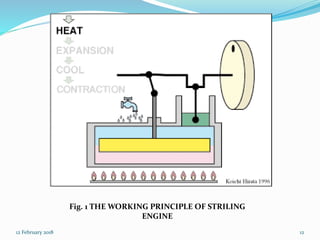

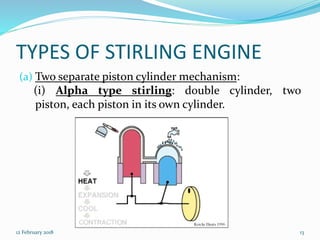

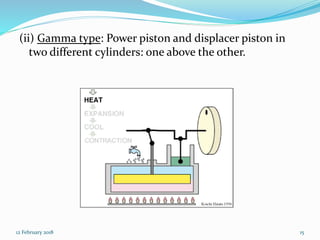

This document summarizes a student project to construct and test a Stirling engine model. It provides background on Stirling engines, describing them as external combustion engines that operate through continuous compression and expansion of air or gas. The document outlines the key parts of Stirling engines, describes how they work through heat transfer between hot and cold cylinders, and classifies the main types. It then details the construction of a gamma-type Stirling engine model for the project, reviews its working principle, and evaluates the engine's performance and potential applications.