This document summarizes research on troubleshooting and improving the performance of an activated sludge process for treating textile wastewater. The textile wastewater has high levels of biological and chemical oxygen demand that can deplete dissolved oxygen if discharged untreated. The researchers identified issues in the aeration tank such as poor sludge settling. They suggest adding biopolymers to improve settling and modifying the secondary clarifier. Sodium bisulfate used in printing was negatively impacting bacteria; replacing it with acetic acid improved efficiency. Adjusting air distribution across the aeration tanks also enhanced performance. With these changes, chemical oxygen demand removal increased from 75-83% and sludge settling improved.

![Mehali J. Mehta et al Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 4, Issue 3( Version 2), March 2014, pp.06-09

www.ijera.com 6 | P a g e

Trouble Shooting and Performance Enhancement in Activated

Sludge Process for Treatment of Textile Wastewaters

Mehali J. Mehta*, Bansari M. Ribadiya**, Rashmita M. Thummar**, Priyanka

V. Patel**, Mihir Vyas***

*(Assistant Professor, Department of Civil Engineering, Sarvajanik College of Engineering and Technology,

Gujarat, India-395001)

** (Student, M.E Environmental Engineering, Sarvajanik College of Engineering & Technology, Gujarat, India-

395001)

*** (Assistant Professor, Environmental Engineering Department, Government Engineering College, Gujarat,

India)

ABSTRACT

The untreated textile wastewater can cause rapid depletion of dissolved oxygen if it is directly discharged into

the surface water sources due to its high Biological Oxygen Demand (BOD) and Chemical Oxygen

Demand(COD) value. This paper focuses on various troubles in performance of activated sludge process and

performance enhancement by suggesting remedial measures to ensure the proper operation of activated sludge

process(ASP).Also, it is noted that modification and alternative use of chemicals such as 45% solution of

sodium bisulphate in burnout printing instead of this 15% of acetic acid and 30% sodium bisulphate is mixed to

improve the overall efficiency in terms of Chemical Oxygen Demand(COD) and Biological Oxygen

Demand(BOD).

Keywords - Activated sludge, Textile wastewater, Performance Enhancement, Trouble shooting

I. Introduction

In this textile mill bleached cloth is colored

with dyes of various types, and printed with various

design, depending on market demand. As a result,

waste water produced in this section is difficult to

treat, especially from the point of view of color

removal and reduction of oxygen demand. The

untreated textile wastewater can cause rapid

depletion of dissolved oxygen if it is directly

discharged into the surface water sources due to its

high BOD value. The effluents with high levels of

BOD and COD values are highly toxic to biological

life [1].

Cotton textile industry wastewater generated

by the different production steps (i.e. sizing of fibers,

scouring, desizing, bleaching, washing,

mercerization, dyeing and finishing) has high pH and

temperature. It also contains high concentrations of

organic matter, non-biodegradable matter, toxic

substances, detergents and soaps, oil and grease,

sulfide, suspended and dissolved solids and alkalinity

[2].

The activated sludge process is the most

widely used secondary treatment process for treating

both municipal and industrial wastewaters. The

removal of the polluting dyes from effluents is an

important problem, particularly for small scale textile

industries where working conditions and economic

status do not allow them to treat their wastewater

before disposal and they have no choice other than

discharging the effluents into the main stream of

water resources. In aeration tank the water was

aerated from the bottom with diffusers to maintain

Dissolved Oxygen concentration above 4mg/l(For

both the bacterial growth and the mixed liquor)[2].

The objectives of this study were: (1) To identify the

problem in aeration tank of effluent treatment plant

treating textile wastewater. (2) To suggest the

remedial measures to ensure the proper operation of

activated sludge process (ASP). (3) To improve the

overall removal efficiency in terms of chemical

oxygen demand (COD) and biochemical oxygen

demand (BOD) from the ASP. (4) To identify the

manufacturing process which produce more COD. (5)

To suggest chemical which reduce the impact on

treatment plant. (6) To control COD in effluent of

different textile process.

RESEARCH ARTICLE OPEN ACCESS](https://image.slidesharecdn.com/b43020609-140419004101-phpapp02/75/B43020609-1-2048.jpg)

![Mehali J. Mehta et al Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 4, Issue 3( Version 2), March 2014, pp.06-09

www.ijera.com 7 | P a g e

Table 1: Characteristics of the textile industry

effluent

Sr.

no

Parameters Values

1 pH 8–10

2 Temperature °C 38–40

3 TSS 180–200

4 TDS 3700–

3900

5 COD 1400–

1600

6 Trace elements (Fe, Zn, Cu, Ni,

Mn)

15–20

Note: All values are expressed in mg/l, except pH

and temperature [3]

A process description of woven cotton and

polyester blended fabric manufacturing is discussed

below as this is one of the major textile material

commonly used all over the world.

Desizing is use to remove sizing material

prior to weaving. Depending on the size that has been

used, the cloth may be steeped in a dilute acid and

then rinsed, or enzymes may be used to break down

the size [4]. Bleaching improves whiteness by

removing natural coloration and remaining trace

impurities from the cotton; the degree of bleaching

necessary is determined by the required whiteness

and absorbency [5]. A further possibility is

mercerizing during which the fabric is treated with

caustic soda solution to cause swelling of the fibers.

This results in improved luster, strength and dye

affinity [6]. Dying is a process in which yarns and

fabric acquire color. Textiles are dyed using a wide

range of dyestuffs, techniques and machines. Printing

is a process which colours and design are printed on

fabric. The most common printing technique is

screen-printing, roller printing and others. Pigments

and dyestuffs are mainly used for printing. In

finishing , yarn or fabric in order to impart the final

touch and also the change properties of the fabric. It

involves brushing or raising to make the surface

hairy, physical treatment to improve the lustre,

softness, to minimize the wash shrinkage and resins

[4].

The activated sludge process consists of two

units - the aeration tank (or basin) and the secondary

clarifier (sedimentation tank). From the bottom of the

secondary clarifier, settled and concentrated sludge is

returned back to the aeration tank to maintain the

mixed liquor suspended solids (MLSS) at desirable

level. Excess sludge produced each day is wasted

from the return sludge line and discharged,

frequently, to a sludge thickener to keep the system

operating at a controlled sludge age (mean cell

retention time, MCRT or sludge retention time,

SRT).

Problems associated with the activated sludge

process:

1. Settling of biomass is difficult.

2. Concentration of biomass in aeration tank is

less.

1. Foaming was observed on the surface of

aeration tank.

1. Microorganisms are continuously carried

over along with effluent from secondary

clarifier.

2. During printing 45% solution of sodium

bisulphate is used in burnout process which

results in bacterial die off due to sodium

bisulphate chemical, and COD was

accounted around 1.5 lakh mg/l in 10 m3/d

flow coming from brasso print process.

II. Experimental Details

2.1 Chemicals use

Chemicals of Burn out Printing

1. Acetic acid (CH3COOH) – 15%

2. Sodium bisulphate (Na2HSO4) -30%

3. Water + gum – 55%

Biopolymer: Activated sludge flocs are

thought to consist of microbial aggregates,

filamentous organisms, organic and inorganic

particles and exocellular polymers. These flocs are

held together by means of exocellular polymers

(biopolymers) and divalent cations to form a 3-

dimensional matrix. Although the flocculation

process is important, it is not well understood. It is

known that bioflocculation is responsible for many of

the changes in biofloc characteristics [7].

Table : 2 Coagulants use in effluent treatment palnt

2.2 Processes Adopted

Wastewater samples were collected from

aeration tank-I, II, III and inlet as well as outlet of

effluent treatment plant (ETP). Samples were

collected in 2 liters white plastic beaker, which have

been thoroughly washed with nitric acid and then

rinsed many times with distilled water. All samples

were preserved inside a refrigerator except samples

for microbial analysis, which were analyzed within

24 hours. Sample analyzed according to Standard

Methods (APHA, 1998). pH was measured by pH

meter. Chemical oxygen demand (COD) was

Chemical Dosing Before pH After pH

Lime 400-500kg/d 8 10.5

Ferrous

sulphate

900-1000kg/d 10.5 6-7](https://image.slidesharecdn.com/b43020609-140419004101-phpapp02/85/B43020609-2-320.jpg)

![Mehali J. Mehta et al Int. Journal of Engineering Research and Applications www.ijera.com

ISSN : 2248-9622, Vol. 4, Issue 3( Version 2), March 2014, pp.06-09

www.ijera.com 9 | P a g e

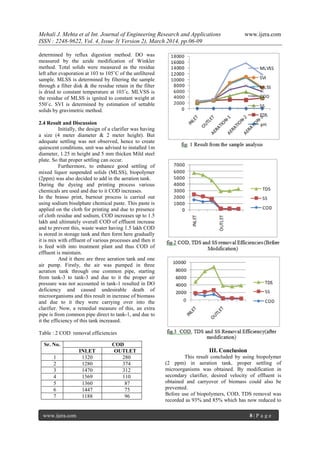

75% and 83% due to modification. Instead of using

45% of sodium bisulphate solution, 15% of acetic

acid and 30% sodium bisulphate is mixed and it

resulted in increase of bacteria in aeration tank. In

dying process, due to use of formic acid, bacterial

growth was not proper and this problem is solved by

using acetic acid in place of it. Normally 2 ppm bio

polymers were used in aeration tank which have now

reduced to 0.1 ppm due to the above modification in

process.

References

[1] Wastewater Engineering Treatment and

Reuse, Metcalf & eddy, published by Tata

McGraw hill education private limited,

335,334.

[2] A. Palaa, E. Tokat , Color removal from

cotton textile industry wastewater in an

activated sludge system with various

additives, Water Resource (2002), 36, 2920-

2925.

[3] K. Kumar, G. Singh, M. Dastdar, T.

Sreekrishnan, Effect of Mixed Liquor

Volatile Suspended Solids (MLVSS) and

Hydraulic Retention Time (HRT) on the

performance of activated sludge process

during the biotreatment of real textile

wastewater, Water Resource and Industry

(2014), 5, 1-8.

[4] http://en.wikipedia.org/wiki/Sizing

[5] http://textilefashionstudy.com/textile-bleach

ing-process-definition-objectivesprocess

parameters-of-bleaching/

[6] http://textilelearner.blogspot.com/2012/02/m

ercerizing-object-ofmercerizing.html# ixzz2

Tp7SgAxl.

[7] Industrial waste water treatment, A.D.

Patwardhan. PHI learning private limited,

second addition ,may 2009,36,37,40,41

[8] Ardem, E. and W. T. Lockett. 1914a.

Experiments on the oxidation of sewage

without the aid of filters. J. Soc. 01

Chemical Industry (England), 33:523-539.

[9] Internetsources:http://www.intechopen.com/

books/advances-in-treating-textile-

effluent/textile-dyeing-wastewatertreatment

[10] Internetsources:http://www.google.co.in/#hl

=en&output=search&sclient=psy-

ab&q=7.%09REMOVAL

[11] Burnett, C., Woelke, A. and Dentel, S. K.

(1997) Dewaterability of ATAD sludge.

WEFTEC '97. 2, 299.](https://image.slidesharecdn.com/b43020609-140419004101-phpapp02/85/B43020609-4-320.jpg)