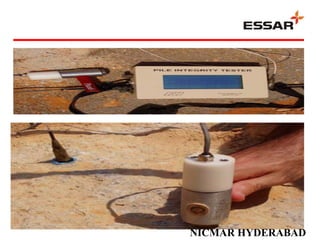

Essar Steel is establishing a steel pellet plant in Paradeep, Orissa requiring pile foundations. The project involves constructing 539 piles of various diameters using the bored cast in situ method with direct mud circulation. Pile tests, including load tests and integrity tests, were conducted. A rate analysis was performed for a sample 500mm diameter pile considering costs of boring, reinforcement, concrete, testing, and contractor overhead and profit to determine the total cost per pile was approximately 78,000 Indian rupees. The status of pile construction was tracked monthly, with over 80% of the piles completed after 4 months.