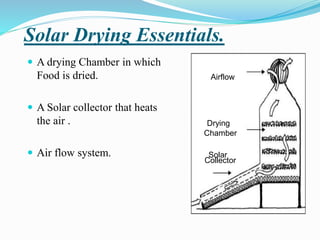

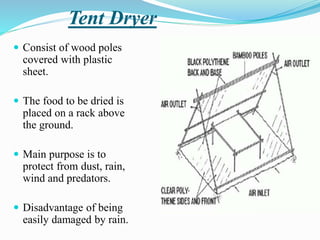

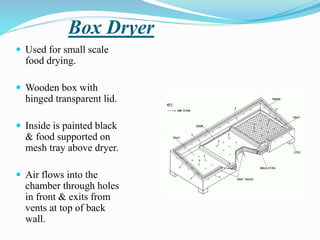

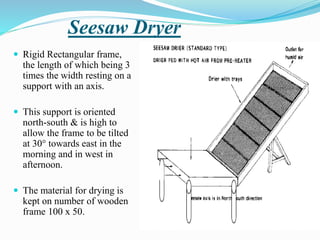

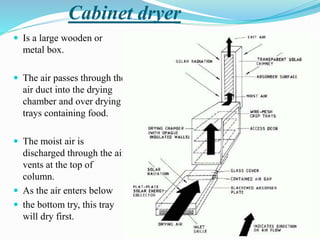

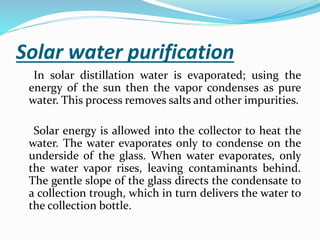

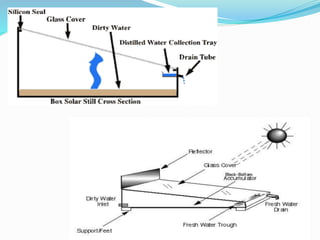

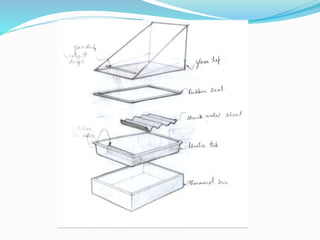

The document discusses solar drying as a method for food preservation, highlighting the disadvantages of traditional natural drying and the benefits of solar dryers in improving product quality and conserving energy. It also covers various types of solar dryers, including tent, box, seesaw, and cabinet dryers, used for different scales of food drying. Additionally, the document explains solar water distillation as an effective method for purifying drinking water, detailing the process and construction of a solar water distiller.