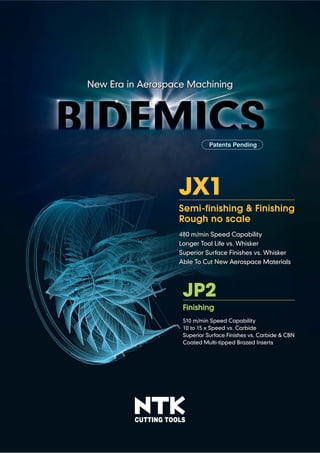

The document introduces new composite materials JX1 and JP2 for machining aerospace alloys. JX1 provides significantly longer tool life compared to whisker ceramics, and can double cutting speeds. It is suitable for roughing, profiling and semi-finishing of heat resistant alloys. JP2 allows for high-speed finishing at over 240m/min with superior finishes to CBN or carbide. It has 10-15 times higher speed capability than carbide. The materials increase productivity versus whisker ceramics and carbide for aerospace machining applications.