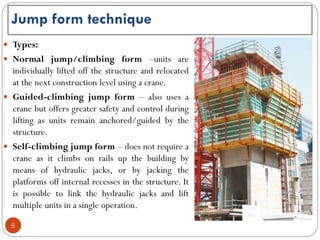

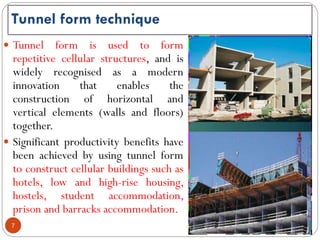

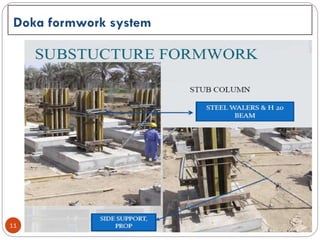

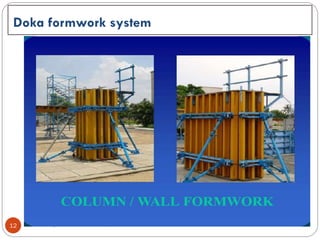

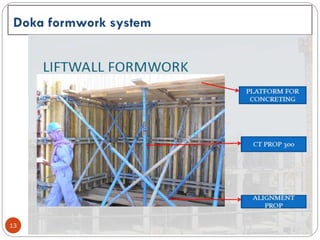

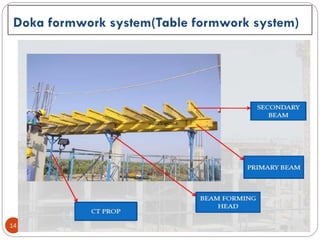

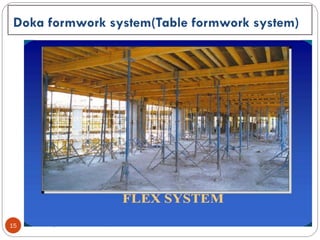

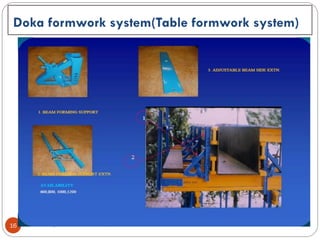

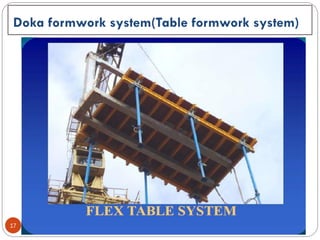

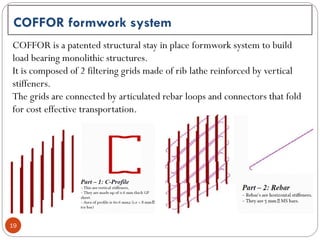

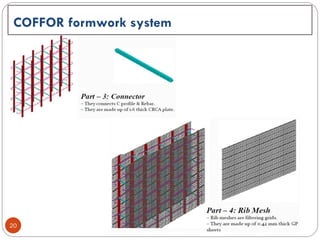

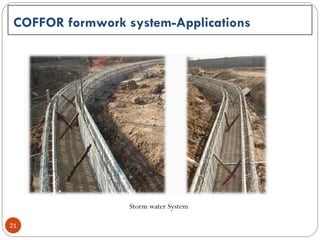

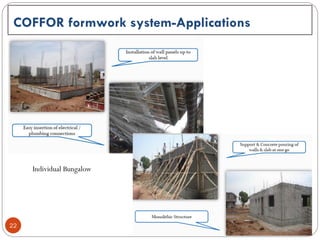

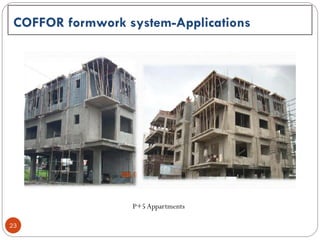

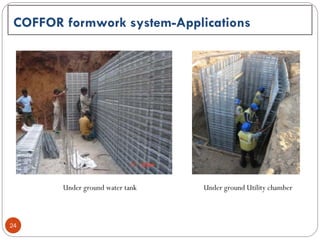

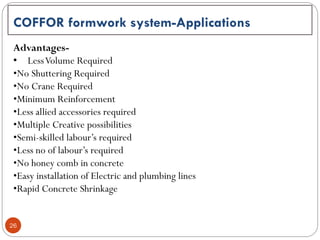

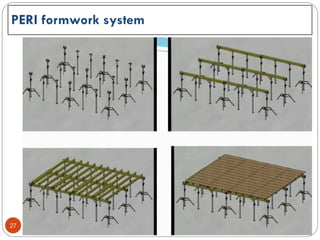

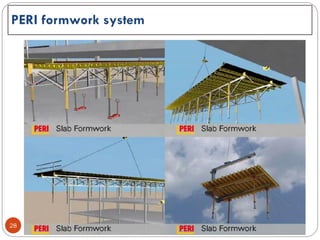

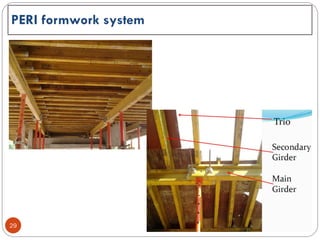

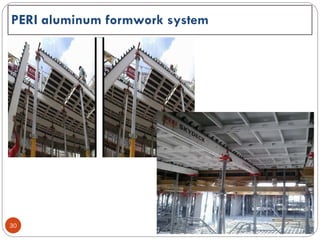

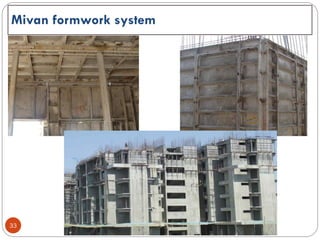

The document discusses various techniques used for formwork in high-rise construction, including slip forming, jump forming, climbing forming, tunnel forming, and table forming. It provides details on slip forming where concrete is continuously poured into a moving form. Jump forming uses movable platforms to construct shear walls and cores more quickly. Tunnel forming constructs horizontal and vertical elements together for efficient construction. The document also discusses various commercial formwork systems used, such as Doka, Coffor, PERI, and Mivan, outlining their components, applications, advantages, and limitations.