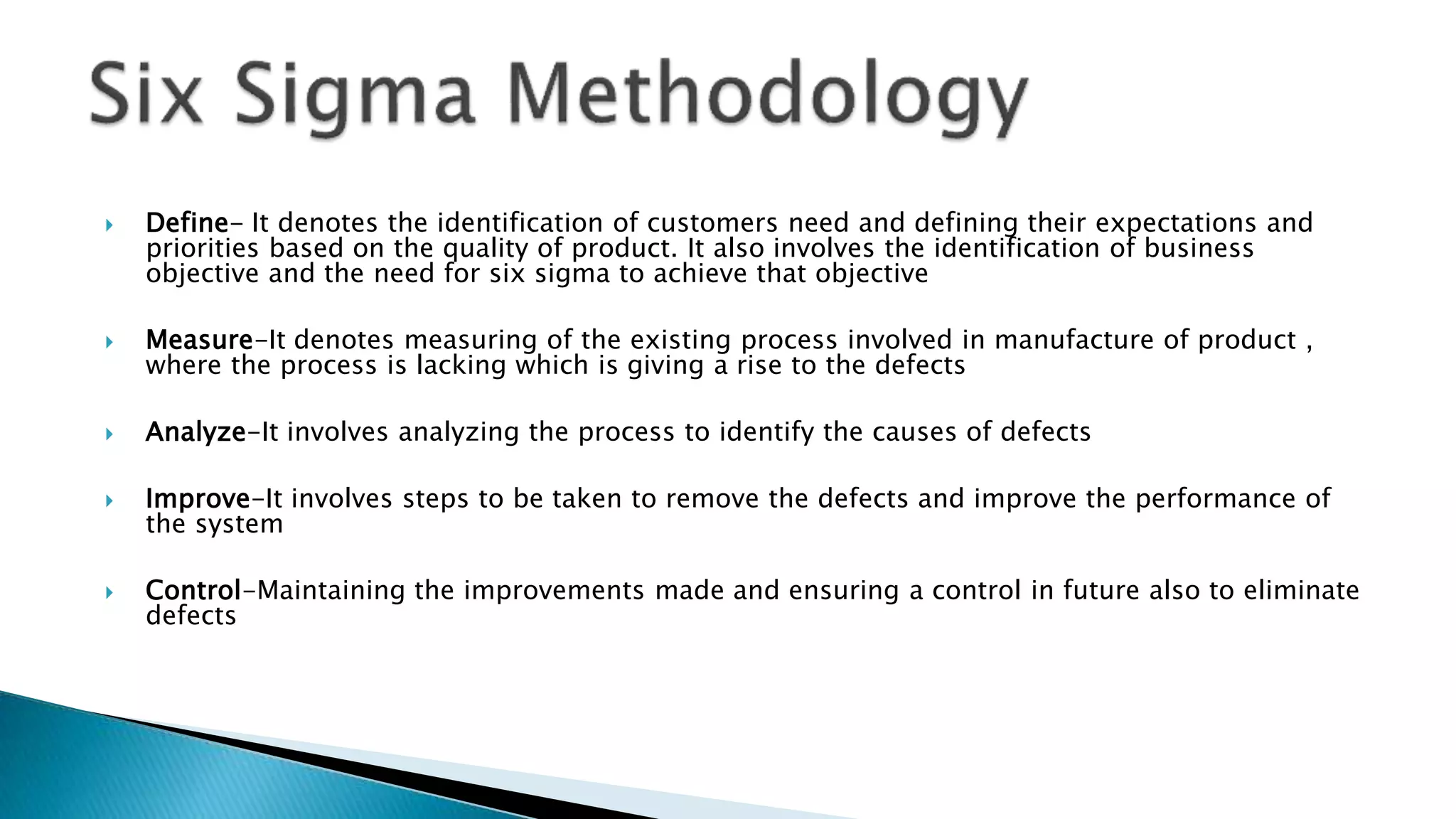

This document discusses Six Sigma, which is a set of techniques for process improvement. It aims to reduce defects to 3.4 per million opportunities by following the DMAIC methodology (Define, Measure, Analyze, Improve, Control). Six Sigma seeks to eliminate defects through statistical analysis and has benefits like quality improvement, cost reduction, and increased profits. It uses tools like flowcharts, control charts, and Pareto charts. Projects are led by Belts (Yellow, Green, Black, Master Black) trained in Six Sigma.