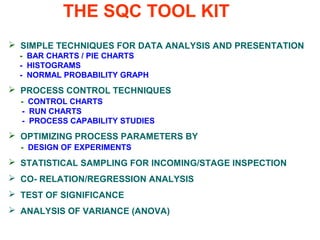

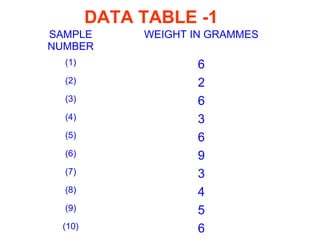

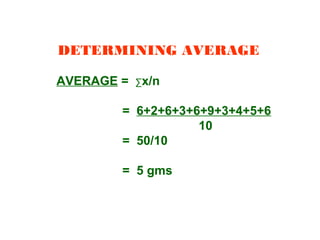

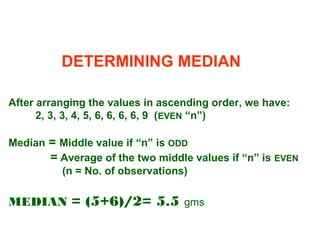

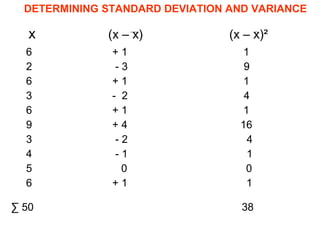

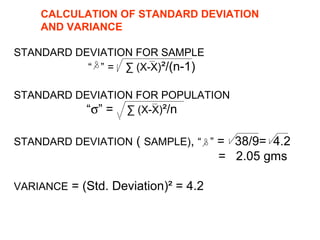

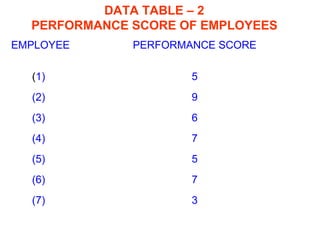

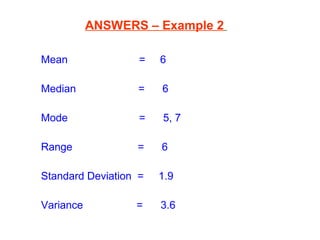

This document provides an overview of statistical quality control (SQC). It defines key SQC concepts like quality control, statistics, and the origins and development of SQC. The document also discusses the advantages of SQC and the basic SQC toolkit, which includes control charts, process capability studies, and statistical sampling techniques. Furthermore, it covers SQC basics such as different data types, measures of central tendency and dispersion, and the causes of variation in processes.