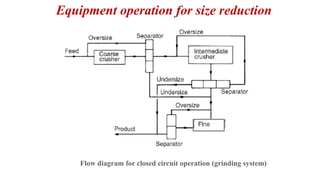

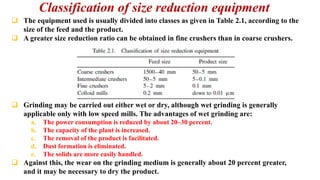

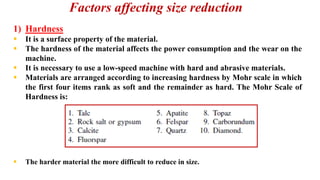

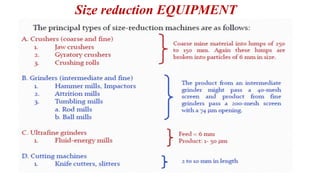

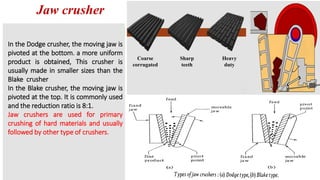

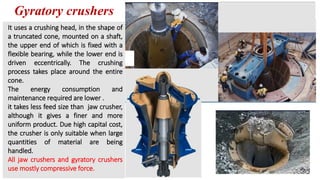

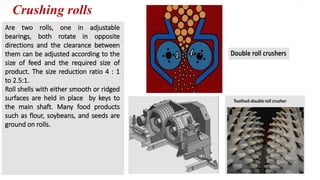

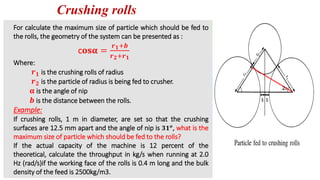

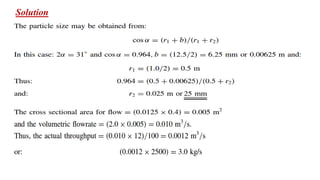

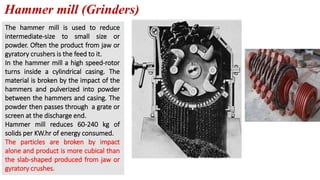

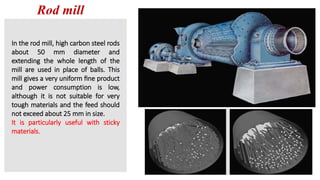

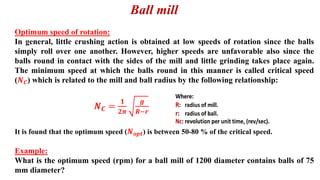

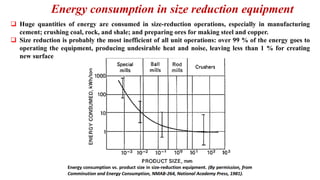

The document discusses equipment operation for size reduction, highlighting two systems: open circuit, where material passes once and may not be fully crushed, and closed circuit, which recycles material for further grinding using multiple crushers. It categorizes size reduction equipment based on feed and product size, factors affecting size reduction like hardness and moisture content, and various types of crushers and mills, detailing their functions and operations. Additionally, the document addresses energy consumption in size reduction and suggests that this process is highly inefficient, consuming significant energy primarily for running the equipment rather than effectively creating new surfaces.