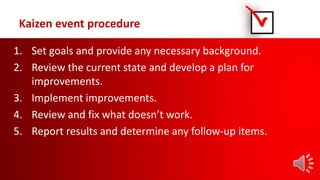

Kaizen is a Japanese philosophy of continuous improvement that emphasizes small, frequent enhancements to work processes involving all employees. It combines action plans for specific improvement events and a cultural mindset of engagement and collaboration. Originating within Toyota, kaizen has been critical to various management theories and aims to foster ongoing progress rather than seeking perfection.