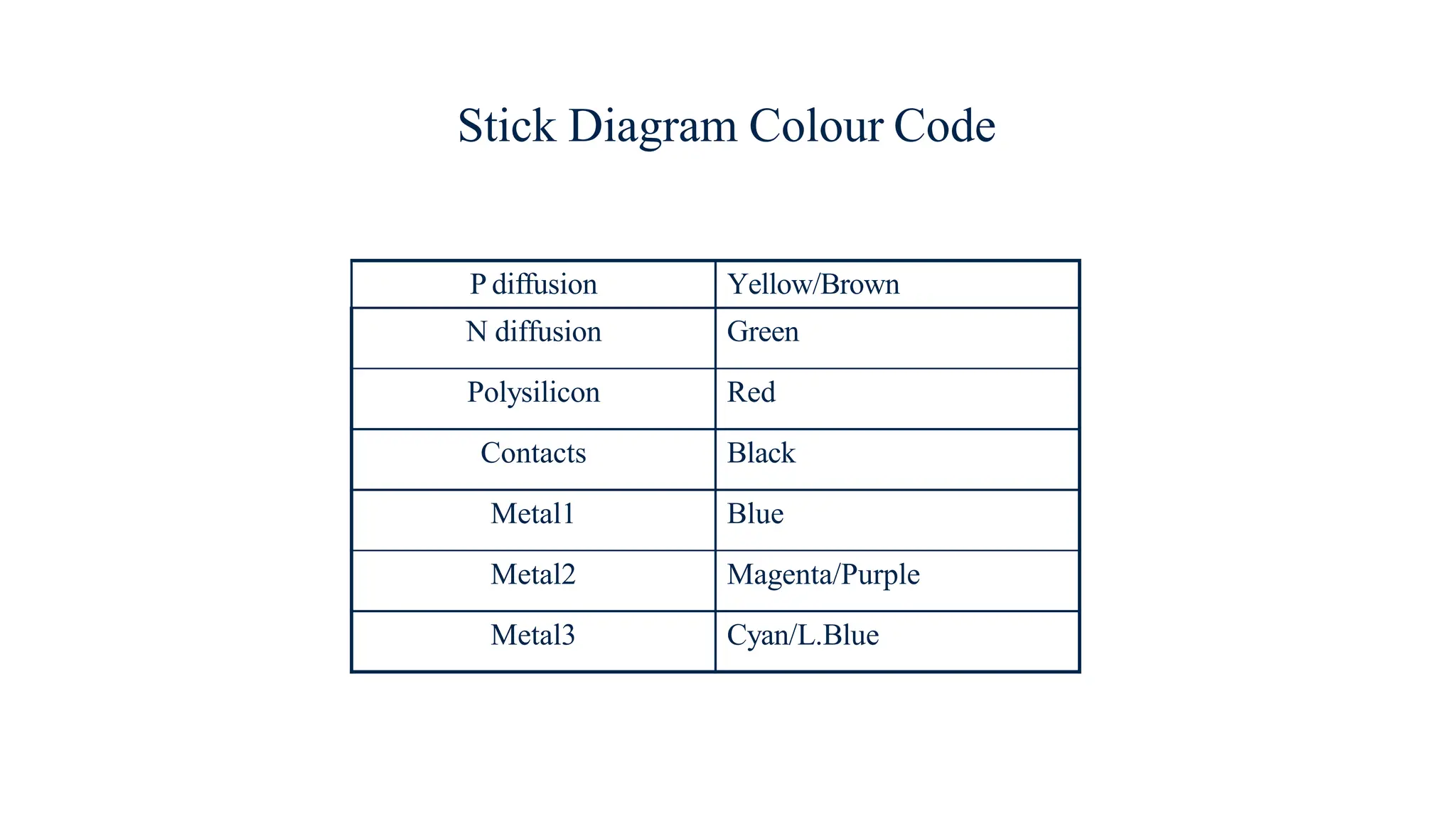

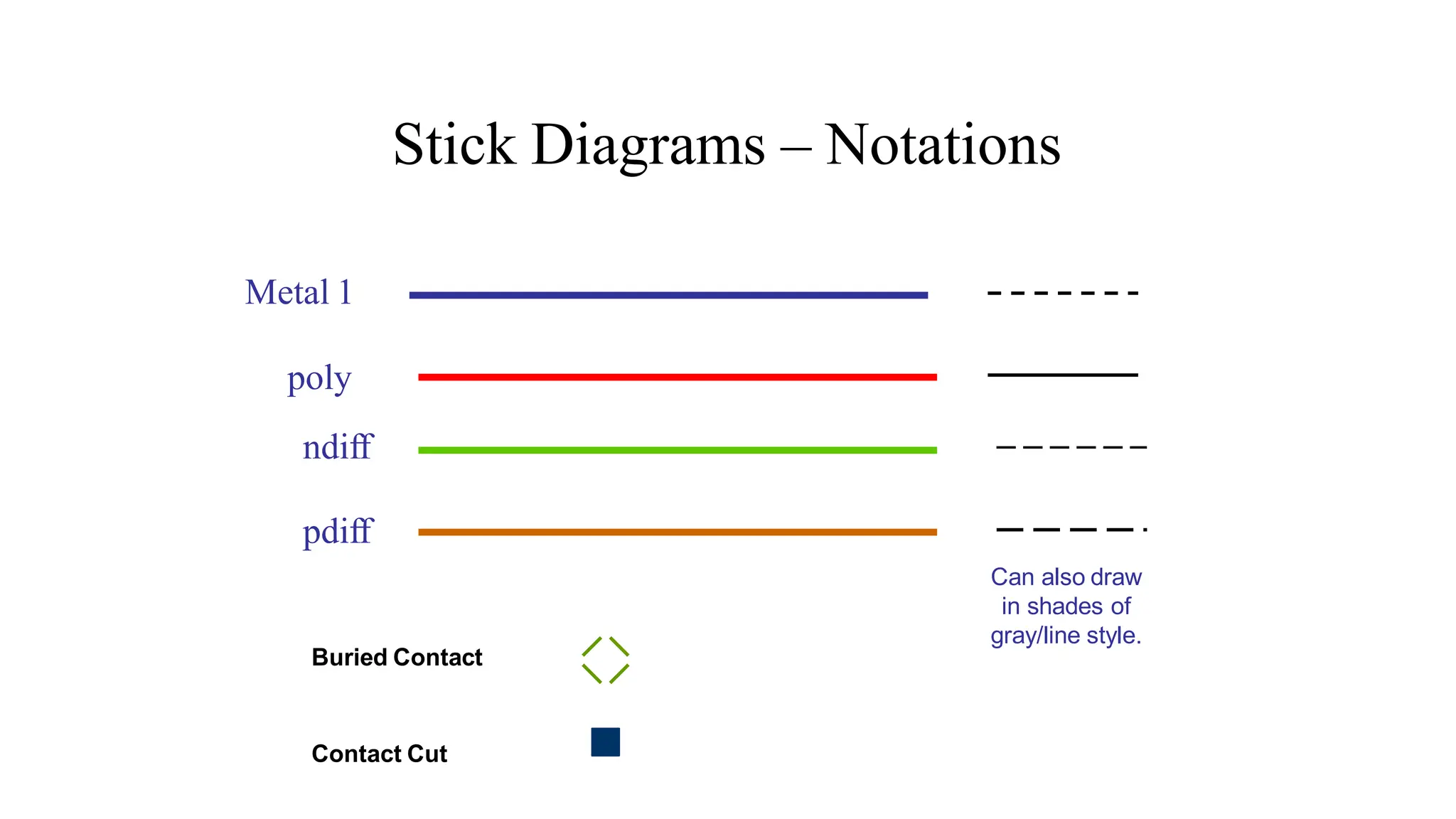

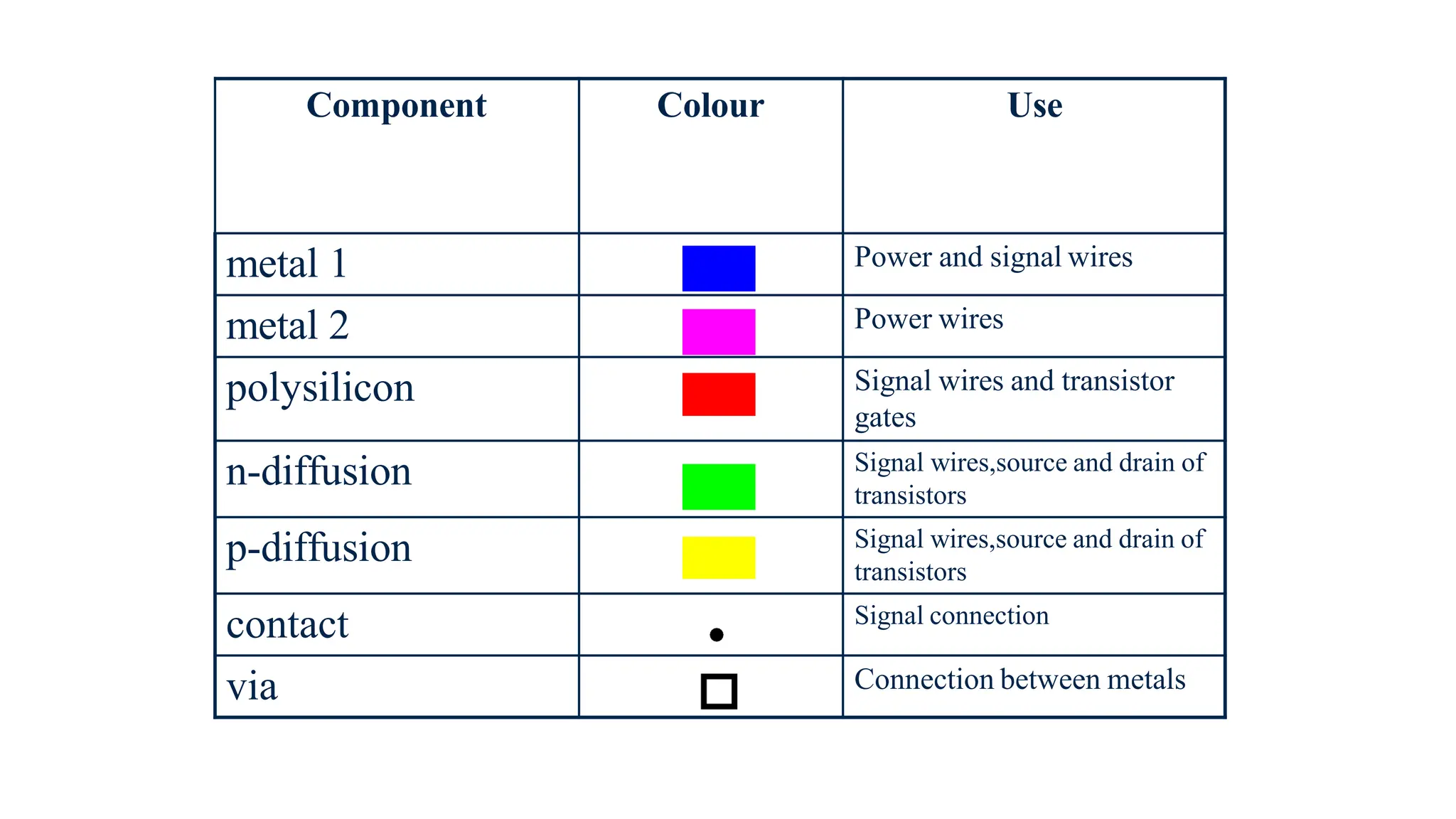

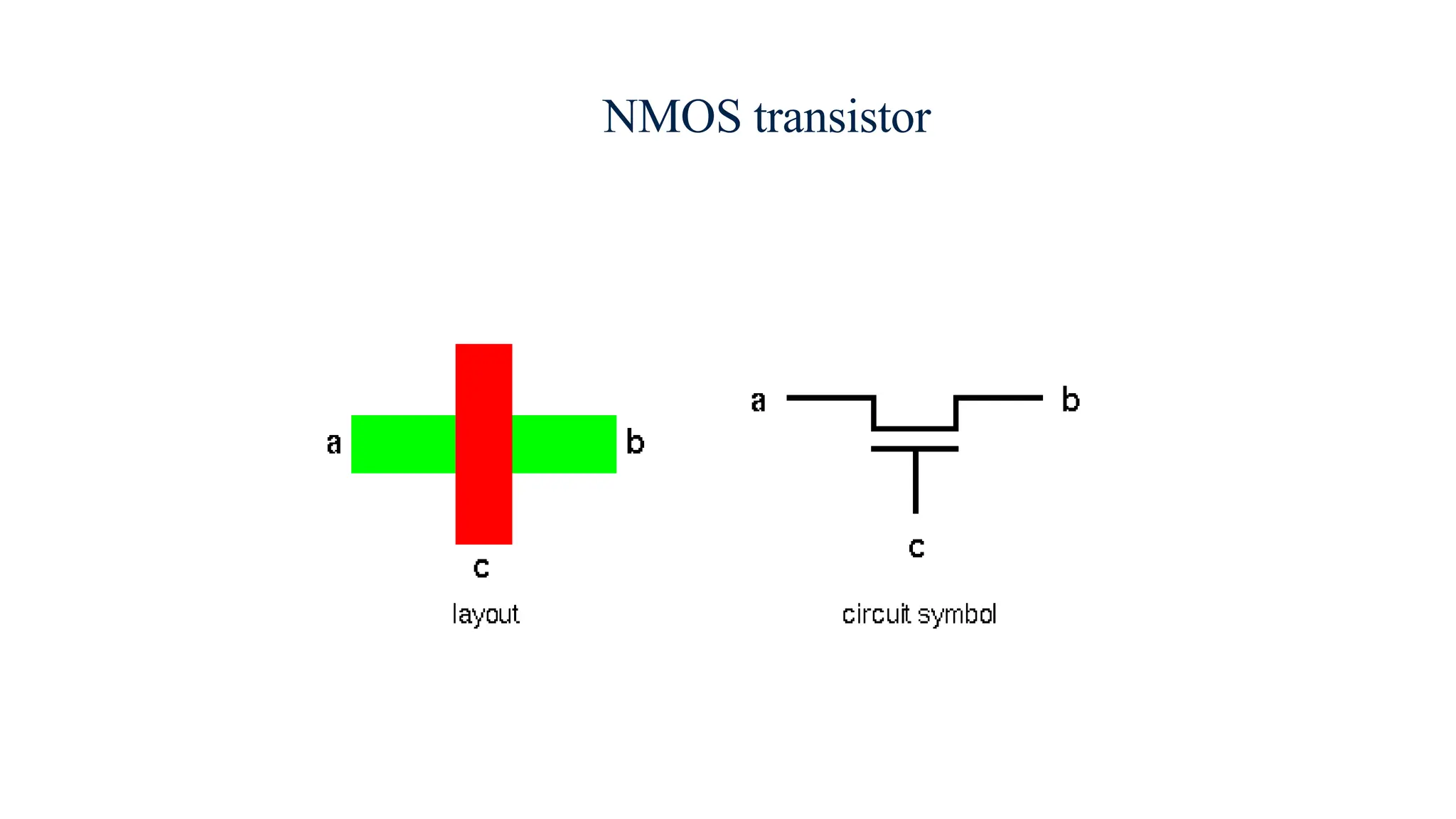

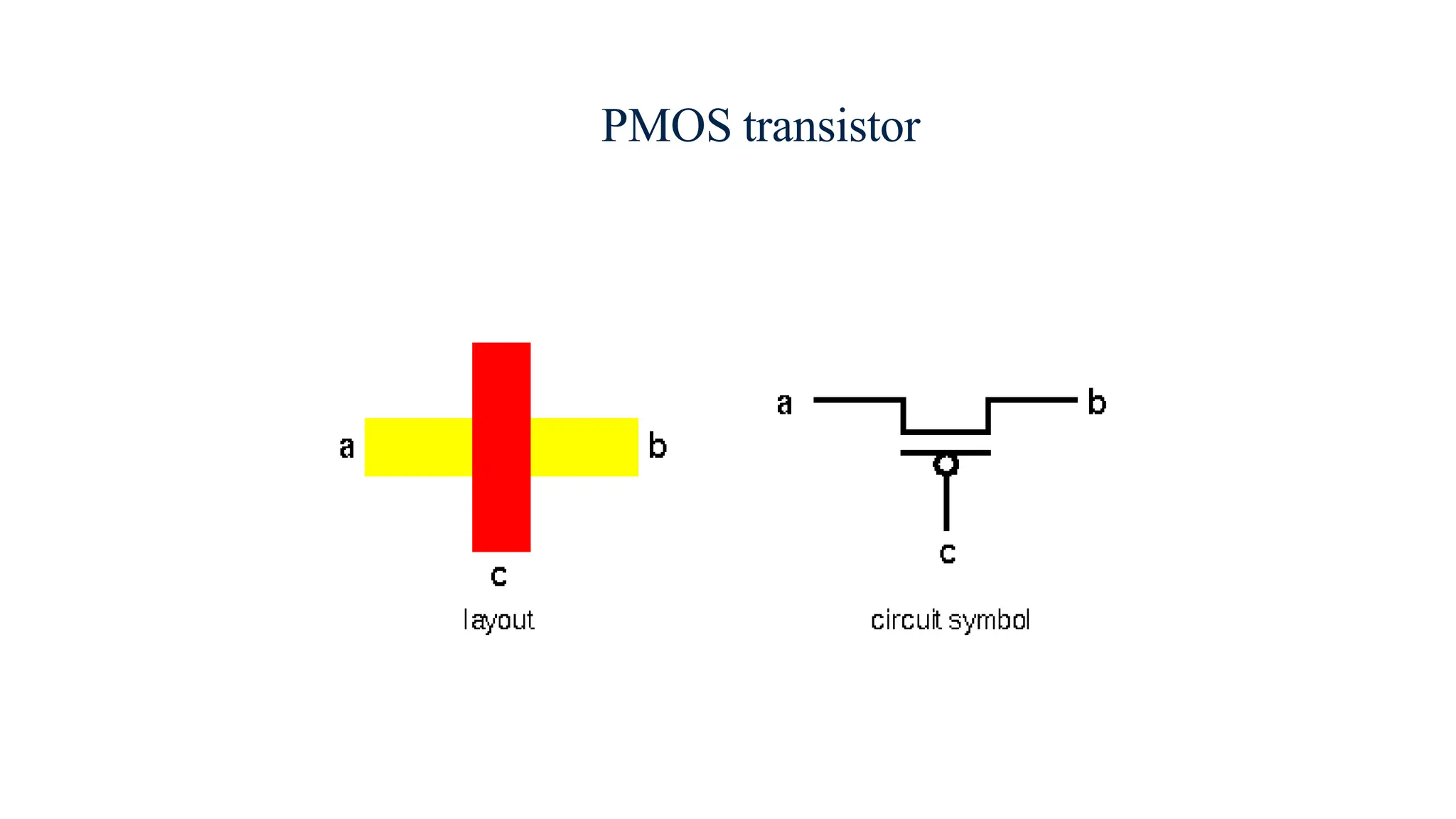

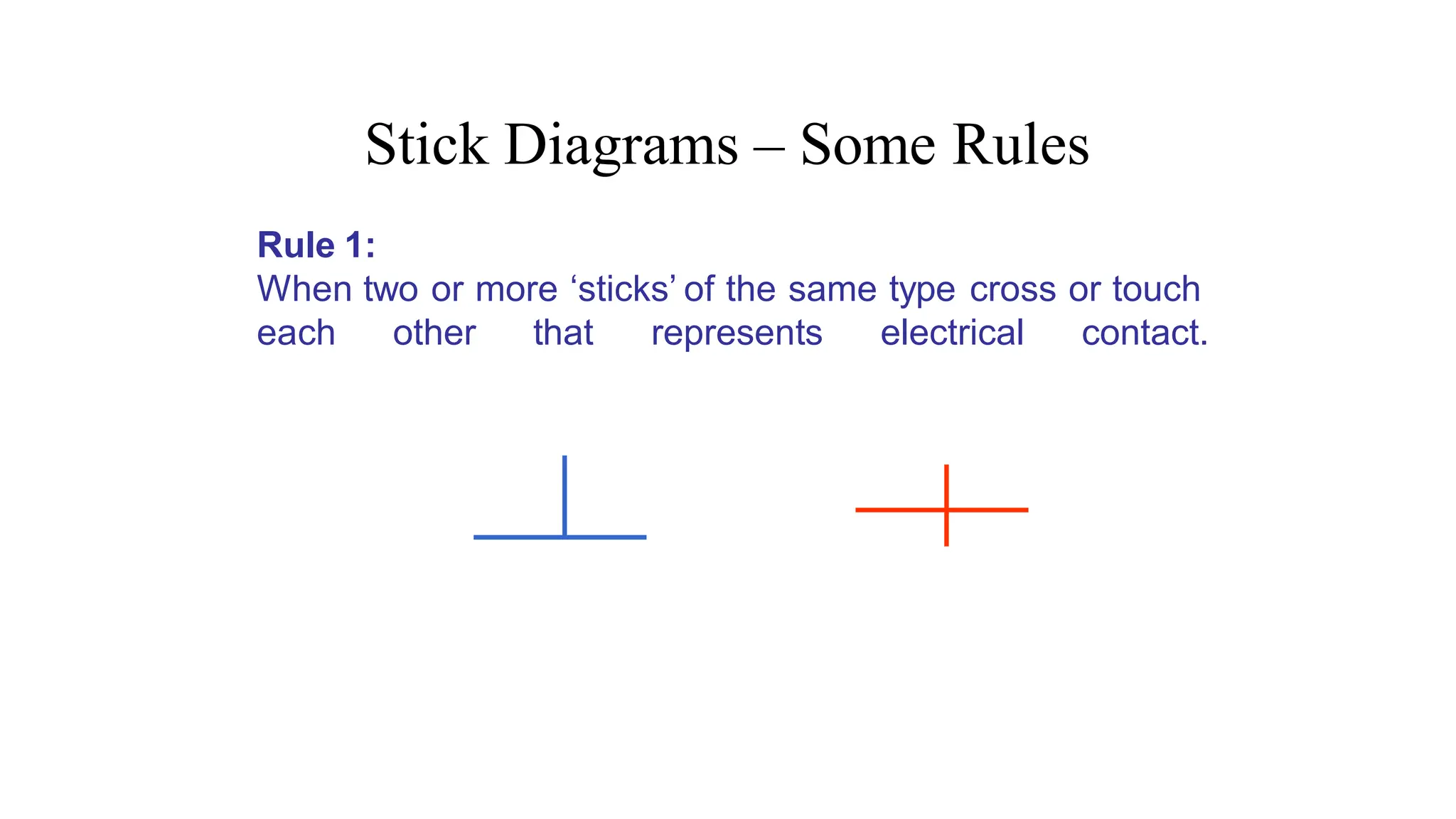

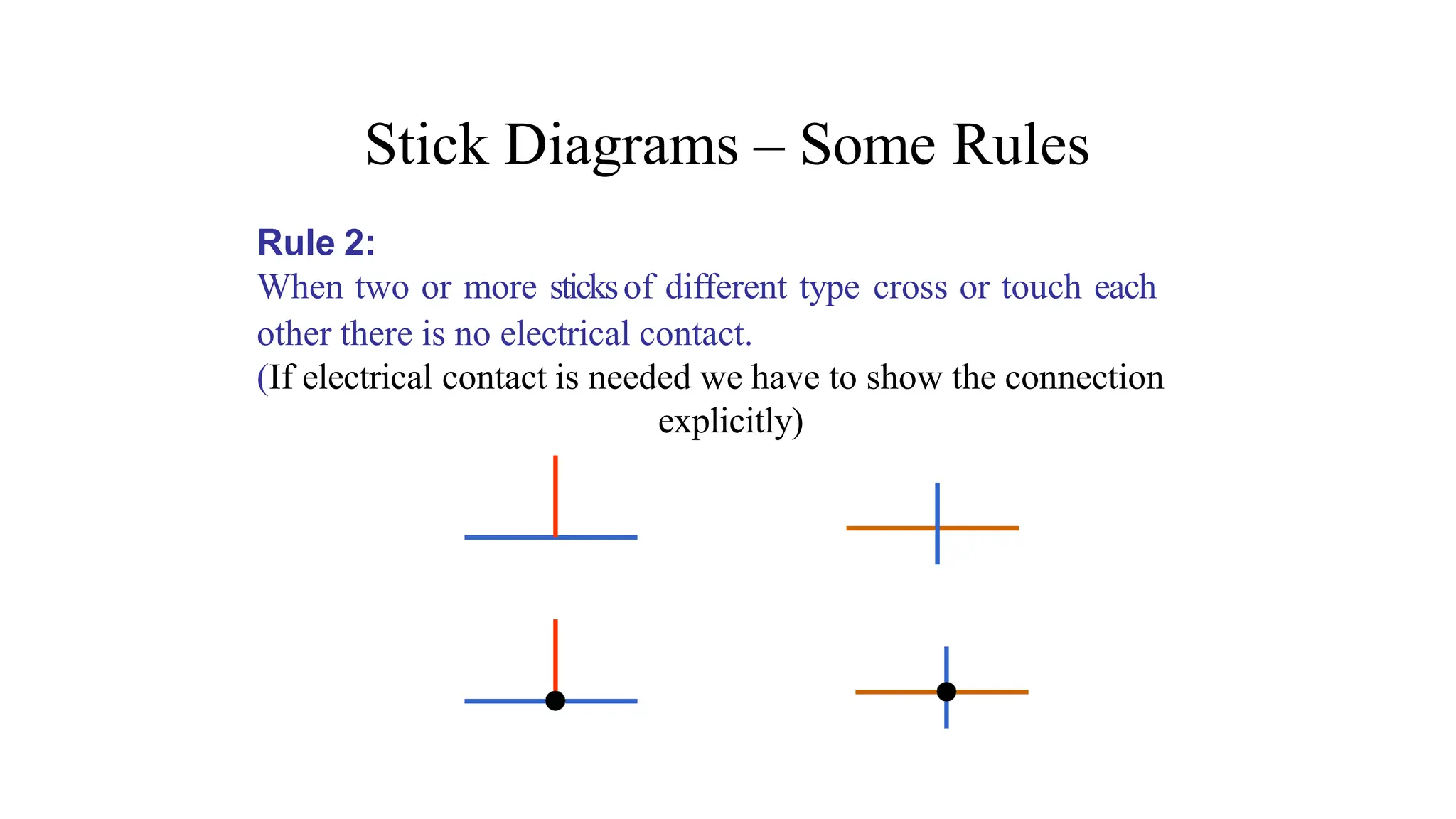

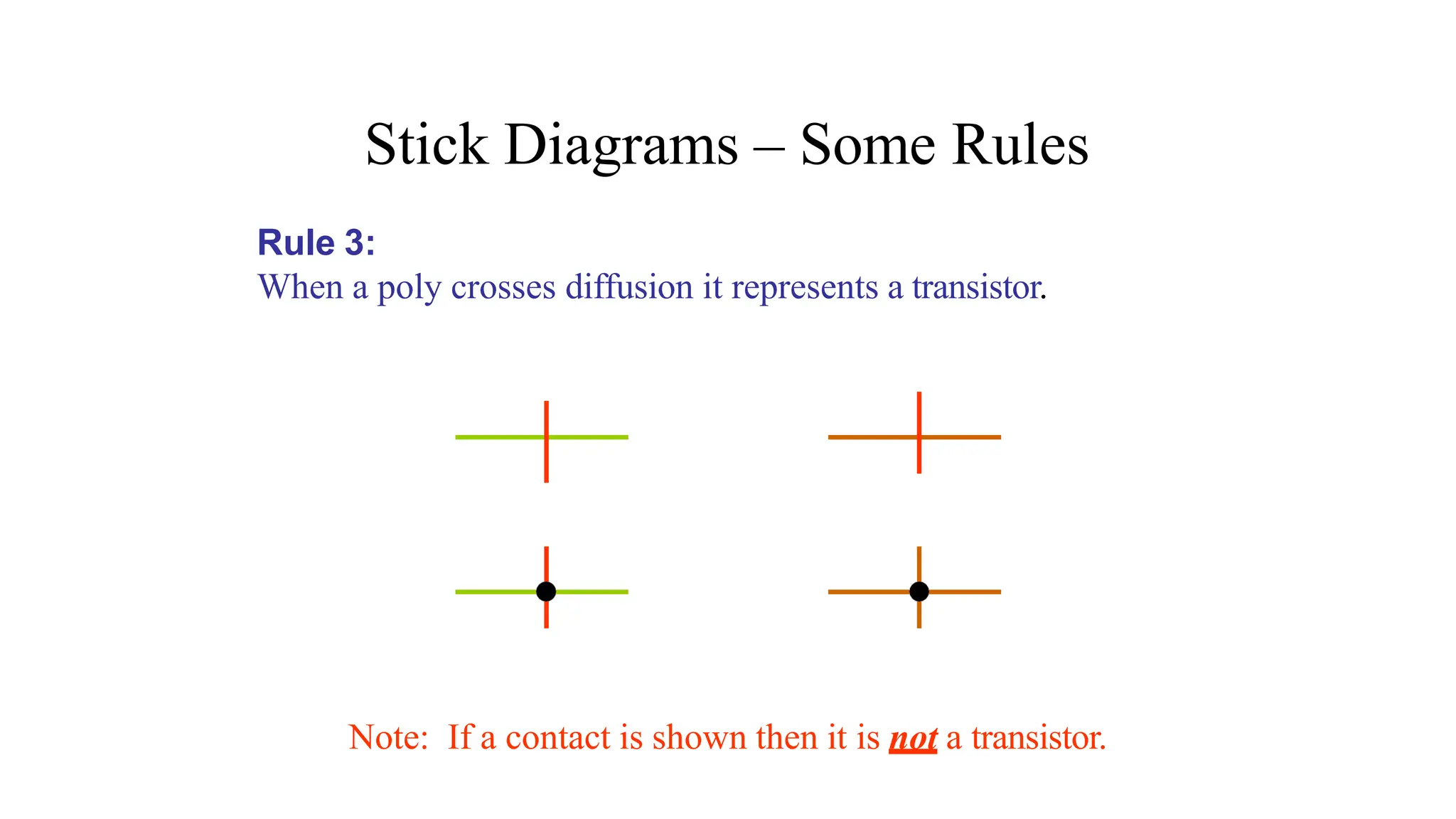

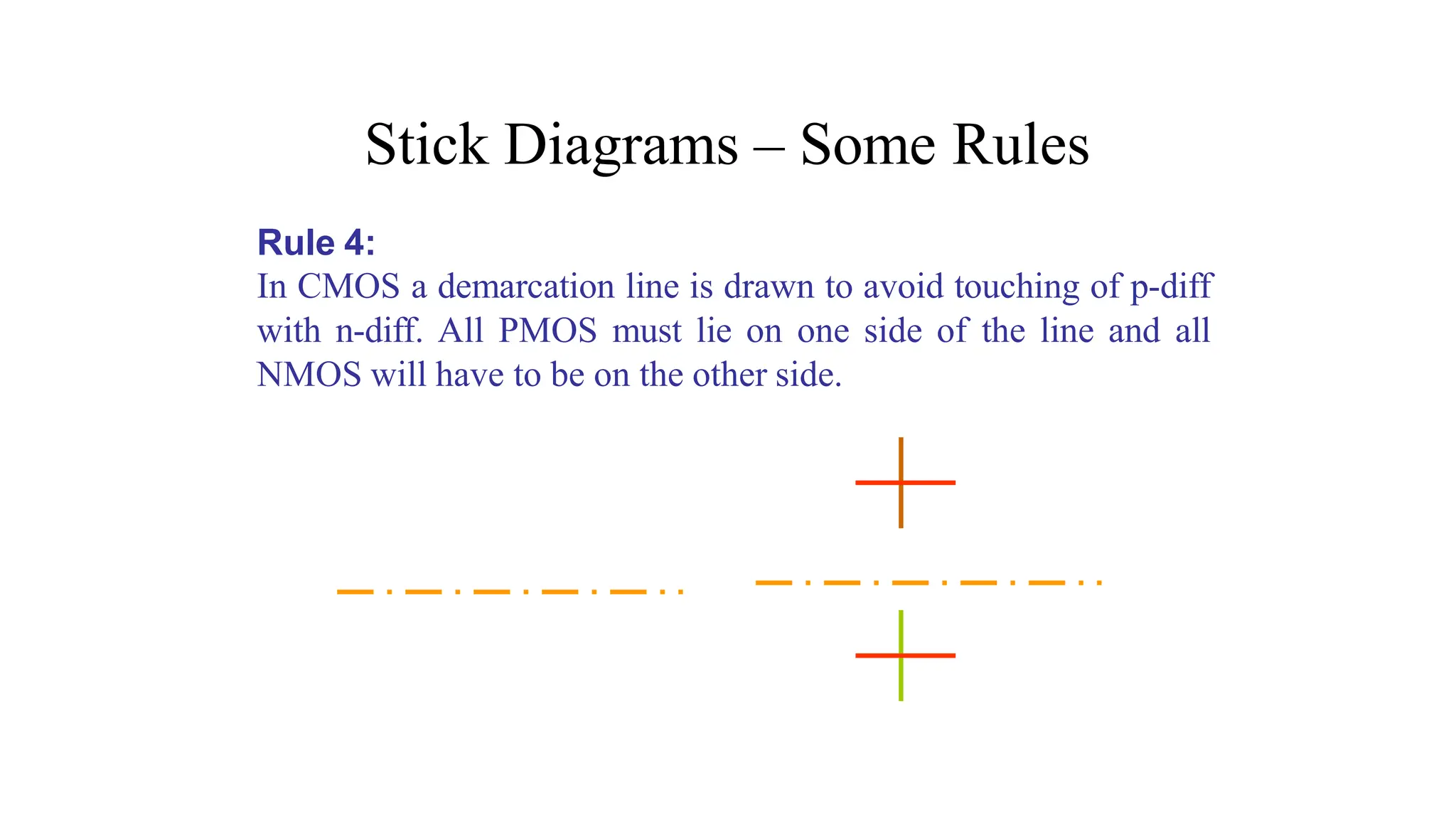

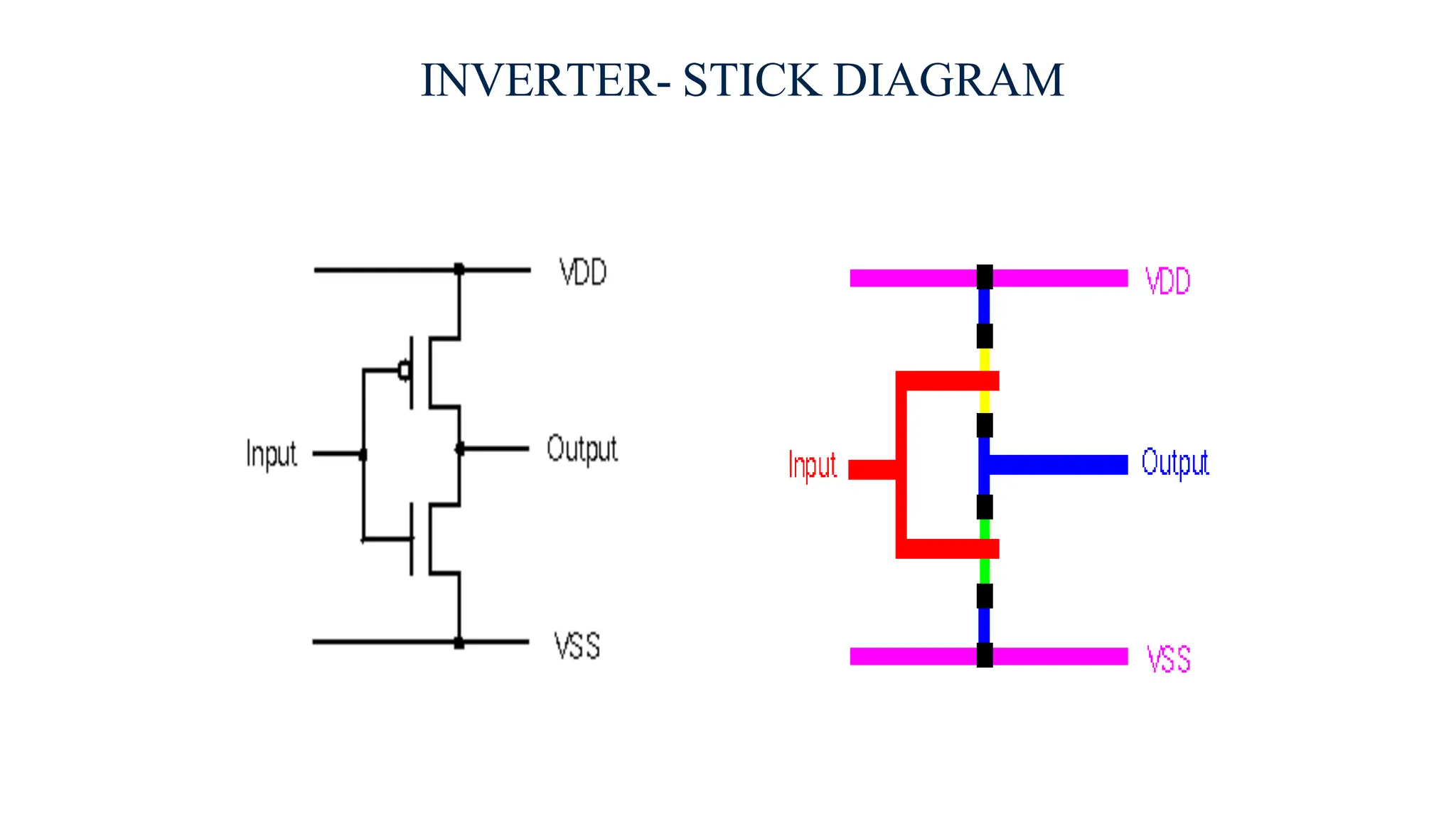

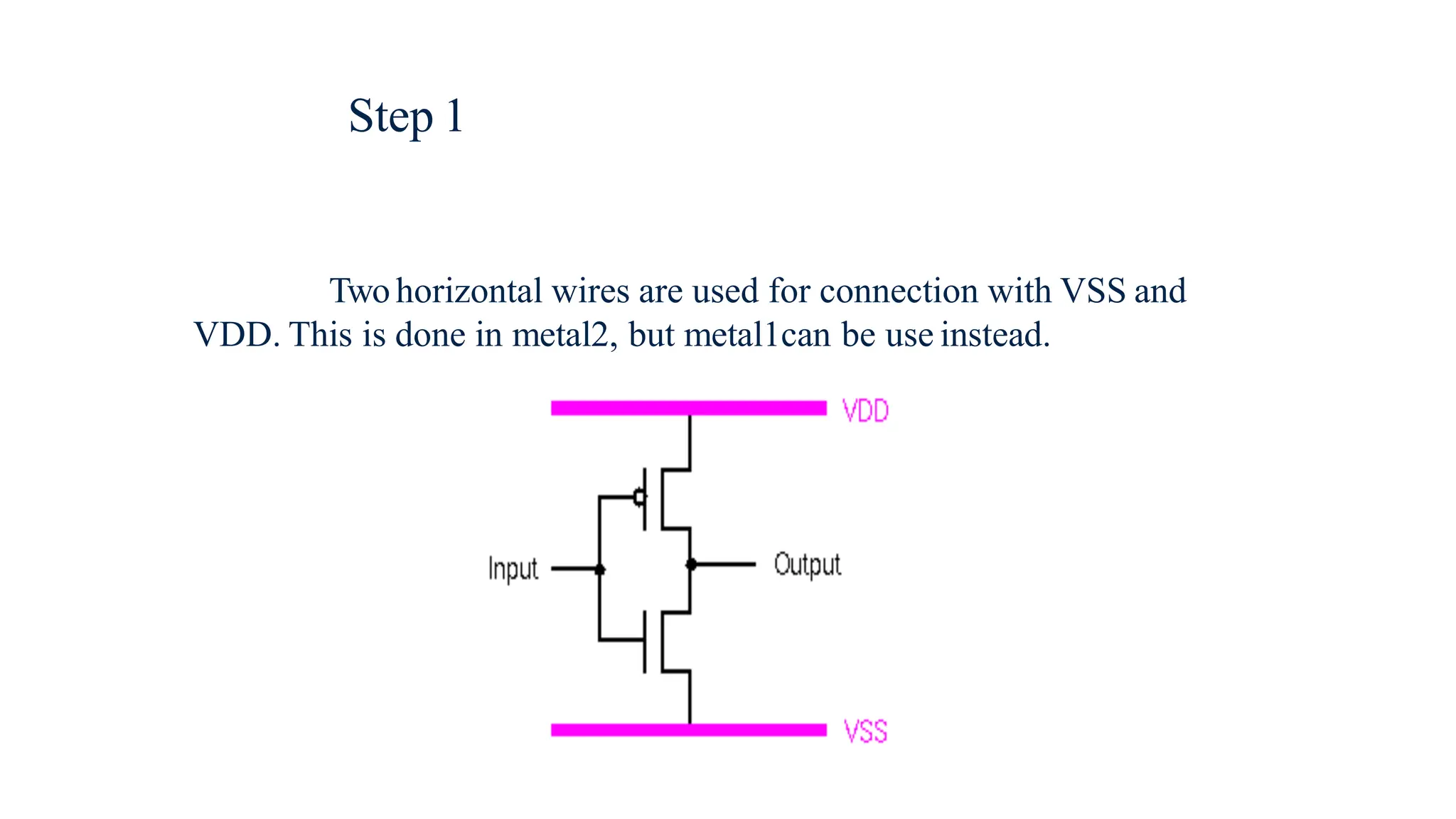

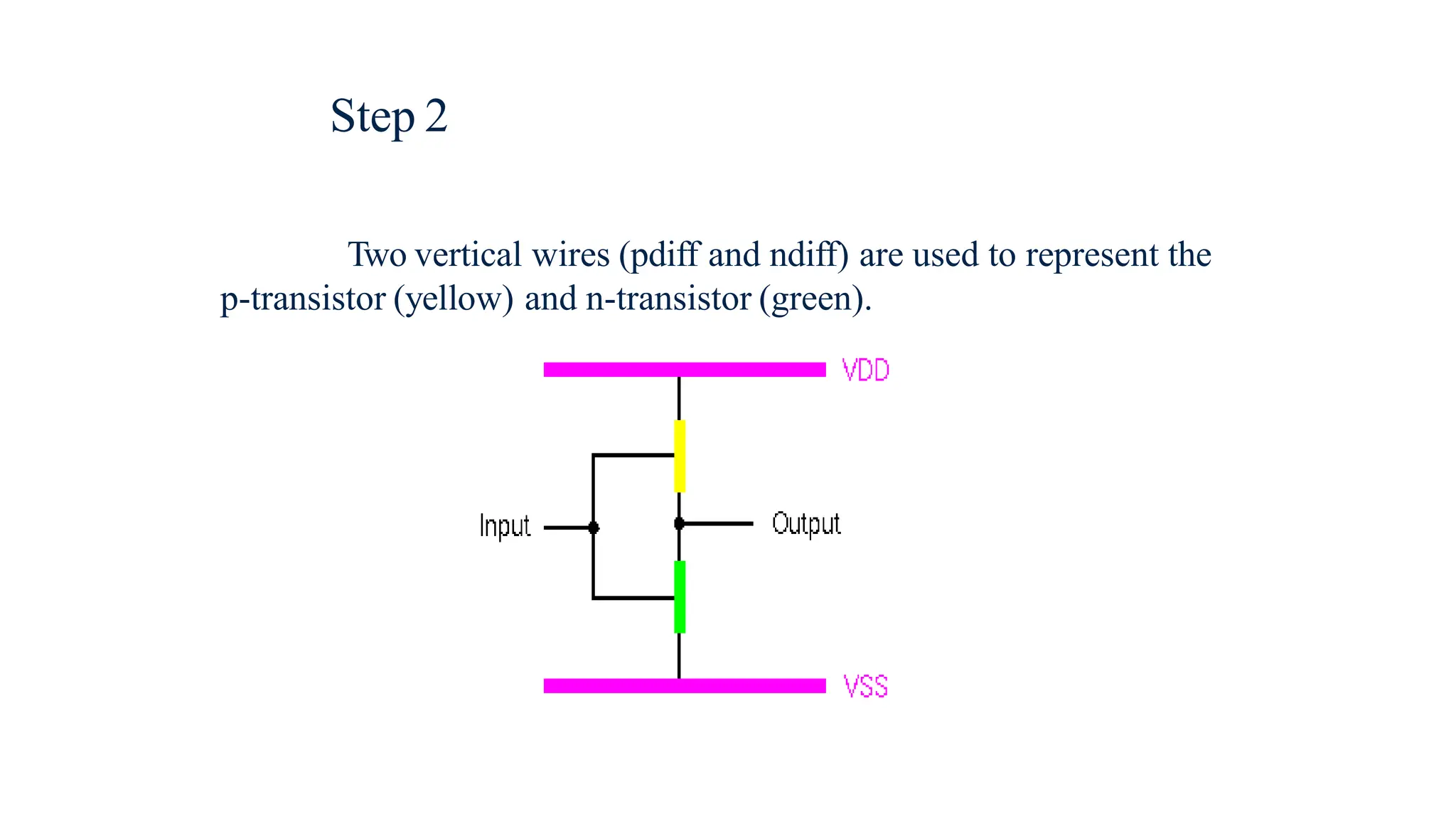

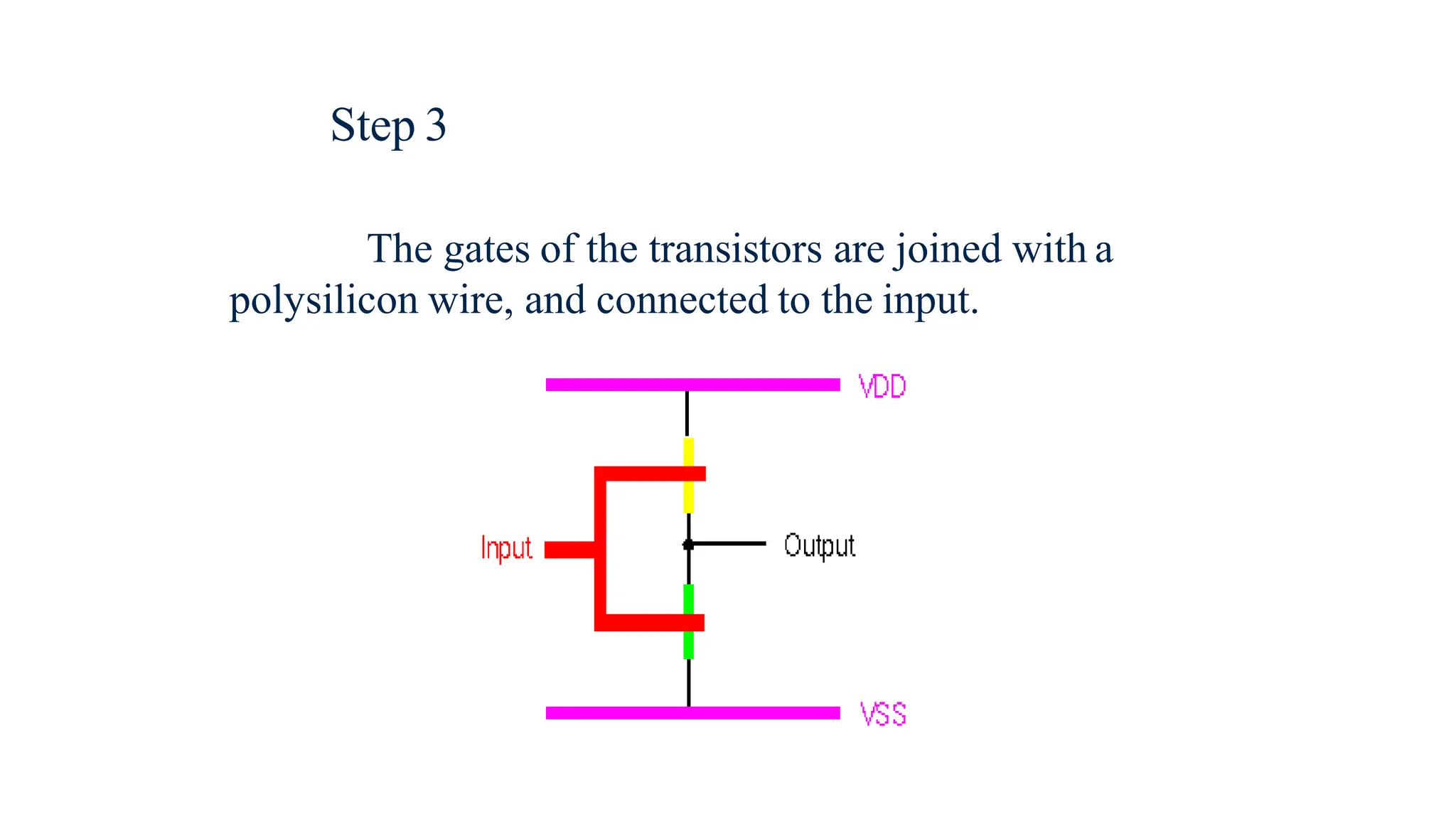

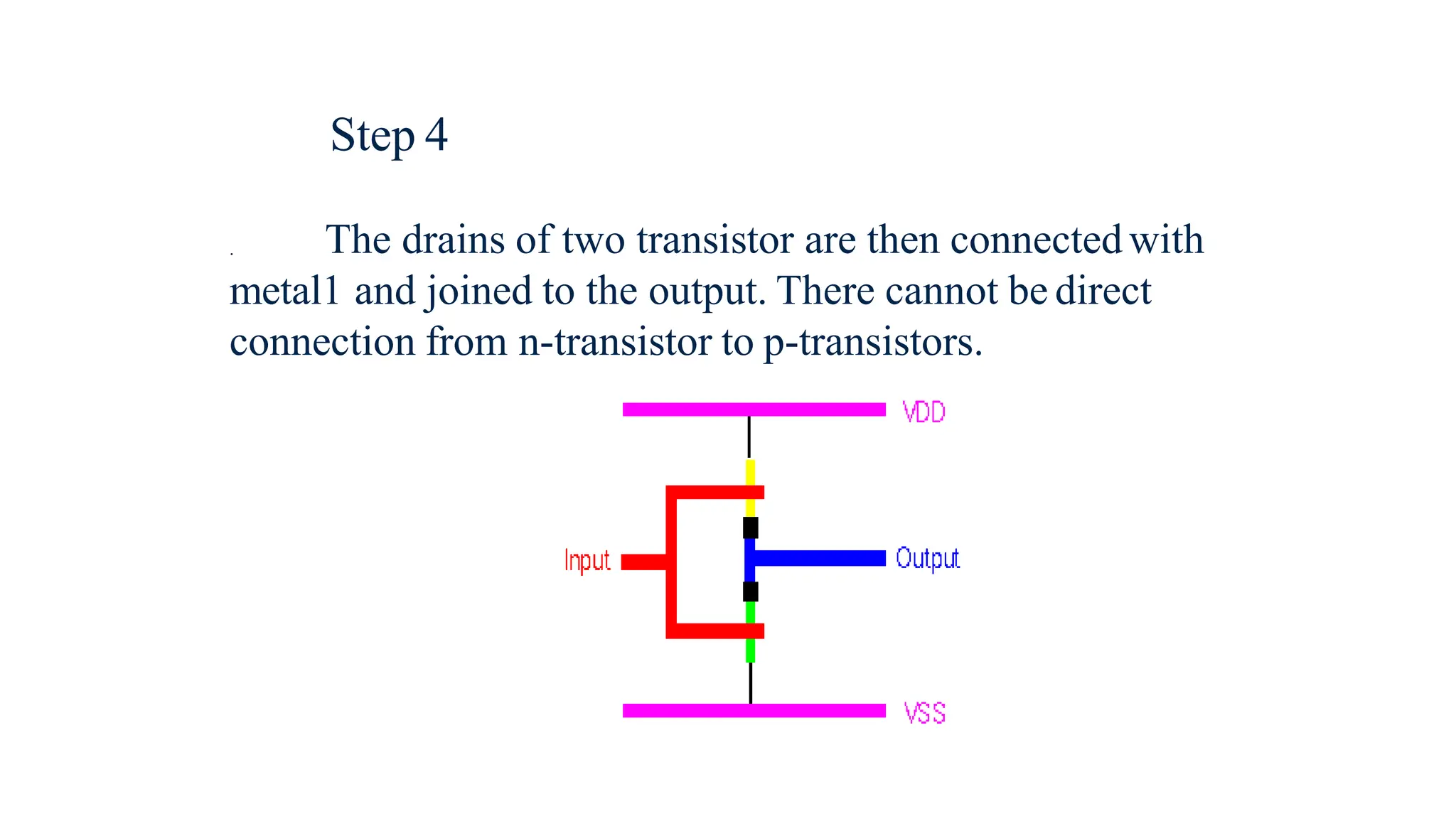

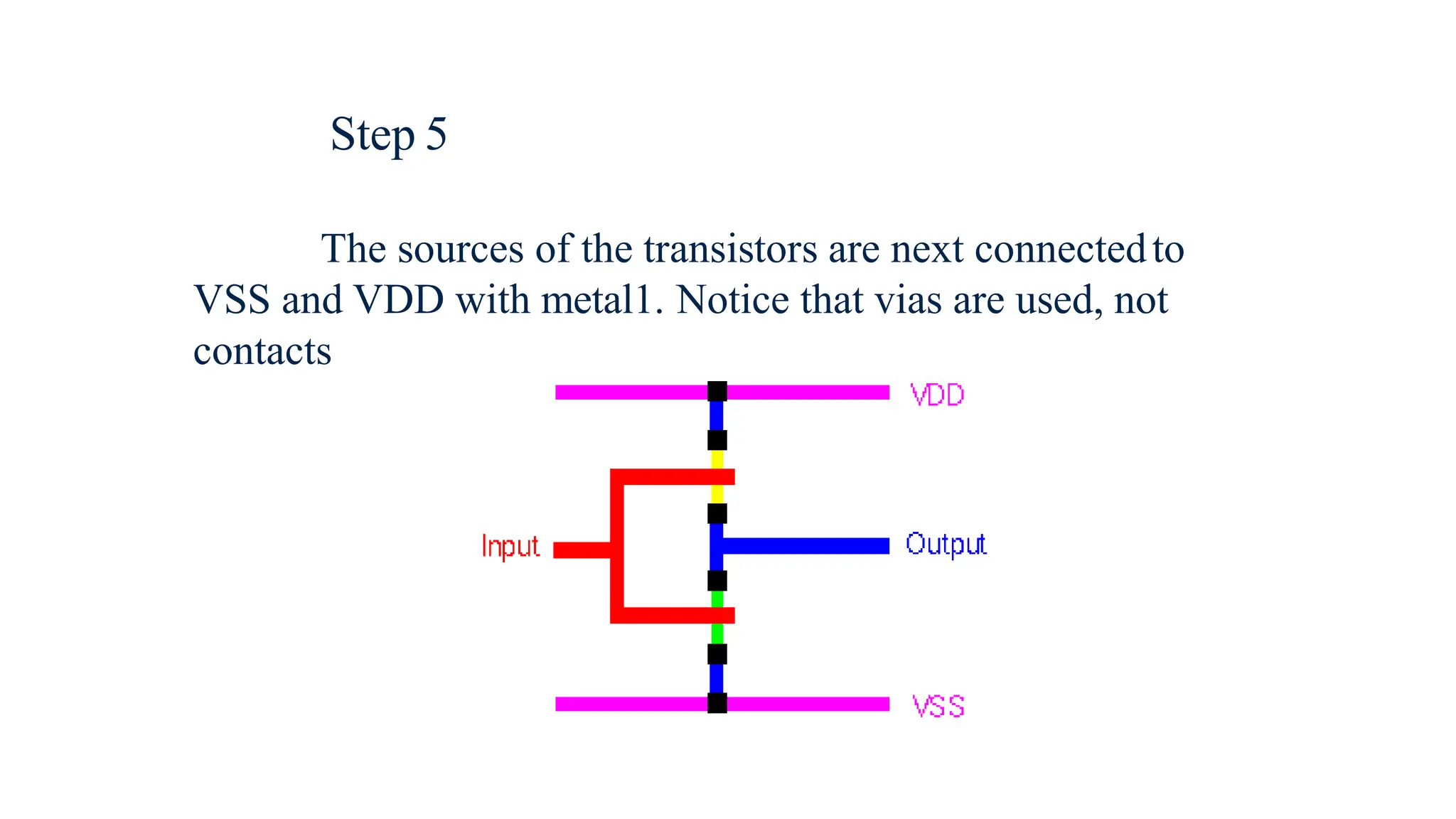

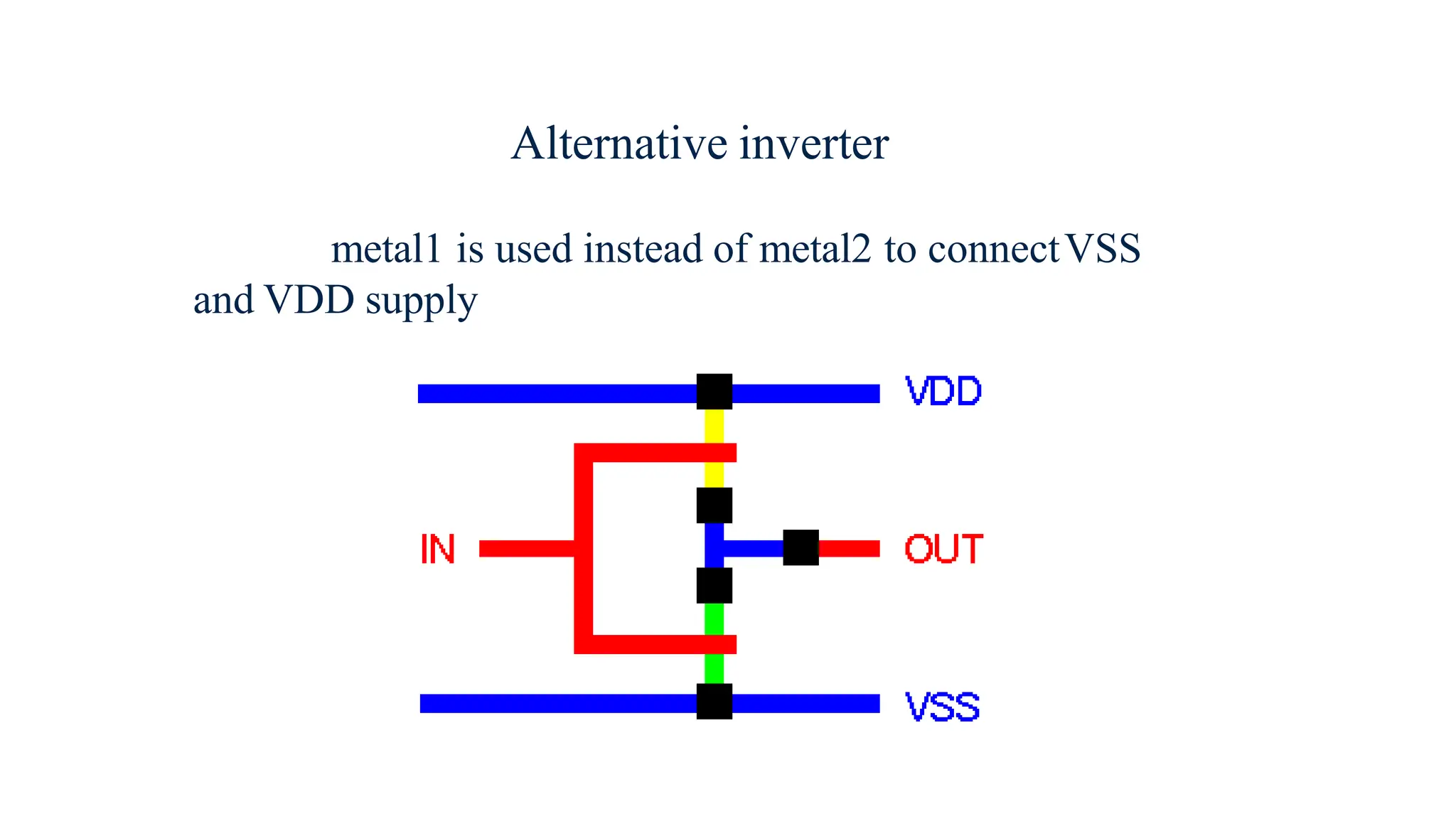

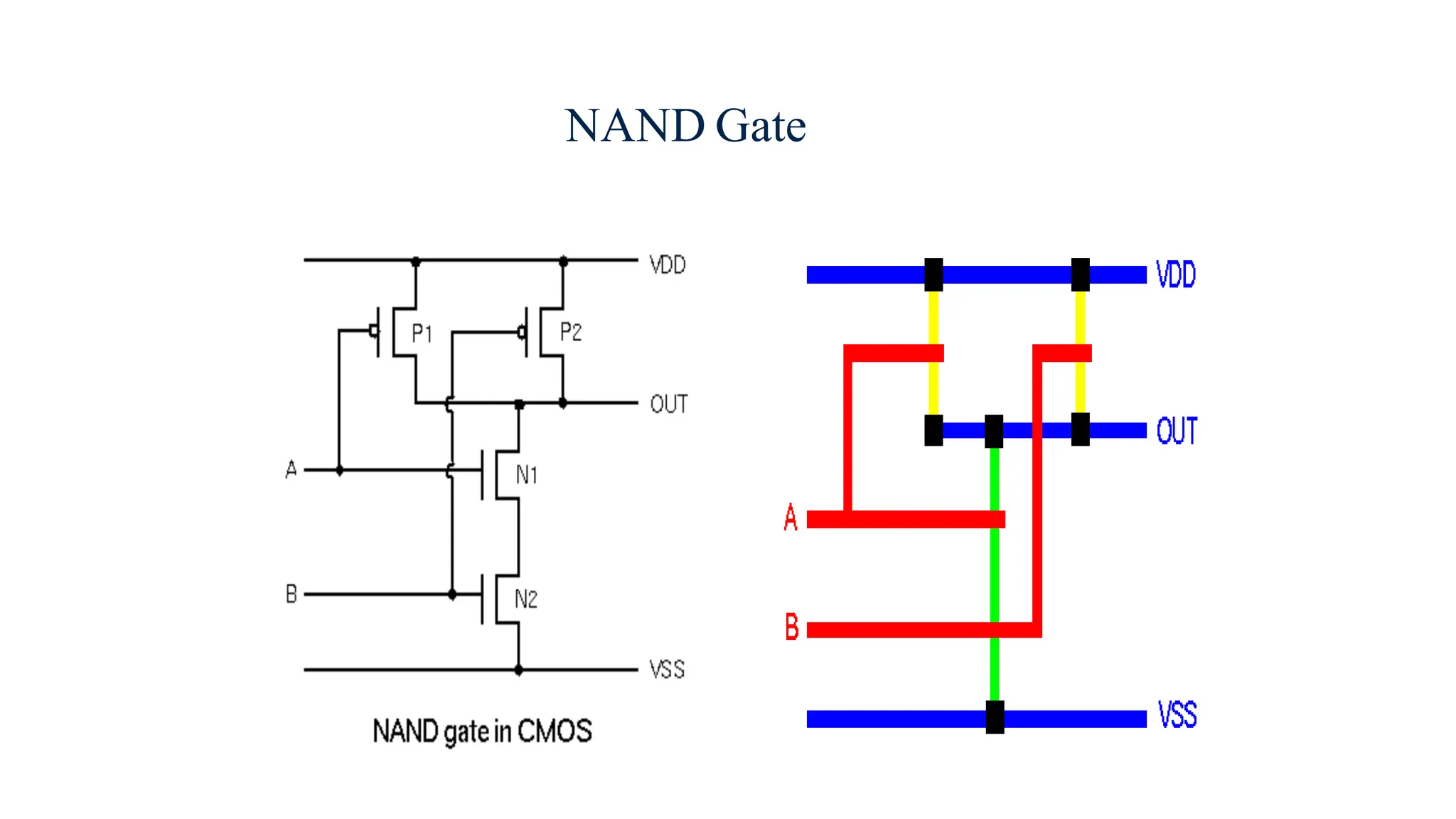

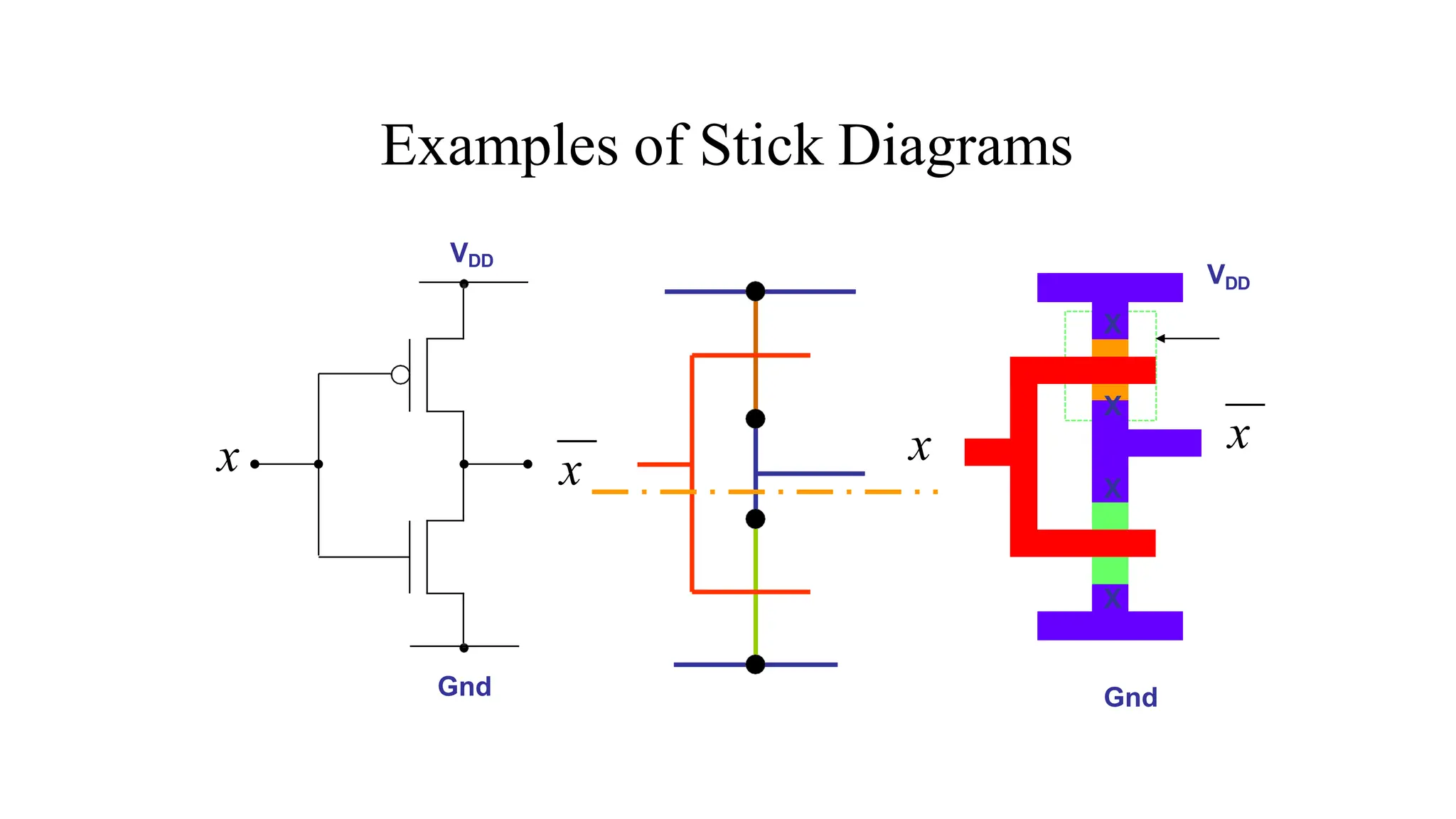

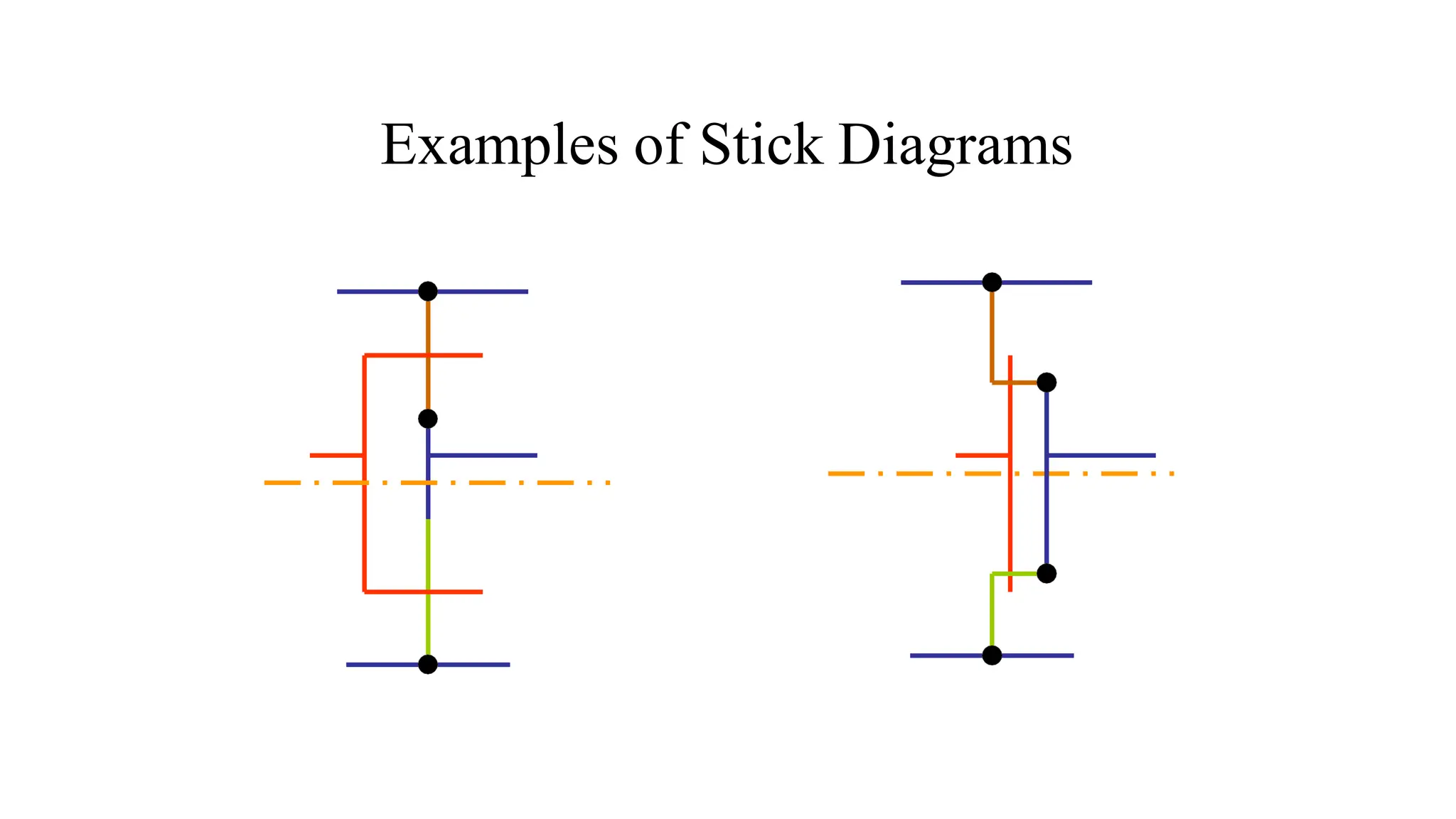

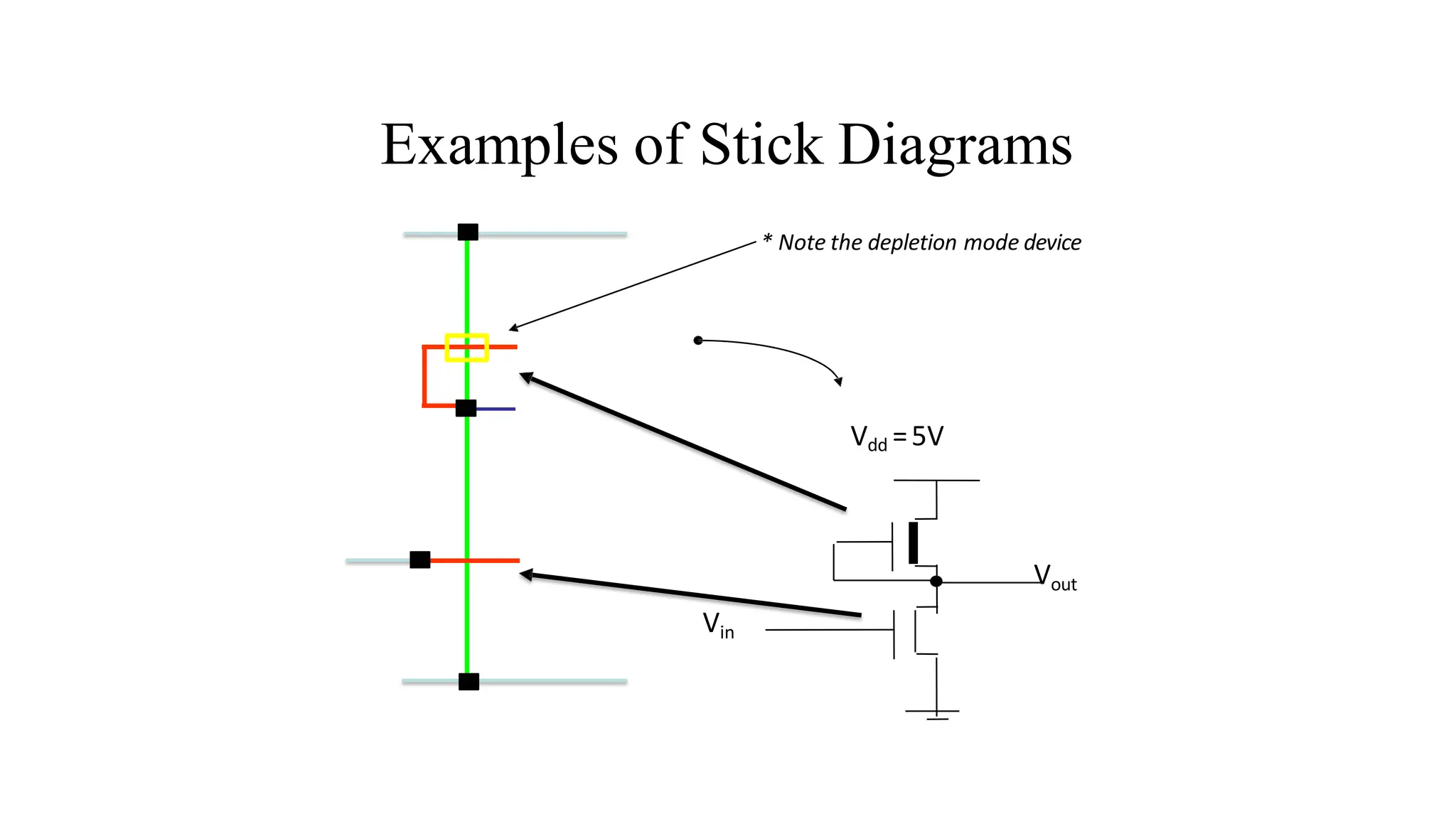

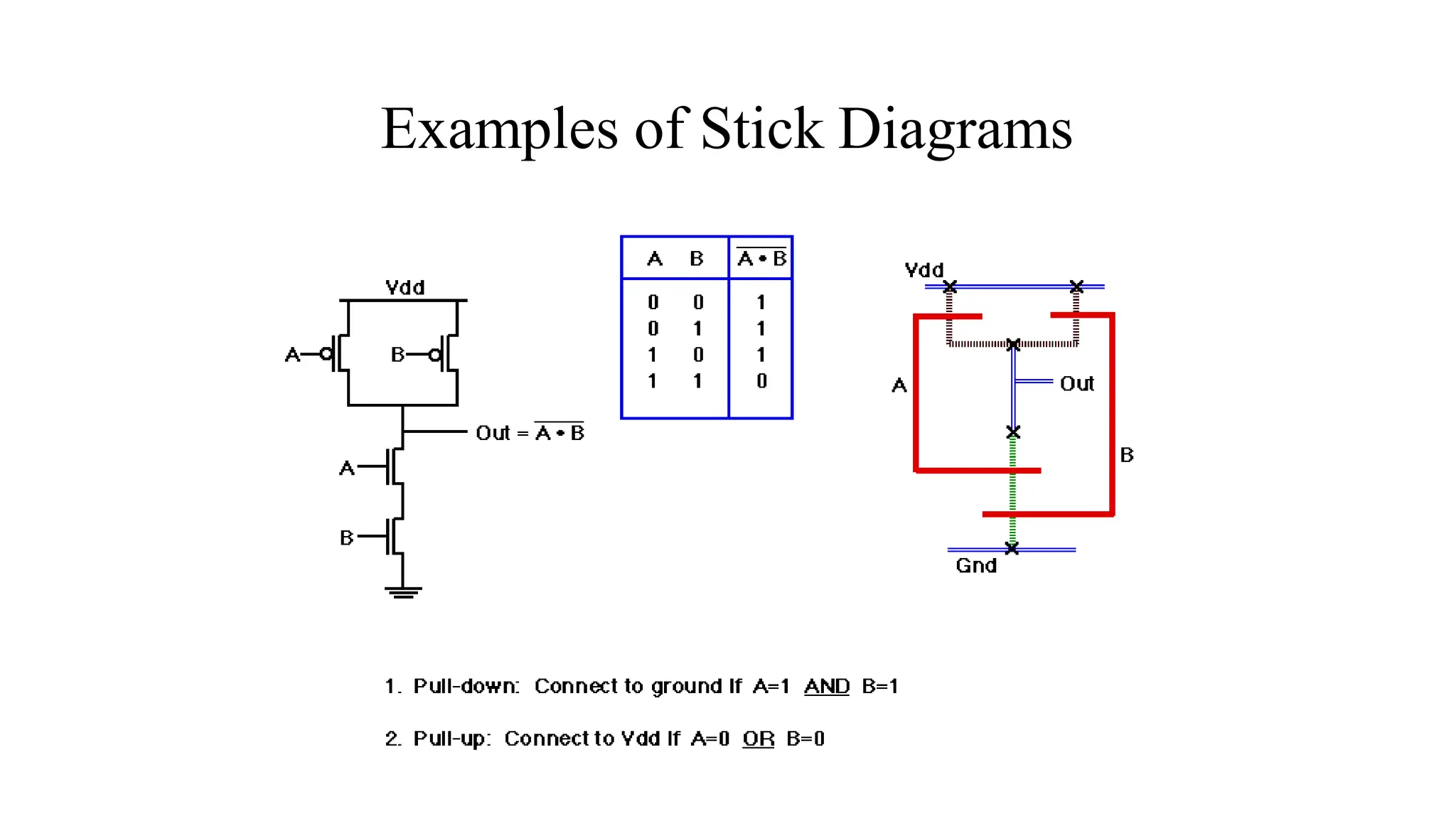

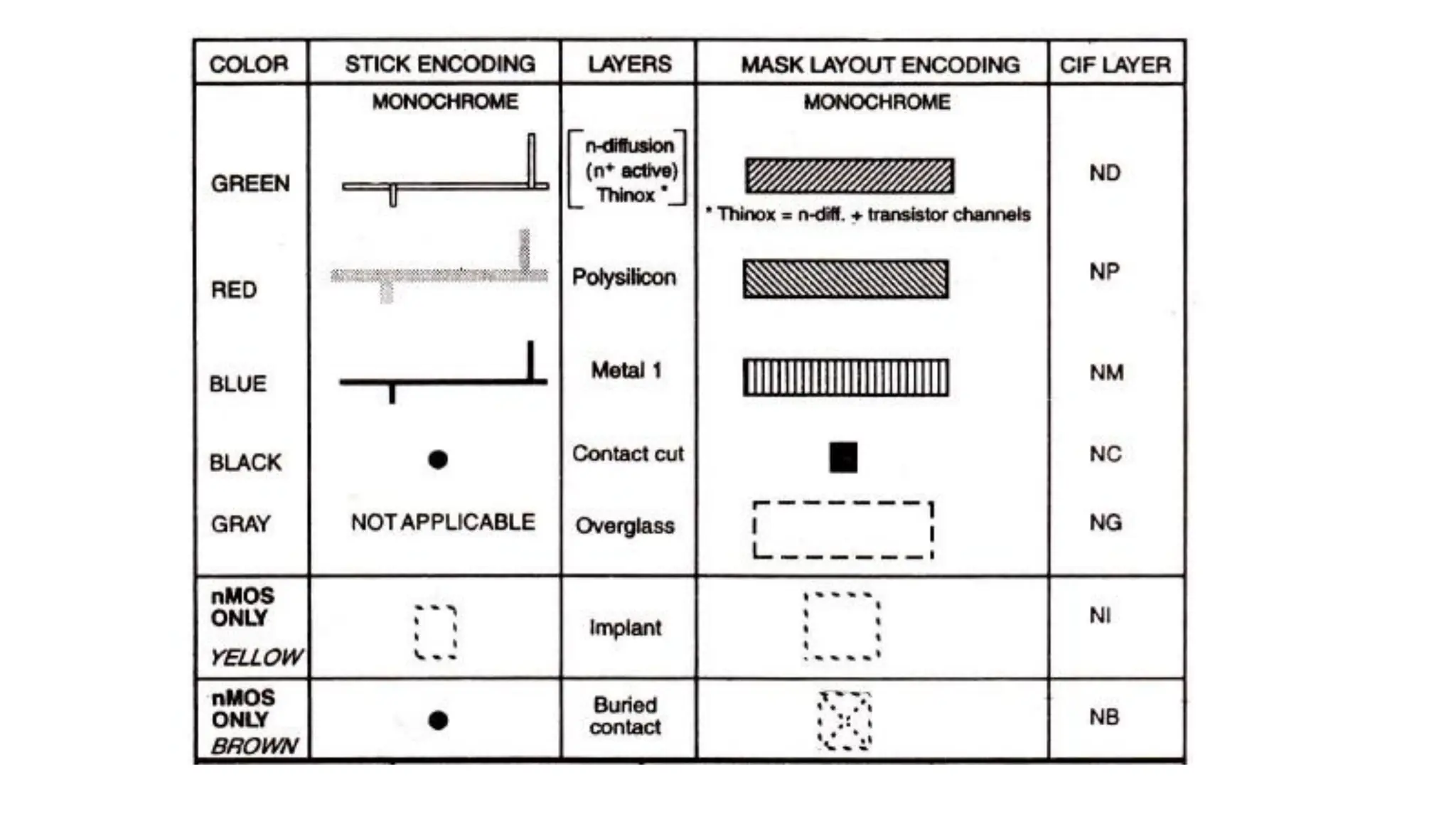

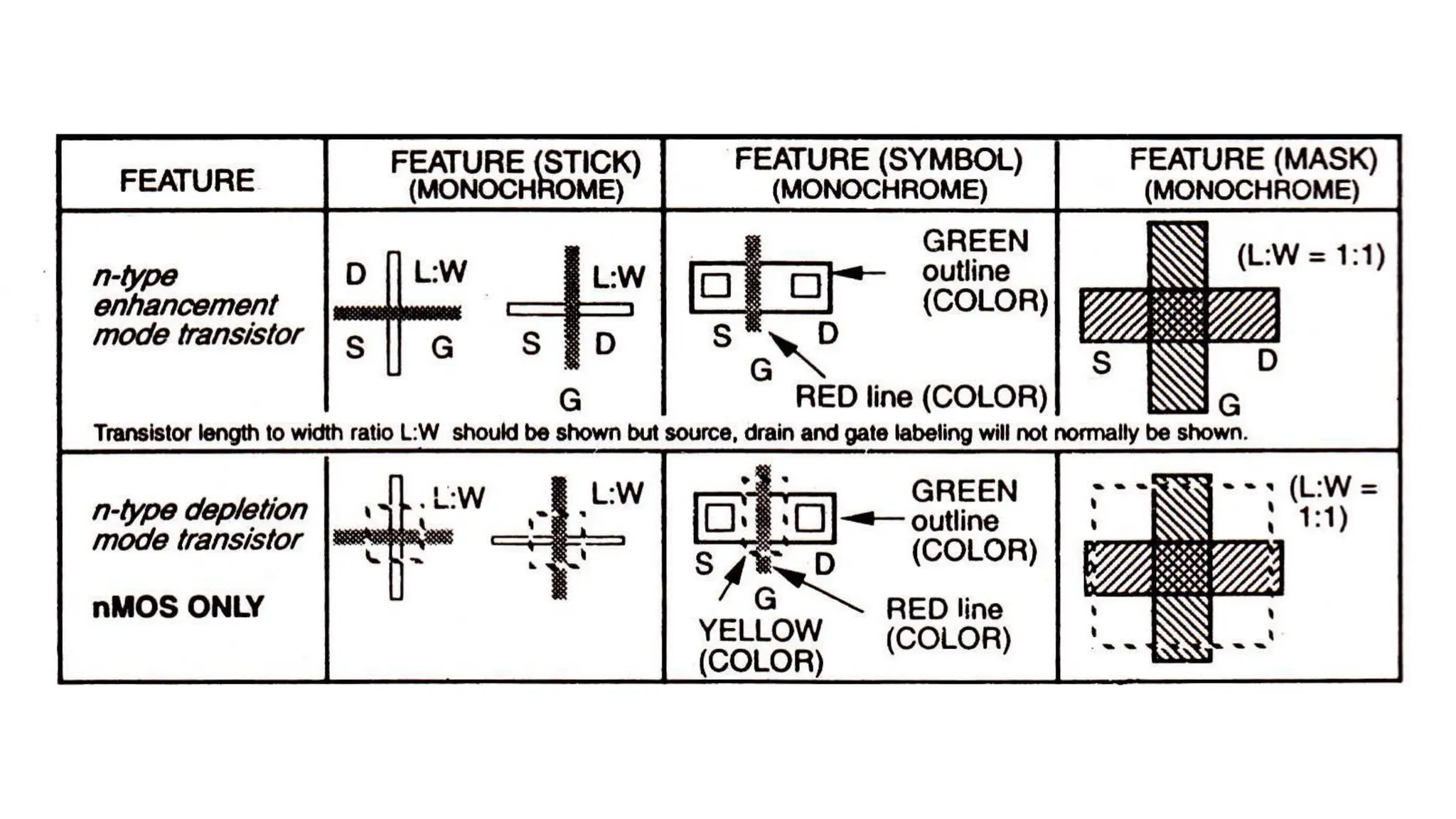

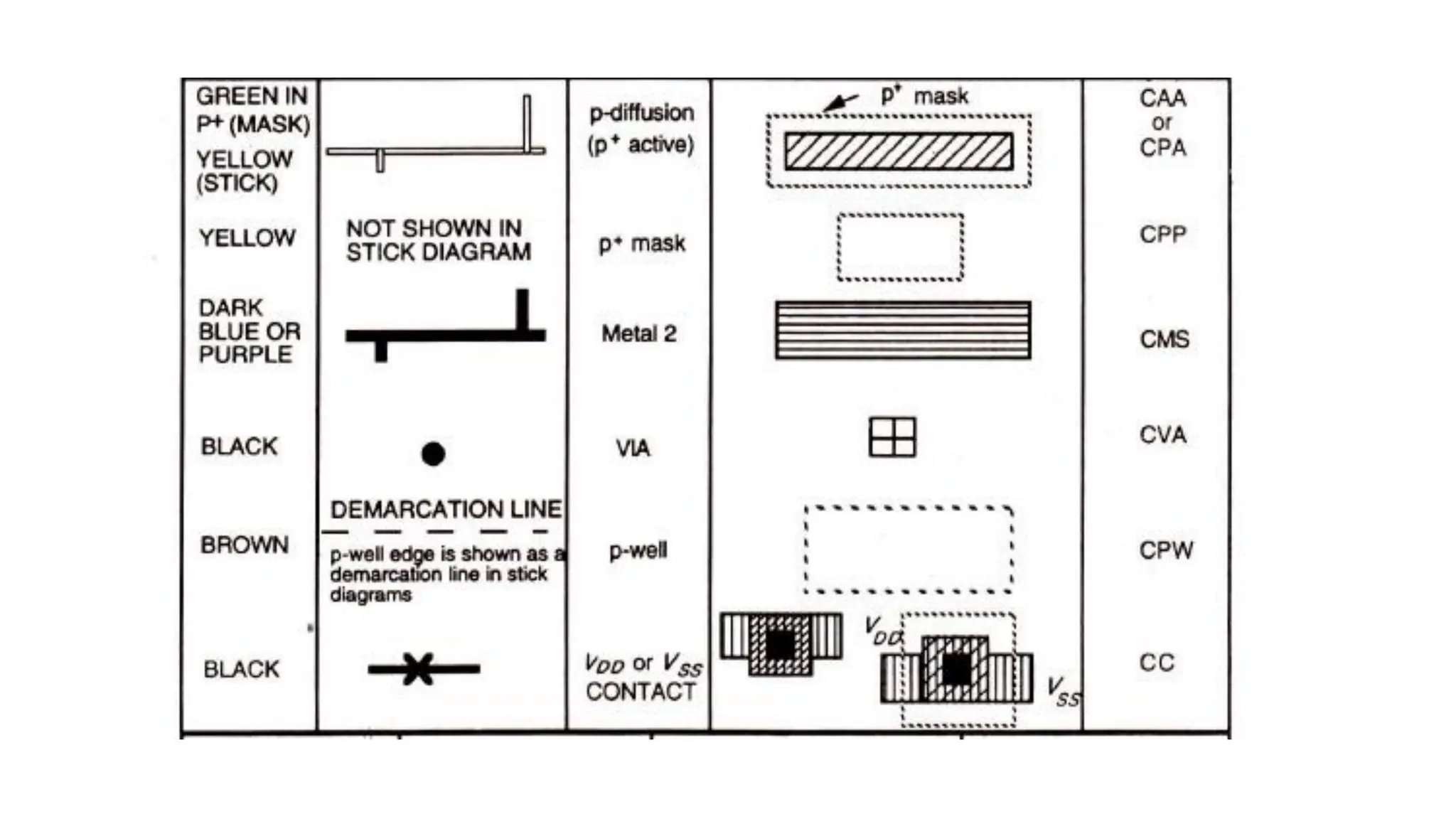

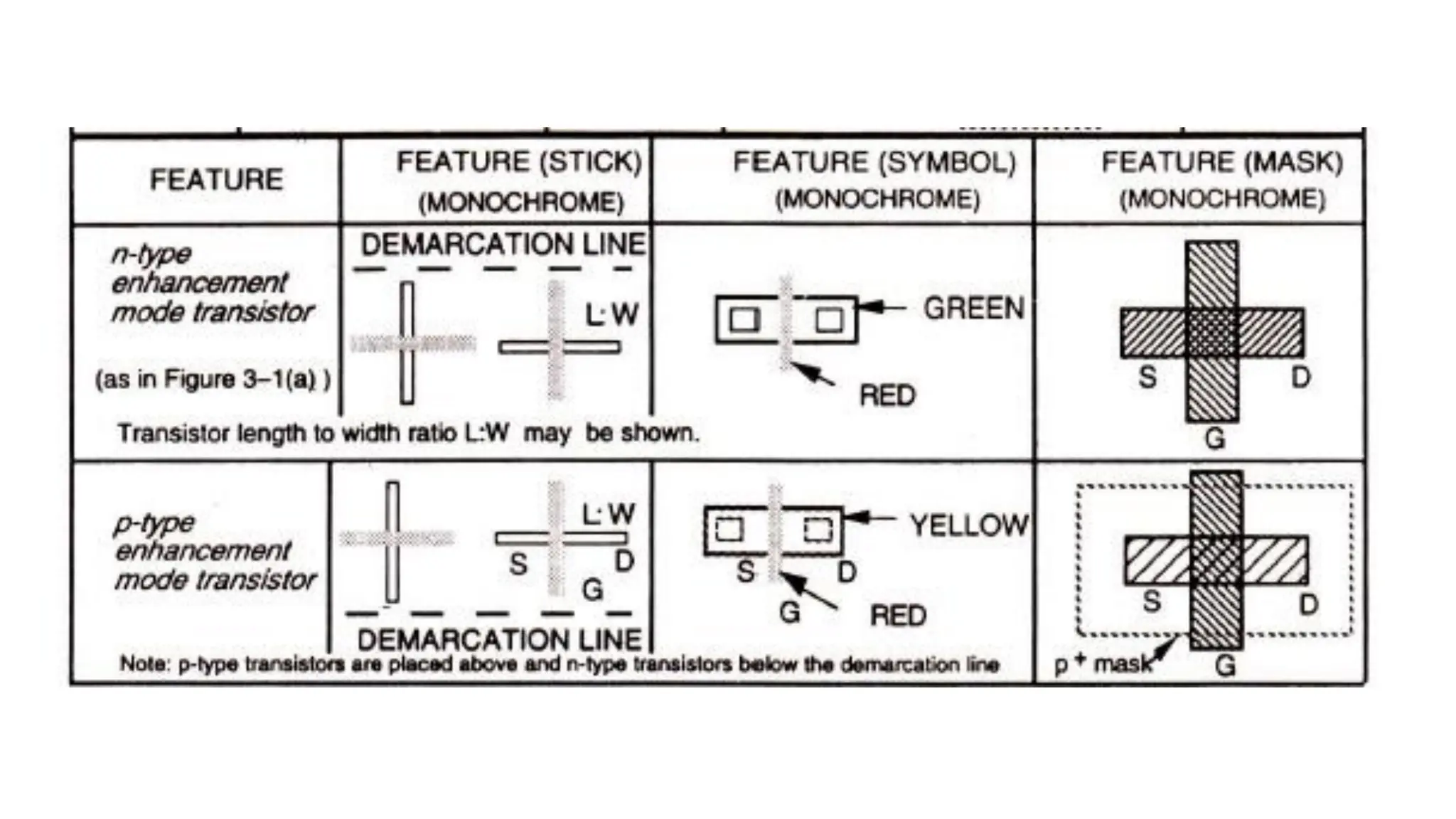

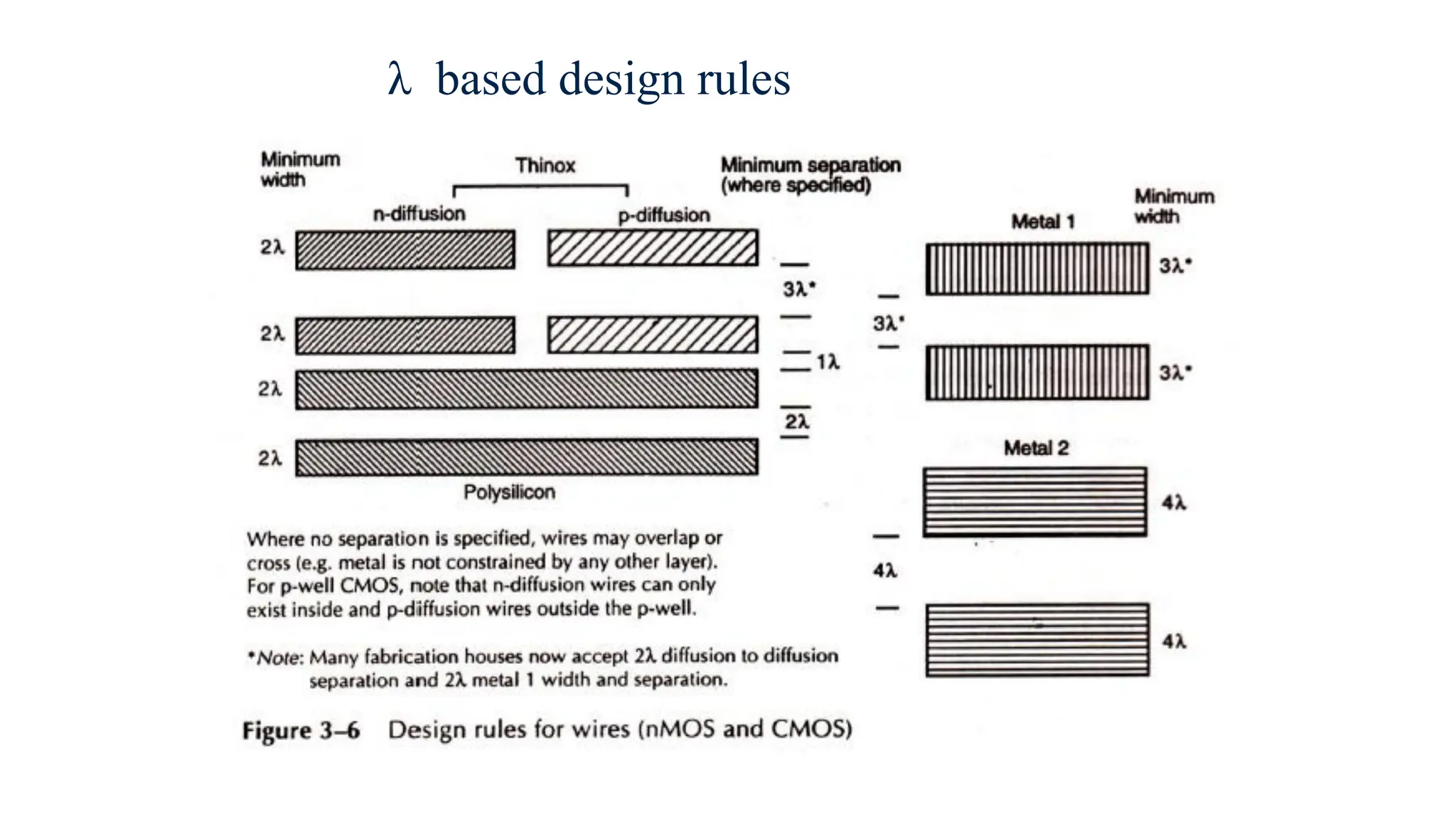

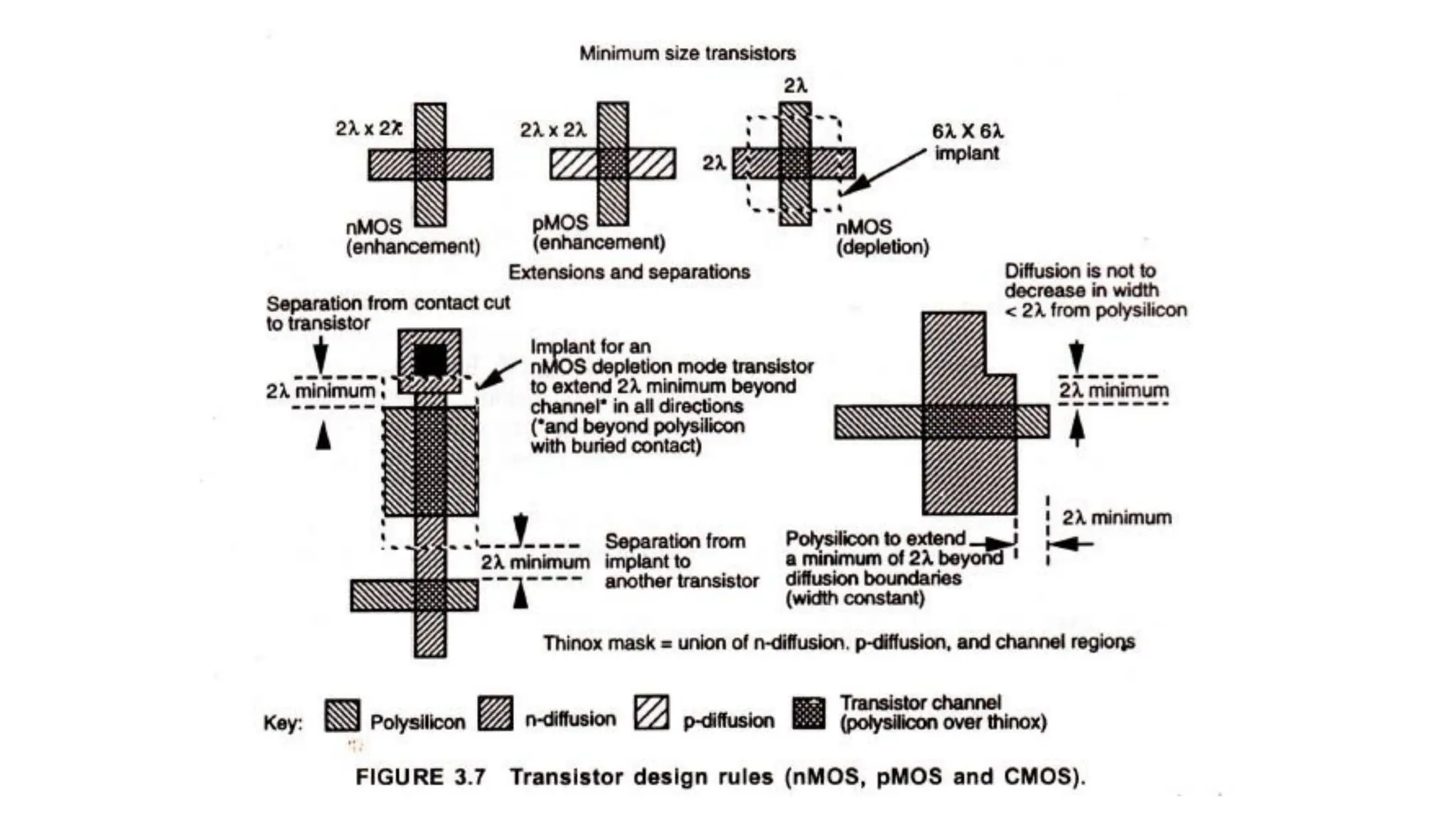

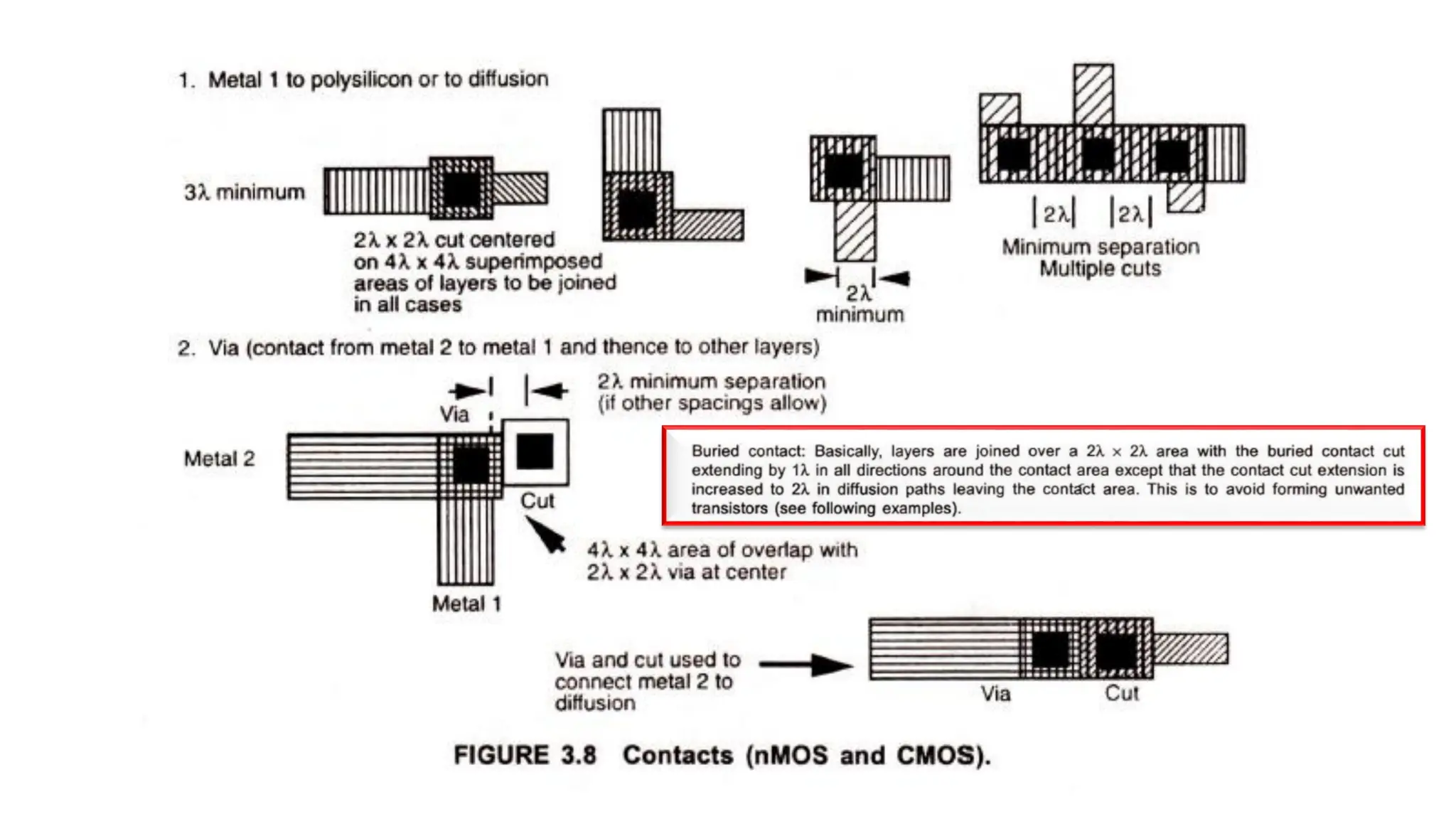

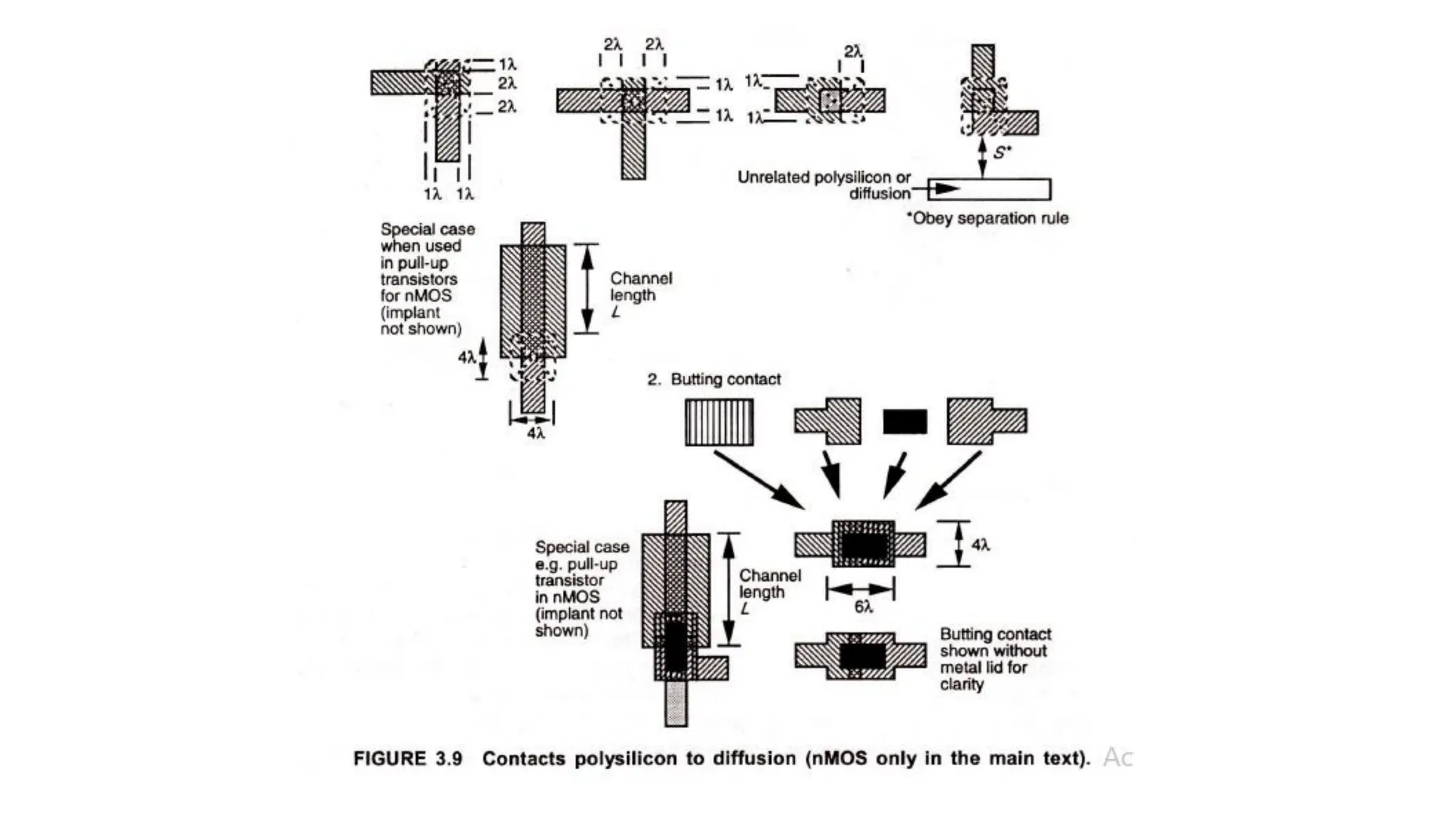

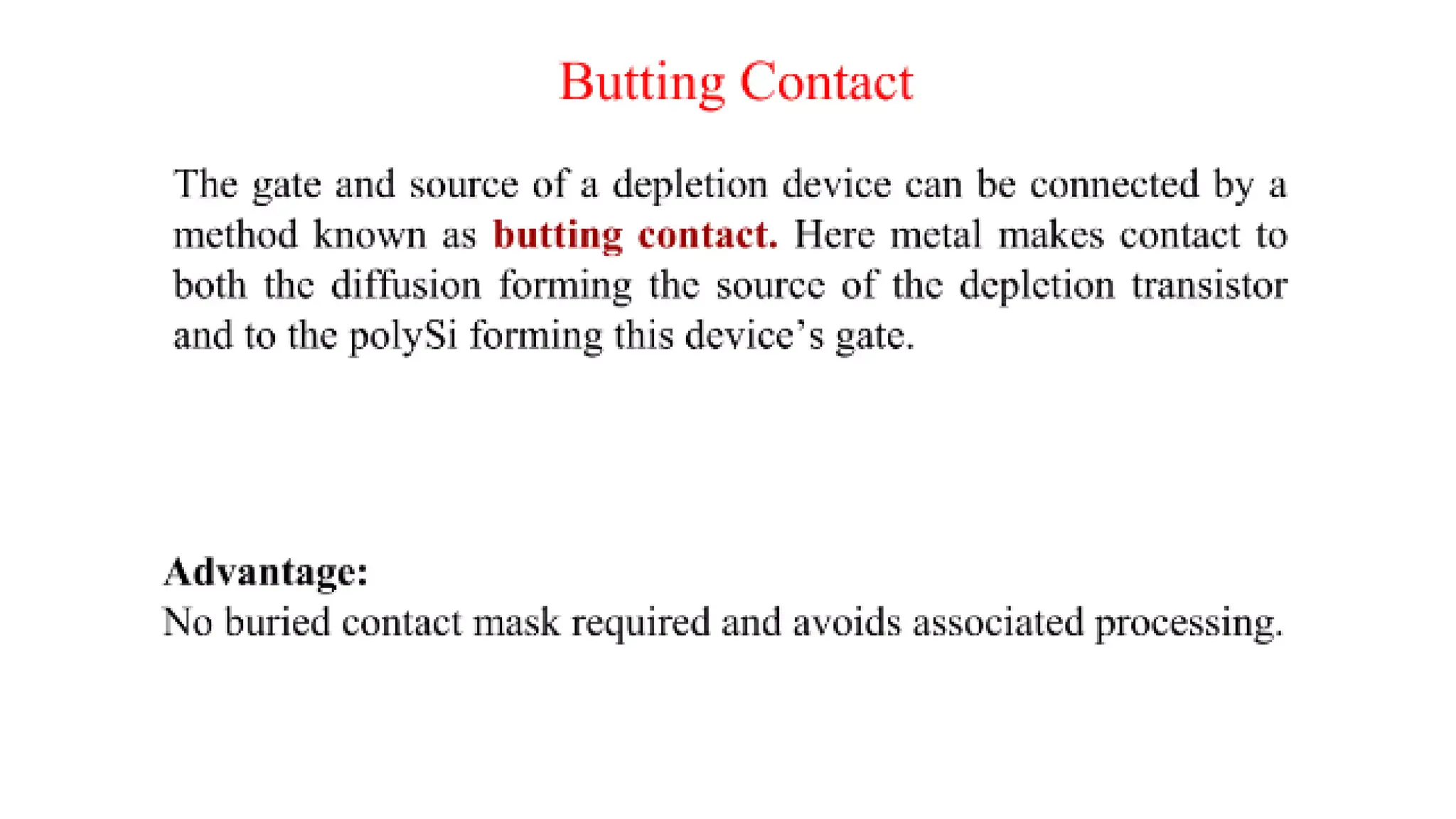

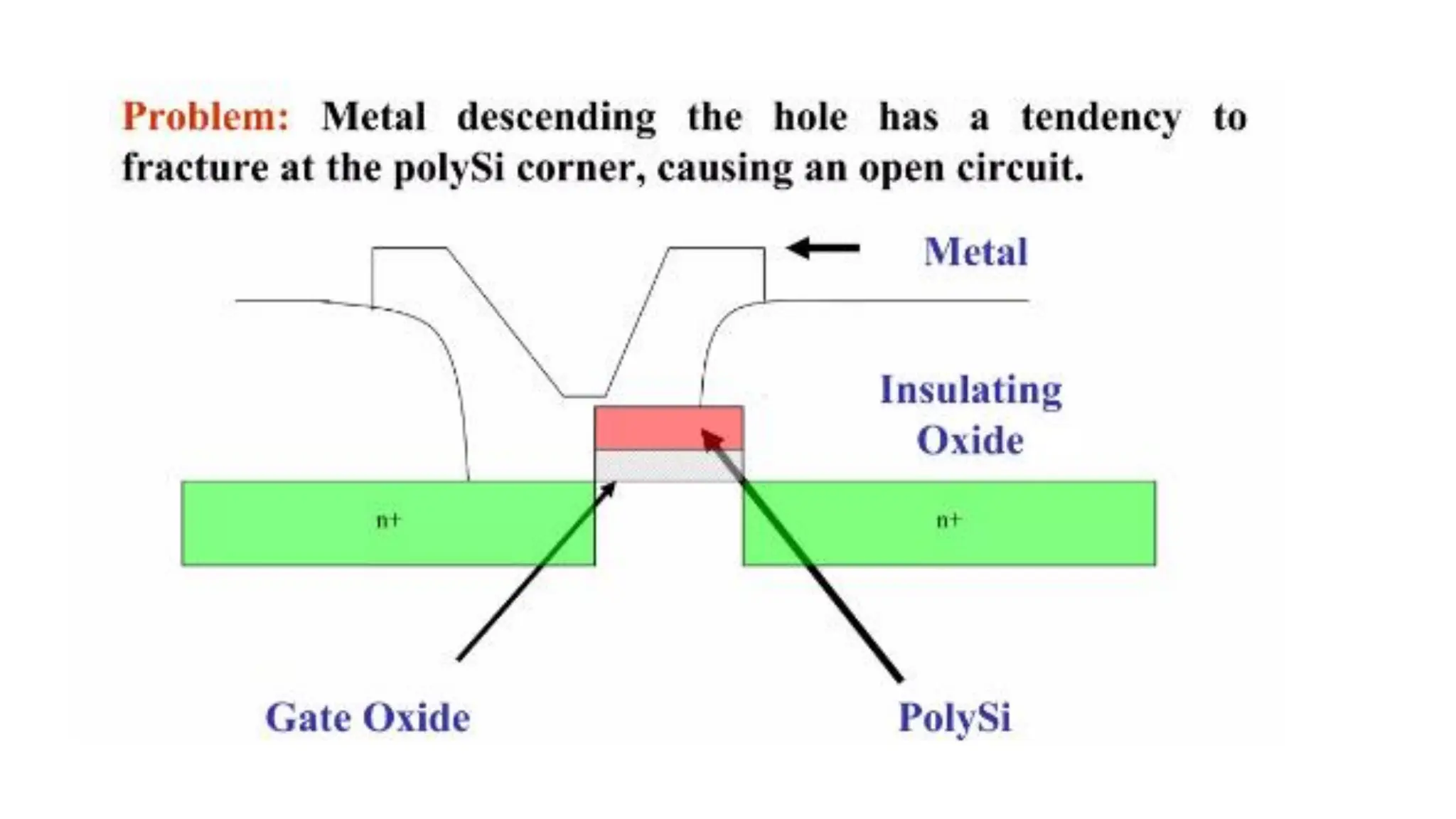

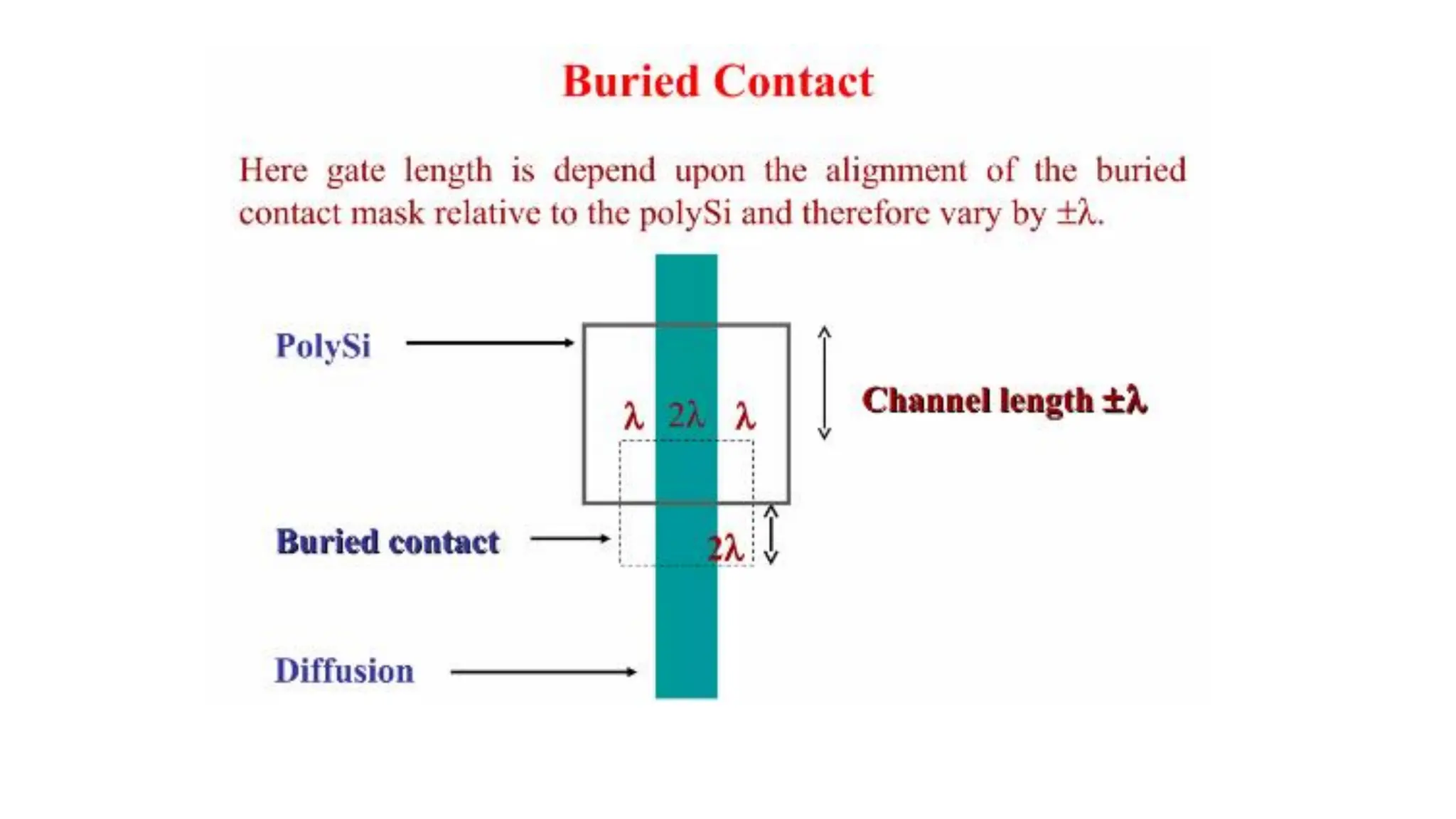

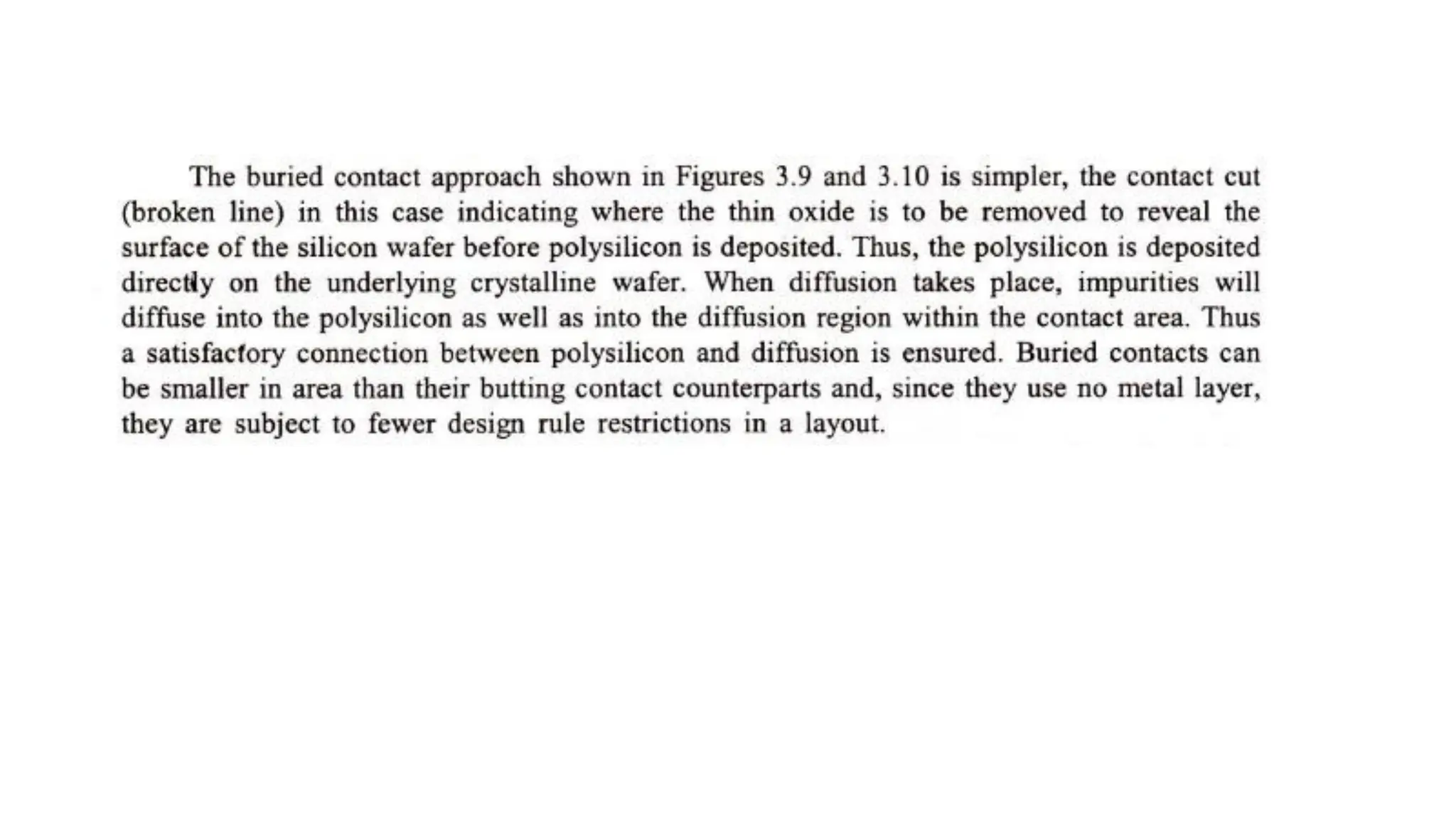

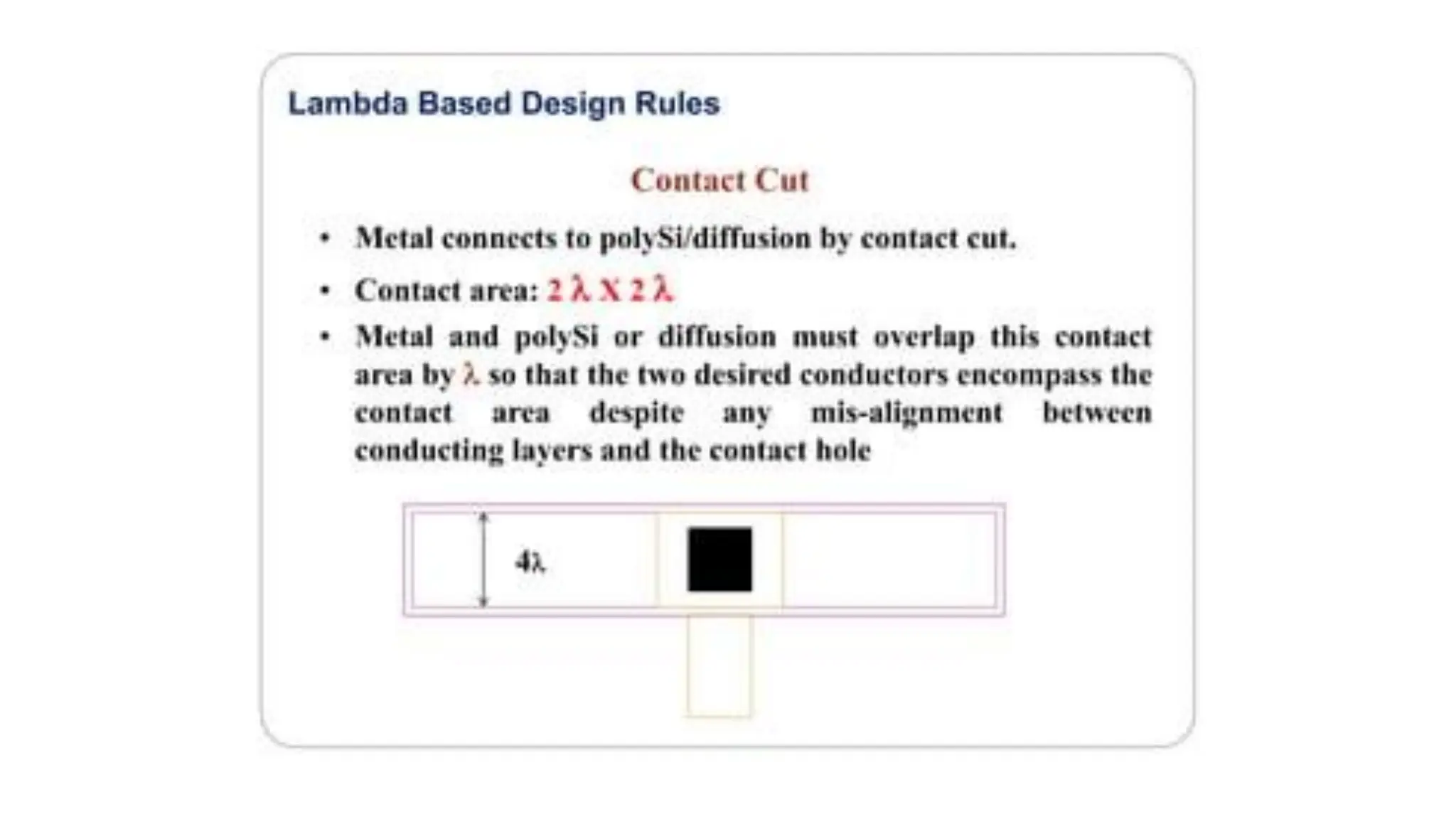

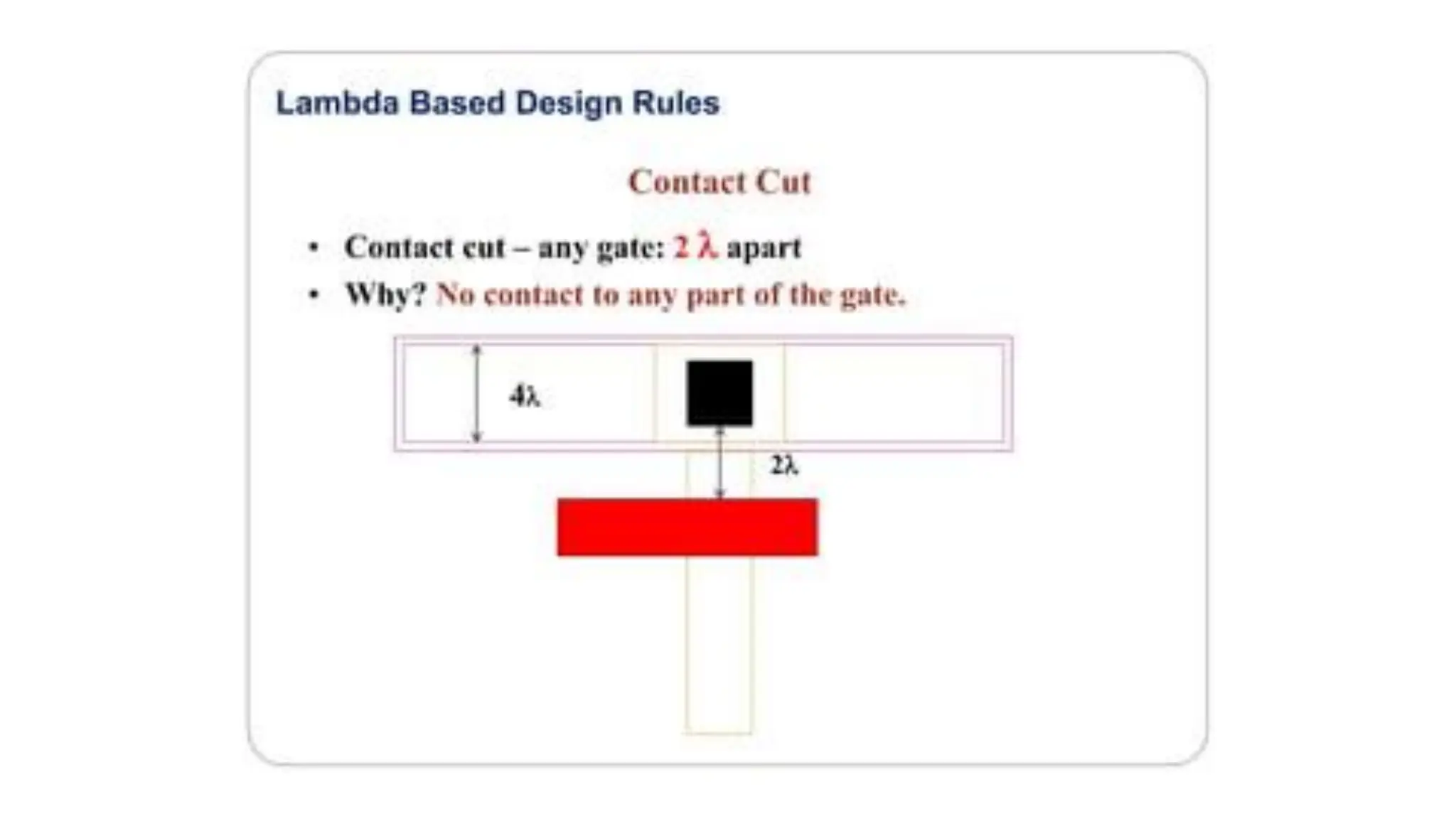

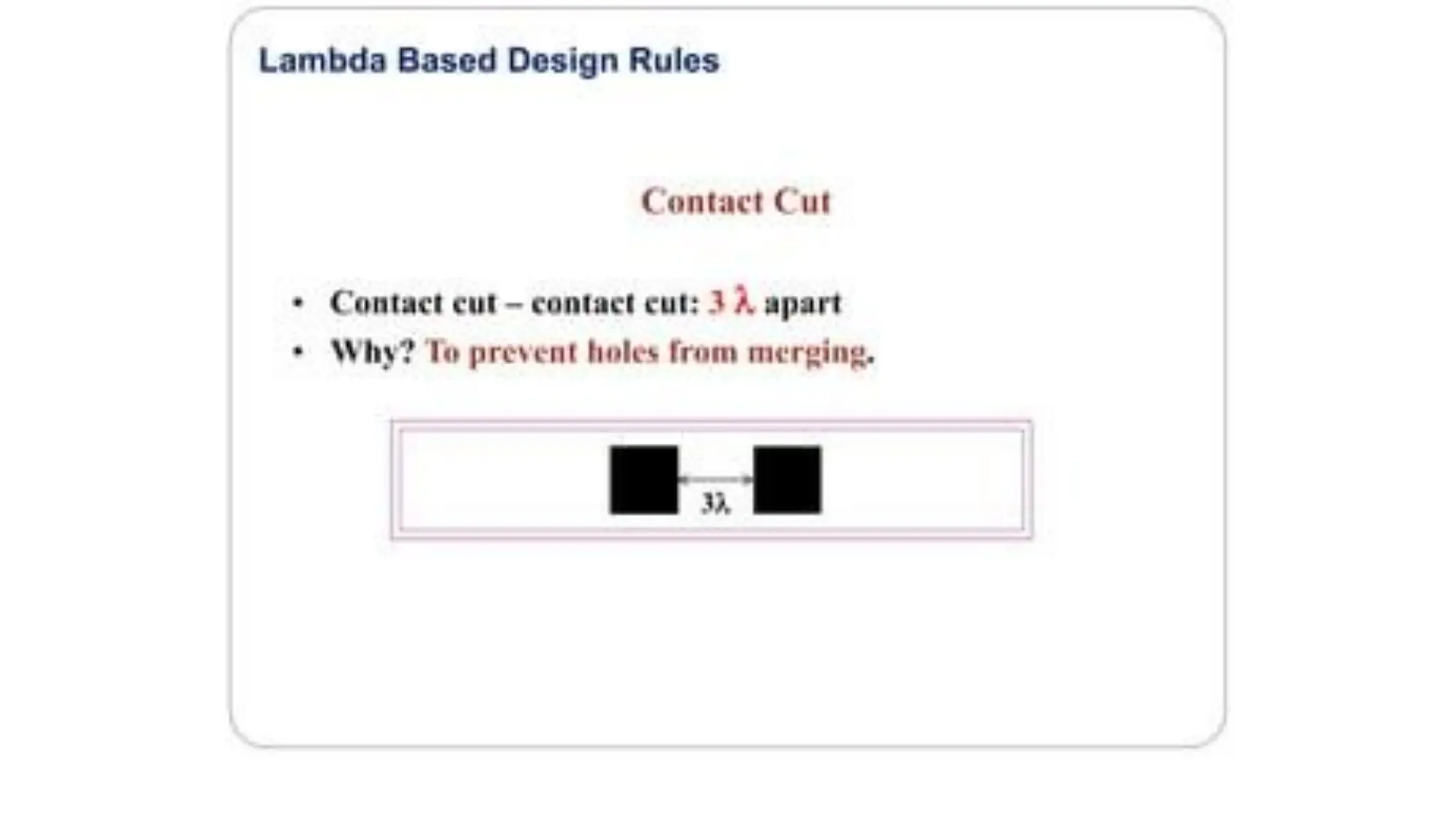

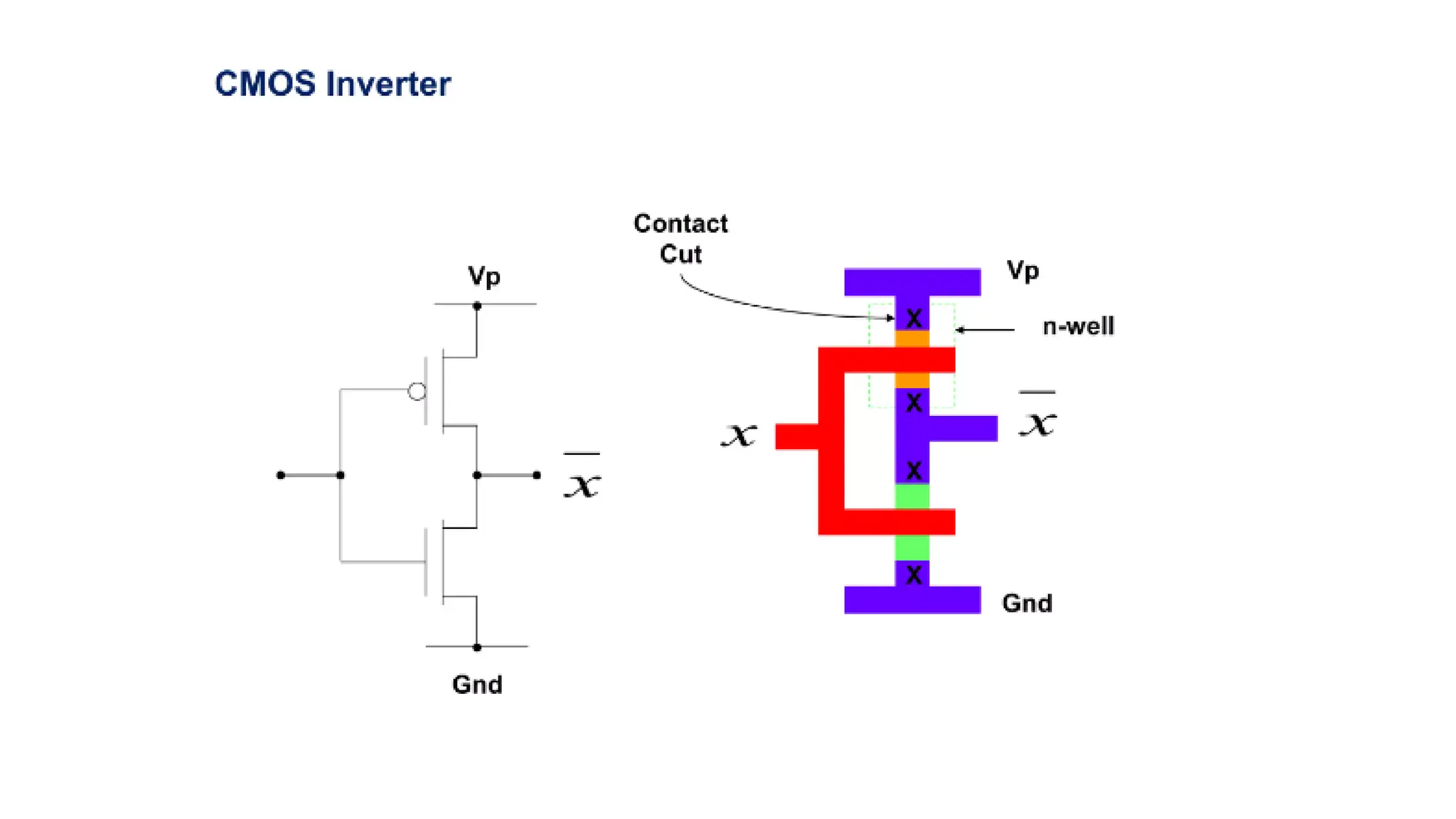

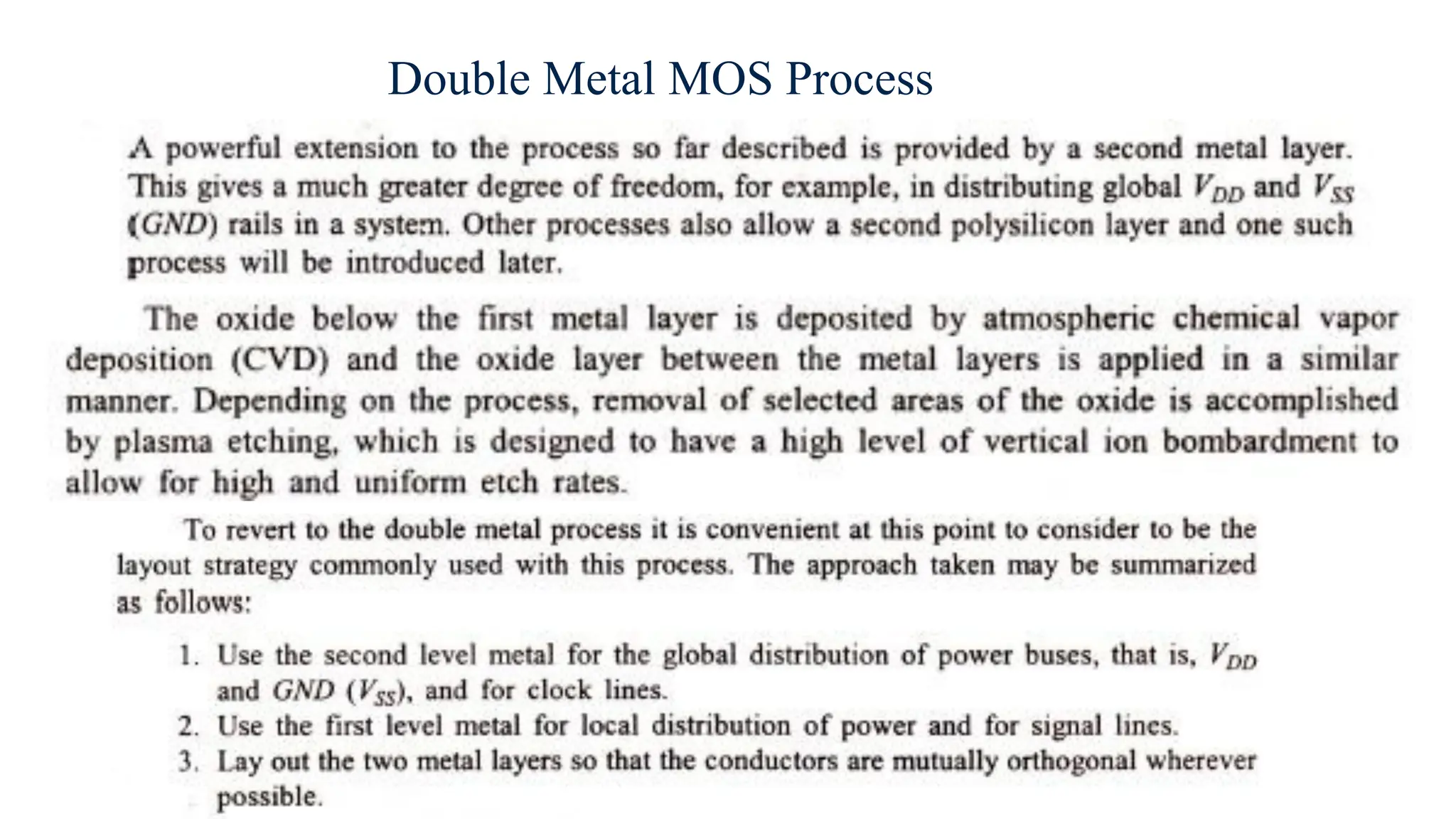

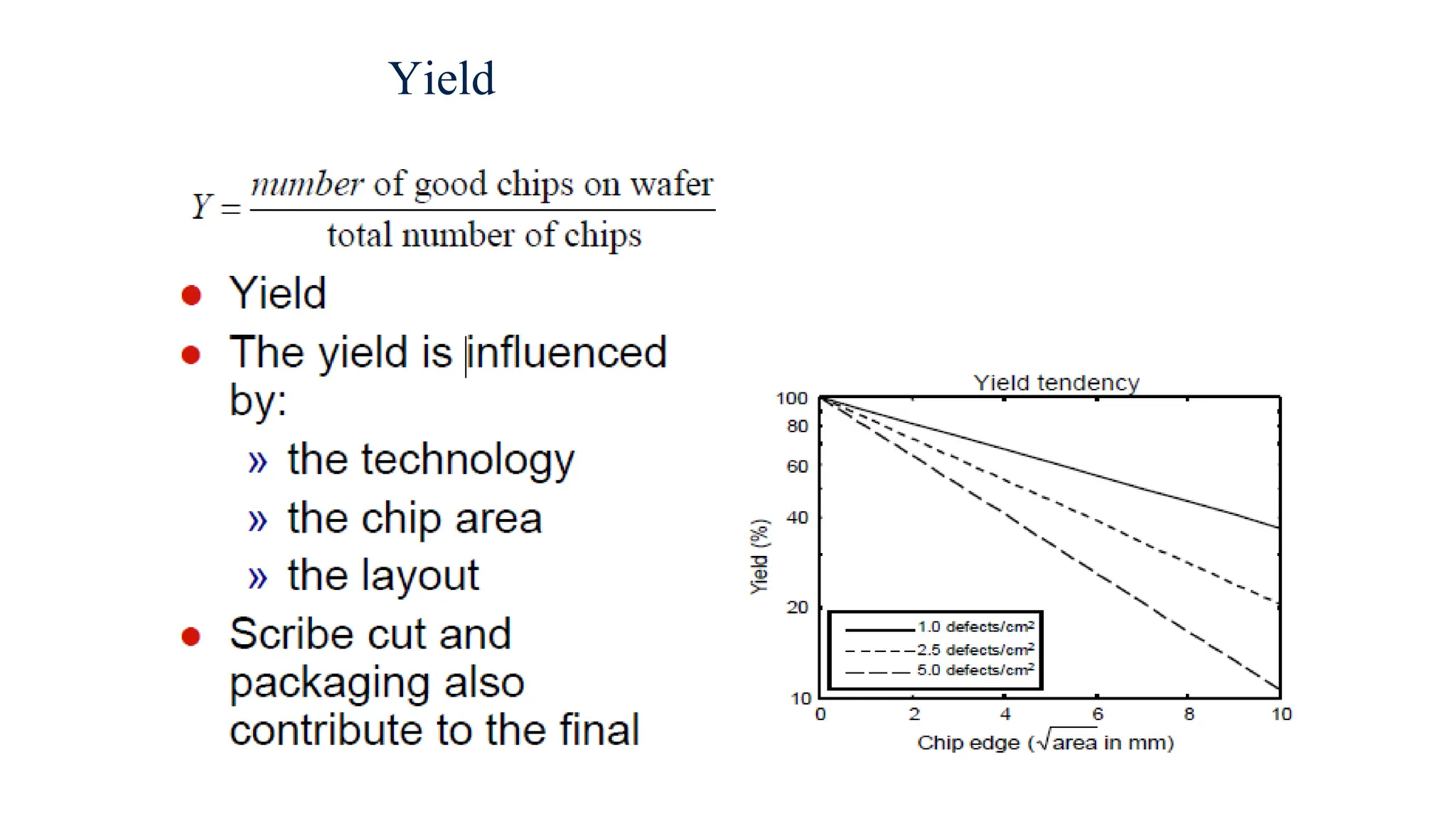

The document explains stick diagrams used in VLSI design, emphasizing their role in visually representing circuit layout and component relationships through color coding. It outlines the conventions and rules governing stick diagrams, such as representing electrical contacts and transistors, as well as providing design rules critical for ensuring functional circuit layouts. Additionally, it discusses the limitations of stick diagrams and the necessity of adhering to design guidelines for optimal yield and circuit reliability.