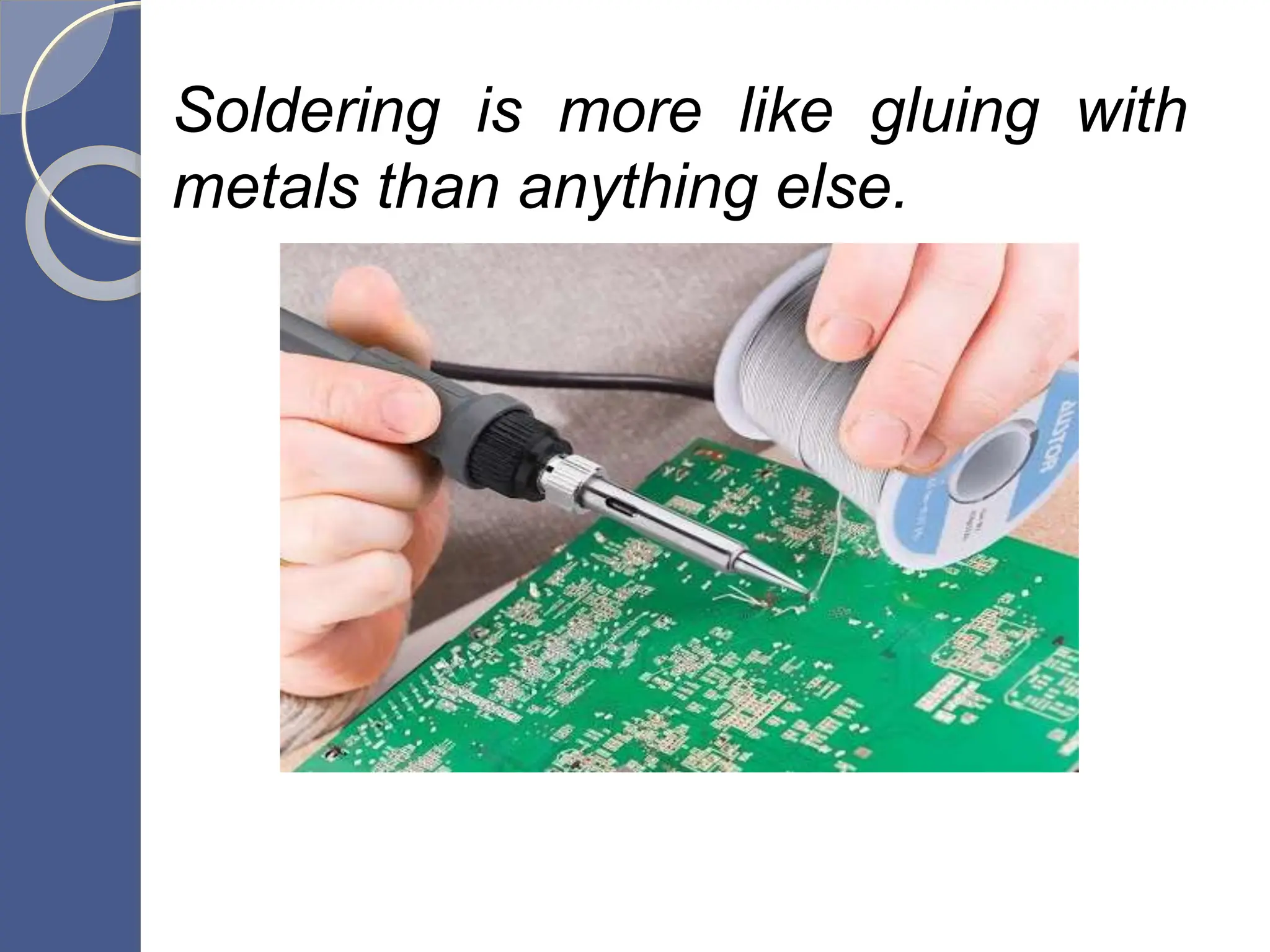

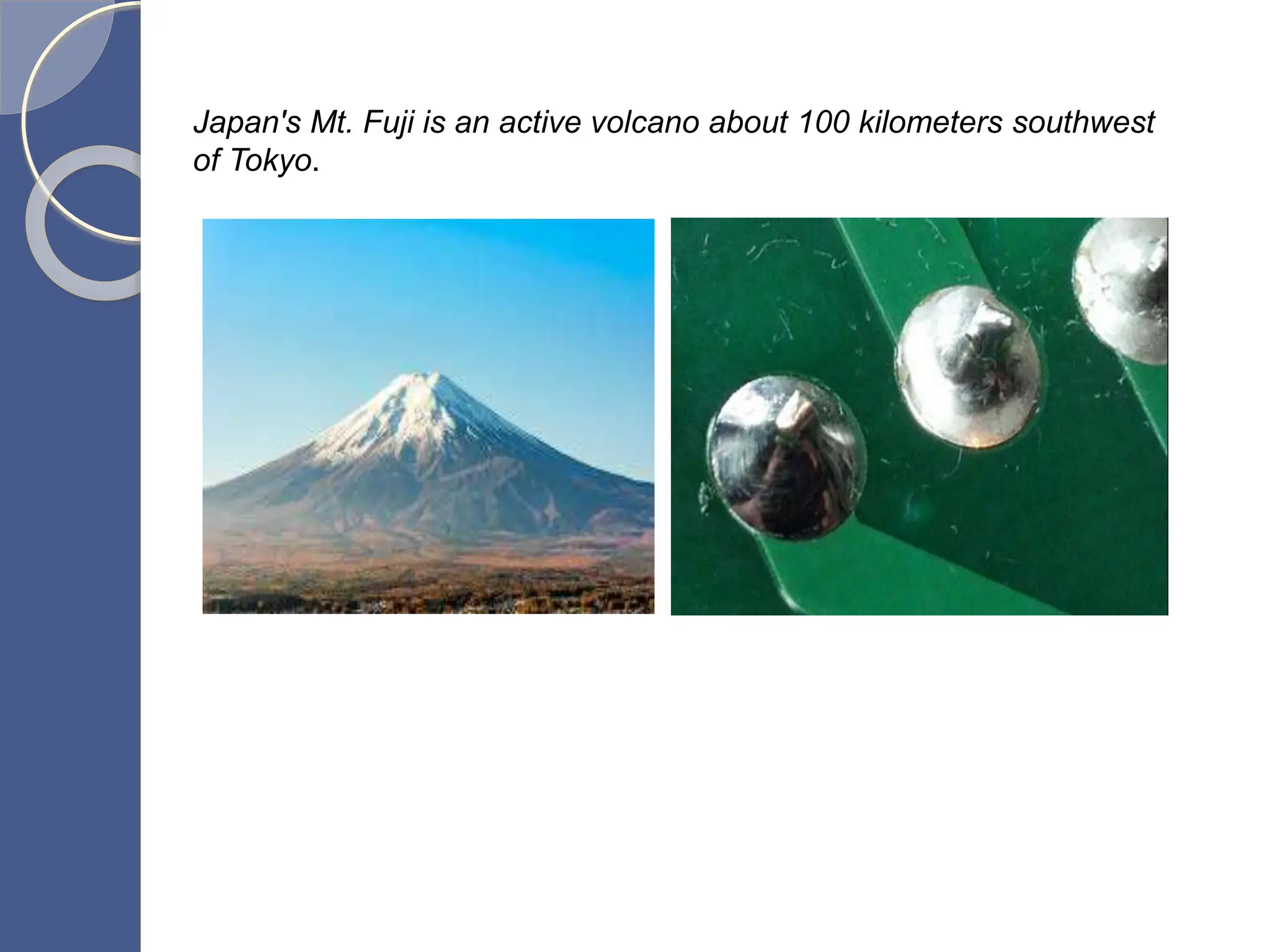

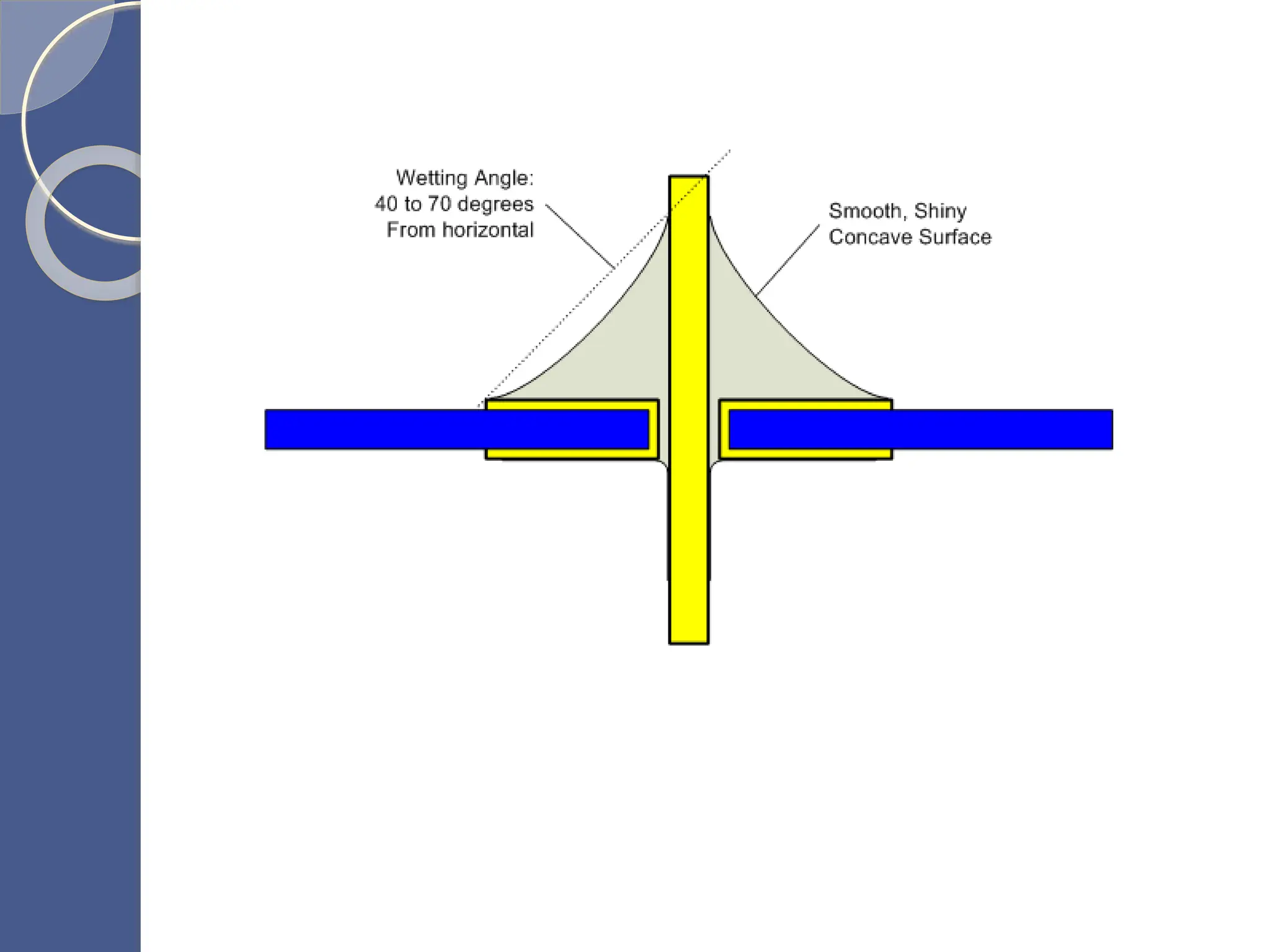

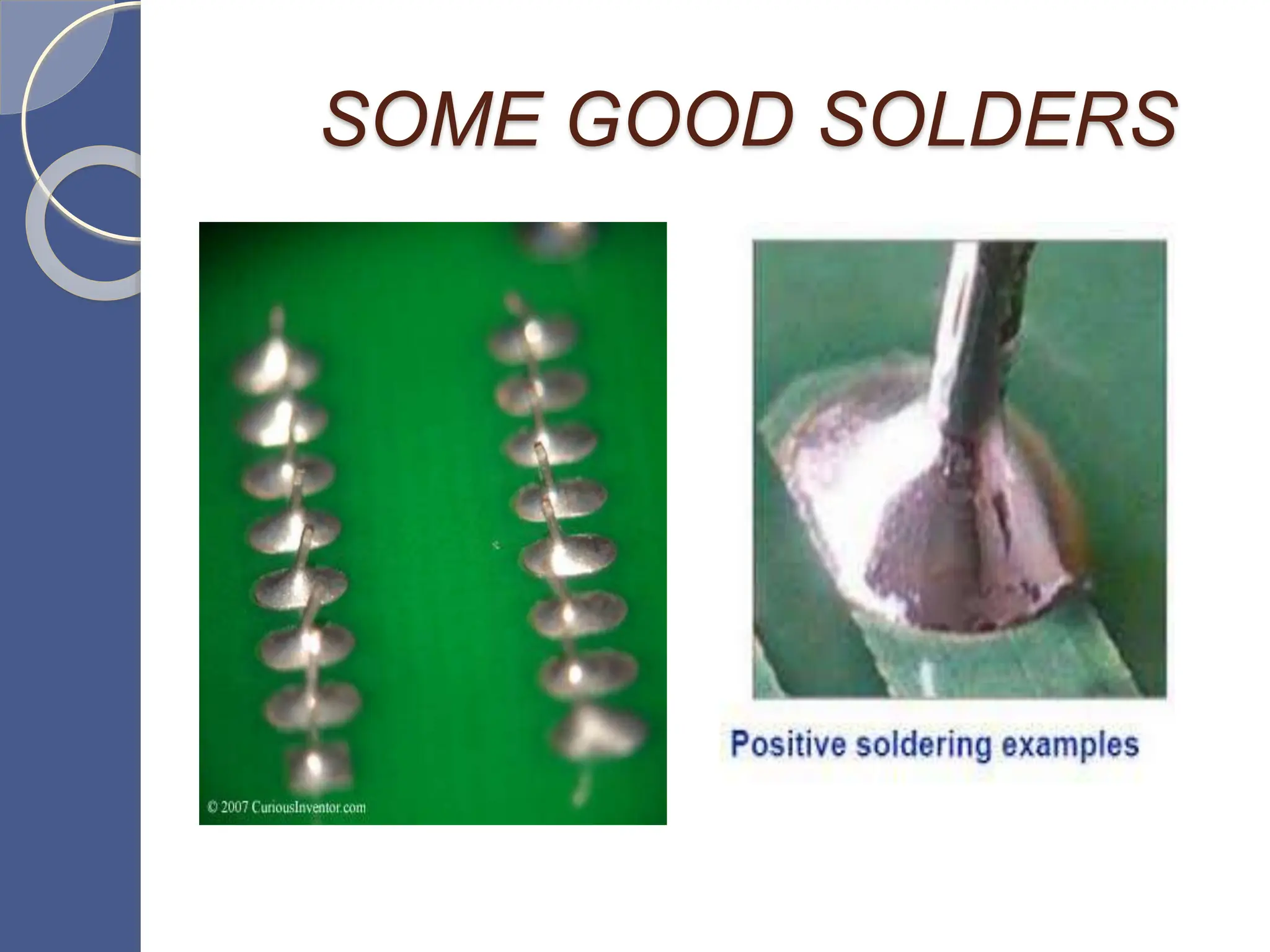

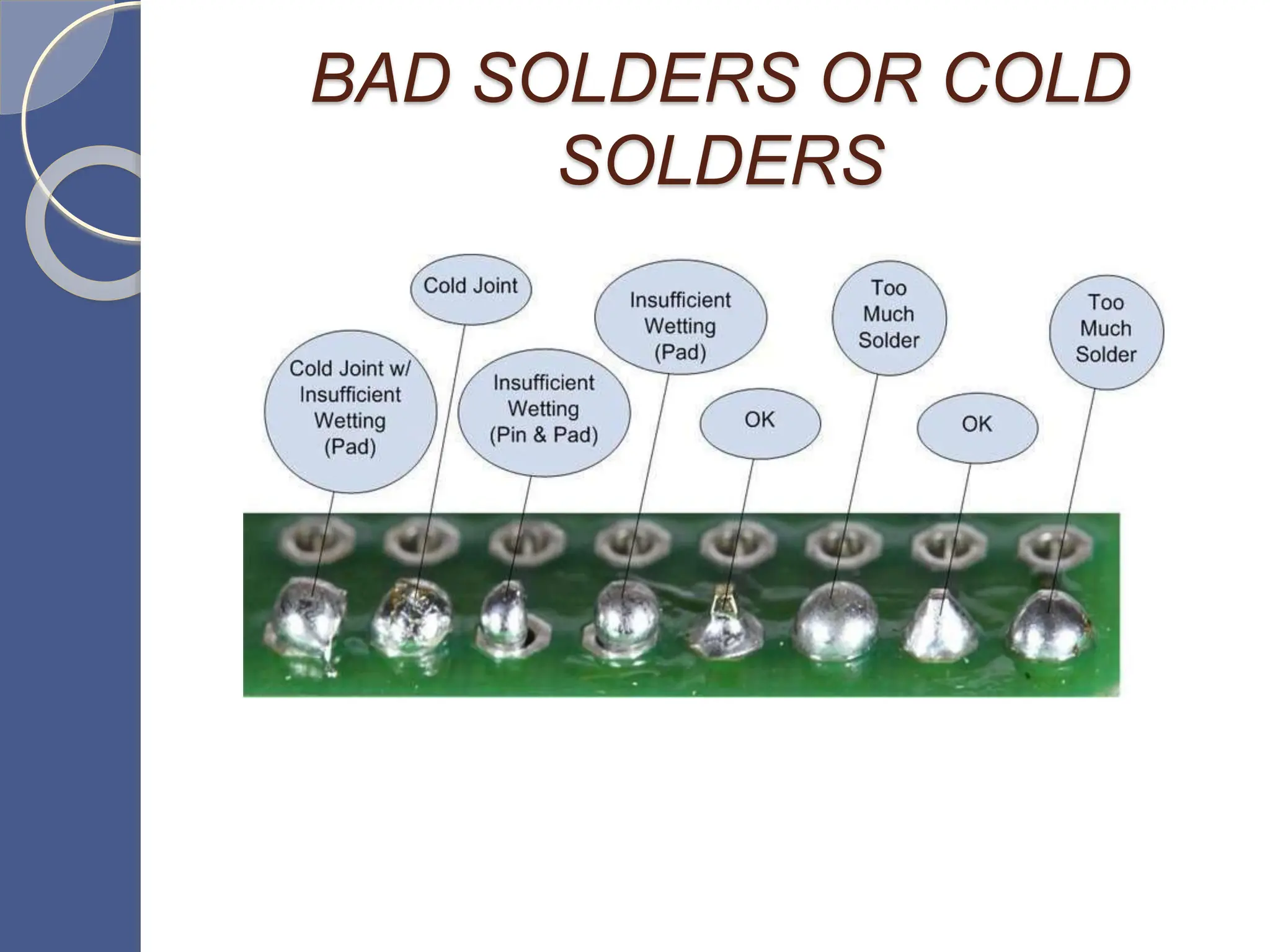

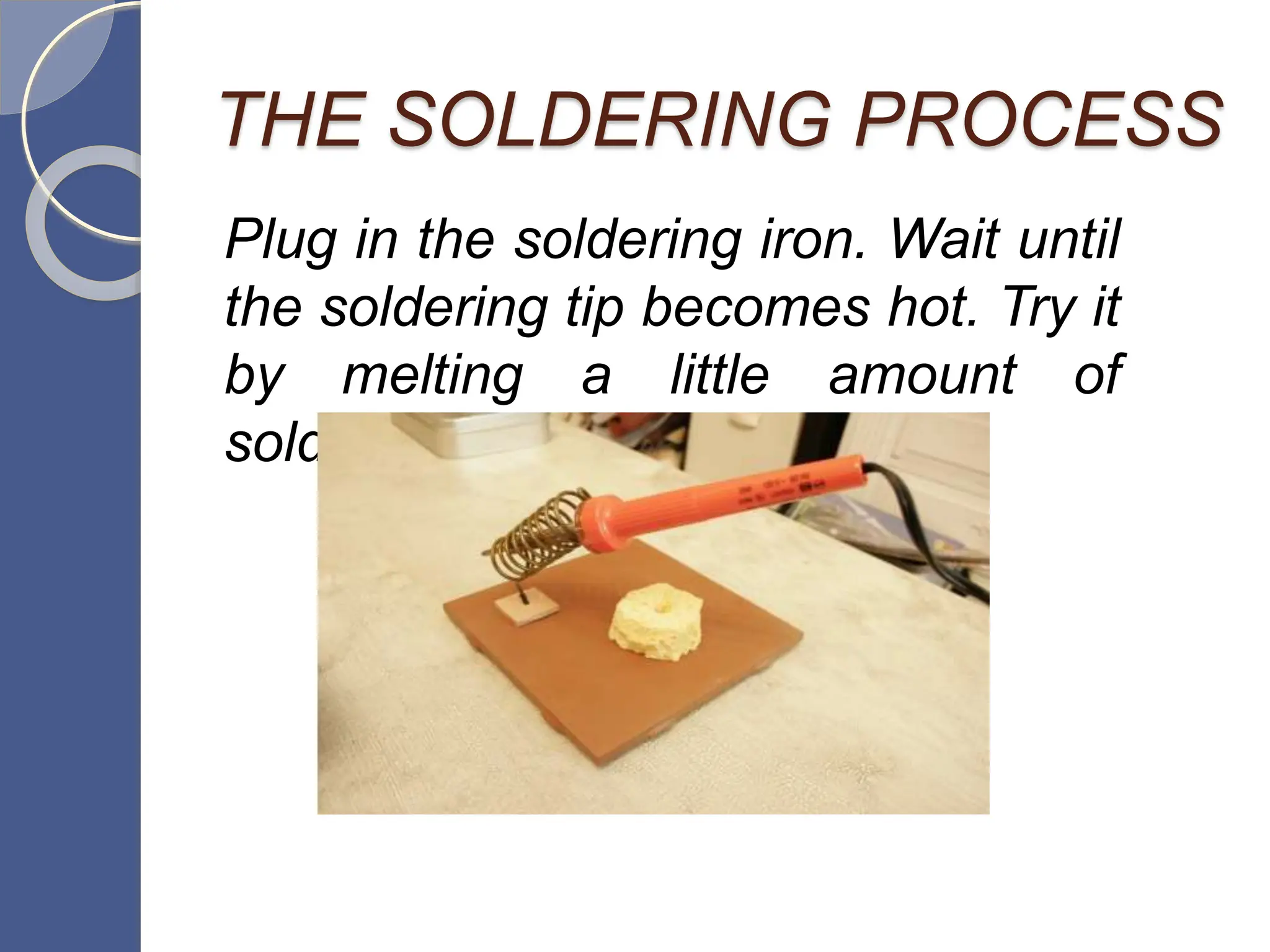

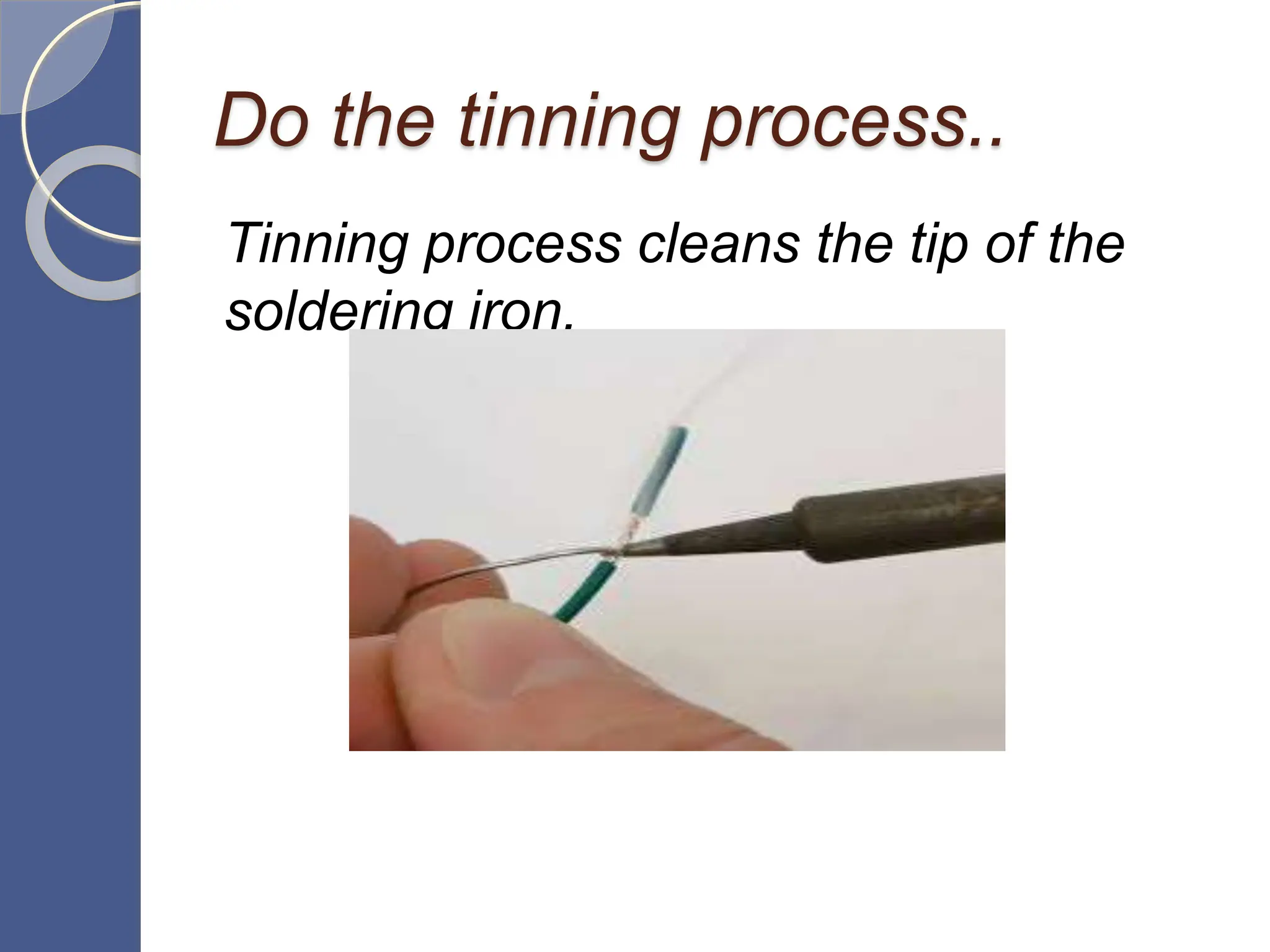

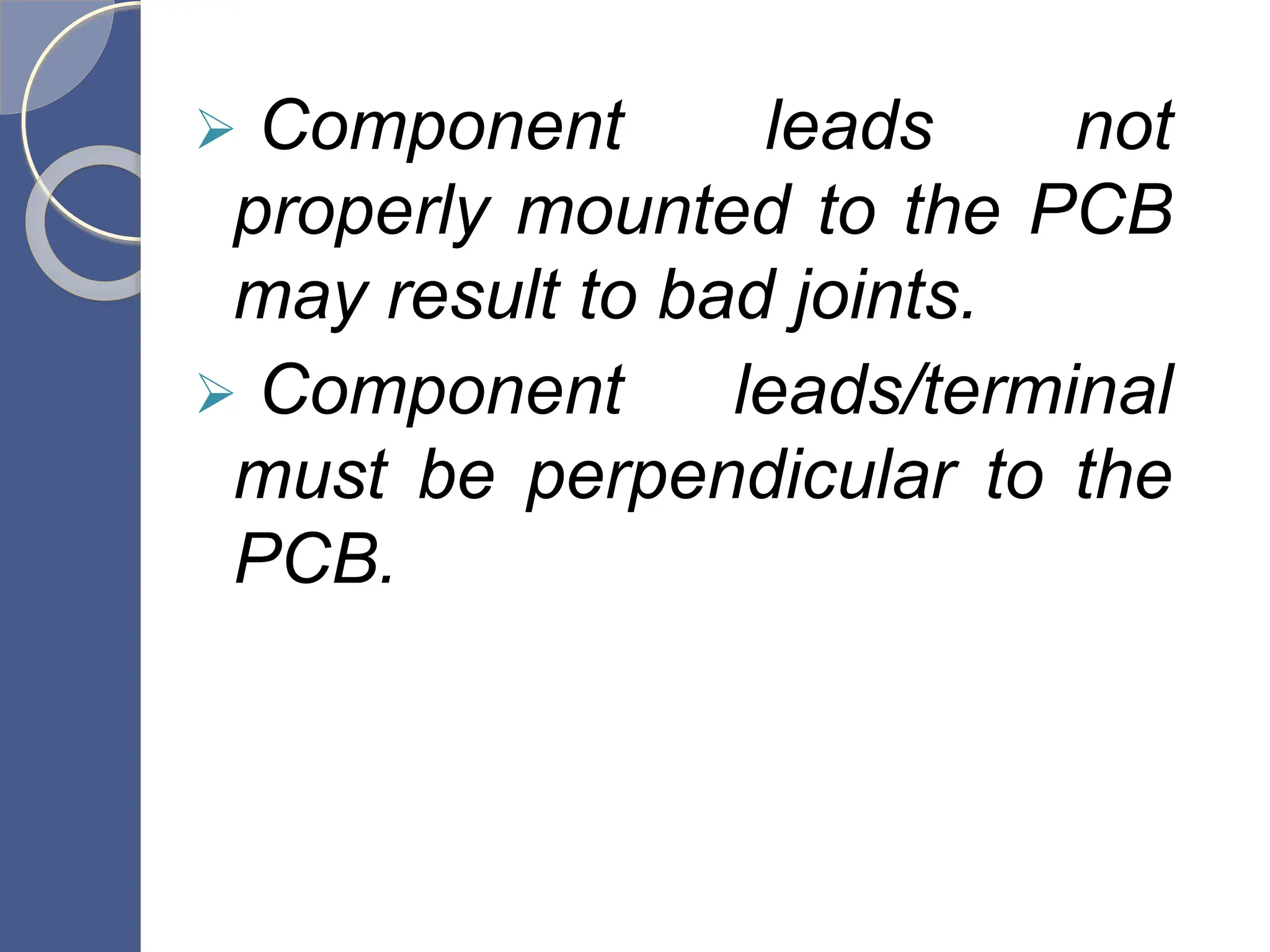

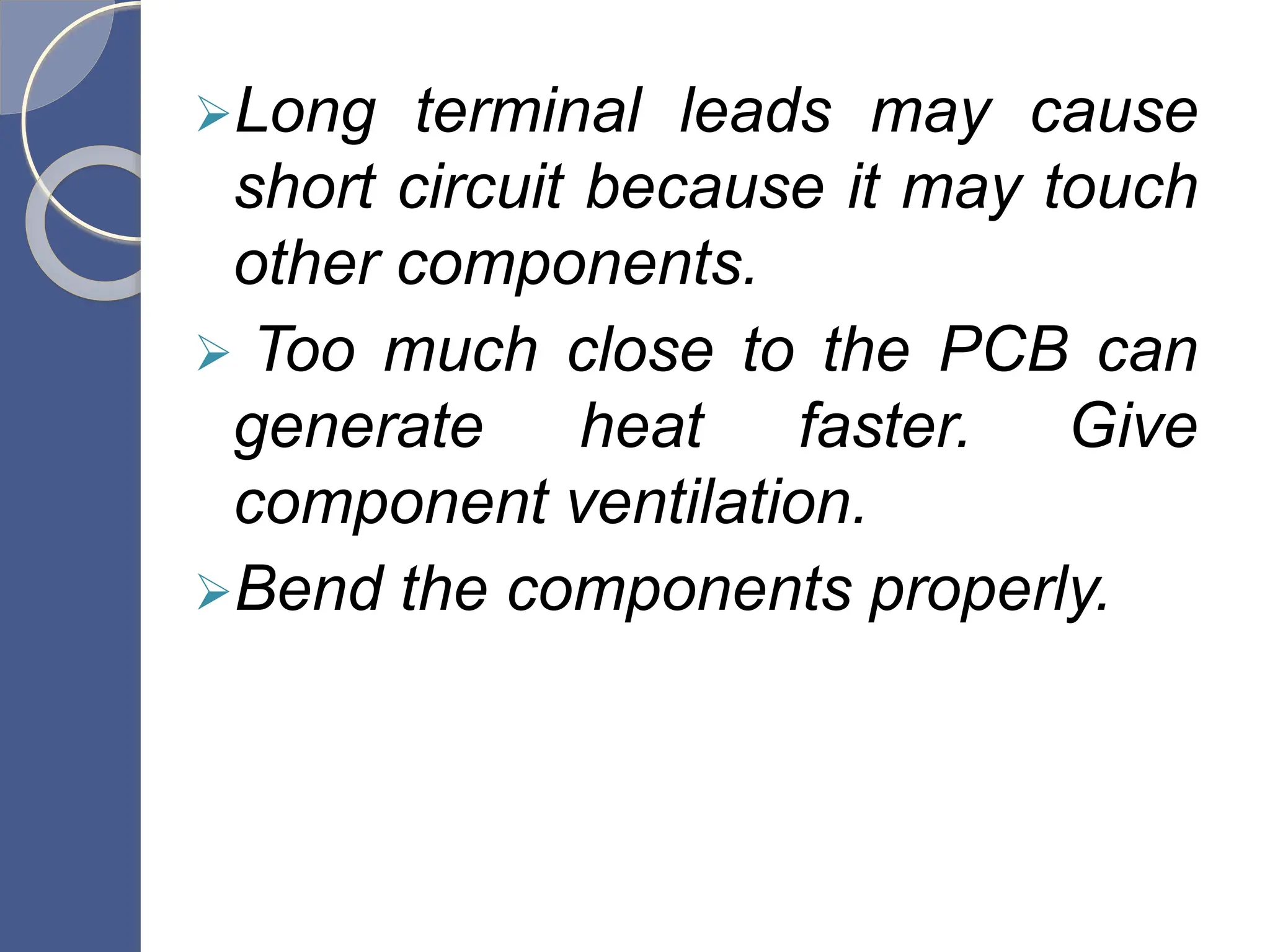

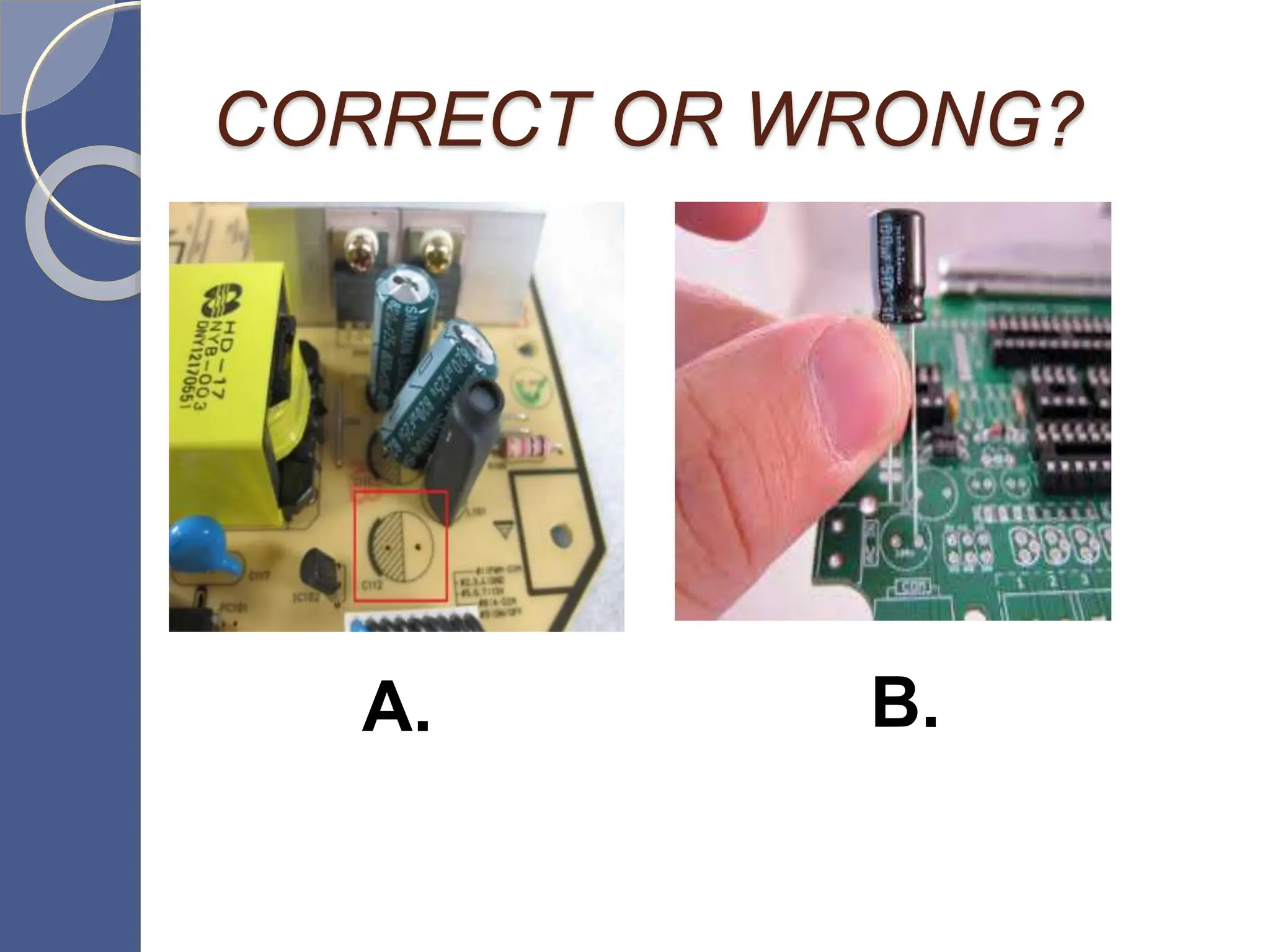

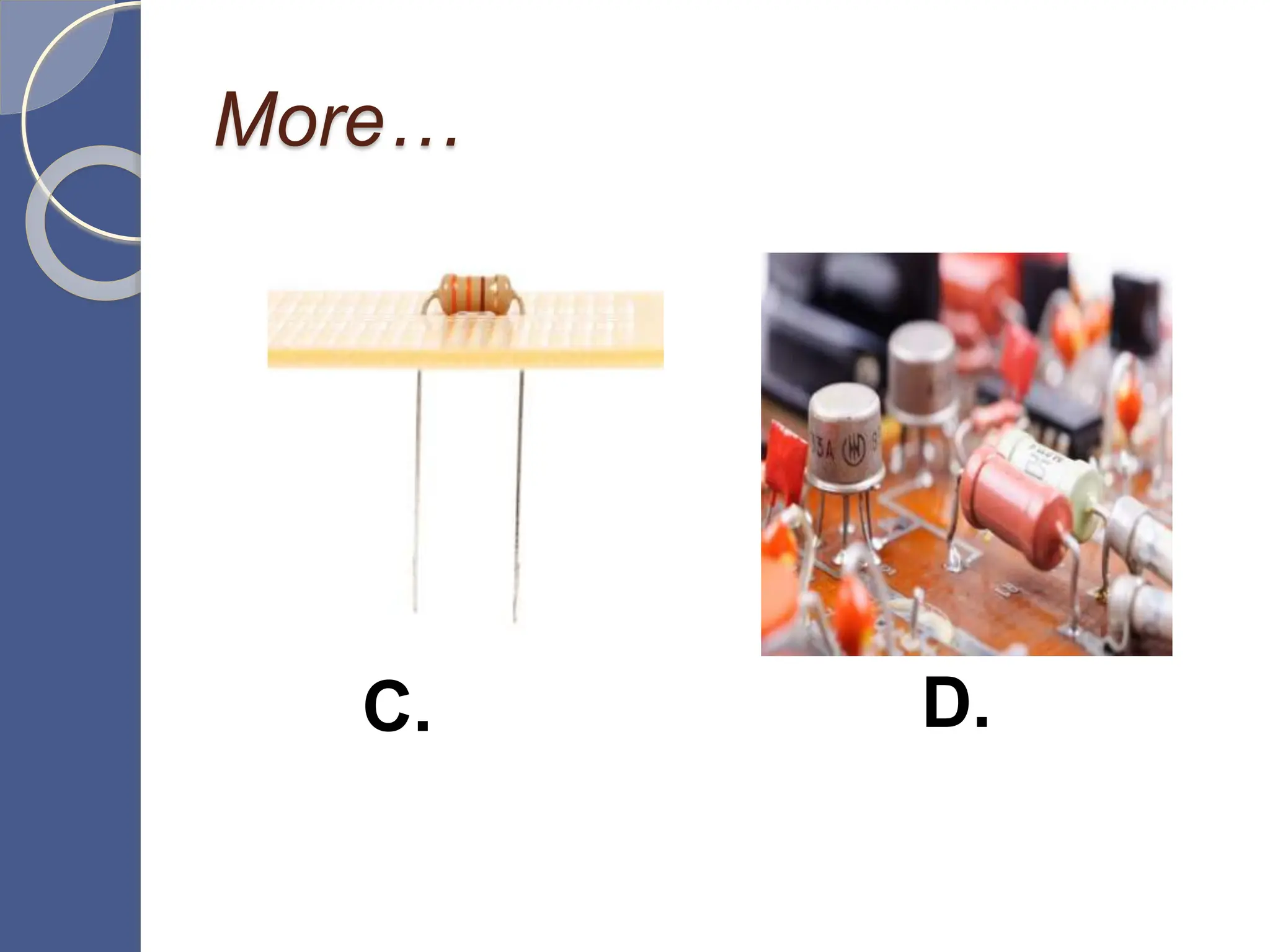

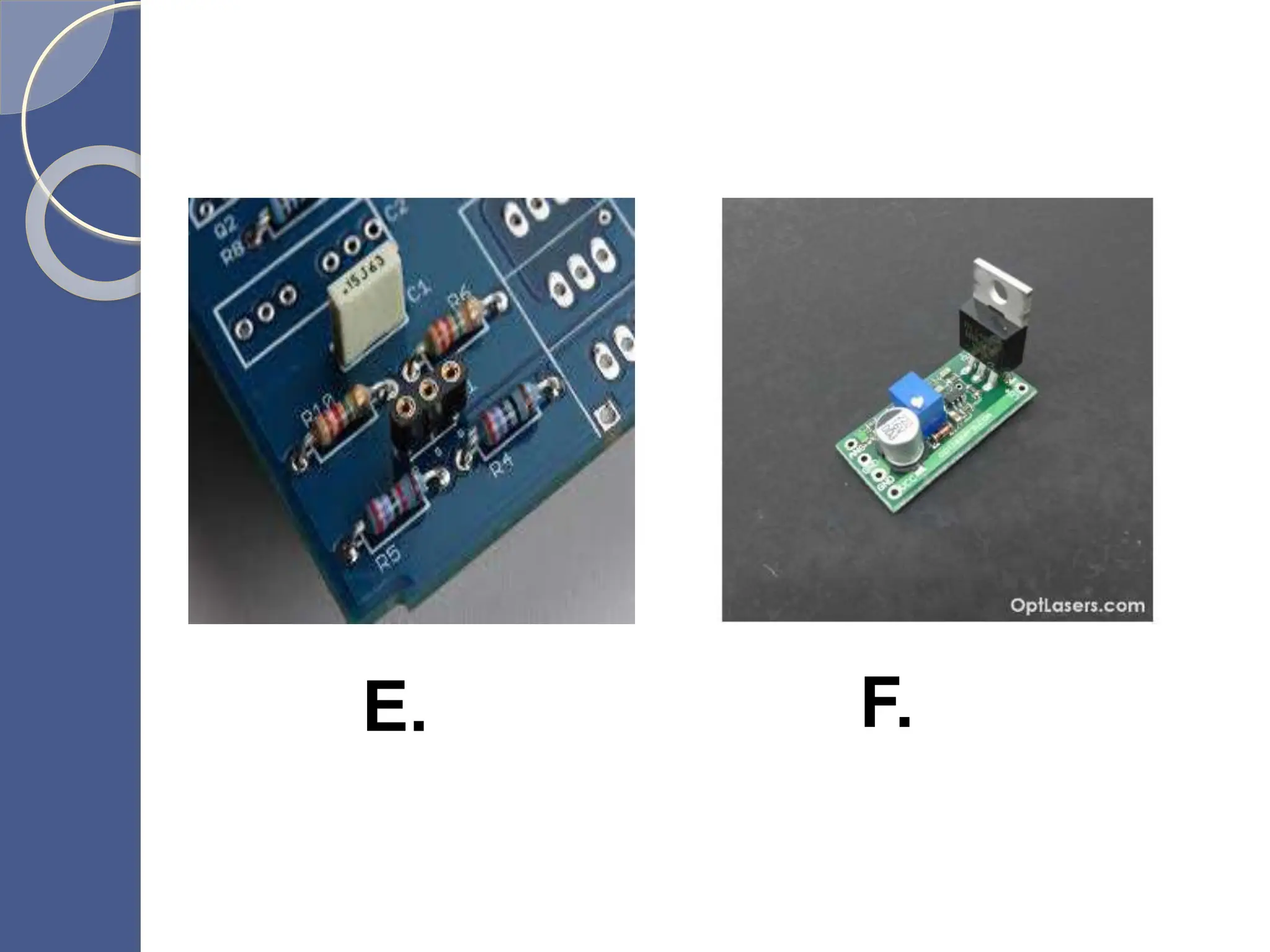

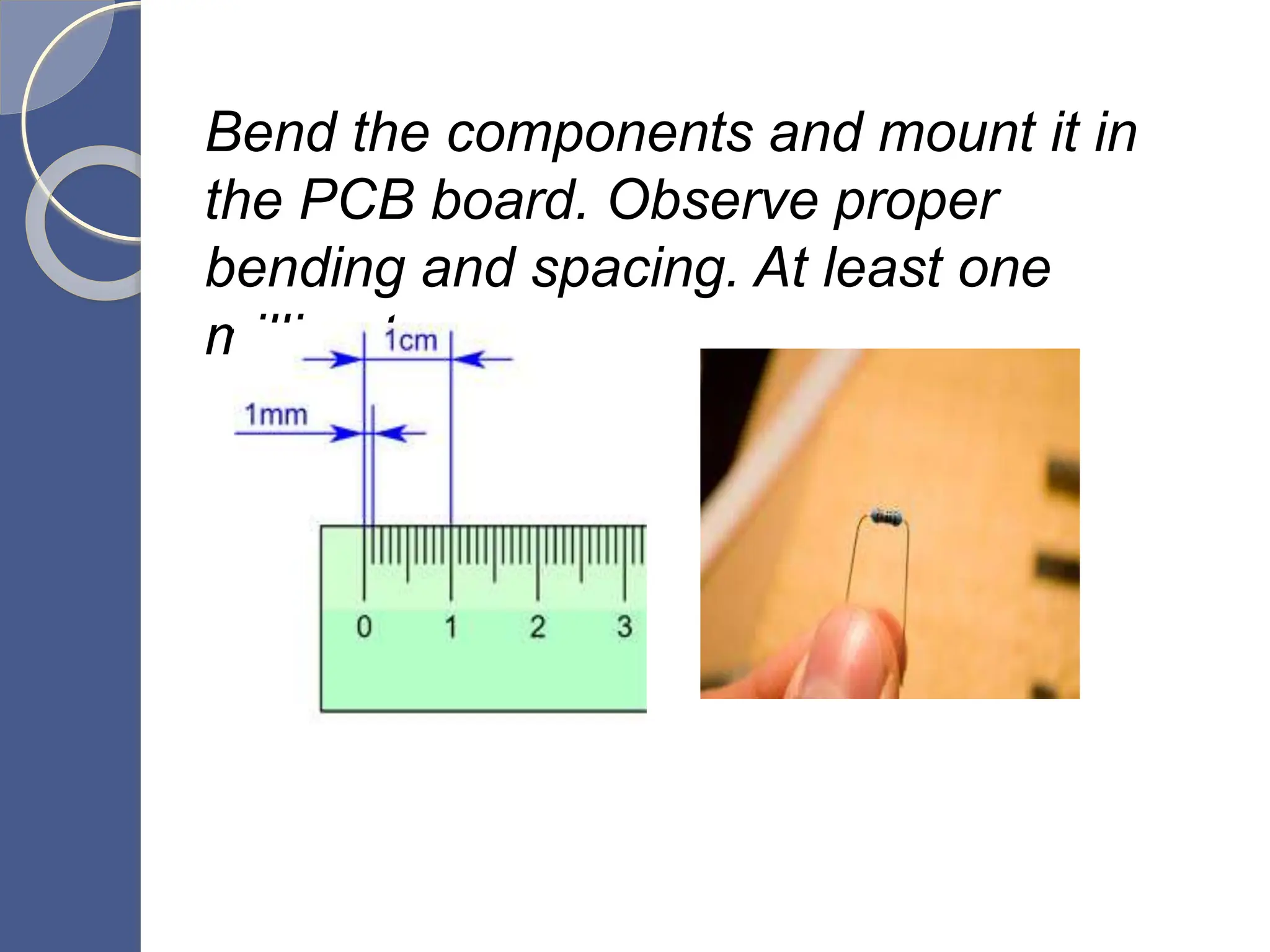

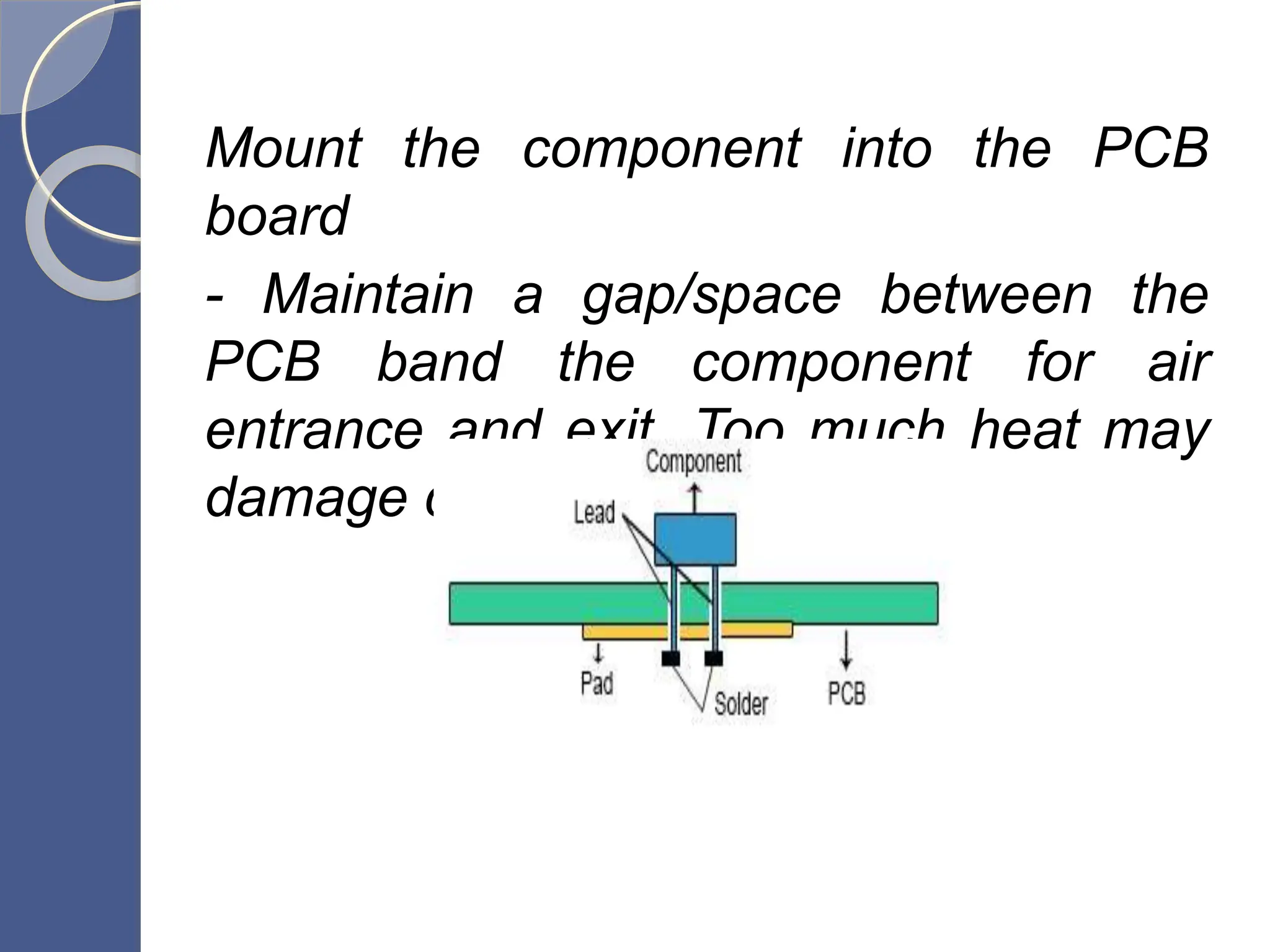

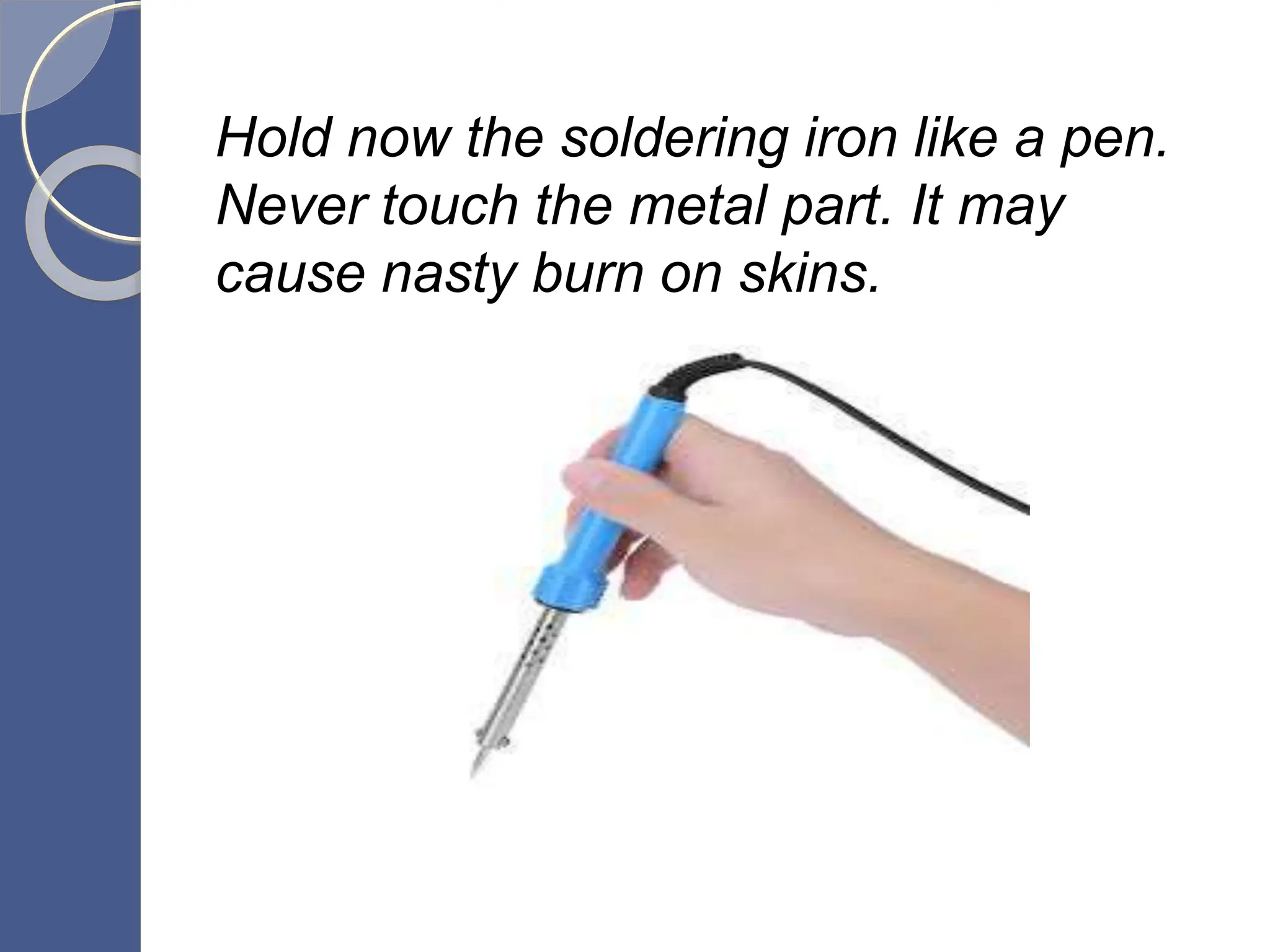

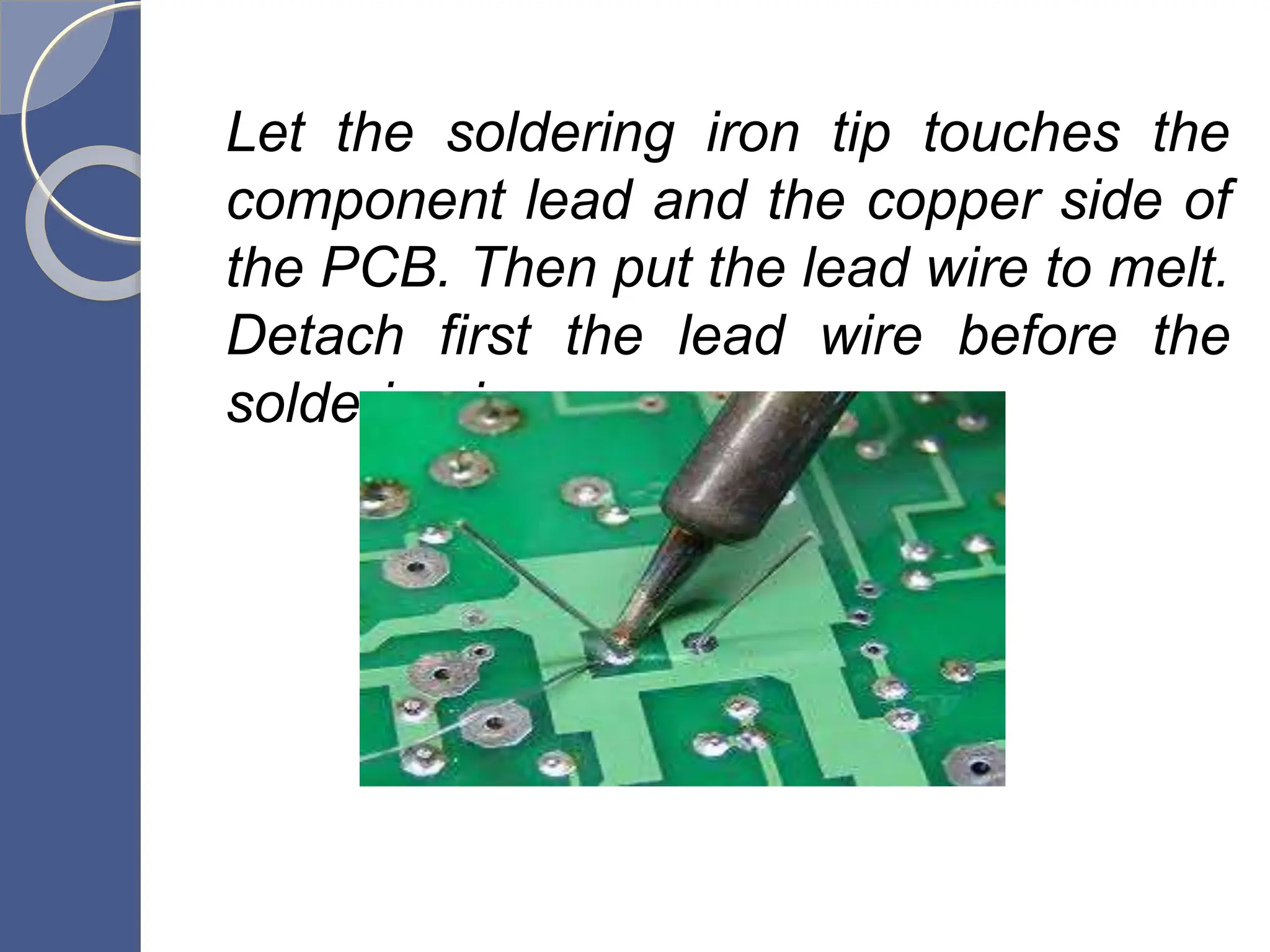

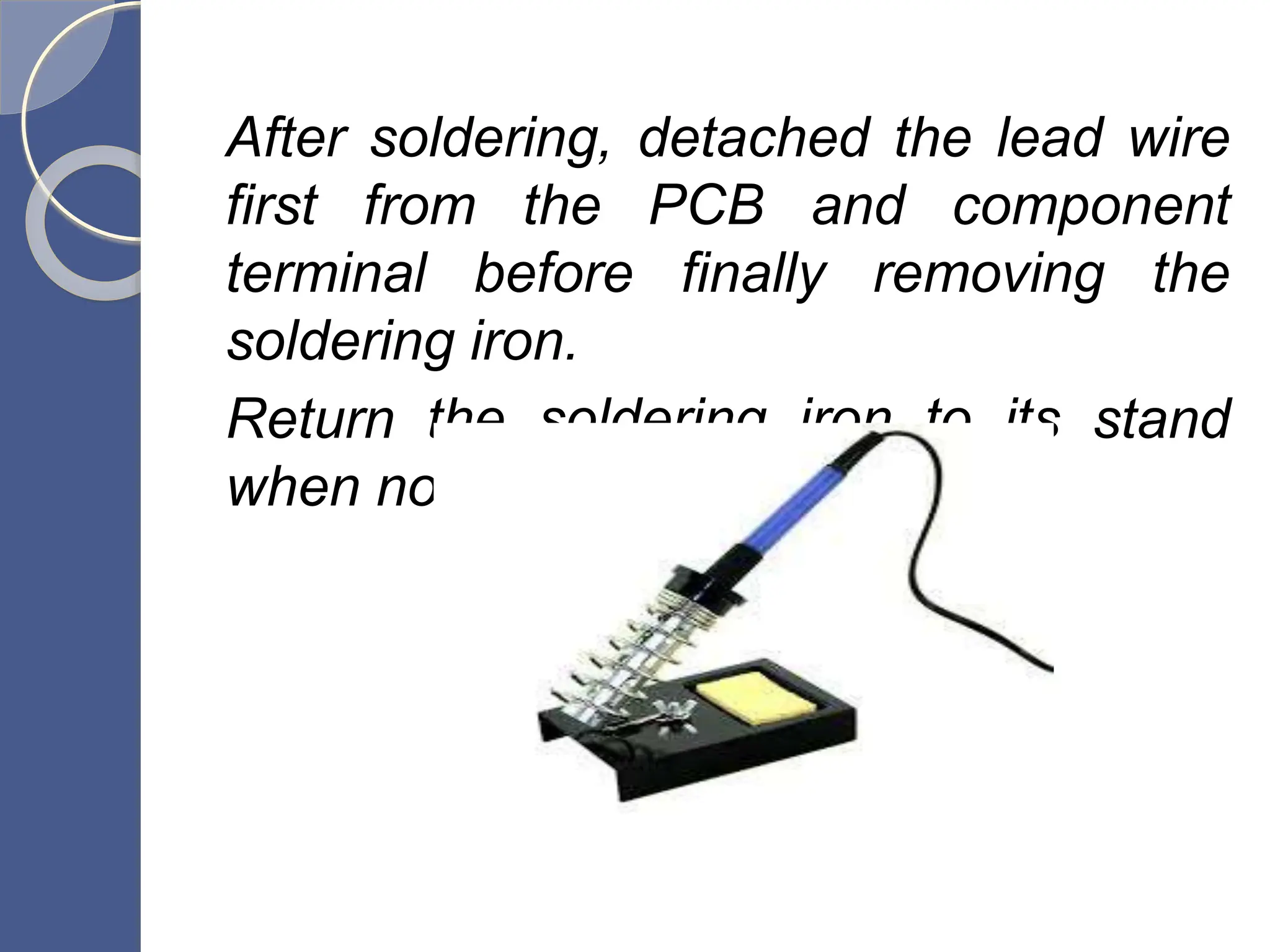

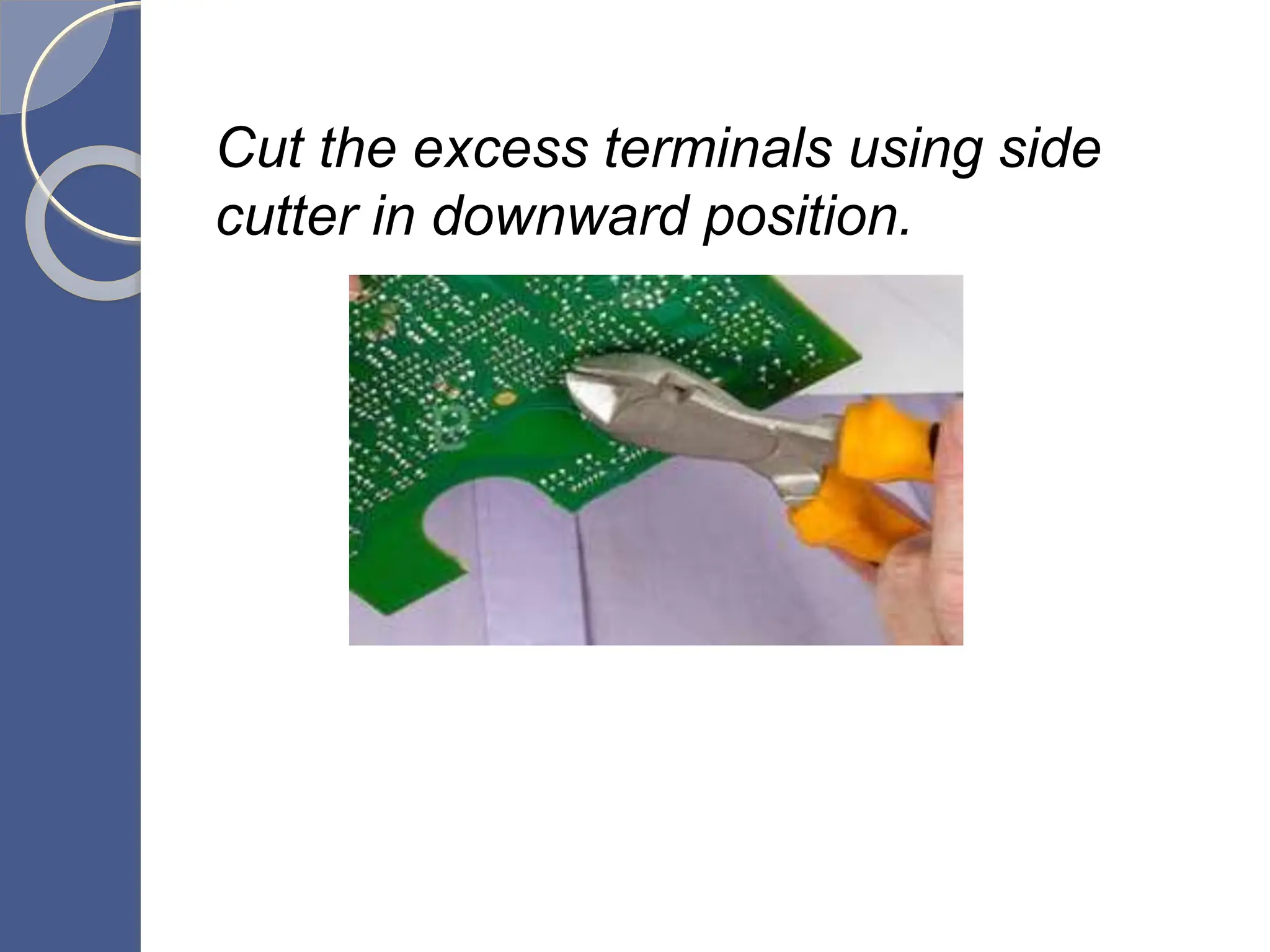

The document provides an overview of soldering, defining it as the joining of metals using low-melting point alloys, specifically focusing on tin and lead. It outlines necessary tools and techniques for effective soldering, details the qualities of good solder, and highlights the importance of proper component mounting on printed circuit boards (PCBs). Additionally, the document emphasizes the safety and procedural steps required during the soldering process.