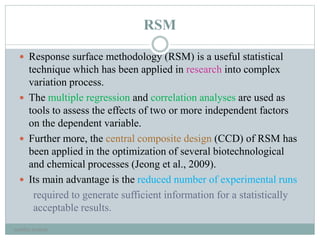

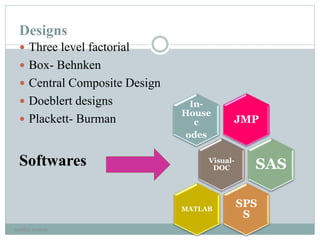

SPSS (Statistical Package for the Social Sciences) is software used for statistical analysis. It was first released in 1968 and was originally developed for analyzing social science data but is now used in other fields like health sciences and marketing. SPSS can perform a variety of statistical analyses like descriptive statistics, bivariate statistics, prediction analyses, and can present results graphically. It uses a four window interface of a data editor, output viewer, syntax editor, and script window. Users enter and manage data in the data editor which has both a data view and variable view. SPSS is useful for summarizing, exploring, and testing hypotheses with data.

![RESULT

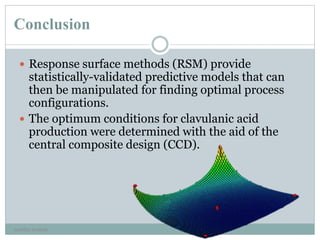

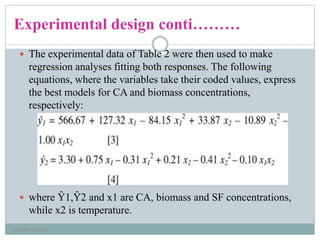

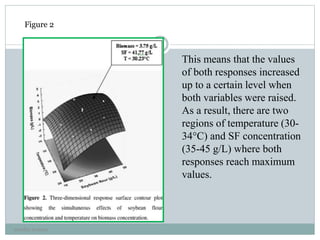

Simultaneous regression by eqs. [3] and [4] provided maximum

predicted values of CA concentration (640 mg/L) at 33.0 °C and

SF = 37.5 g/L, and of biomass concentration (3.75 g/L) at 30.2 °C

and SF = 41.77 g/L, respectively. These predicted values are only

1.7 % higher and 3.8% lower than the experimental ones, thus

demonstrating the validity of the models employed.

neethu asokan](https://image.slidesharecdn.com/spssrsm-copy-191204192814/85/Spss-amp-rsm-copy-35-320.jpg)