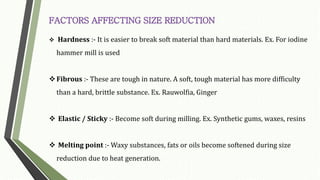

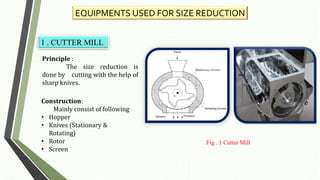

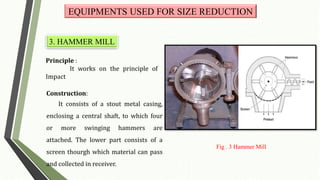

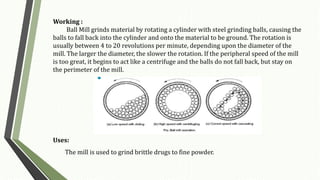

This document discusses size reduction, which is the process of reducing drugs into smaller pieces or fine powder. It defines size reduction and lists its purposes. Factors that affect size reduction include hardness, fiber content, elasticity, melting point, and hygroscopicity. Common size reduction methods are cutting, compression, impact, attrition, and shear. Equipment used for size reduction includes cutter mills, roller mills, hammer mills, and ball mills. Cutter mills use knives to cut materials while roller mills use compression between rollers. Hammer mills rely on impact from hammers and ball mills use impact and attrition from balls within a rotating cylinder.