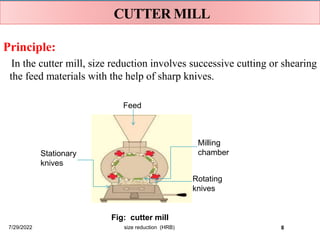

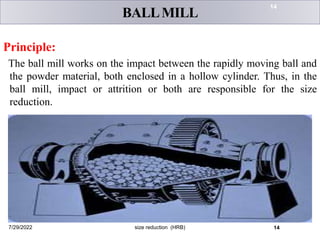

Size reduction is the process of reducing larger particles into smaller particles using external forces. It has several objectives like increasing surface area, separating constituents, improving handling, and facilitating mixing. The key mechanisms of size reduction are cutting, impact, compression, attrition, and combined impact and attrition. Several types of mills are used for size reduction including cutter mills, roller mills, hammer mills, ball mills, fluid energy mills, and edge runner mills. Factors like hardness, moisture content, and ratio of feed size influence size reduction effectiveness.