This document provides an overview of various livestock and fodder development programmes in India, including:

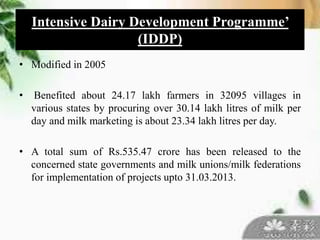

1) Integrated Dairy Development Programme launched in 1993-94 to benefit farmers.

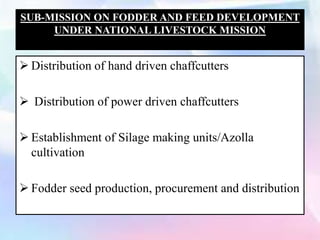

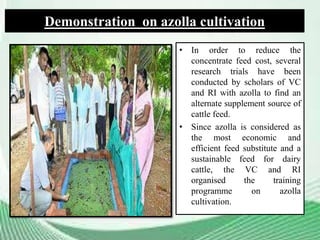

2) National Livestock Mission launched in 2014-15 with the goal of improving livestock production and reducing demand-supply gaps. It includes the Sub-Mission on Fodder and Feed Development.

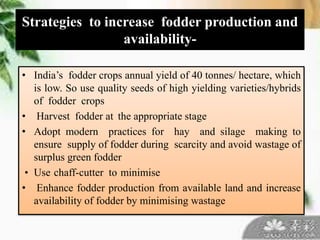

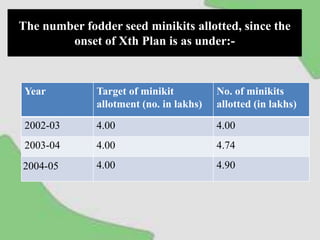

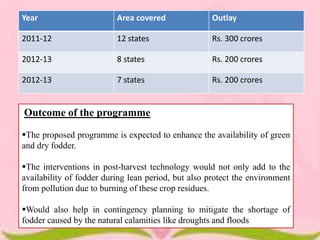

3) Accelerated Fodder Development Programme implemented since 1987 to promote fodder production through quality seeds, technologies, and minimizing wastage.

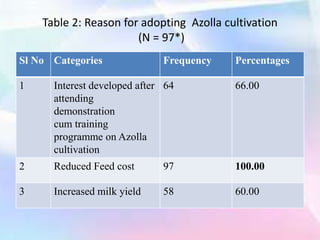

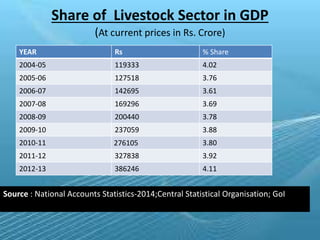

![The Planning Commission’s Working Group on Animal Husbandry and

Dairying looking into the demand and supply of fodder resources in India

arrived at the following estimated fodder status

Demand and Supply

Status of Fodder

Resources in India

(in Million Ton)

Supply Demand Shortfall

Green Dry Green Dry Green Dry

2000 384.5 428 988 549 604 121

2005 389.9 443 1025 569 635 126

2010 395.2 451 1061 589 666 138

2015 400.6 466 1097 609 696 143

2020 405.9 473 1134 630 728 157

[Source: Draft Report of the WG on Animal Husbandry and Dairying for 5-year Plan

(2002-2007). Planning Commission of India. August 2001.]](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-11-320.jpg)

![Livestock and fodder programmes

1]Fodder Minikits under Integrated Fodder Development Programme

2]Subsidy for Hand operated Chaffcutter under Integrated Fodder

Development Programme

3] Cattle Shed subsidy scheme under Integrated Fodder

Development Programme

4]Fodder Minikits under Tribal Area Sub Plan(TASP) Scheme

5]Subsidy for Hand operated Chaffcutter under Tribal Area Sub Plan

(TASP) Programme

6]Fodder Minikits under Health Package Programme

7]Subsidy for Hand operated Chaffcutter under Schedule Caste Sub

Plan(SCSP)](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-14-320.jpg)

![• Implemented – 2002- 2005

• Objective- Popularize the latest improved fodder varieties

amongst the farmers

• African tall Maize, Lucerne, Bersem, Sorghum, Oats,

M. P. Chari, Red Chari, Sudan Chari, Chinese Cabbage &

Congosignal.

1] Central Minikit Testing Programme on Fodder

Crops](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-15-320.jpg)

![The Scheme ‘Integrated Dairy Development Project (IDDP) in

Non-Operation Flood, Hilly and Backward Areas’ was

launched in 1993-94 on 100% grant-in-aid basis.

2] Integrated dairy development programme

(1993-94)](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-17-320.jpg)

![Sl.

No

Scheme Year Implementing

agency

Amount

sanctioned

1 Grassland development

including grass reserves

(100% GOI share)

2005-06 Karnataka Milk

Federation Bangalore

BIRDS Belgaum

100:0

2 Fodder seed production

& distribution programme

2006-07 Karnataka Milk

Federation Bangalore

75:25

3] Enrichment of straws & cellulosic waste scheme:

(100% GOI)](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-19-320.jpg)

![• Launched in 2014-15

• Quantitative and qualitative improvement in livestock

production systems and capacity building of all stakeholders.

• Reduce the demand –supply gap

4. National Livestock Mission

NLM has 4 submissions as follows:

1] The Sub-Mission on Fodder and Feed Development

2] Under Sub-Mission on Livestock Development

3] Sub-Mission on Pig Development in North-Eastern Region

4] Sub-Mission on Skill Development, Technology Transfer and

Extension](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-20-320.jpg)

![• Central Sector Scheme for a period of 2011-12 to 2018-19

Objectives

• To help increase productivity of milch animals

• To help provide rural milk producers with greater access to

the organised milk-processing sector.

Fodder Development-

Extension initiatives/interventions for fodder

development, including support for improved fodder seed

production, fodder production on contract, demonstrations for

silage making, and reducing wastage of dry fodder through

enrichment & densification

5] National Dairy Plan](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-23-320.jpg)

![• Implemented in -2010

• Objective- Production of fodder through promotion of

integrated technologies and processes for enhancing the

availability of fodder throughout the year.

Strategies of this programme

1]Production of Quality Seeds: Strengthening SAU’s

2]Production of Fodder

3]Adoption of appropriate technologies for Post Harvest

Management

6] ACCELERATED FODDER DEVELOPMENT PROGRAMME (AFDP)](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-25-320.jpg)

![• Year of Commencement – 1987 ( modified in 2005 & 2010)

Objectives

• Demonstration of Azolla cultivation and production units

• Introduction of hand driven chaff-cutter

• Introduction of power driven chaff-cutter

• Establishment of silage making Units

7] Centrally Sponsored Fodder and Feed

Development Scheme](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-26-320.jpg)

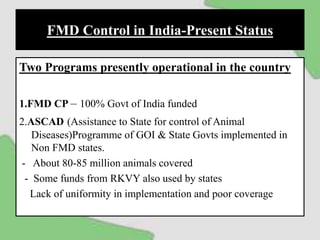

![• Implemented in -October 7, 2014

• Procurement of vaccine

• Inspection of cold chain in transit and during storage

• Ensure timely supply of vaccines to the respective

states as per demand

8] FMD-CP: Foot and Mouth Disease Control

Programme](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-27-320.jpg)

![Objective-

Protection mechanism to the farmers against any eventual loss

of their animals due to death

Claim Procedure

In the event of death of an animal, immediate intimation should

be sent to the insurers and the require steps should be follow.

9] Livestock Insurance Scheme](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-29-320.jpg)

![• RKVY.docx

Under this scheme

• Milking Machines- 50% subsidy basis

• Chaff Cutters: 33% subsidy basis

• Supply of calf feed: female calves of 3 to 4 months age

borne out of Artificial Insemination will be enrolled and

260 Kg of calf feed will be supplied for a period of 12

months along with health care

• Feed & Fodder Development

10] Under RKVY](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-31-320.jpg)

![• Implemented in 2015-16

• Backended subsidy of 33% to farmers belonging to Scheduled

Caste and Scheduled Tribes and 25% to other small and

marginal farmers will be provided to establish cattle, sheep,

goat, pig, poultry units in availing maximum loan of Rs.1.20

lakh from commercial banks (The subsidy to SC/ST has been

revised from 33% to 50% )

1] Pashu Bhagya](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-33-320.jpg)

![2] Karnataka Livestock Development Policy -

2010 (Draft) -Fodder resource development

I. Qualitative and quantitative improvement in fodder production through

utilizing waste land/Goumalas

II. Popularizing ,enrichment of crop residues, area specific mineral mixture and

ensilaging of fodder.

III. Popularizing silvipasture development through incentives.

IV. Fodder densification units /fodder banks to be established through PPP

models

V. Local bodies/gram panchayats to be supported for establishing fodder tree

nurseries and for silvipasture development](https://image.slidesharecdn.com/studiesonlivestockandfodderdevelopmentprogrammesinindia-210307134311/85/Studies-on-livestock-and-fodder-development-programmes-in-india-34-320.jpg)