This document outlines a study on analyzing piled raft foundations using finite element analysis in ANSYS. It begins with an introduction to different types of foundations and focuses on piled raft foundations. The document discusses the methodology, which includes defining elements, material properties, meshing, boundary conditions, and nonlinear static analysis. It then validates the ANSYS model against theoretical calculations and literature findings. Finally, it presents parametric studies on the effects of pile diameter and length combinations on the ultimate load capacity and settlement of piled raft foundations in sand. The key findings are that using larger diameter piles in the center of the raft and smaller diameters at the edges provides higher load capacities with less settlement.

![LITERATURE STUDY

[3] Oh. et.al.(2008) FINITE ELEMENT MODELING OF PILED RAFT IN SAND

using PLAXIS.

Raft thickness doesn’t affect the load carrying capacity of foundation

[17] Ningobham Thoiba Singh & Baleshwar Singh studied INTERACTION

ANALYSIS FOR PILED RAFTS IN COHESIVE SOILS (2008) using Ansys

Increase in raft thickness hasn’t improved the foundation behavior

greater raft thickness is not generally advantageous in reducing overall

or maximum settlement, provide optimum raft thickness

Addition of piles increases the load carrying capacity of a raft with

reduction in settlement.

Axial load is maximum at top portion of pile and is minimum at the tip.

[5] Srilakshmi & Chetan Gowda suggested that raft thickness does not have

influence on unifrom settlement & ultimate load capacity of foundatiom 14](https://image.slidesharecdn.com/33c5a03a-ceef-44ee-856a-b5c7a71e333c-160819021238/75/Mtech-Project_2013_ppt-14-2048.jpg)

![LITERATURE STUDY

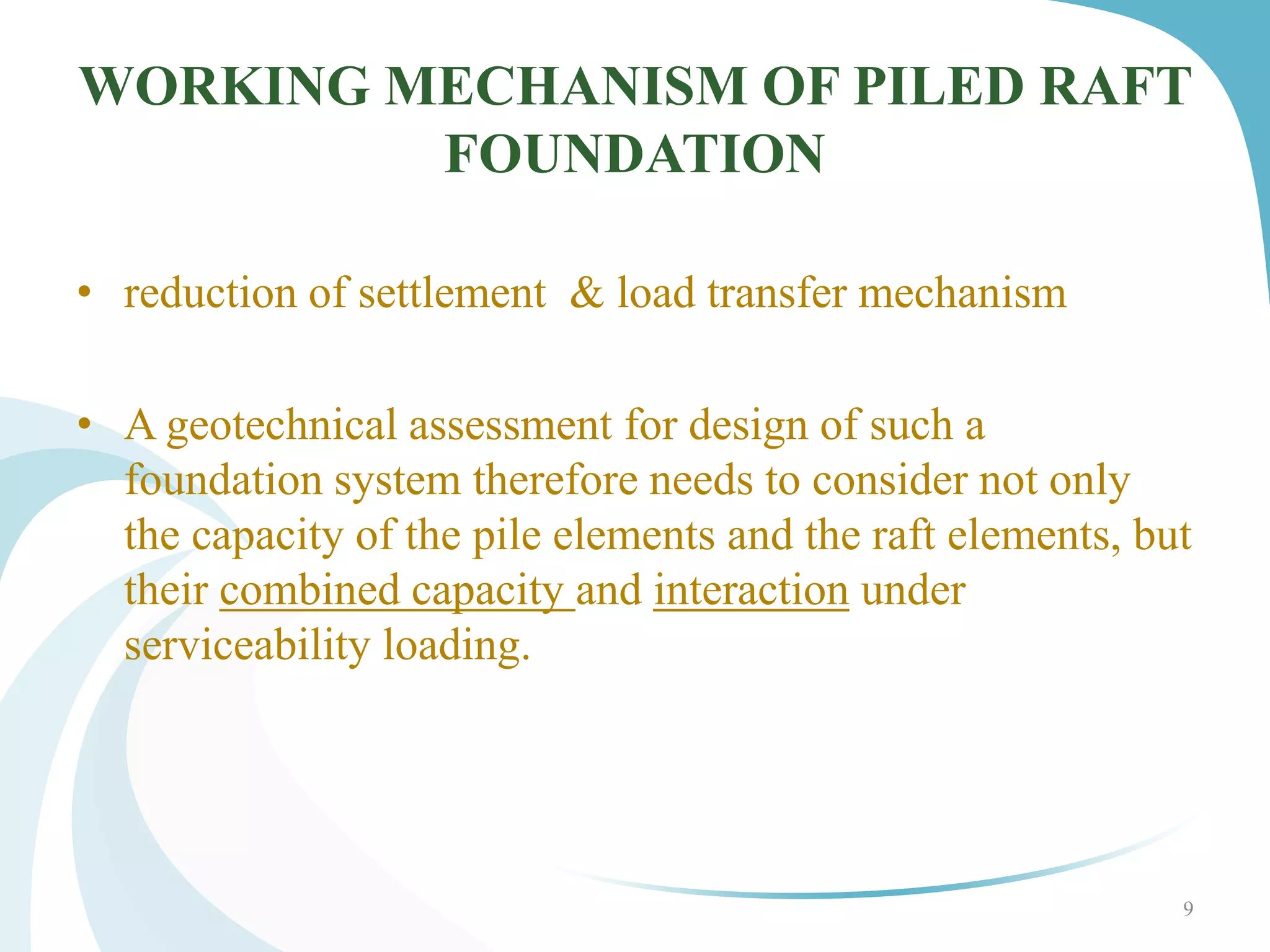

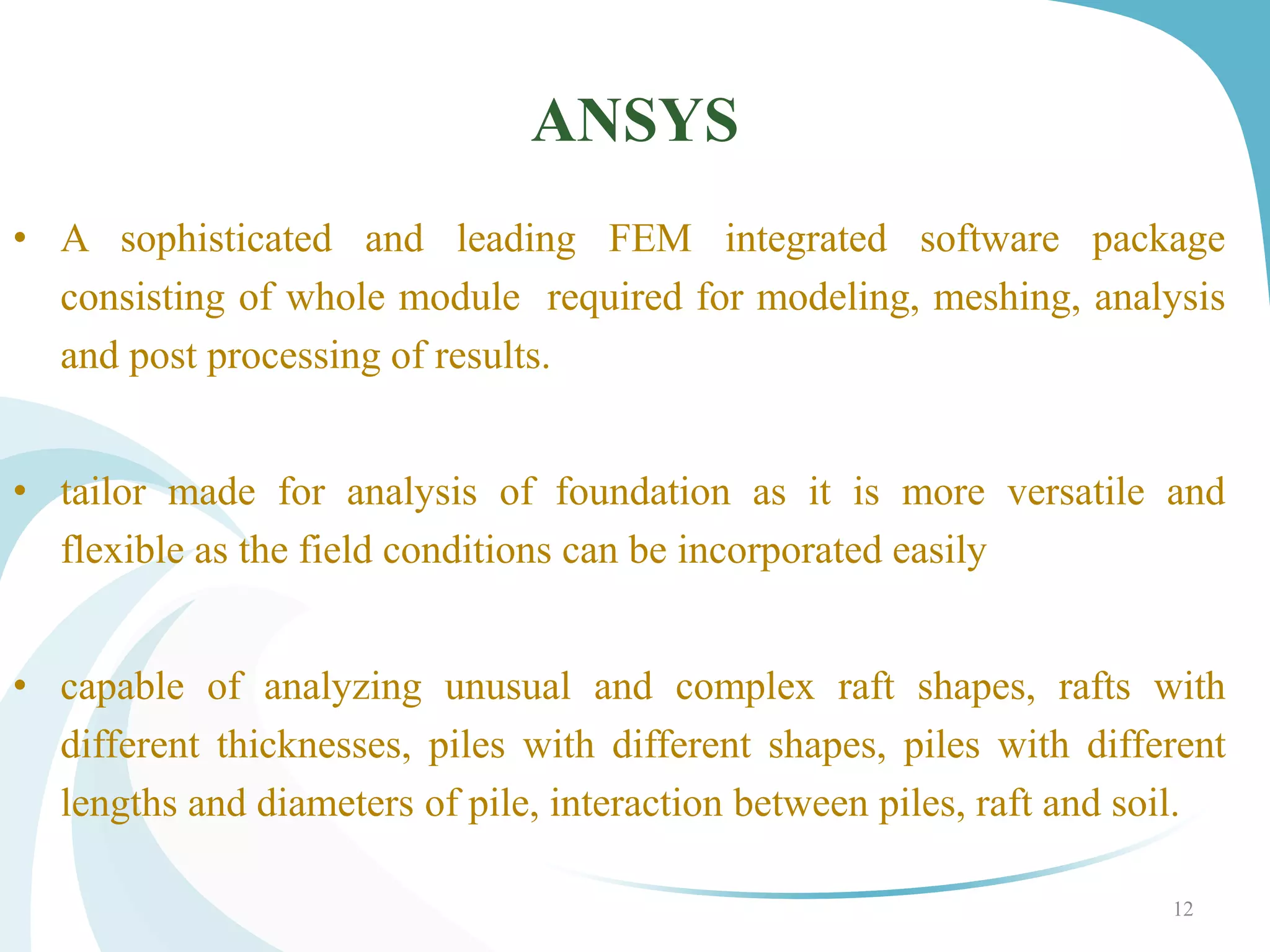

Poulos et al.[7] Piled Raft Foundations for Tall

Buildings (2011) have used PLAXIS-3D to study

proposed piled raft foundation for INCHEON Tower at

S.Korea using the concept of Base embedment of Raft

with & without Soil for cases under horizontal &

vertical loading

• the bending down of rafts at corners and centre is

reduced in the case of basement wall embedment .

They have found out that Piled raft behaves

safely in high raised buildings when subjected to

horizontal & vertical loads.

15

Fig.6 Foundation layout

172 piles of 2.5m dia

lengths varying from

36m to 66m

Raft thickness of 5.5m

vertical basement of

the raft 14.6m(9.1+5.5)

below ground surface

level and 1.2m in

thickness

Fig.6](https://image.slidesharecdn.com/33c5a03a-ceef-44ee-856a-b5c7a71e333c-160819021238/75/Mtech-Project_2013_ppt-15-2048.jpg)

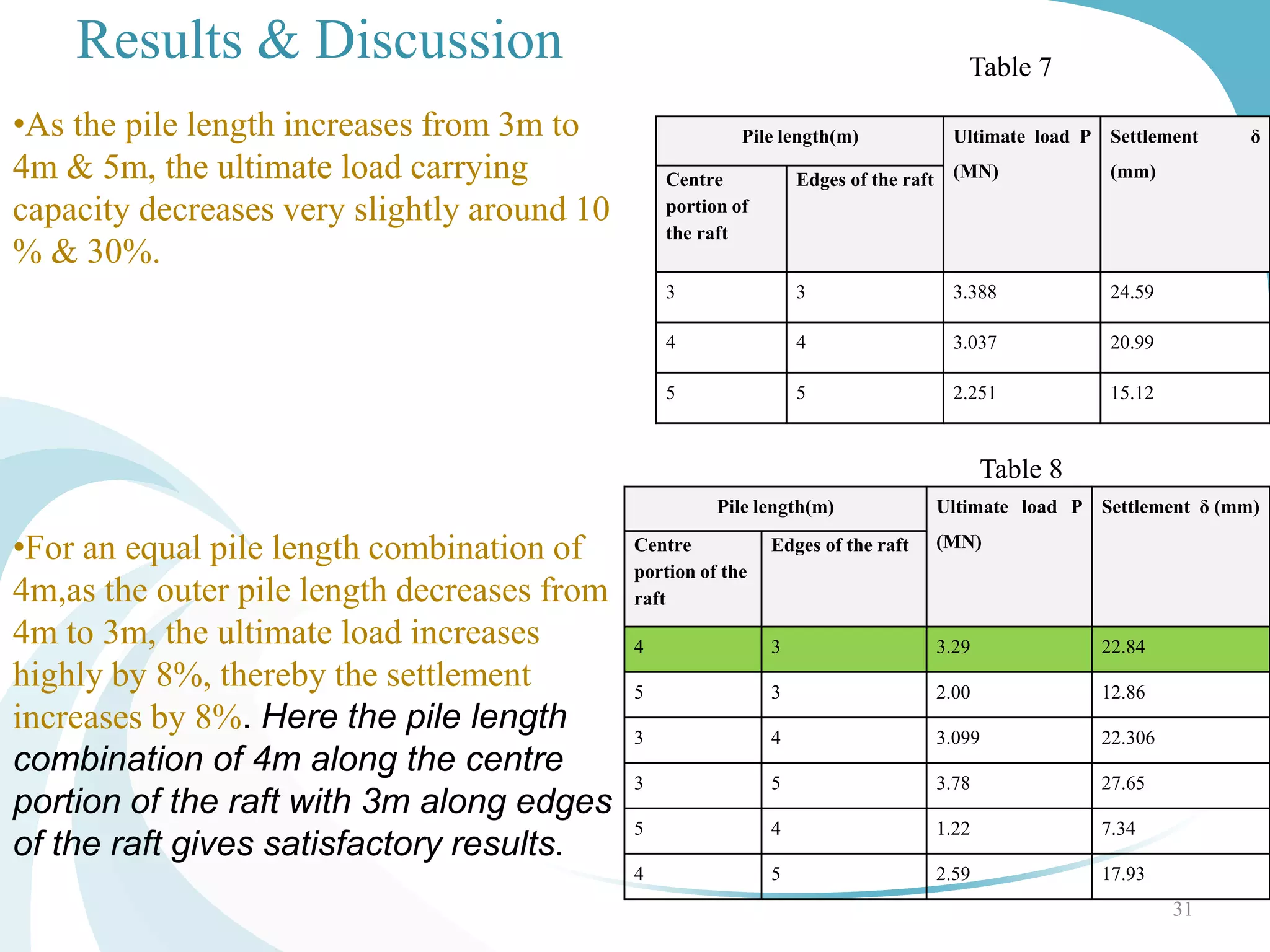

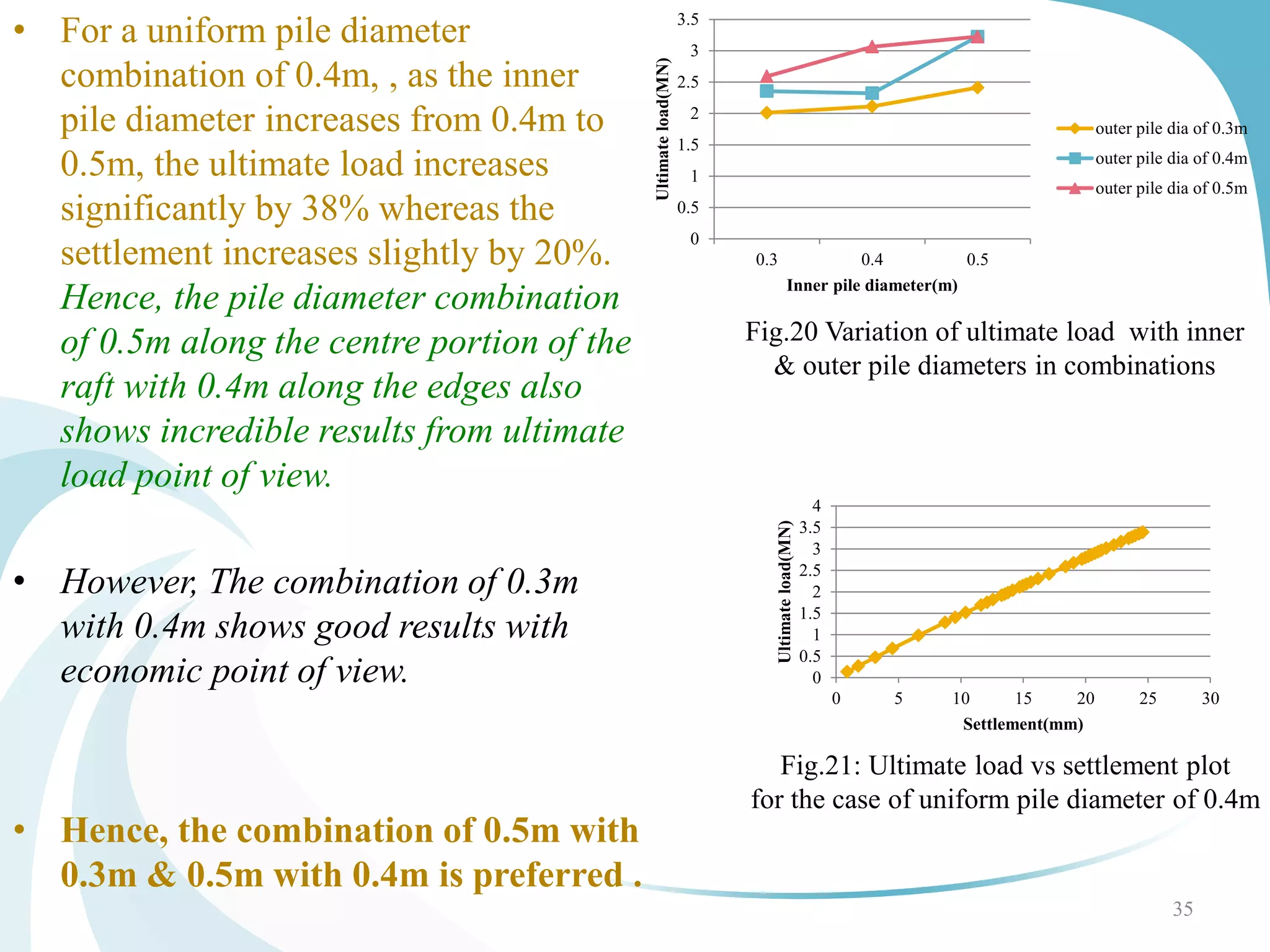

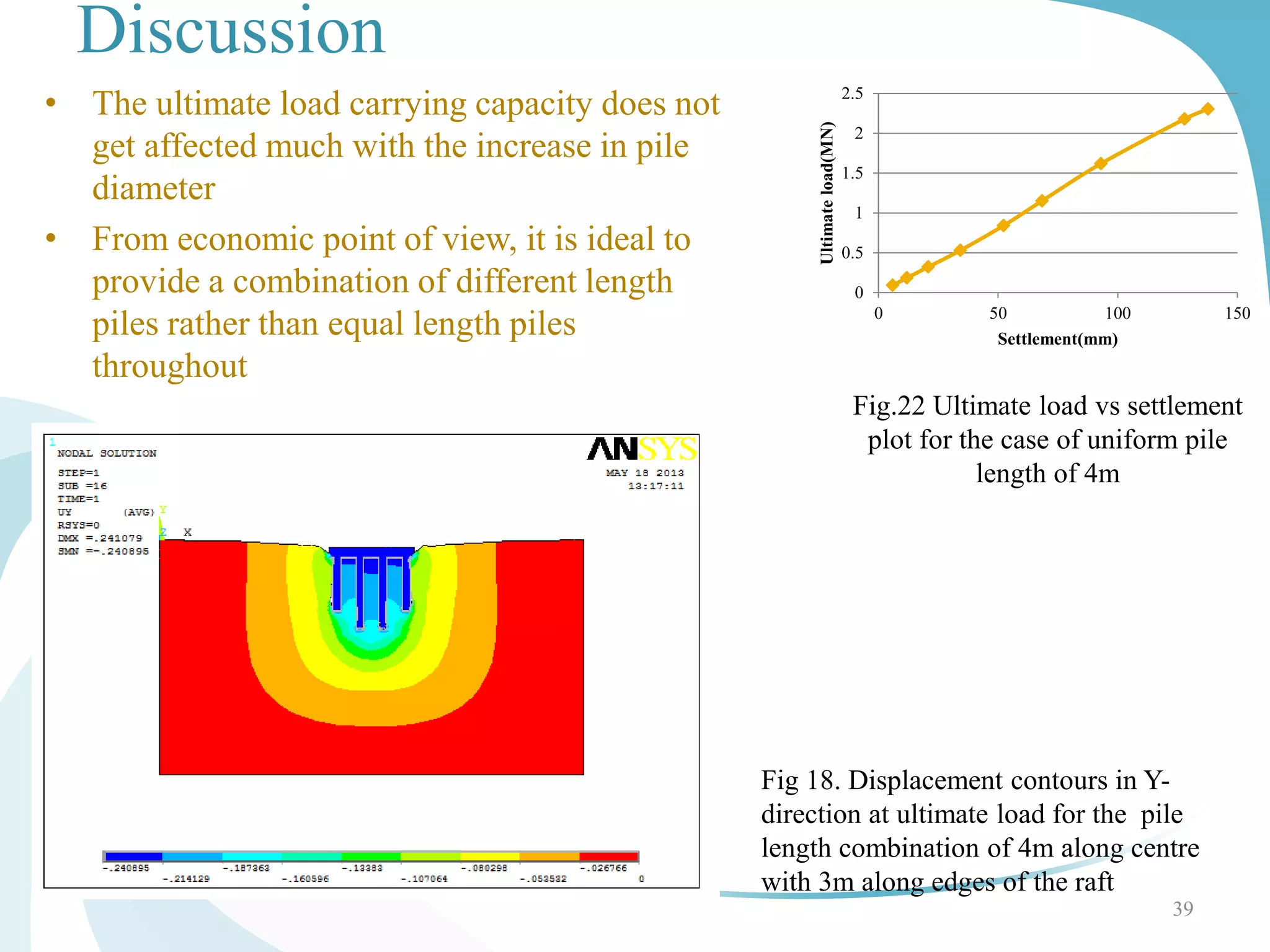

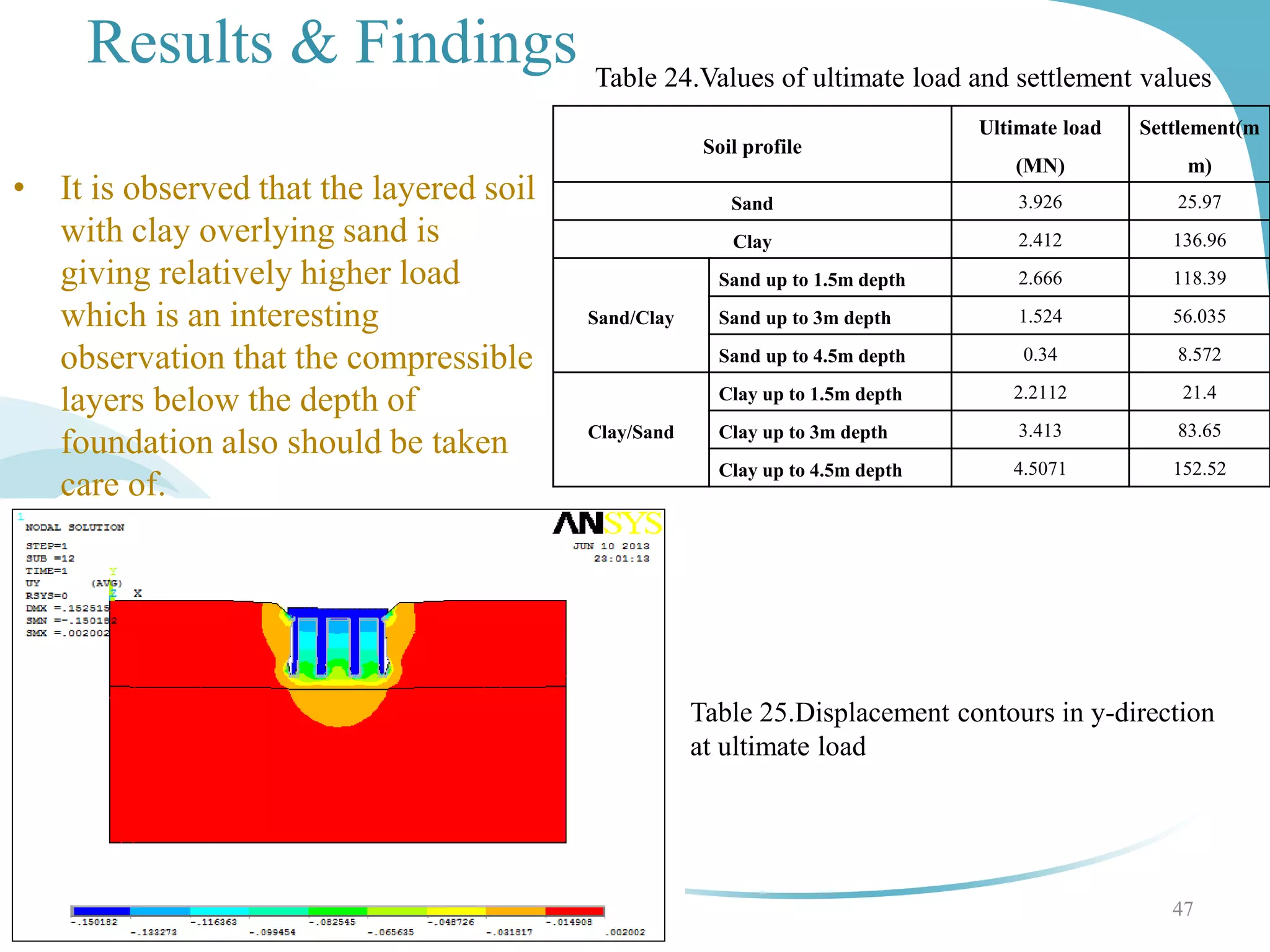

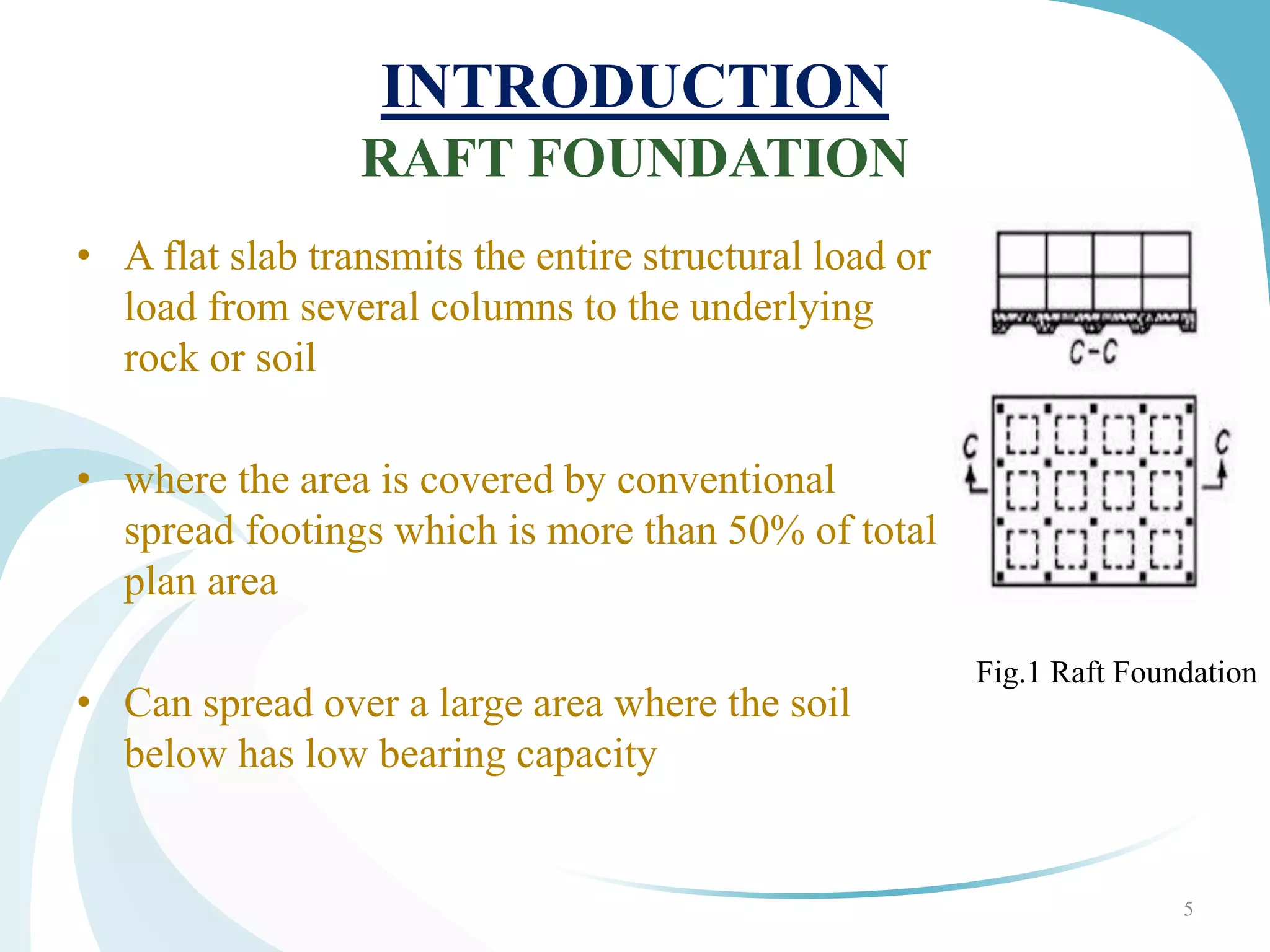

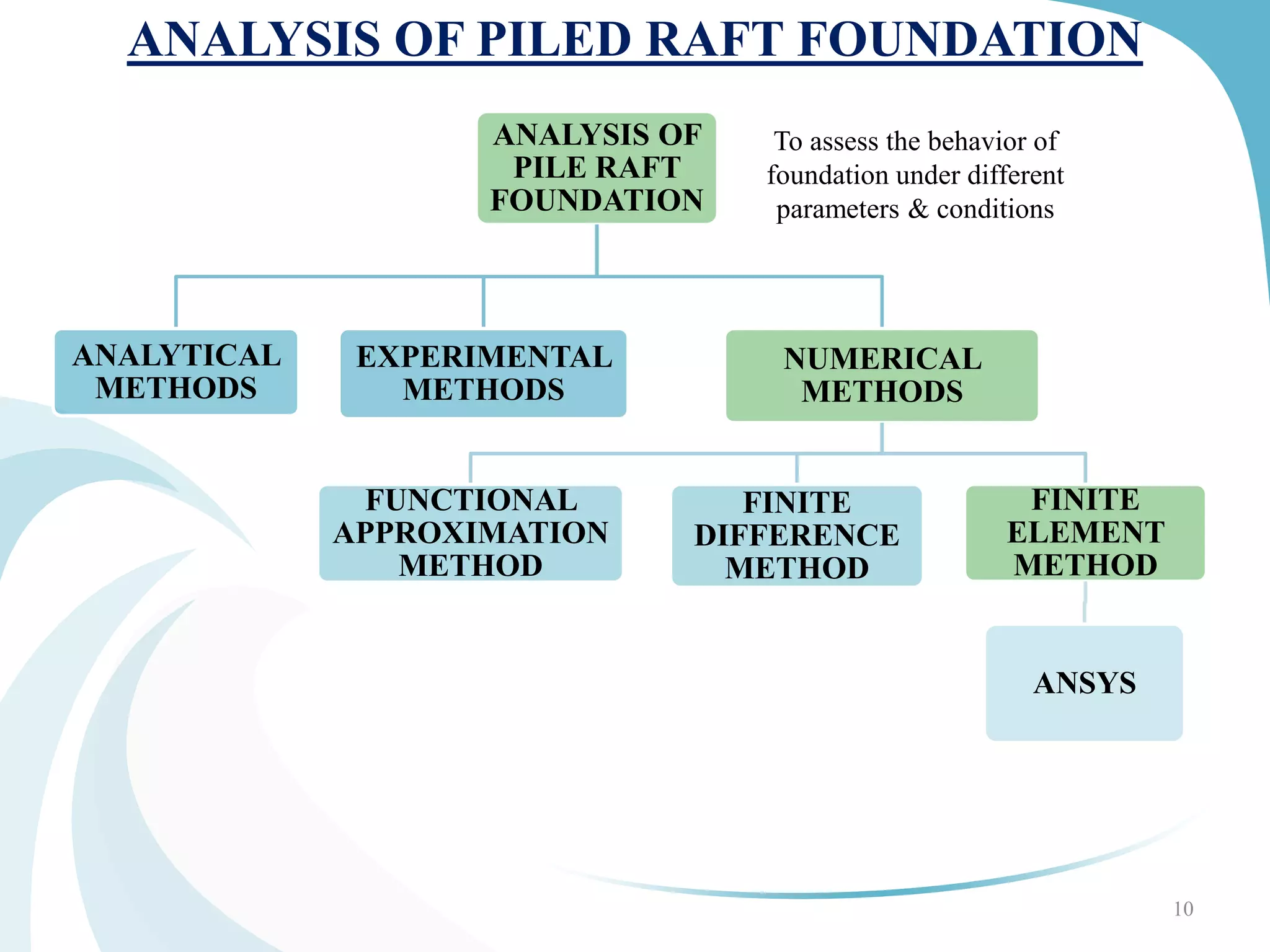

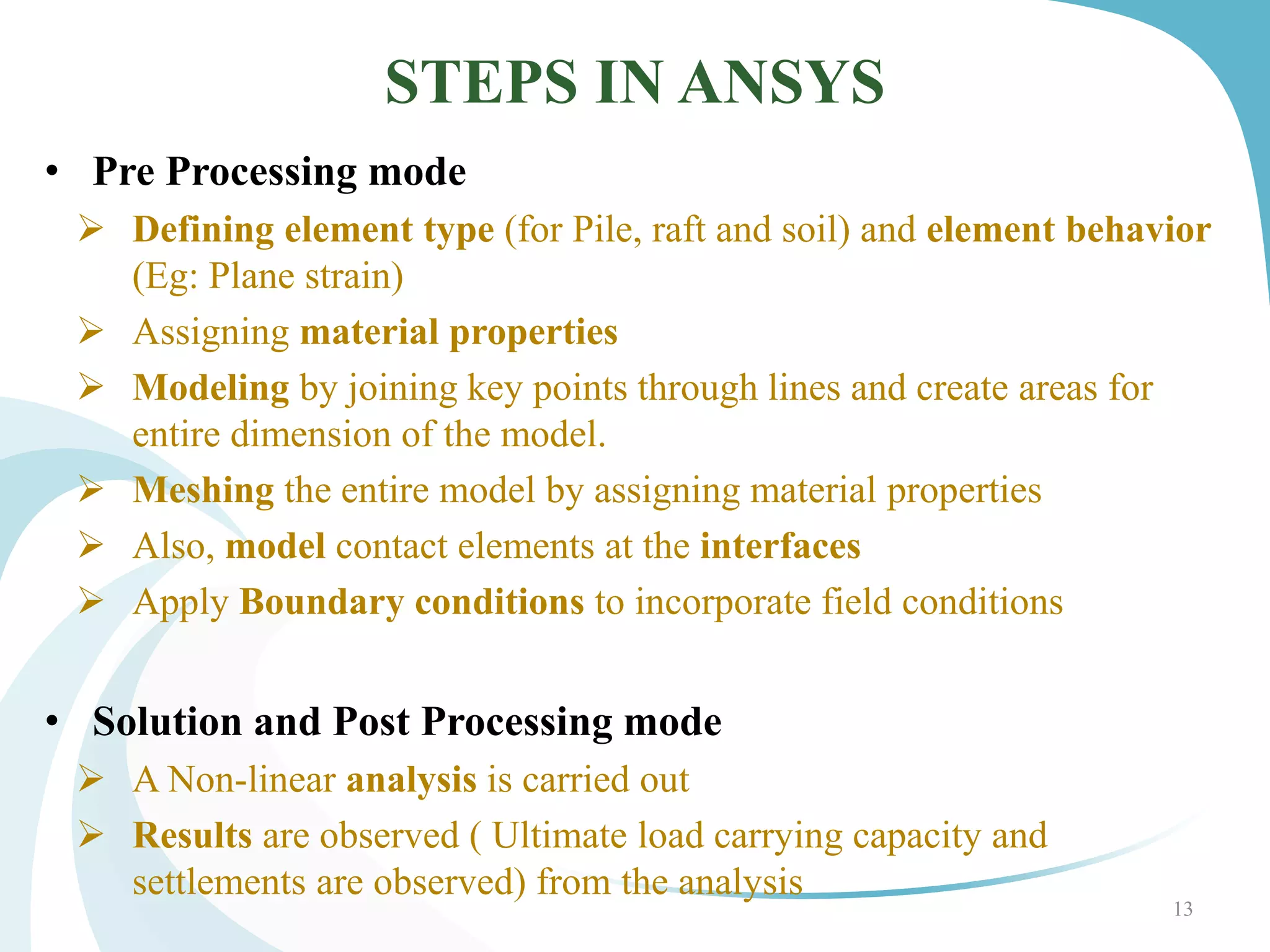

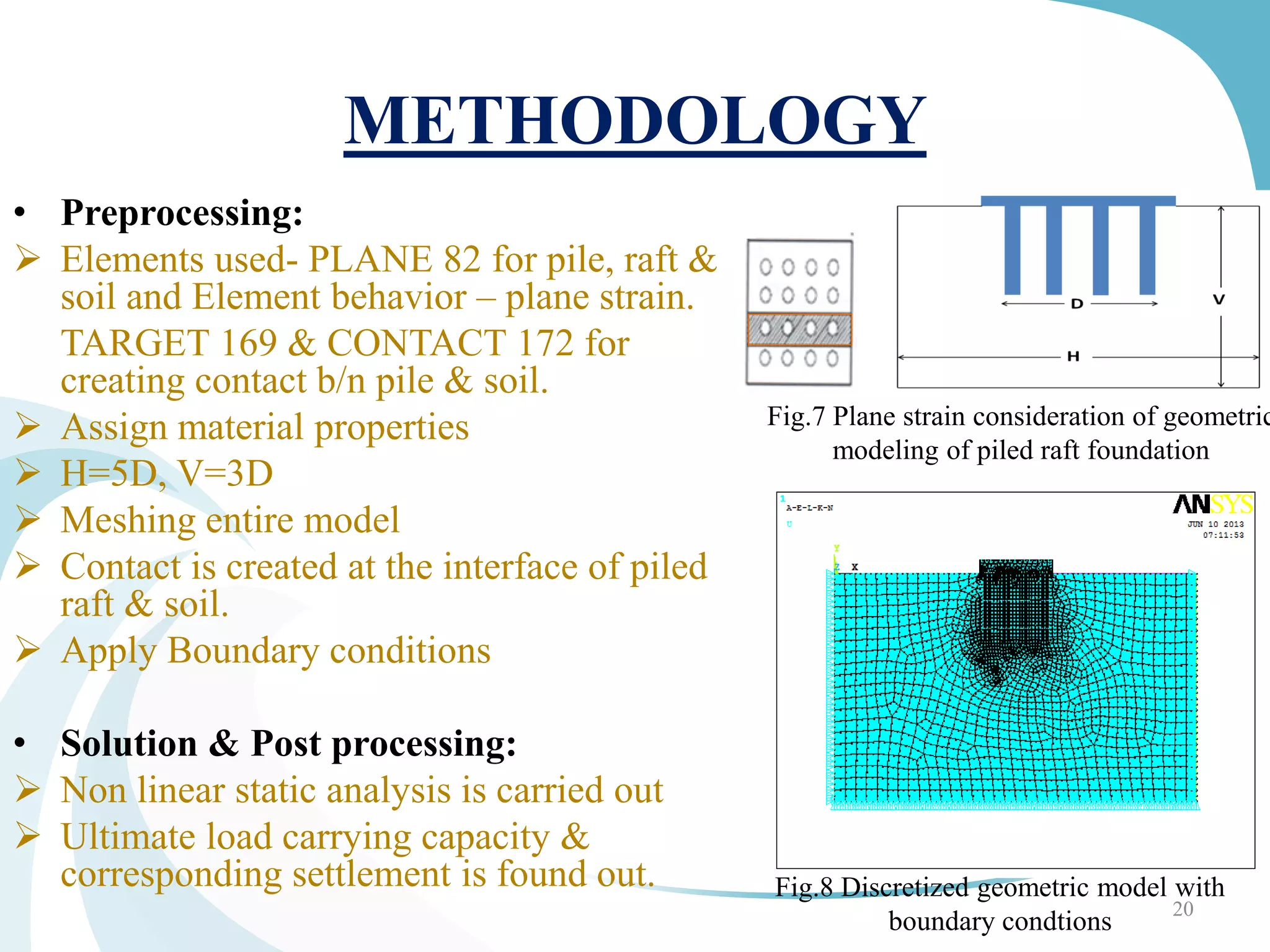

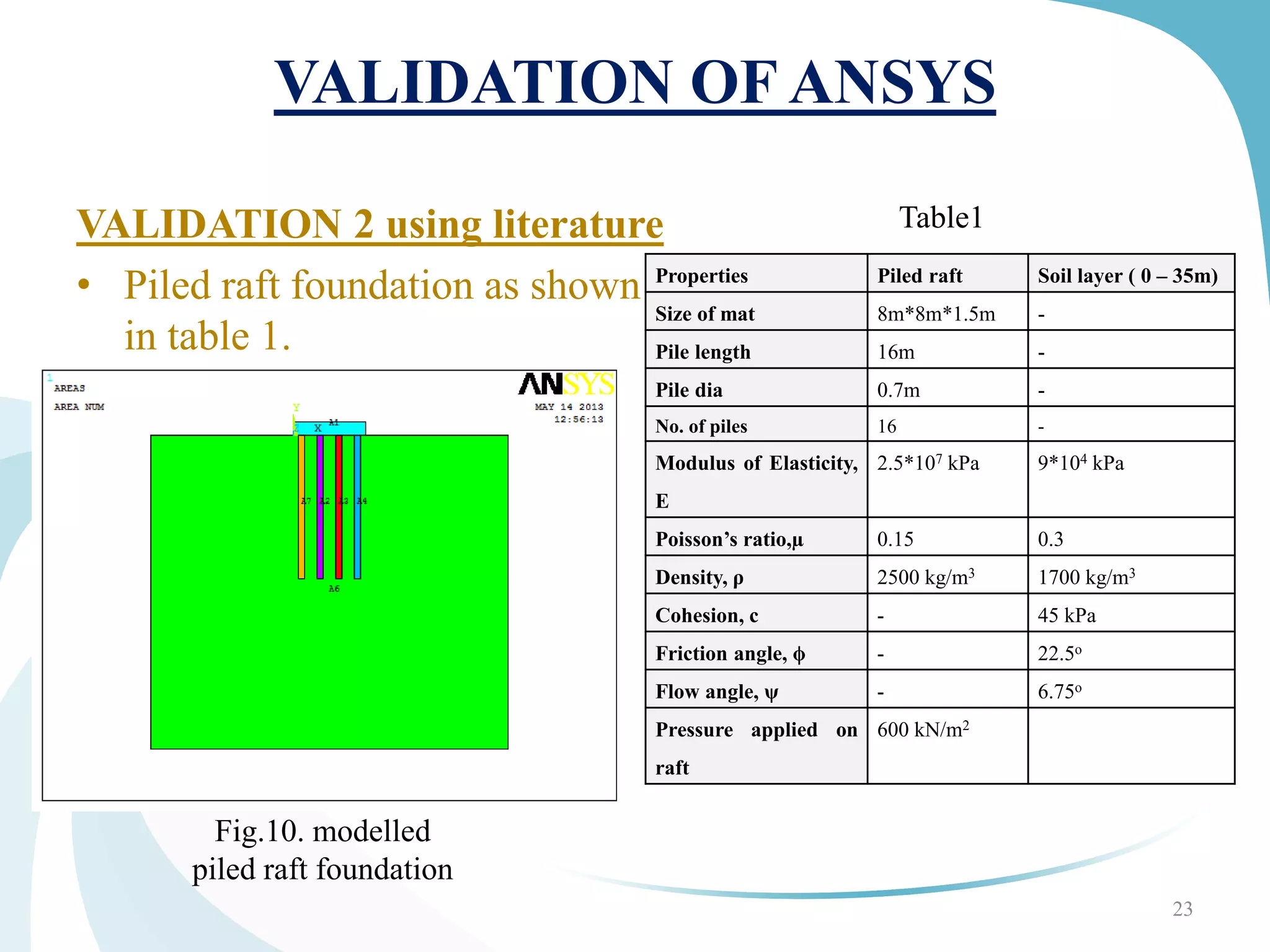

![VALIDATION OF ANSYS

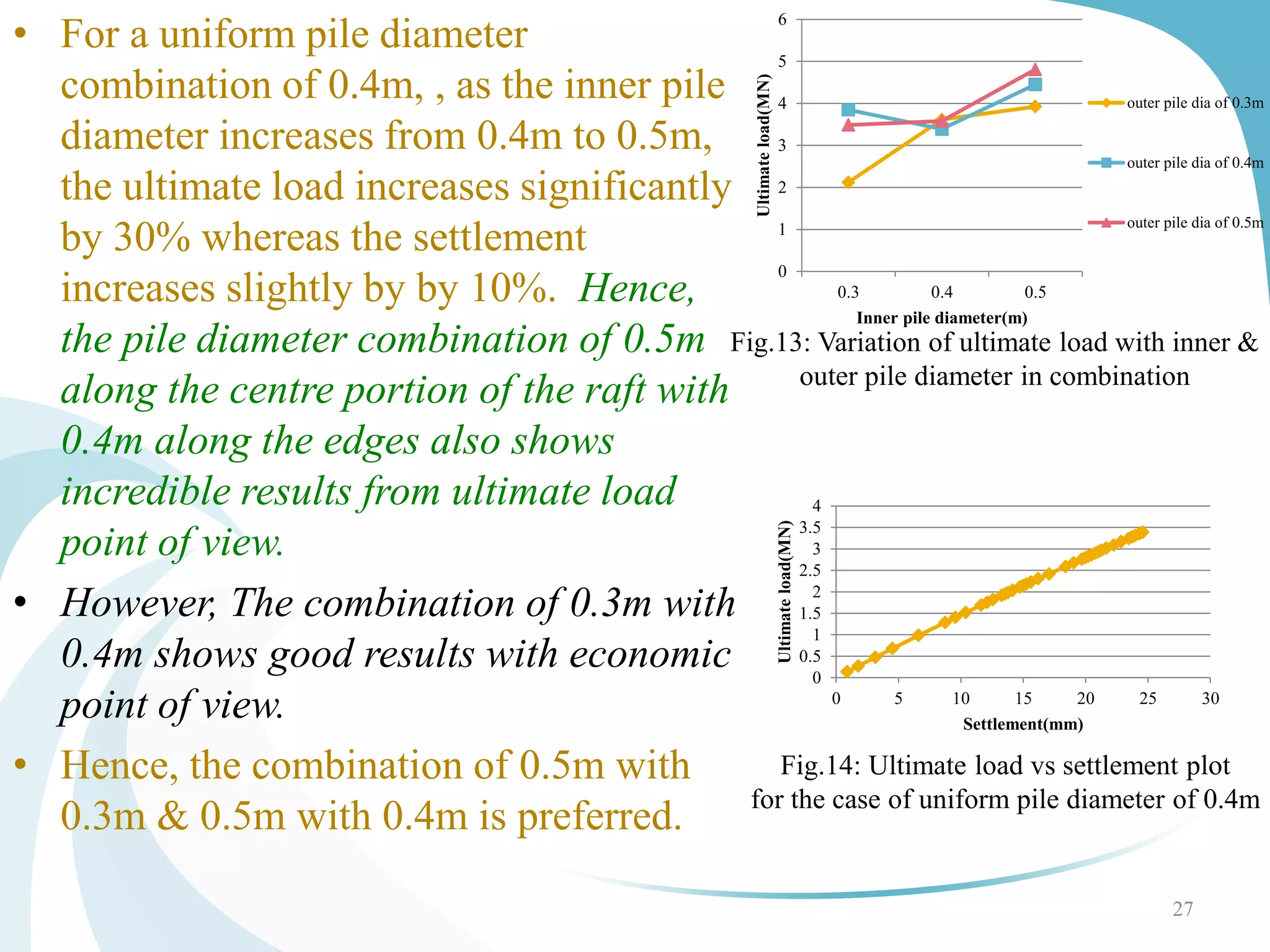

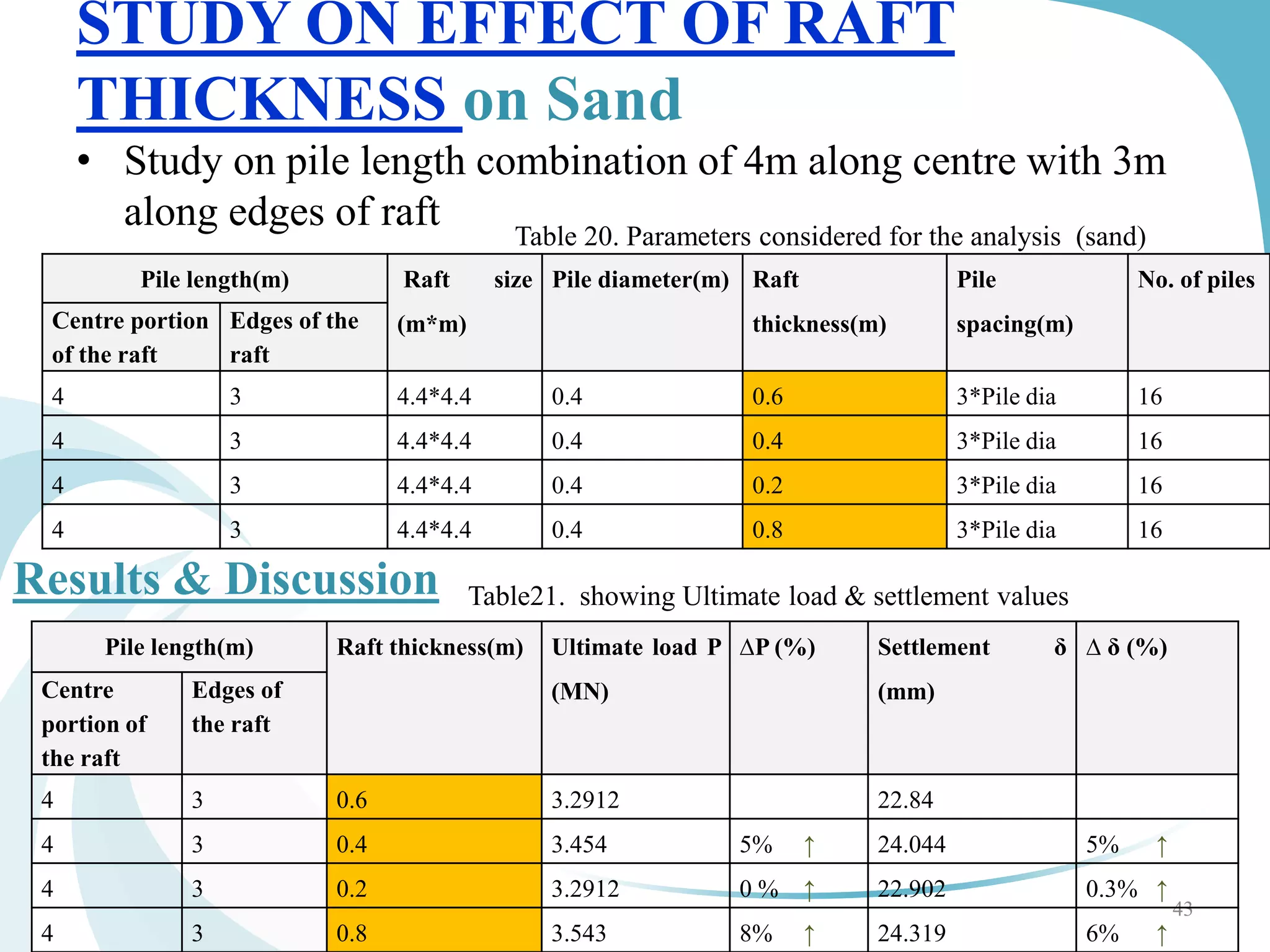

VALIDATION 1 using formula

• Unpiled Raft foundation of size 5m×5m ×0.5m

[3,5,6,11,16,29,30,31]on a single layer soil.

The calculated settlement was 94.3mm.

22

Fig.9: Settlement contours for a

raft foundation

Here, from 2D

analysis, the

Settlement is found

out to be 95.4mm.](https://image.slidesharecdn.com/33c5a03a-ceef-44ee-856a-b5c7a71e333c-160819021238/75/Mtech-Project_2013_ppt-21-2048.jpg)

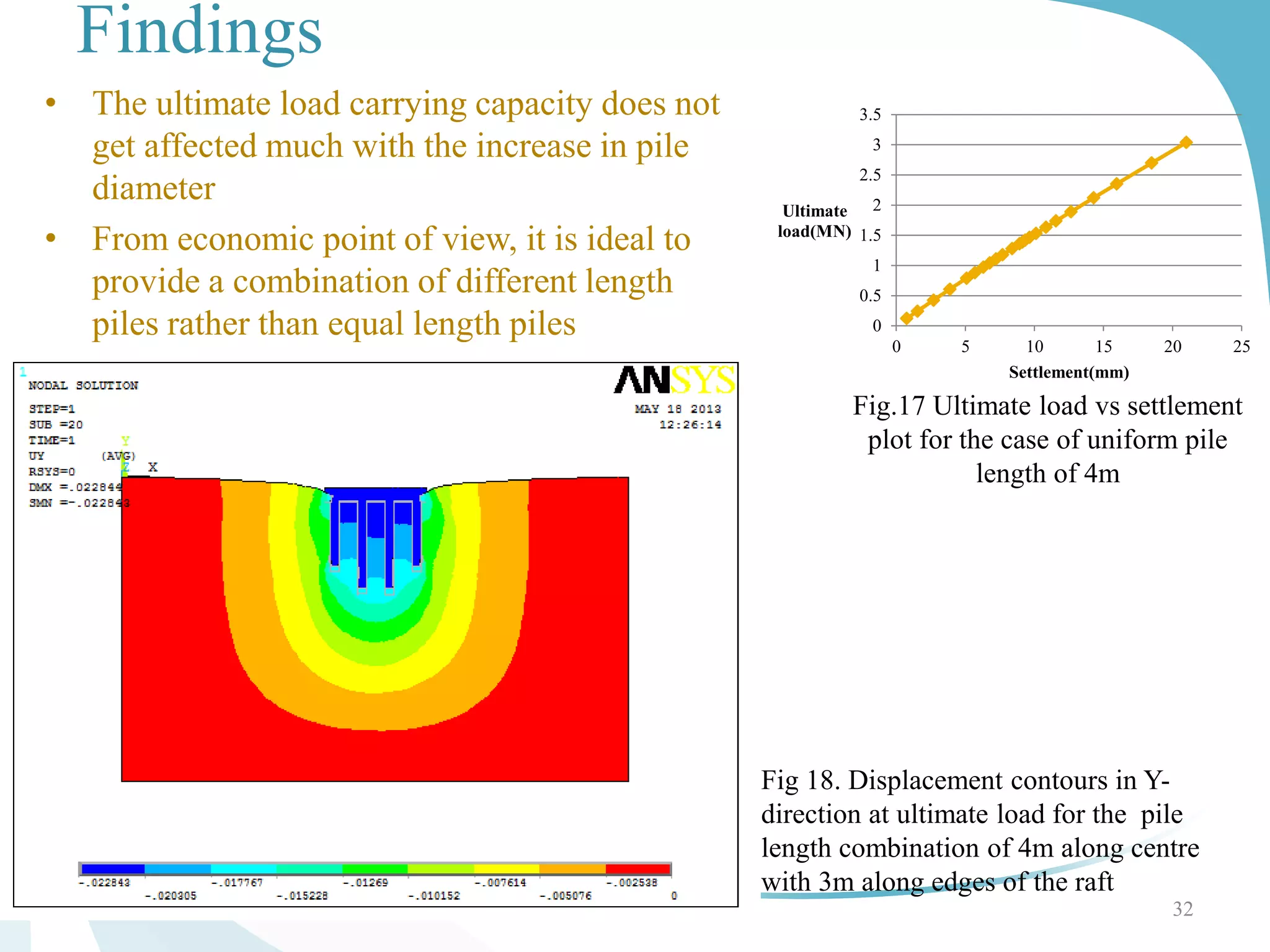

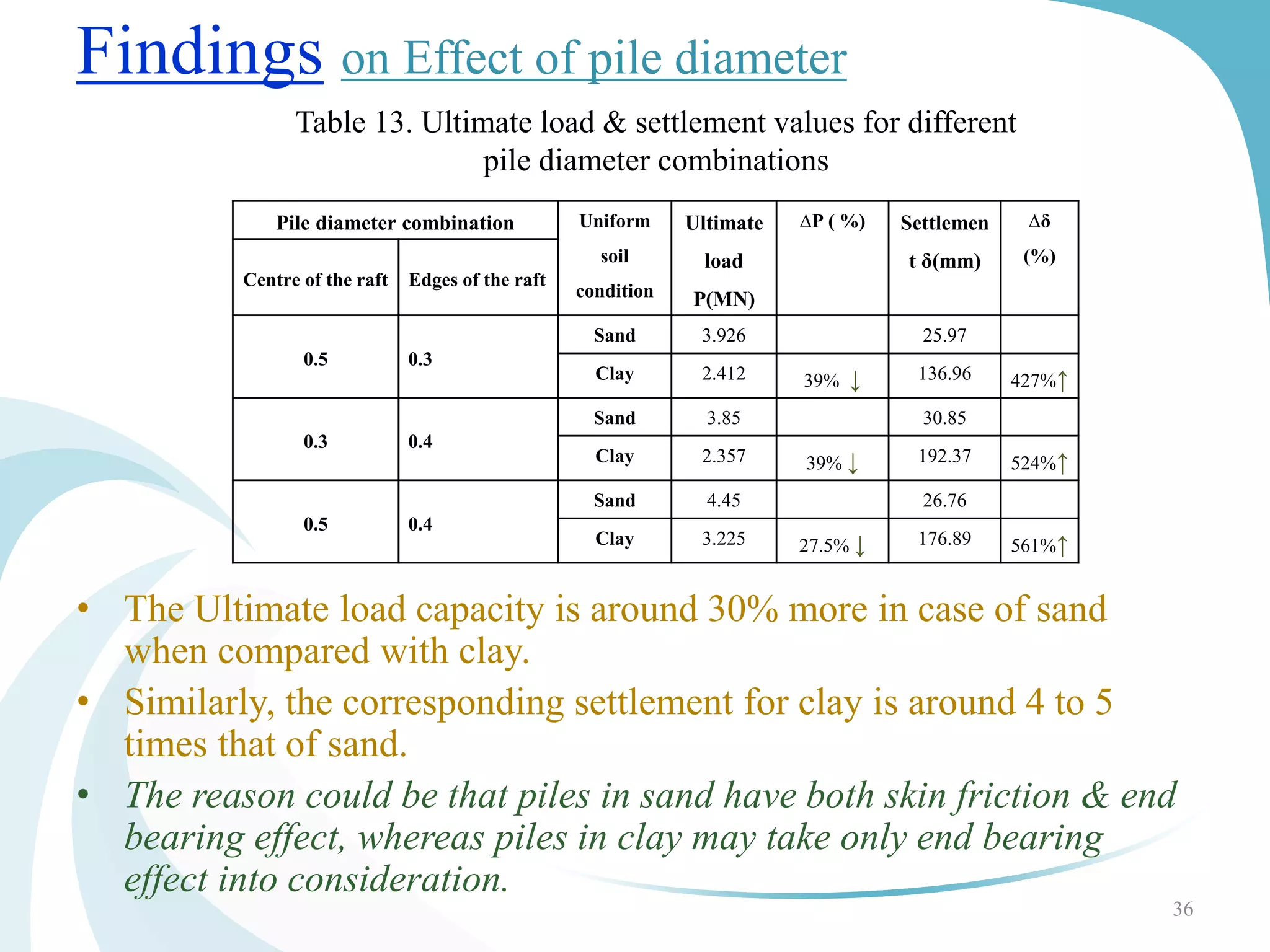

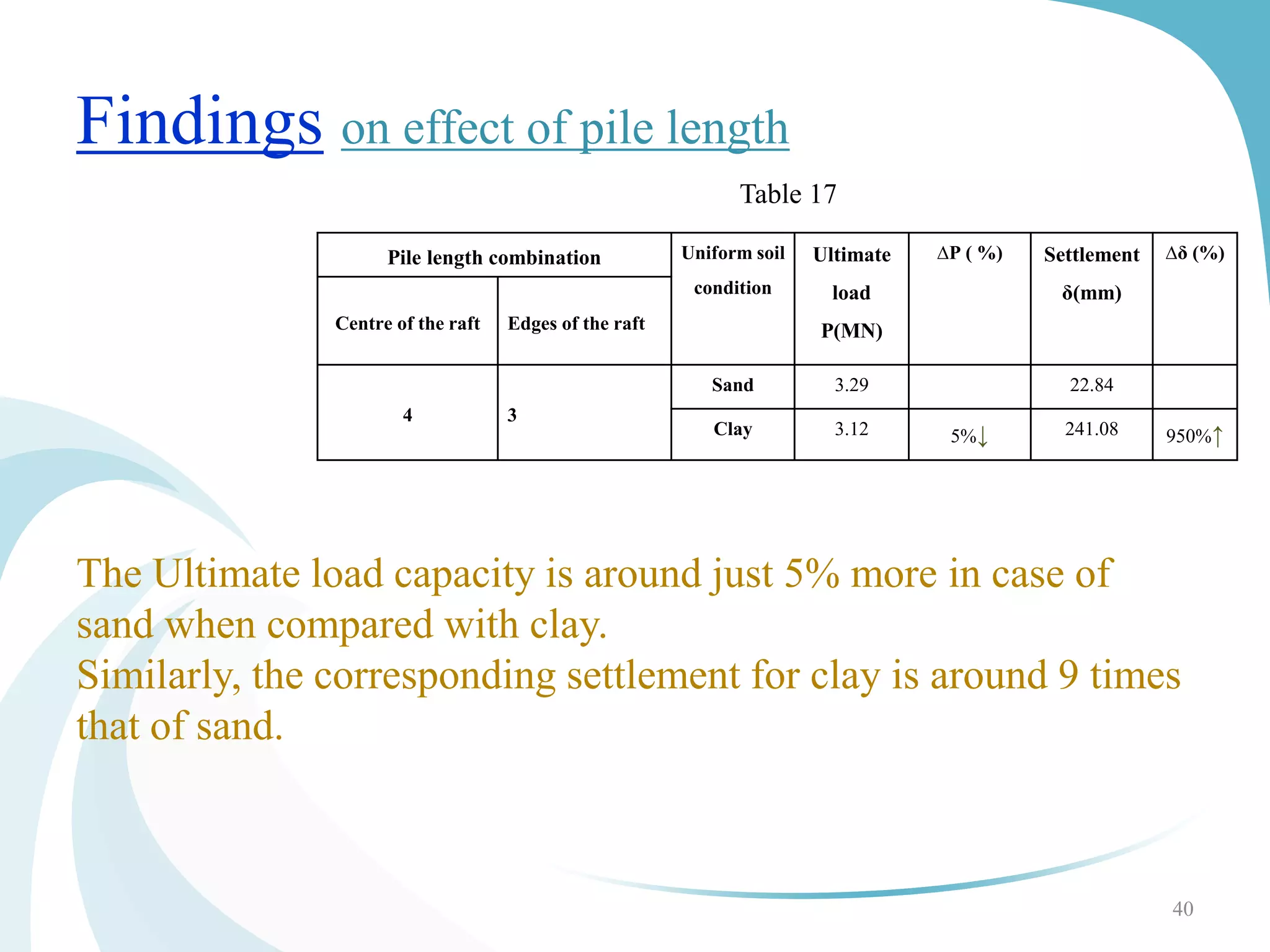

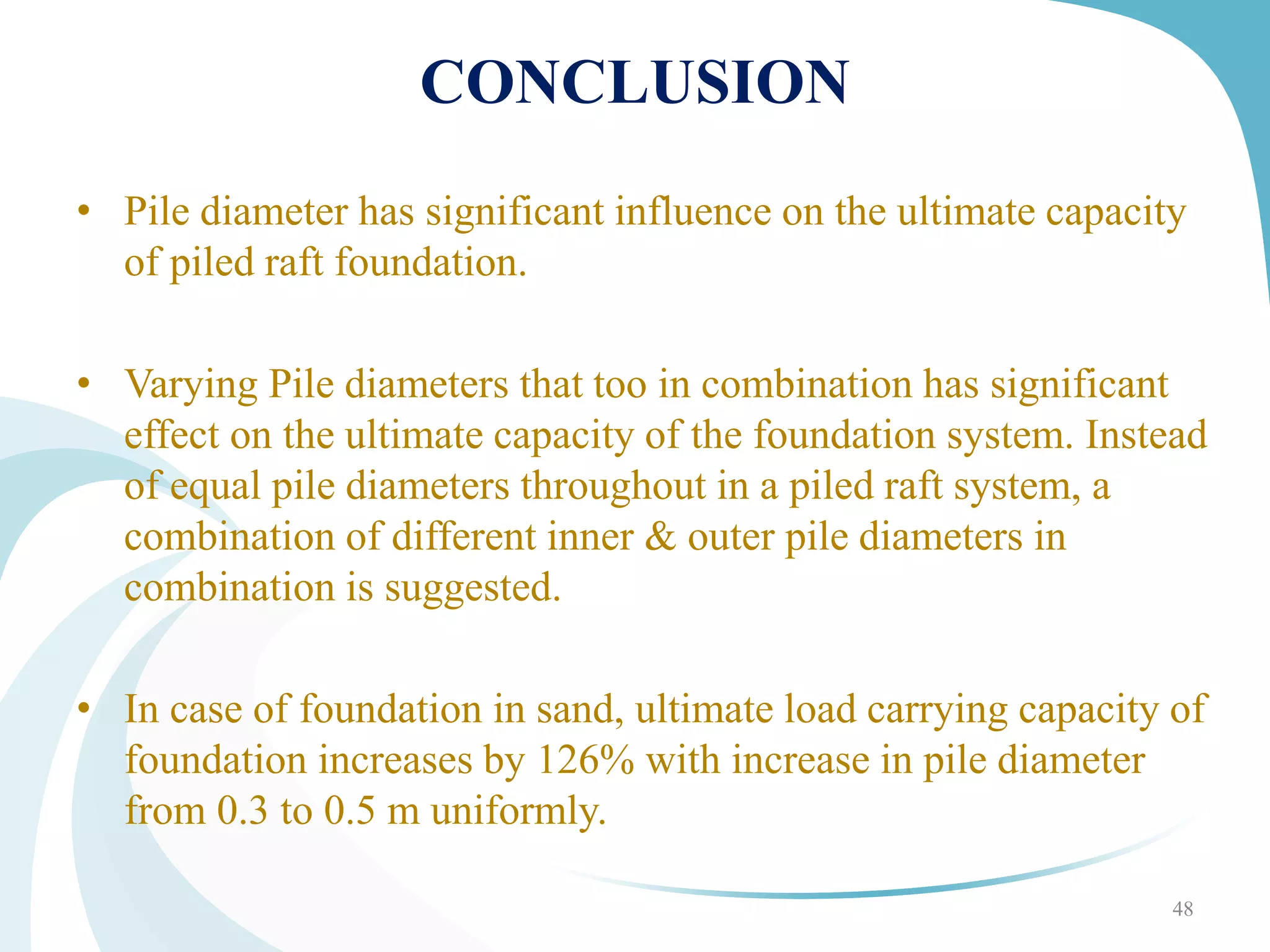

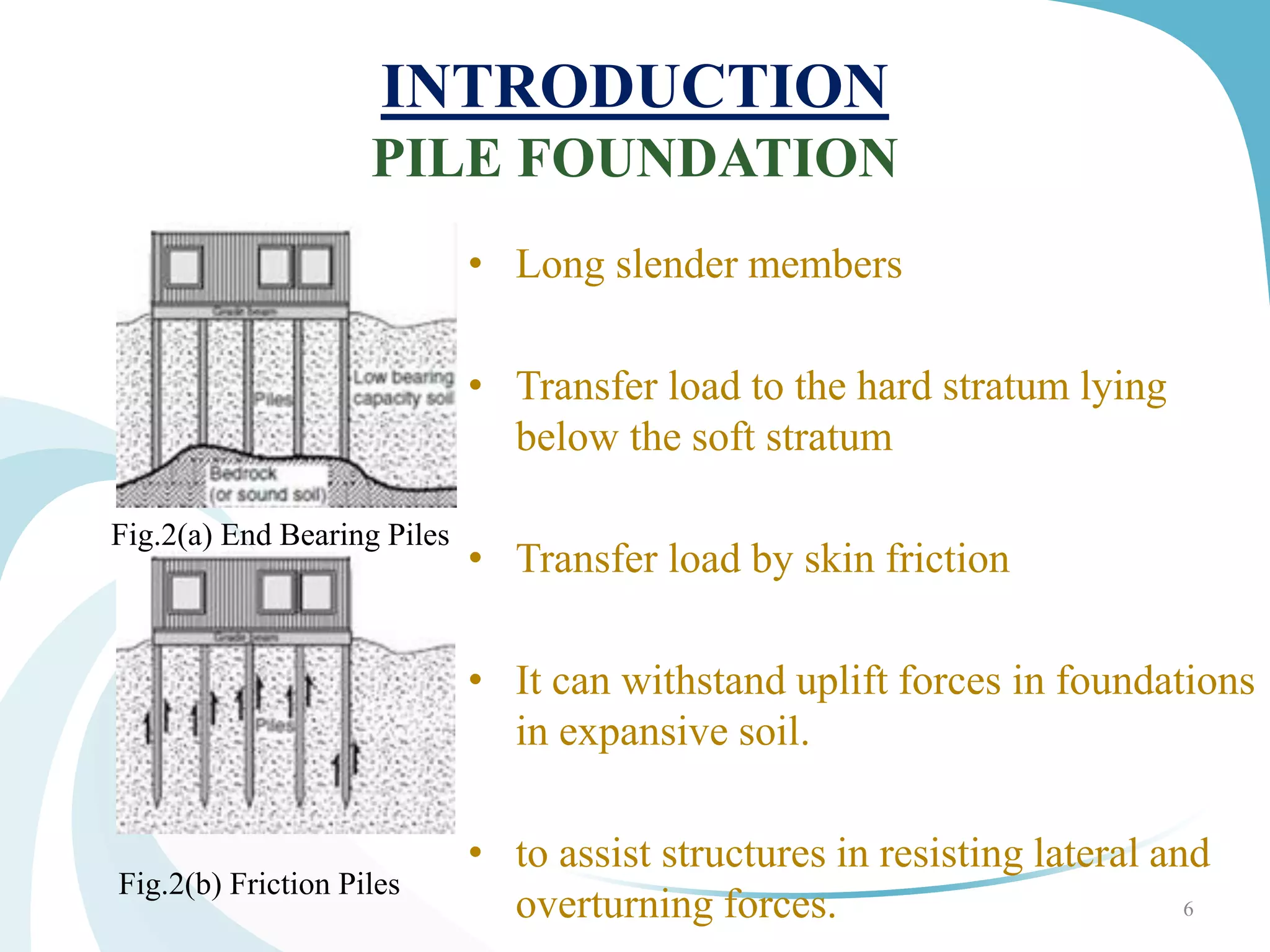

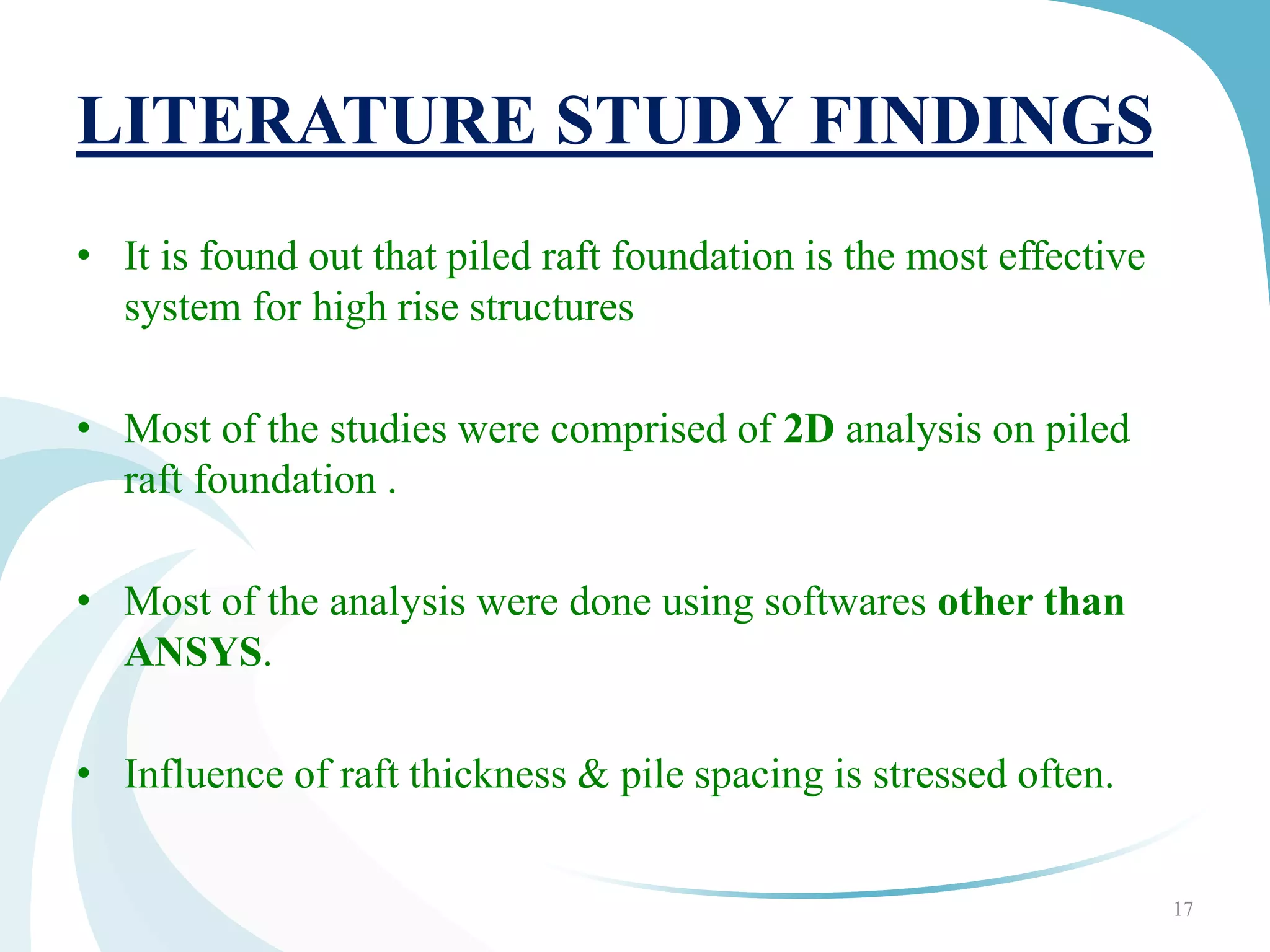

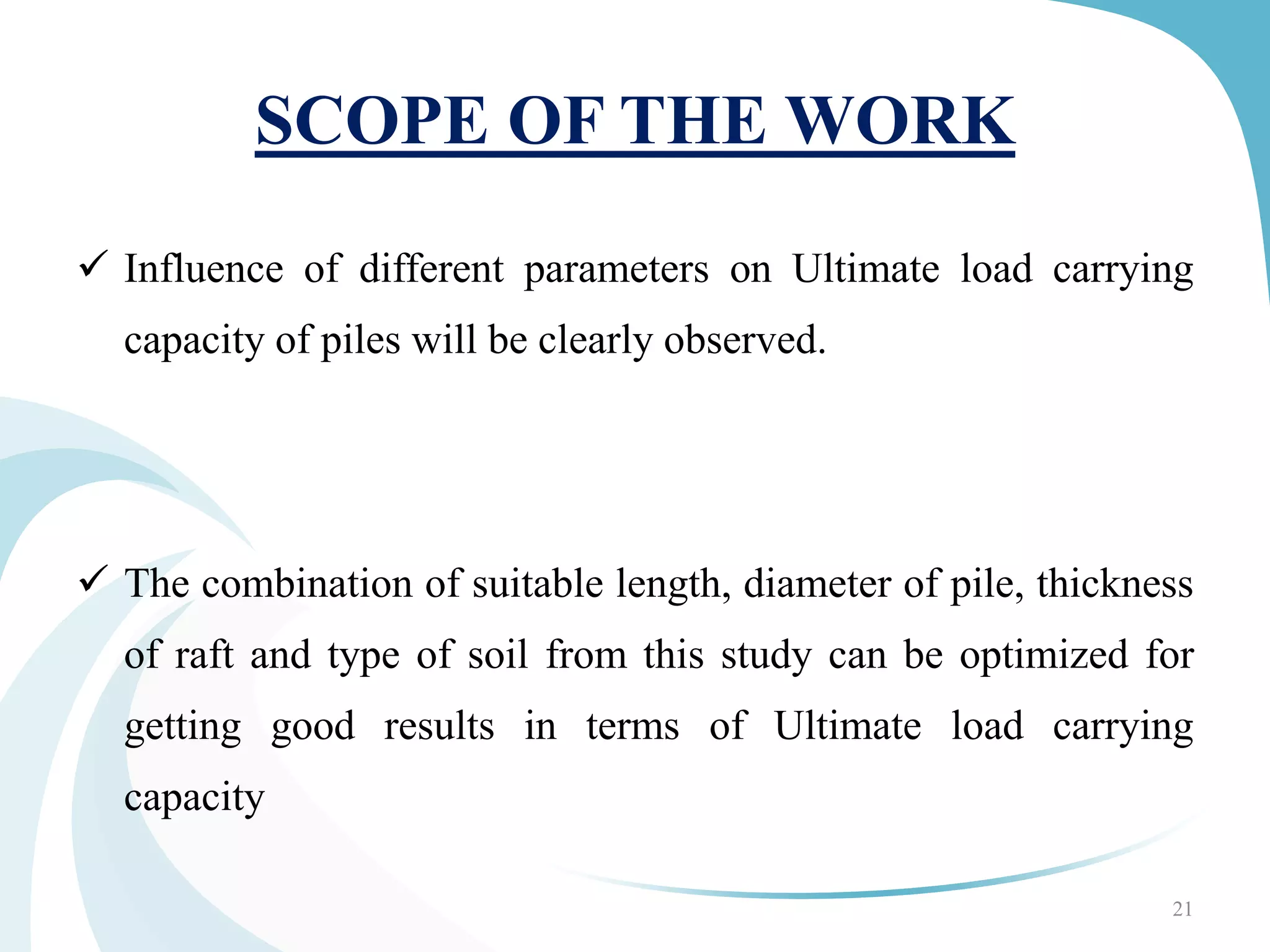

![24

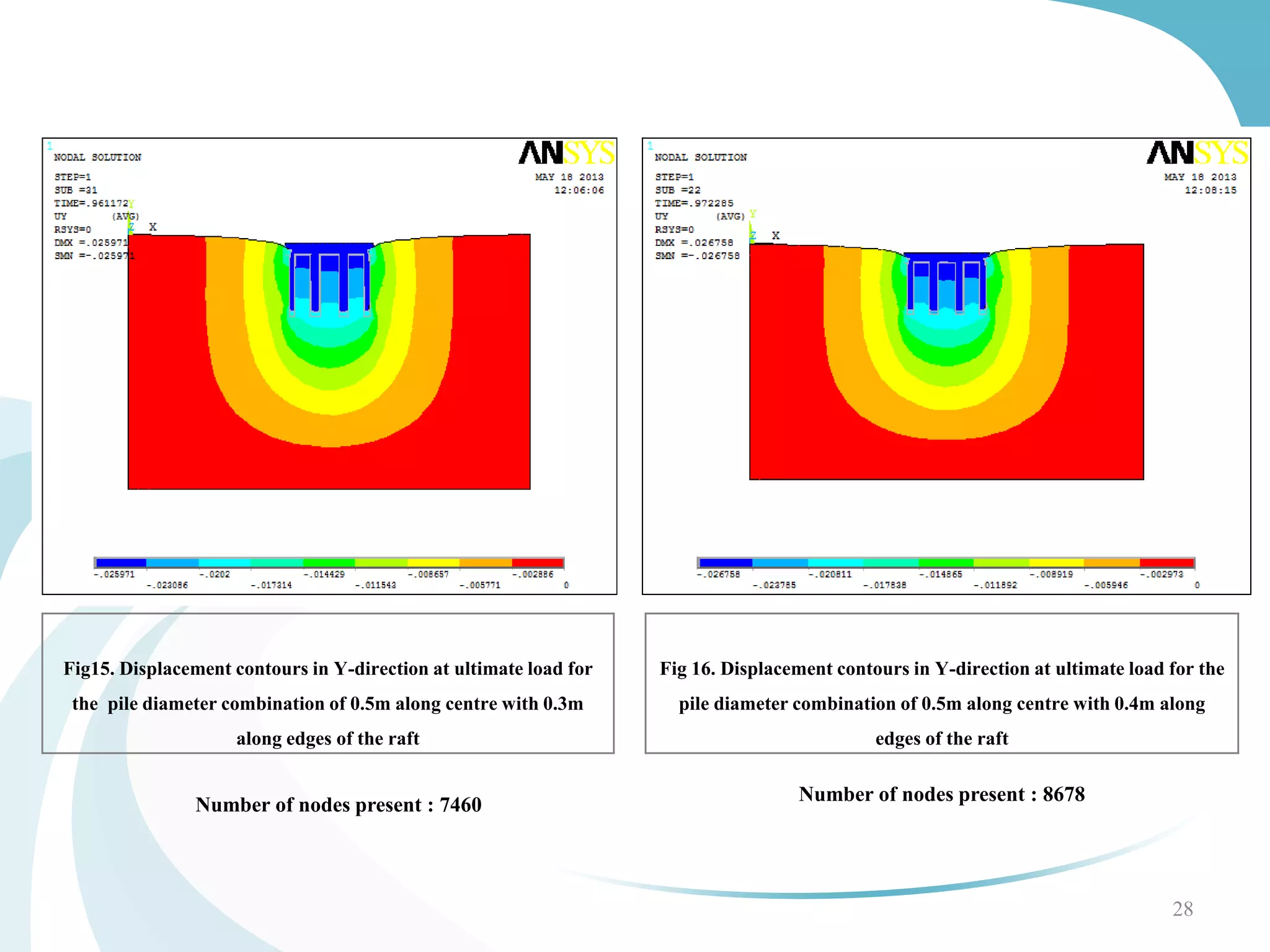

Fig.11: Displacement contours along y-

direction

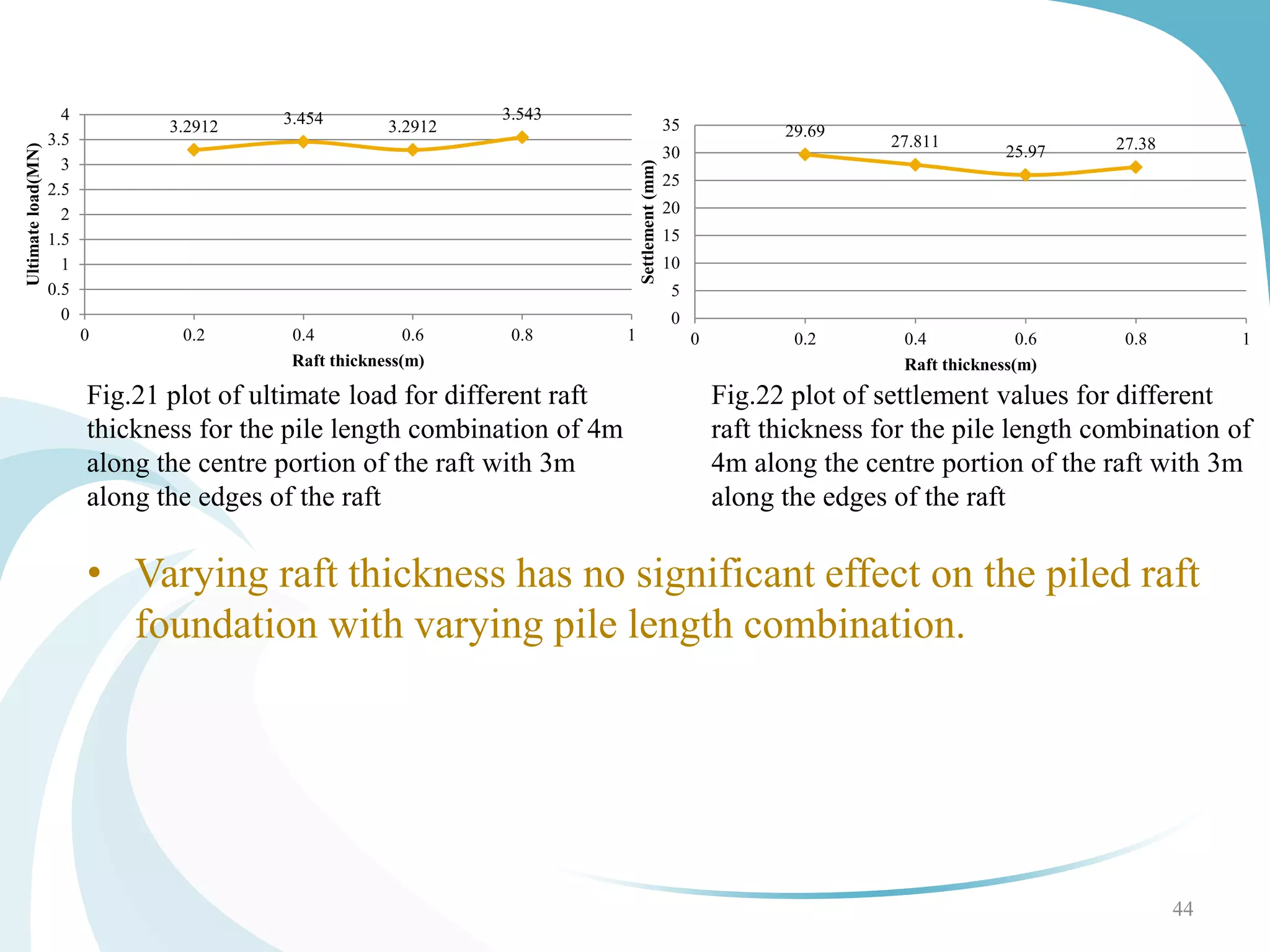

VALIDATION 2 using literature

From the literature[3], the

settlement was found out to be

64.3mm.

From ANSYS, the settlement

obtained was 69.414mm.

Hence, the results obtained from ANSYS are compatible with the

calculated theoretical results.](https://image.slidesharecdn.com/33c5a03a-ceef-44ee-856a-b5c7a71e333c-160819021238/75/Mtech-Project_2013_ppt-23-2048.jpg)