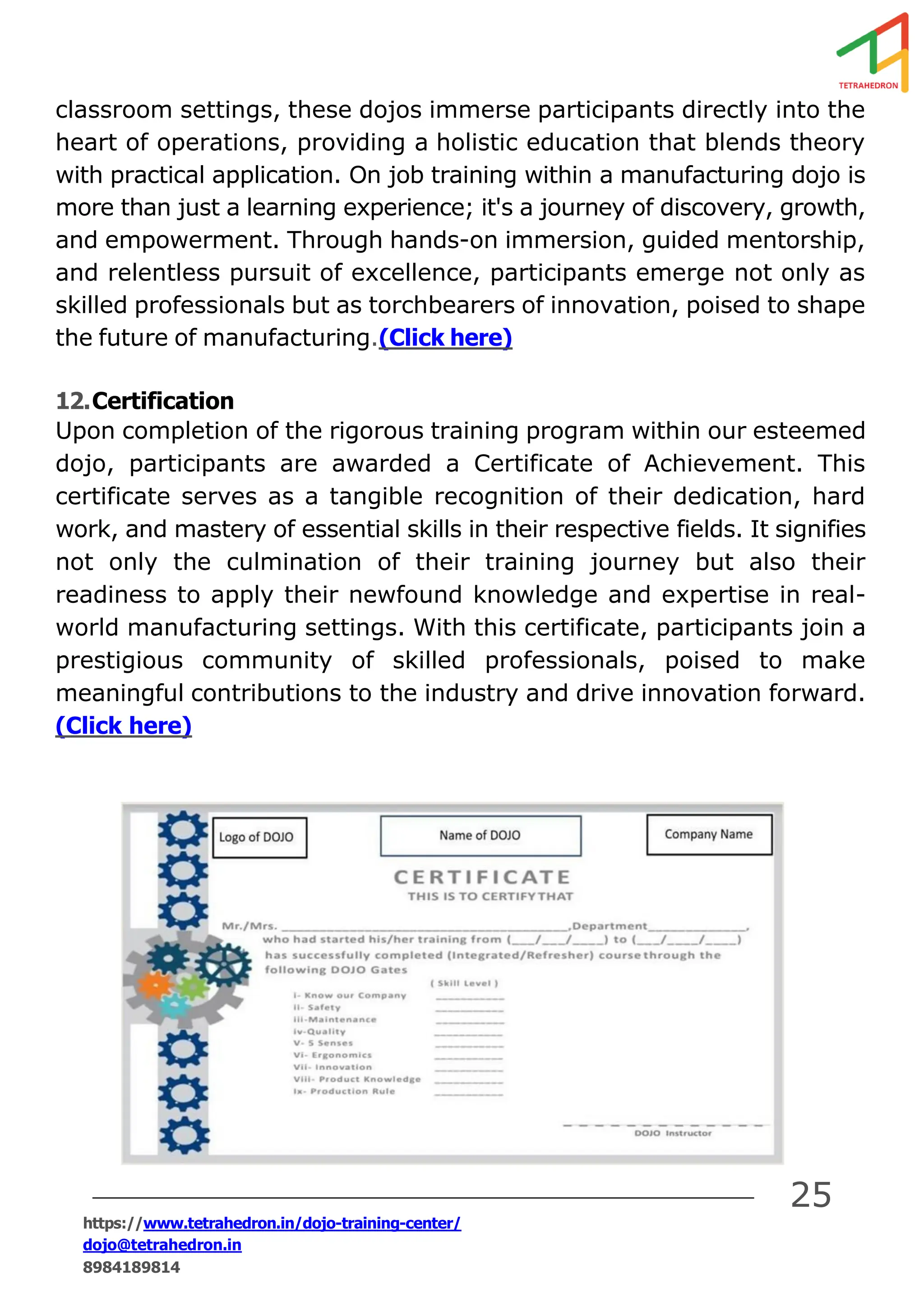

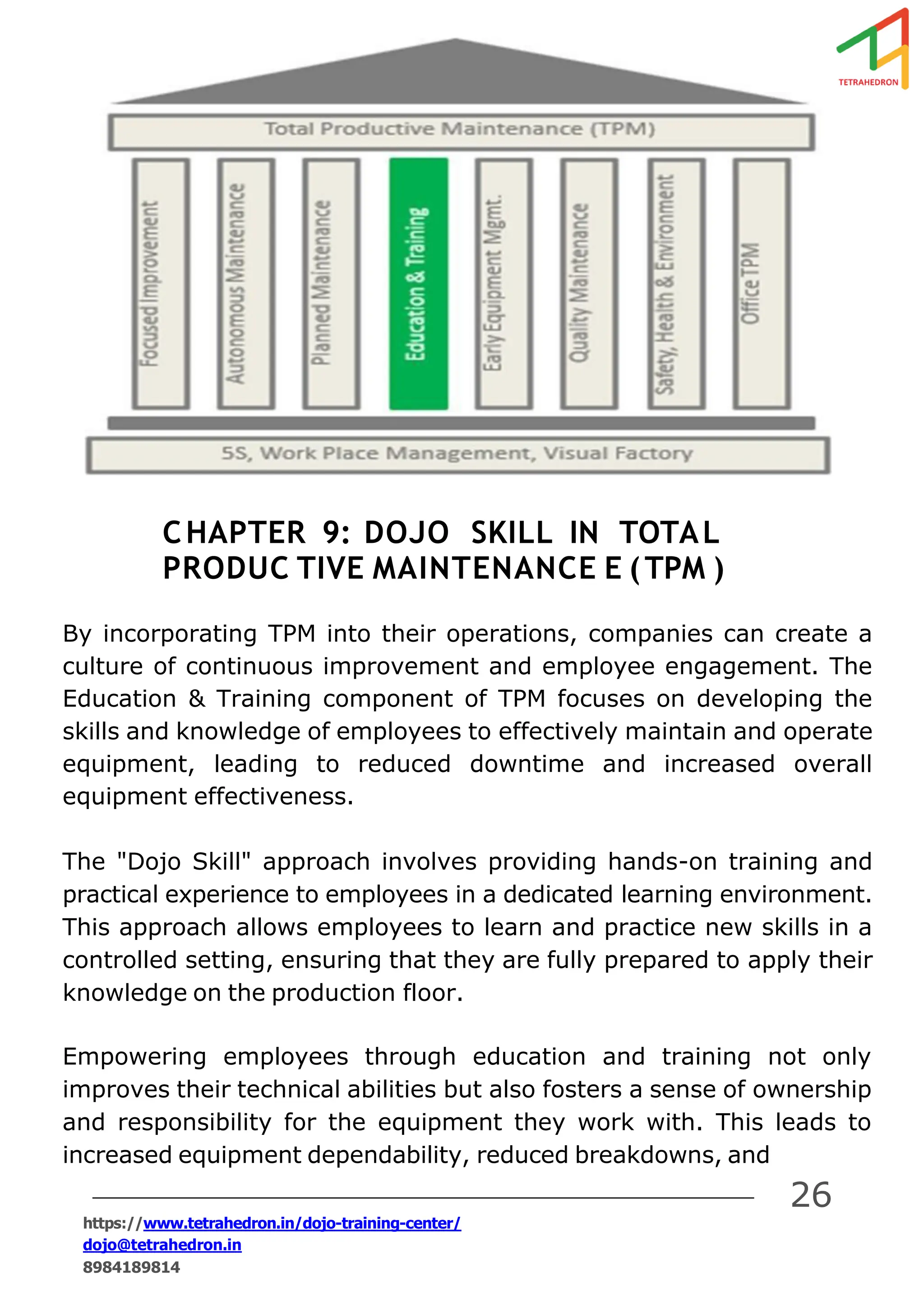

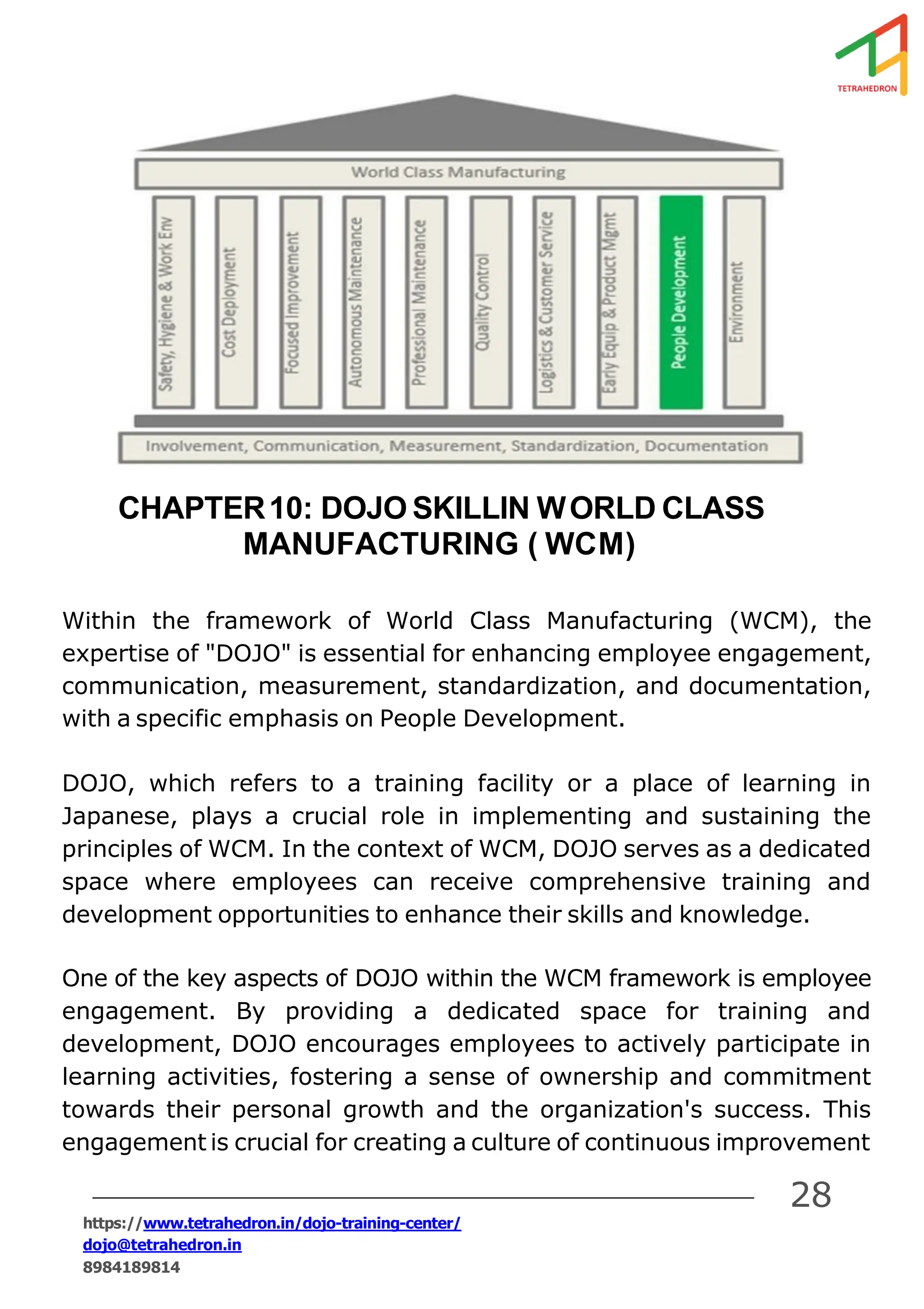

The document outlines the concept of dojo training centers, which facilitate practical training for new employees in manufacturing environments, enhancing their skills through repetitive practice and immersive learning. Originating from a Japanese term for martial arts training spaces, dojos focus on fostering continuous improvement, cross-departmental collaboration, and the development of both technical and soft skills. The training methodology emphasizes experiential learning, feedback, and a culture of accountability to ensure employees transition effectively into their roles, contributing to organizational success.