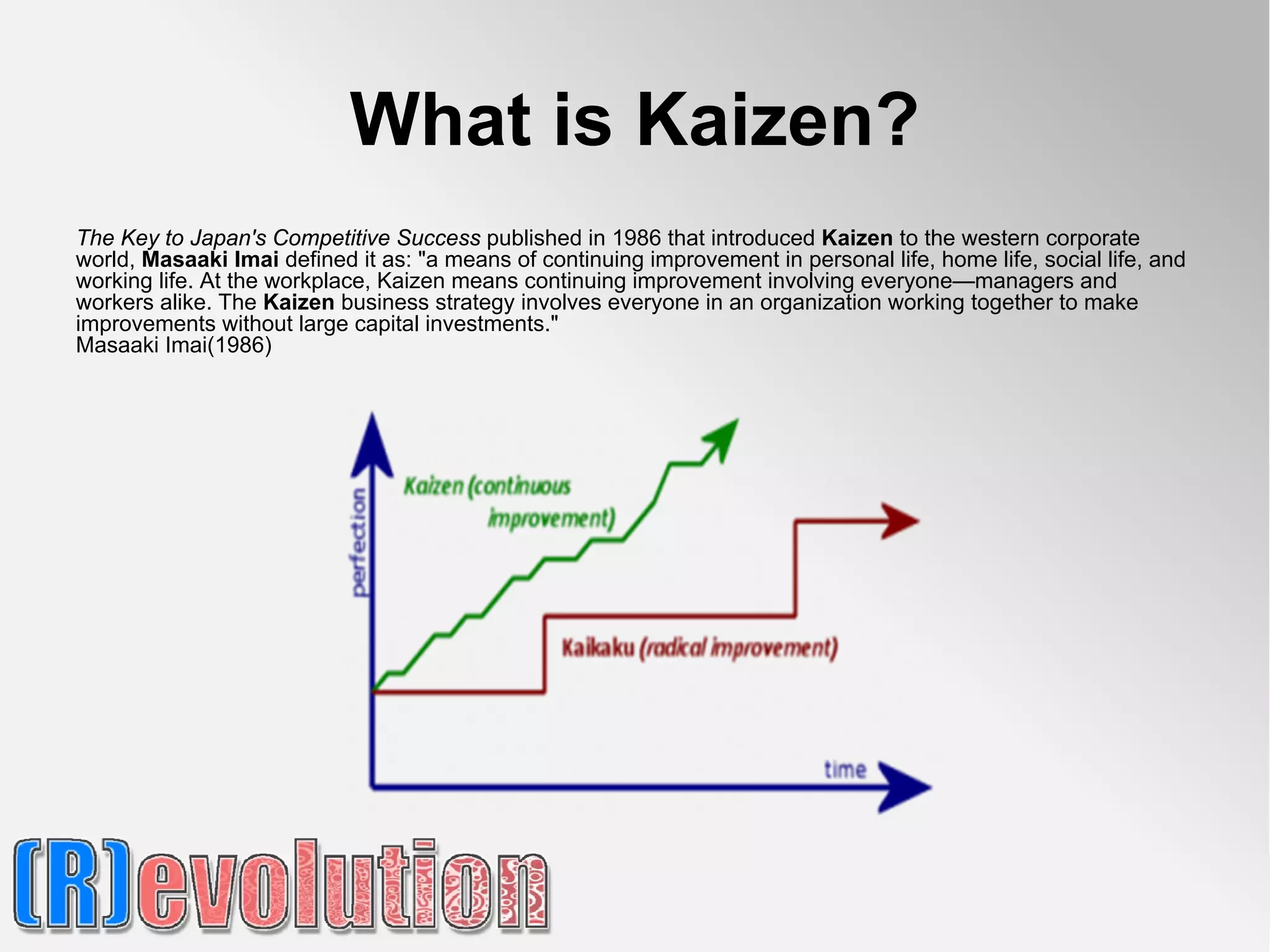

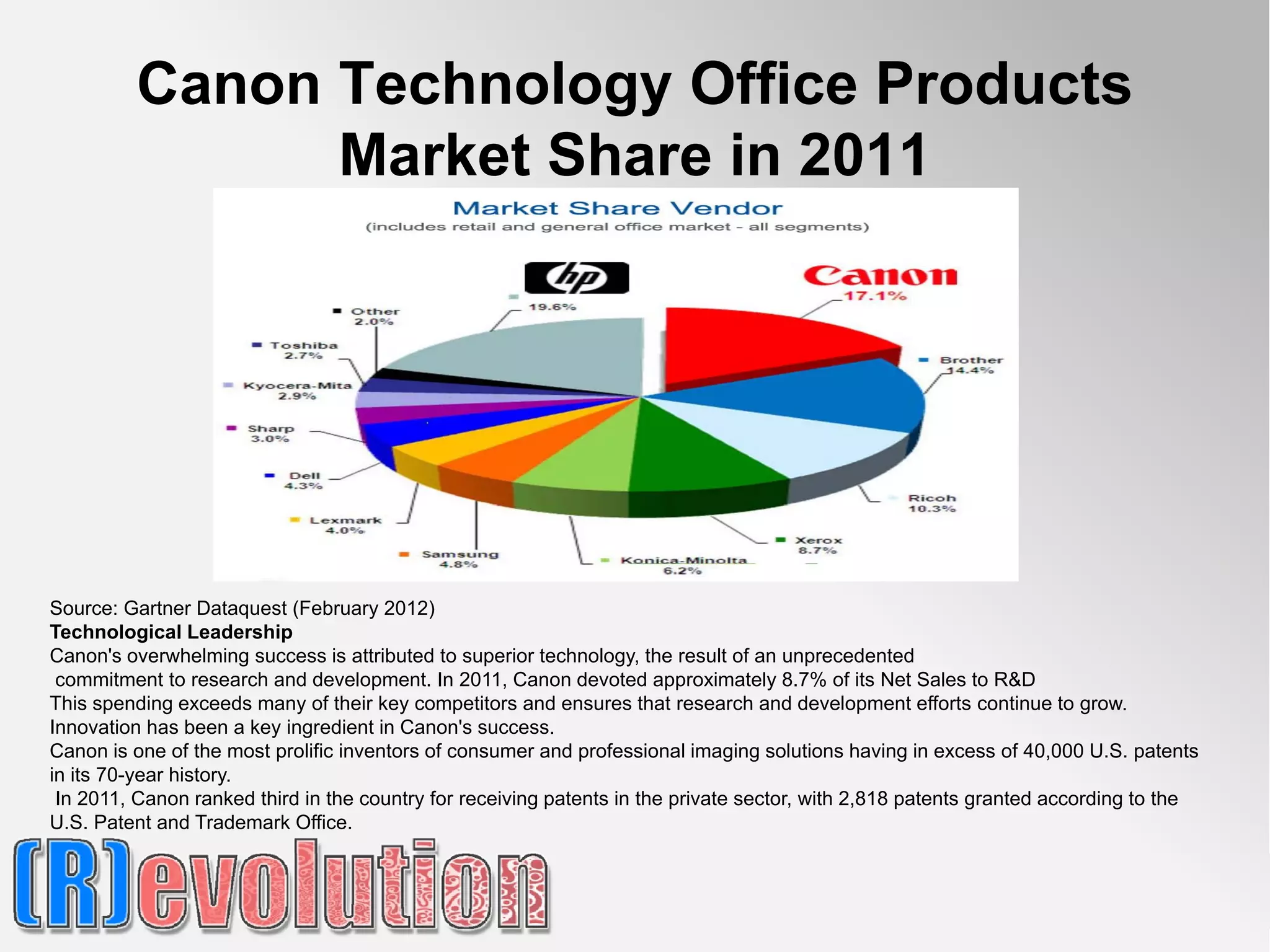

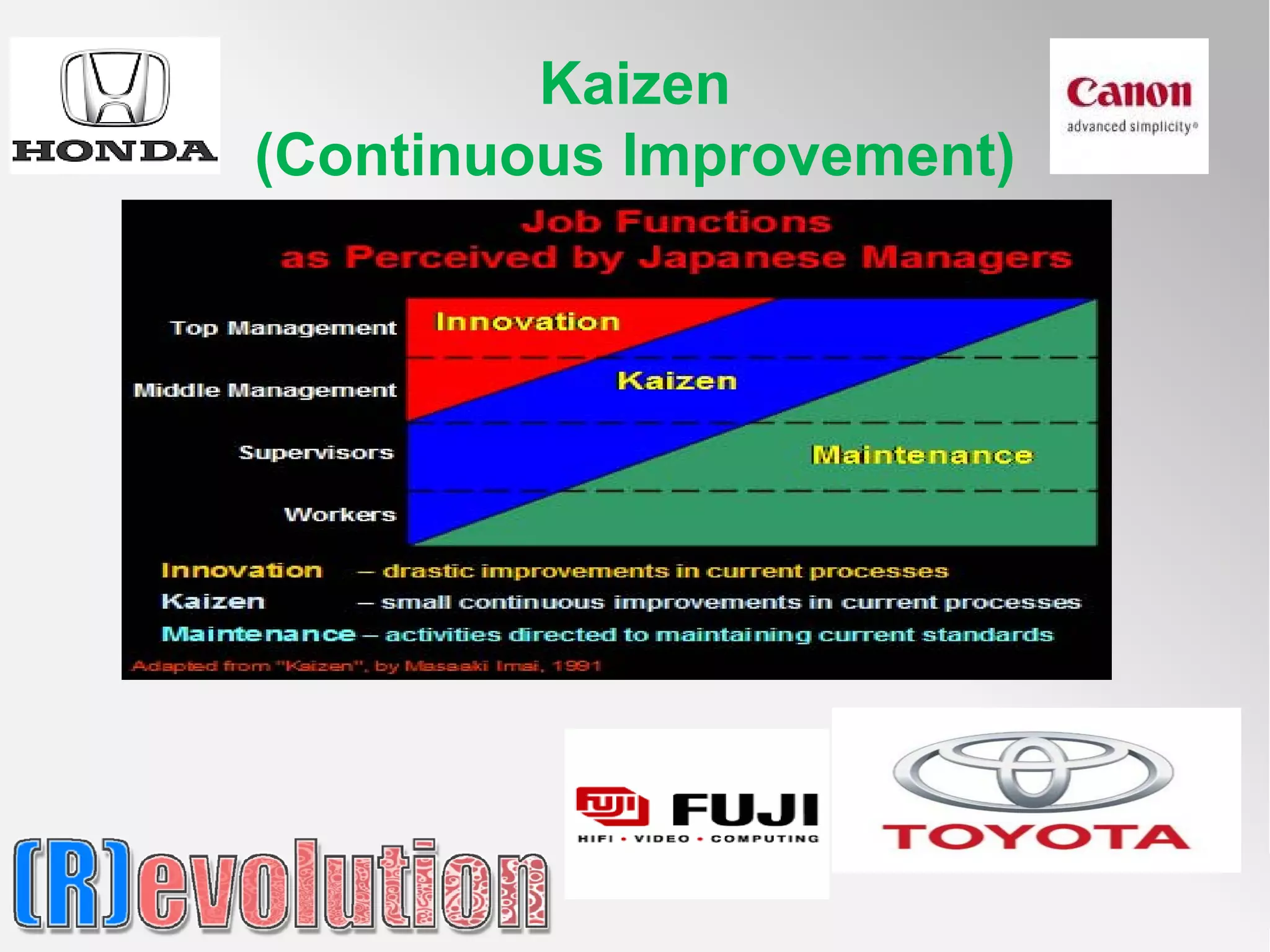

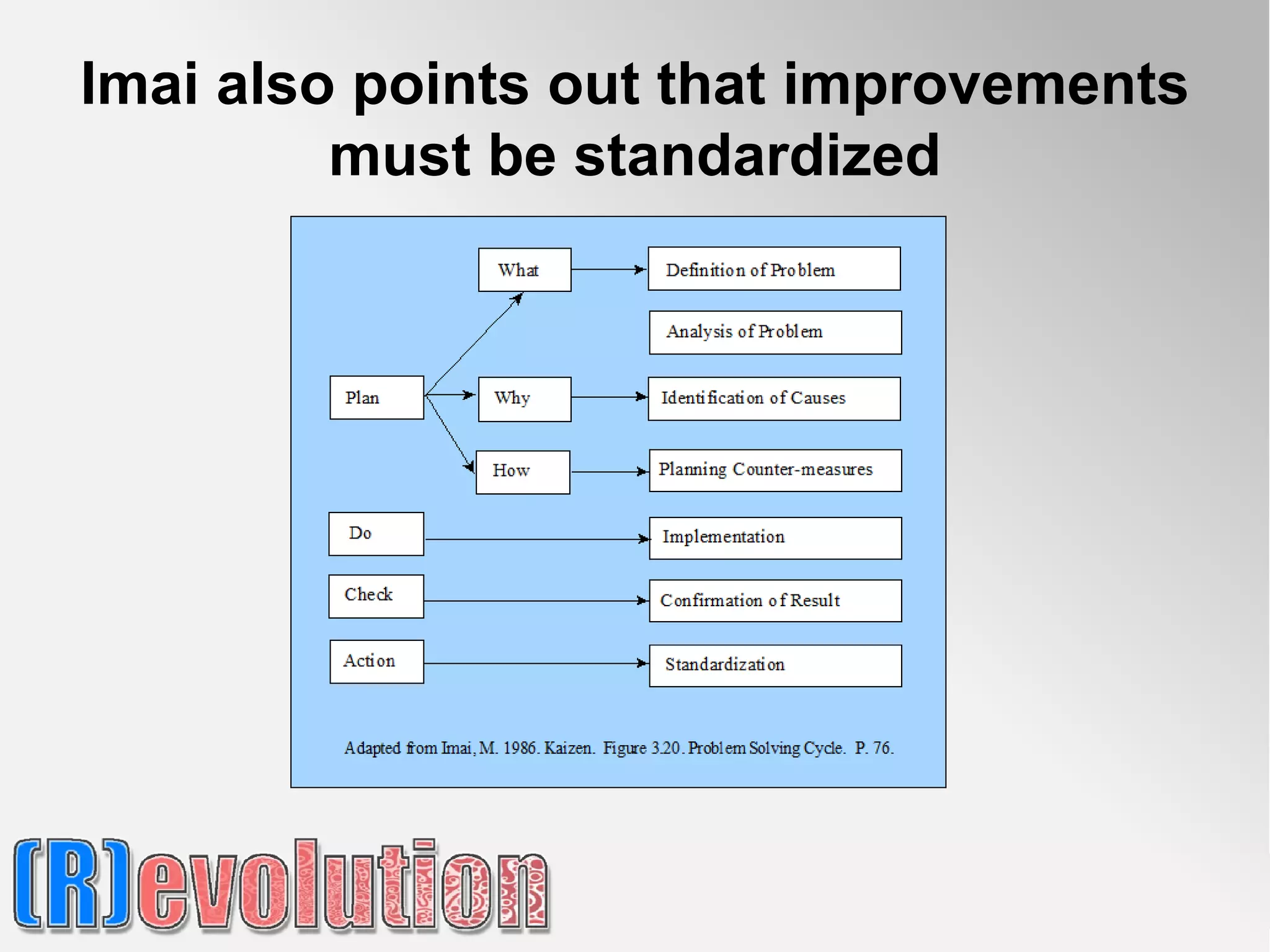

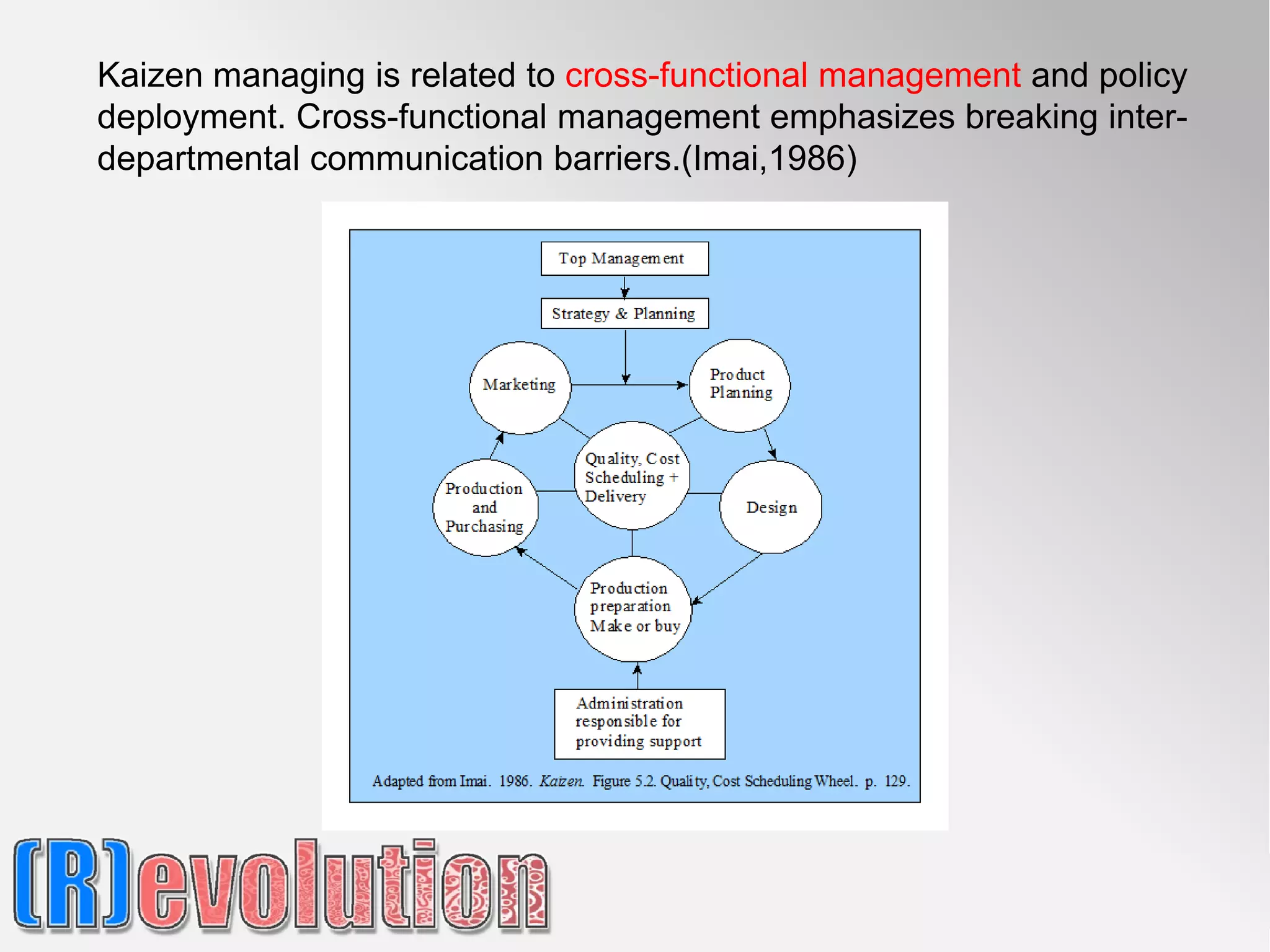

The document discusses strategies for evolutionary change and continuous improvement processes like Kaizen. [1] Evolutionary change emphasizes small, incremental changes through a learning process whereas radical change can cause resistance. [2] Kaizen is a Japanese philosophy of continuous improvement involving everyone in an organization making ongoing small suggestions for improvement. [3] The principles of Kaizen emphasize that human resources are a company's most important asset and that improvement should be based on quantitatively evaluating processes.