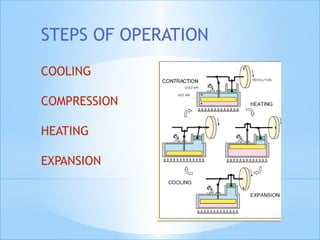

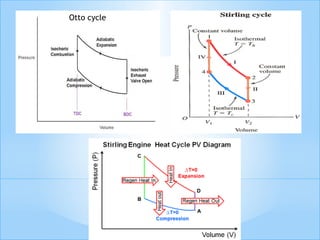

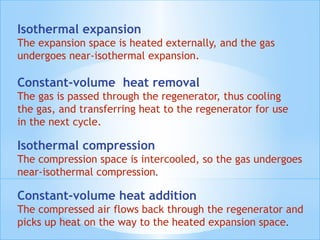

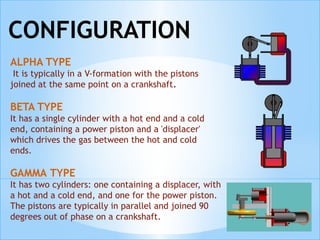

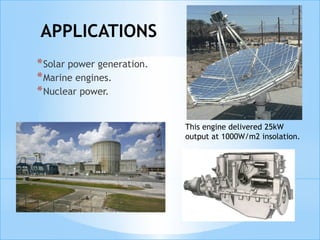

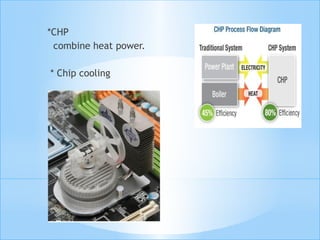

The document provides an overview of the Stirling engine, an external heat engine invented in 1816 that operates through a cyclic process of air or gas compression and expansion. It describes the Stirling cycle's steps, types of Stirling engines (alpha, beta, gamma), along with their advantages, such as flexibility and low explosion risk, as well as disadvantages like size and power limitations. Applications of the Stirling engine include solar power generation, marine engines, and combined heat and power systems.